CNC milling, or Computer Numerical Control milling, is a machining process that uses computerized controls to precisely cut and shape materials into complex parts. This technology is essential in modern manufacturing due to its ability to produce intricate and accurate components efficiently, widely utilized in industries like aerospace, automotive, and medical.

Milling curved surfaces is more challenging than flat or straight-edge milling. Curved surfaces require special techniques and careful planning to achieve the desired contours and finishes. These surfaces are commonly found in advanced components such as turbine blades, automotive parts, and medical implants.

This article focuses on the specific challenges and techniques of CNC milling curved surfaces. It aims to provide practical insights and detailed information to help you master the milling of curved surfaces, enhancing your ability to produce precise and high-quality parts.

CNC milling, or Computer Numerical Control milling, is a machining process where computerized controls direct cutting tools to shape materials into precise components. This process evolved from manual milling, where machinists operated milling machines by hand. With the advent of CNC technology in the 1960s and 1970s, milling machines became automated, significantly increasing the precision, efficiency, and complexity of parts that could be produced.

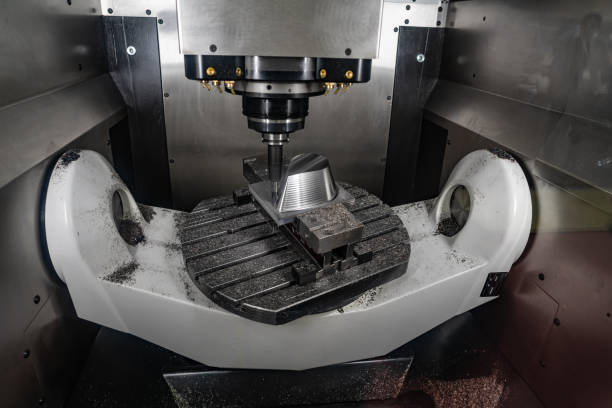

Key components of CNC milling machines include the CNC controller, which interprets the digital instructions; the spindle, which holds and rotates the cutting tool; and the worktable, where the material is secured. Additional components such as cooling systems, tool changers, and enclosures enhance the machine's functionality and performance.

There are several types of CNC milling machines, each suited for different applications:

● Vertical Milling Machines: These machines have a vertically oriented spindle, which moves up and down. They are ideal for flat surfaces and simple geometries.

● Horizontal Milling Machines: These machines have a horizontally oriented spindle, which allows for the milling of heavier and more complex workpieces. They are often used for cutting slots and grooves.

● Multi-axis CNC Machines: These advanced machines can move the spindle and workpiece in multiple axes (typically 3 to 5 axes), allowing for the creation of intricate and complex parts with curved surfaces.

Several fundamental milling operations are essential for various applications:

● Face Milling: Involves cutting a flat surface perpendicular to the spindle axis. It's used to create a smooth, flat finish on the top of the workpiece.

● Peripheral Milling: Also known as slab milling, this operation cuts along the edge of the workpiece with the axis of the cutting tool parallel to the surface being machined. It is used for producing long, straight cuts and contours.

● End Milling: Uses an end mill cutter to produce slots, pockets, and intricate contours. The cutting tool rotates on an axis perpendicular to the workpiece surface, allowing for precise cutting of complex shapes.

In CNC milling, curved surfaces can be categorized into three main types:

● Concave Surfaces: These are inward-curving surfaces resembling a bowl or a hollow shape. Milling concave surfaces requires precise control to ensure smooth and accurate contours, often used in components like molds and turbine blades.

● Convex Surfaces: These are outward-curving surfaces similar to a dome or a bump. Achieving a consistent finish on convex surfaces can be challenging, but they are common in parts such as gear teeth and certain automotive components.

● Complex 3D Surfaces: These surfaces combine multiple curves and angles, creating intricate geometries. Examples include sculpted parts in aerospace and automotive industries, where both aesthetic and functional precision are crucial.

Curved surface milling is essential in various industries, contributing to the production of high-precision and high-performance components:

● Aerospace Components: Curved surfaces are prevalent in aerospace for parts like turbine blades, airfoils, and fuselage components. Precision milling ensures these parts meet strict aerodynamic and performance standards.

● Automotive Parts: From body panels to engine components, the automotive industry relies on curved surface milling to produce parts that are both functional and aesthetically pleasing.

● Medical Implants: Custom implants, such as hip joints and dental implants, often feature complex curved surfaces that must fit precisely within the human body. CNC milling ensures the necessary accuracy and biocompatibility.

● Consumer Electronics: The sleek and ergonomic designs of modern electronic devices, like smartphones and laptops, often incorporate curved surfaces. Milling allows for the production of these smooth, appealing contours.

