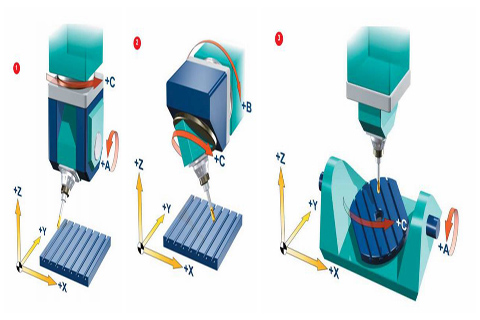

5-Axis machines utilize the typical X, Y, and Z-axes in conjunction with the A and B-axes so that your tools can get to five sides of a part, no extra turning or setup required.

When someone uses the term “5-axis” they are typically referring to the ability of a CNC machine to move a part or a tool on five different CNC axes at the same time. 3-axis machining centers move a part in two directions (X and Y), and the tool moves up and down (Z). 5-axis CNC machining centers can rotate on two additional rotary axes (A and B), which help the cutting tool approach the part from all directions.

5 Axis Machining is a type of CNC Machining. The electromechanical procedure which manipulates apparatuses around three axes to five axes, with high accuracy and precision, cutting off excess materials to create components and parts is called CNC machining. CAD creates the starting design, which is to be machined by CNC machining process. The design is now translated into several CNC codes to give programmed instructions to the apparatuses in a CNC machine.

A 5-axis CNC machine works automatically with minimal human intervention. It uses rotary cutting tools to shape materials placed on the machine platen.

However, placing the material on the platen is the last phase in the 5-axis CNC machining process. The first step in 5-axis CNC machining is making a CAD design of the part and translating it into CAM. CAM, or computer-aided manufacturing, is software that helps generate CNC alphanumeric language or G-code.

The next phase in the process is uploading the G-code into the 5-axis CNC machine. The G-code is very important since it contains instructions that would direct the machine on the toolpath and the right tool for machining.

Working on a 5-axis machine minimizes setups, allows for faster cycle time, produces less scrap, increases spindle uptime, and, contrary to popular belief, actually lessens the need for highly trained individuals, giving your shop the ability to open its possibilities.

The ability of this type of machining to work on 5 different faces of a workpiece simultaneously offers several advantages to many industries. These benefits range from cost efficiency to effective machining. Here are the major benefits of 5 Axis CNC Machining.

1. Machine Complex Shapes

The additional axis added to this machine makes machining designs and geometries with high complexity easy. Also, machining difficult angles and arcs, which is previously achievable using multiple special fixtures, has become feasible with 5-axis CNC machines. In addition, the ability of this machine to rotate parts during a single operation makes it possible to achieve desired geometries with the need for complex machines or fixtures.

2. High Precision and Repeatability

Manual machining operations require extra setups for optimal machining. But these extra setups often introduce design variability and error, causing machinists to lose alignment during machining. However, 5-axis CNC milling involves minimal setups, eliminating the possibility of errors while improving accuracy.

Also, with most 5-axis CNC machines used by machinists today, there is no need for manually repositioning the workpiece during machining. This guarantees improved machining tolerances. What’s more, using shorter cutting tools in some machine configurations improves tool lifespan while ensuring repeatability.

3. Effective Setup Operations

The process of setting up a 5-axis CNC machine is relatively easier than setting up a 3-axis machine. The reason is that 5-axis CNC machines allow work on five surfaces simultaneously. Moreover, 5-axis machines enable the machining of contoured parts with a single structure. However, for conventional 3-axis machines, several setups are necessary to work on several faces.

4. Quality Surface Finish

The surface finish with a 5-axis CNC machine is smoother due to the presence of additional axes. These additional axes bring the workpiece closer to the cutting tool, making it easier to achieve desired shapes. It also allows the use of shorter cutting tools for machining.

With shorter cutting tools, there is little to no vibration, which reduces the incidence of marks on the surface of finished products. Moreover, there is an improvement in spindle utilization for machining angled surfaces when employing the vertical machining process.

5. High Production Efficiency

The 5-axis machining can effectively reduce the machining time and auxiliary time of the parts. It has a large range of spindle speed and feeds rage, allowing the machine to perform a powerful large cutting capacity. 5-axis CNC is entering an era of high-speed machining. The rapid movement and positioning of 5-axis machining and high-speed cutting processing reduce the turnaround time for semi-finished products.

