Choosing the right 5-axis gantry milling machine is essential

A 5-axis gantry milling machine requires a substantial financial commitment. Choosing the machine that best satisfies your specific requirements might be challenging because so many options are available from different brands and features. The ideal machine for your application can be chosen, but there are important considerations to make.

This article will go over crucial factors to bear in mind and practical advice to assist you in narrowing down your options and selecting the 5-axis gantry milling machine that offers the greatest features, functionality, quality, and value for your specific application demands and price range. By heeding this guidance, you can have a machine that consistently satisfies your production needs for many years.

A 5-axis gantry milling machine is a powerful and versatile machine

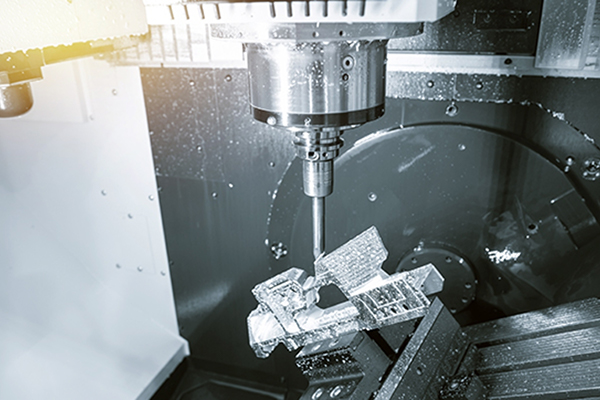

A 5-axis gantry milling machine is a powerful and versatile machining tool used in various industries, including aerospace, automotive, mold-making, and general manufacturing. In contrast to traditional milling machines, which typically operate on three axes, a 5-axis gantry machine contains two additional rotating axes, commonly referred to as the A and B axes (X, Y, and Z).

Additionally, 5-axis gantry milling machines frequently include powerful CNC (Computer Numerical Control) systems and software, which provide comprehensive simulation and programming capabilities. Further boosting efficiency and accuracy, these characteristics enable effective tool path development, collision avoidance, and machining operation optimization.

The structure of a 5-axis gantry milling machine is designed to provide stability, rigidity, and precise movement to achieve accurate machining results. While specific designs may vary among manufacturers, the basic components and layout of the machine remain consistent.

● Gantry: This consists of two vertical beams and a crossbeam that connects the tops of the vertical beams. The crossbeam moves horizontally along the vertical beams. This forms the X and Y axes of the machine.

● Spindle unit: The spindle which holds the milling cutter is mounted on the crossbeam. The spindle moves with the crossbeam along the X and Y axes.

● Column: The vertical column provides a stationary vertical reference for the Z axis movement. The spindle can move up and down along the column, forming the Z axis.

● Rotary axes: The spindle head usually has two rotary axes - the A axis that tilts the spindle and the C axis that rotates the part chuck. These form the 4th and 5th axes of the machine.

● Part fixture: The part to be machined is secured to a rotary chuck or fixture that mounts on the machine table. It provides the rotational motion for the C axis.

● Control system: The CNC control system controls the precise movements and coordination of all 5 axes during machining operations.

● Tool changer: An automatic tool changer is used to switch between different cutters in the spindle.

● Coolant system: A coolant system supplies coolant to the cutting area to lubricate, cool and flush away chips during machining.

5-axis CNC machine operates by the motions and synchronization of all 5 axes

Similar to a gantry milling machine, a 5-axis CNC machine operates by carefully regulating the motions and synchronization of all 5 axes (X, Y, Z, A, and C) throughout a machining process. The fundamental procedures are as follows:

● The part to be machined is securely clamped to the part fixture, which is mounted on the machine table. This provides the rotational motion for the C axis.

● The appropriate cutter is selected and loaded into the spindle unit using the automatic tool changer.

● The CNC program containing code for all 5-axis movements, speeds, and feeds is loaded into the control system.

● The control system activates the appropriate motors and drives to move the gantry (X and Y axes), spindle (Z axis), and rotary axes (A and C axes) according to the program.

● The spindle is rotated at the required speed, and the cutter is lowered into the workpiece using the Z axis.

● As the cutter engages the material and starts removing material, coolant is supplied to flush away chips and lubricate the cutter.