| Type | Working Principle | TCP Management | Advantages | Limitations | Common Applications |

| 5-Axis | Workpiece stationary, tool moves along X, Y, Z axes and rotates around A, B axes simultaneously | TCP must be precisely controlled | High flexibility, accuracy, and surface finish; reduced cycle time | High cost; complex programming; TCP management challenging | Medical, manufacturing |

| 3+2-Axis | Workpiece fixed at specific angle, then 3-axis machining performed | TCP discontinuous between angle changes | Simpler programming; lower cost; can machine complex features | Cannot cut all faces simultaneously; limited flexibility | Mold making, tooling |

| 4+1-Axis | Workpiece stationary, tool moves along X, Y, Z axes and one rotary axis sequentially | TCP fixed during each operation | Simpler programming; lower cost; can access multiple faces | Limited flexibility; cannot cut all faces simultaneously | Automotive, electronics manufacturing |

5-axis CNC machining is ideal for creating parts that require extremely complex geometries, high quality, tight tolerance or even performing traditional machining on odd or tilted surfaces. The following are common industries that make use of 5-axis machining:

1. Medical industry: The high precision that is generated from 5-axis CNC machining, makes it easier to produce precise medical devices, implants, and healthcare equipment. For those medical equipment manufacturers, 5-axis CNC machining is cost-saving and productive.

2. Automotive industry: used to manufacture complex automotive parts, such as engine parts, transmission parts, suspension systems, etc.

3. Mold manufacturing: 5-axis machine tools are used to manufacture complex molds and models, such as plastic injection molds, metal casting molds, etc.

1. The basic component of the Janssen fuselage-casting. Some manufacturers of castings sacrifice the material of bed castings and reduce the number of temperings to reduce costs. Janssen's castings are made according to size

For analysis and research on material mechanics, correct tempering and aging treatment should be performed to meet the mechanical performance requirements of the material.

2. Spindle components: Janssen focuses on every component, and we know that the quality of the components' installation has a great impact on accuracy. It consists of spindle box, spindle motor, spindle, bearings, couplings, motor plate, plum blossom pad, and other parts, and is controlled by the production department at all levels.

3. Feeding components: It consists of Janssen feed three-axis servo motor, three-axis mechanical transmission device and displacement measuring element. The power of the three-axis servo motor will affect the speed and strength of the feed. The three-axis mechanical transmission device is composed of screw rods, guide rails, sliders, bearings, couplings, etc. The grade of the screw and the guide rail are the guarantee of accuracy. The size of the screw and the size of the guide rail are the guarantee of whether the machine tool can perform heavy cutting.

4. CNC operating system: The CNC part of the Janssen machining center is composed of CNC device, PLC servo motion device and operation panel. Operating systems include Germany's Siemens, Japan's Mitsubishi and Fanuc, etc.

5. Automatic tool changing system The automatic tool changing device consists of a tool magazine, a manipulator and other components. The automatic change device of the Janssen machining center can greatly shorten the change time, without manual work, and it is not semi-automatic and increases the efficiency of processing.

6. Auxiliary devices: 72 hours of continuous testing before leaving the factory. The chairman, Mr. Lin, is a technical engineer and personally participates in the factory testing of every machine tool. Auxiliary devices include lubrication, cooling, drainage, protection, hydraulic, pneumatic and detection system parts. In order to ensure the long-term operation of the machining center.

Since 2003, we at Janssen have organized and equipped a strong R&D department with unique innovative spirit and technology

department.

1. More than 30 employees with 15 years of R&D experience

2. More than 50 employees have 10 years of experience in the R&D department.

3. The technical department has more than 35 employees.

4. We allocate more than 7.5% of our turnover as research and development funds every year to enhance our independent research and development capabilities and continuously improve our

Improve the accuracy and cost performance of various CNC machine tools.

After-sales Service:

1. Pre-sales service: Janssen’s sales team will provide users with the best processing solutions, including machine tools

Selection, option configuration, tool and fixture selection, lubricating oil, cutting fluid management and other series of services. and

Turnkey projects available.

2. Maintenance response time: Our company has a service team of up to 50 people and is equipped with complete services

The car will respond within 2 hours after receiving the user’s notification of a breakdown.

3. Parts inventory: Janssen has a dedicated production workshop and parts inventory in Xiamen, with strong strength

Thick, complete inventory, commonly used parts are available in each office to provide users with the fastest

Repair parts.

4. Warranty: The equipment is provided with a one-year warranty from the date of acceptance. During the warranty period, due to

Our company is responsible for free repairs for equipment failures caused by normal users. If it is caused by improper use by the user

In case of failure, a cost fee will be charged after the service.

5. Maintenance charges after the warranty period: The charging standard is clearly stated at the actual price, and only the cost is charged, so as to be open and public.

Serve users with the concept of justice and fairness.

6. Special old user service department: closely track the use of machine tools and handle maintenance complaints in a timely manner.

7. Maintenance supervision: The general manager also serves as the director of the after-sales service department, supervising the quality of maintenance services in real time.

quantity and protect customer rights.