● The coordinated movements of the 5 axes allow the cutter to cut complex 3D shapes, pockets, contours, and angles on the workpiece.

● The process is repeated for each cutting operation, tool change, and move to a new location, all controlled by the CNC program.

● After completing the program, the machined part is unclamped and removed from the fixture.

5-axis CNC machine brings many benefits

Keys benefits of a 5-axis CNC machine:

● Complex 3D part machining: The ability to rotate the spindle and tilt/rotate the part allows the machining of complex 3D geometries with undercuts, pockets, tapered holes, and angled surfaces. This improves part design flexibility.

● Higher efficiency: 5-axis machines require fewer setups and tool changes since they can access all sides of a part in one fixture. This improves machining efficiency and reduces non-cutting time.

● Better surface finish: The 5-sided machining capability yields smoother, more uniform surfaces and finishes.

● Increased accuracy: The coordinated movements of 5 precisely controlled axes enable more accurate machining of complex contours and angles to tighter tolerances.

● Reduced manufacturing costs: The benefits of speed, efficiency, and accuracy translate to lower per-part production costs through higher throughput, less scrap, and rework.

● Improved part consolidation: The ability to machine complex intersections and pockets enables the consolidation of multiple parts into a single complex component. This reduces part count and assembly costs.

● Application versatility: 5-axis milling machines can be used for various applications across multiple industries like aerospace, mold making, die casting, automotive and medical.

● Higher milling productivity: Machining can be performed at higher feed rates on 5 sides of the part, resulting in significantly higher material removal rates and spindle utilization.

There are various things to think about when selecting a 5-axis gantry milling machine to make sure you make an informed choice. The following advice will assist you in the selection process:

Machine structure and design is one of the most important factors

Machine structure and design can greatly influence the machine's performance, capabilities, and overall value. A machine's strong gantry structure, which offers stability and stiffness during machining processes, is something to look for. Think about the machine's architecture, especially where the spindle, tool changer, and cooling system are located.

Provide simple access for tool replacements and maintenance. Examine the building materials, such as steel or cast iron, to guarantee durability and reduce vibrations. Considering this factor upfront can help ensure you purchase a machine that meets your specific needs.

The control system and software form the "brain" of the machine tool and dictate what it is capable of. The control system and software significantly influence the performance and user experience of the machine.

Make that the equipment has a practical and user-friendly control system. Consider looking for features like sophisticated programming ability, simulation tools, and CAD/CAM software compatibility.

Choosing the right options that match your specific needs now and in the future is critical for a successful 5-axis gantry milling machine purchase. Thus, thoroughly evaluate all control system and software aspects during your machine selection process.

Carefully calculating the required work envelope and size based on your specific part geometries and machining needs will help you choose a machine with capabilities matching your application. An undersized device will be very limiting, while an oversized machine may be more expensive than needed.

Choose the machine's size and capacity based on your unique requirements. Consider the machine's maximum workpiece size, weight limit, and dimensions. Additionally, verify that it can support the pieces you plan to produce in size and weight.

Accuracy and precision are critical performance metrics for 5-axis milling machines. Taking the time to understand the specifications, testing methods, component quality, and real-world capabilities as described by the provider is essential for ensuring the machine you choose is a good fit for the tolerances and geometries you need to machine.

Choose a machine that gives excellent precision and accuracy. Think about things like surface finish capabilities, positioning precision, and repeatability. This is essential, especially when working with intricate items requiring precise tolerances. So be sure to ask plenty of questions regarding accuracy and precision during your selection process.

The spindle is the "engine" of the machine tool, and its performance characteristics have a major influence on the machine's capabilities, productivity, and part quality outcomes.

Analyze the machine's spindle speed and power. Greater power lets the machine handle more rigid materials and more demanding cutting tasks, while higher spindle speeds enable quicker cutting rates. The right spindle specs should be chosen based on your particular machining needs. So, carefully evaluating spindle speed and power ranges based on your specific tooling, materials, and intended applications

Testing the machine's ability to work accurately and effectively with your intended tooling and work-holding methods is invaluable during selection. It can uncover potential compatibility issues, accuracy concerns, and accessibility problems before purchasing.

Think about the machine's choices for tooling and workholding and if they are available and compatible. Look into whether your present tooling systems will work with the machine or whether you will need to purchase new tooling. Make sure the machine has appropriate workholding options so that your workpieces may be held securely.

Maintenance and service of the providers should be carefully considered

Understanding how maintenance and service will be handled over the machine's life - from service recommendations to schedules to potential downtime to spare part costs - is essential information for evaluating the total cost and productivity impact of a given 5-axis gantry milling machine option.

Find out how the manufacturer or supplier is known for its customer care and assistance. Ask about the pricing and availability of replacement components. You can rapidly replace worn-out or broken components if your supply chain is trustworthy.

Besides, think about the manufacturer's warranty coverage and technical assistance and training availability.

Carefully evaluating ROI requires a holistic view of the machine's total costs and value-adding benefits to determine financial feasibility and identify the option with the optimal balance of performance and value.

The machine's price should be compared to its features, capabilities, and estimated return on investment once you have established your budget. Although cost must be considered, value for money should take precedence over initial cost.

Additionally, consider the possible ROI based on greater output, shortened setup times, and better part quality.

Referring to unfiltered user reviews and references during your 5-axis gantry milling machine selection process can help verify manufacturer claims, uncover potential issues, and identify which options will likely provide the best experience and value in real-world use.

Thus, don’t hesitate to ask for testimonials and references from other users of the same or comparable equipment. These experiences might offer insightful information about the equipment's effectiveness, dependability, and enjoyment.

Operator training and knowledge levels impact nearly every aspect of a 5-axis gantry milling machine's performance and value over time. Therefore, take into account the expertise and training needed to run the machine correctly. Check whether the supplier or manufacturer offers materials or training programs to familiarize operators with the machine's features and functions.

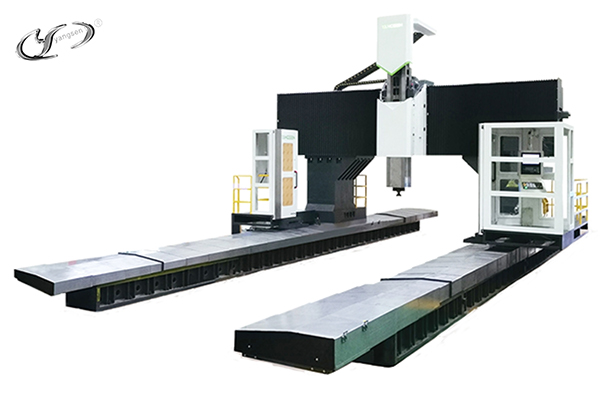

Yangsen is a leading Chinese manufacturer and seller of high-quality CNC machines

Yangsen is a leading Chinese manufacturer and seller of high-quality CNC machines, including 5-axis gantry milling machines. Yangsen is one of China's top exporters of CNC machines. It was established in 2003 and is based in the province of Fujian. They manufacture various machines like lathes, milling machines, machining centers, and gantry routers under their own brand.

Yangsen's series 5-axis gantry milling machines offer outstanding value and performance for the price. Their models come with various work envelopes, making them suitable for multiple part sizes. Their gantry structures' built quality and rigidity ensure high precision and repeatability. The accuracy of linear axes is up to 0.005 mm. Yangsen also designs and supplies customized 5-axis gantries based on customer requirements.

Yangsen has over 20 years of expertise in the CNC machine business and the knowledge and skills required to design, construct, and manufacture high-quality 5-axis gantry milling machines that meet the demands of modern enterprises. They offer competitive pricing and excellent post-purchase support. So if you're looking for a cost-effective yet high-performing 5-axis gantry milling machine solution, Yangsen is a trusted option.

In summary, there are several important factors to evaluate when choosing the right 5-axis gantry milling machine for your production needs. By carefully considering, you can narrow your options to find a machine that meets your requirements.

While there are many reputable brands, Chinese manufacturers like Yangsen offer competitive options with outstanding value and performance. So take the first step and contact Yangsen to find the suitable 5-axis gantry milling machine to boost efficiency, productivity, and part quality for your manufacturing operations.