Milling curved surfaces presents several challenges that require careful consideration and advanced techniques:

● Toolpath Generation: Creating an effective toolpath for milling curved surfaces is complex. The toolpath must account for the curves' varying angles and depths to ensure consistent and accurate material removal.

● Surface Finish Quality: Achieving a high-quality surface finish on curved surfaces can be difficult due to the varying angles and the need for smooth transitions. Optimizing cutting parameters and using the right tools are crucial for a flawless finish.

● Tool Wear and Breakage: Milling curved surfaces can cause uneven wear on cutting tools due to the constant changes in contact angles and forces. This can lead to premature tool wear or breakage, affecting both quality and efficiency. Regular monitoring and appropriate tool selection are essential to mitigate these issues.

Selecting the right cutting tools is critical for successful CNC milling of curved surfaces. Each tool type has unique characteristics suited for specific applications:

● Ball Nose End Mills: These tools have a hemispherical end, which makes them ideal for machining complex 3D contours and curved surfaces. The rounded tip reduces the risk of tool marks and ensures a smooth finish, making them perfect for intricate mold cavities, die shapes, and aerospace components.

● Bull Nose End Mills: Featuring a flat end with rounded corners, bull nose end mills are useful for both roughing and finishing operations. The rounded edges help in reducing stress concentrations, minimizing the likelihood of tool breakage when machining steep or deep curved surfaces.

● Tapered End Mills: Tapered end mills have a conical shape, which provides greater strength and rigidity, making them ideal for milling deep cavities and intricate details on curved surfaces. These tools are often used in mold making and other applications requiring precise and stable cutting.

The choice of tool material and coatings plays a significant role in performance, tool life, and surface finish quality:

● High-Speed Steel (HSS): HSS tools are durable and tough, making them suitable for general-purpose milling. However, they wear out faster than carbide tools, especially when milling hard materials or high-speed operations.

● Carbide Tools: Carbide tools are harder and more wear-resistant than HSS, making them ideal for high-speed milling and machining hard materials. They maintain their cutting edge longer, ensuring consistent performance and better surface finishes.

● Coatings (TiN, TiCN, AlTiN): Applying coatings to cutting tools enhances their performance and longevity. Titanium Nitride (TiN) improves wear resistance and reduces friction. Titanium Carbo-Nitride (TiCN) offers better hardness and lubricity, ideal for harder materials. Aluminum Titanium Nitride (AlTiN) provides excellent thermal stability and wear resistance, making it suitable for high-speed and high-temperature applications.

Effective CNC milling of curved surfaces relies on advanced software for design, toolpath generation, and simulation:

● CAD Software (SolidWorks, AutoCAD): Computer-Aided Design (CAD) software is used to create detailed 3D models of the parts to be milled. SolidWorks and AutoCAD are popular CAD programs that allow designers to develop precise and complex geometries, which are essential for milling curved surfaces.

● CAM Software (Mastercam, Fusion 360): Computer-Aided Manufacturing (CAM) software translates CAD models into toolpaths that CNC machines follow. Mastercam and Fusion 360 are widely used CAM programs that provide advanced features for generating efficient and accurate toolpaths for curved surfaces, including adaptive clearing, contouring, and finishing strategies.

● Simulation Software: Before actual machining, simulation software helps visualize and optimize the milling process. It identifies potential issues like tool collisions and inefficient toolpaths. Integrated simulation features in CAM software, as well as standalone programs, are crucial for ensuring the milling process will proceed smoothly and without errors.

Effective process planning for milling curved surfaces starts with careful design considerations:

● CAD Model Preparation: Preparing a detailed and accurate CAD model is the first step. The model should represent the final product with precise dimensions and features. Designers must ensure that all curved surfaces are well-defined and that the model includes any necessary fillets, radii, and transitions. High-resolution modeling helps avoid discrepancies during machining and ensures the toolpath generation is accurate.

● Surface Continuity and Smoothness: Maintaining surface continuity and smoothness in the CAD model is crucial for achieving a high-quality finish. Designers should use advanced CAD tools to check for and eliminate any discontinuities, sharp edges, or abrupt changes in curvature that could cause issues during machining. Smooth transitions between surfaces ensure that the milling process can produce a consistent and smooth finish.

Selecting the right toolpath strategy is essential for efficient and precise milling of curved surfaces:

● Parallel Milling: This strategy involves machining the surface in parallel passes, typically along a single axis. It is straightforward and effective for relatively simple curved surfaces. Parallel milling provides a uniform finish but may require additional passes for more complex geometries.

● Z-Level Milling: Also known as contour or waterline milling, this strategy involves milling the surface in horizontal layers or "slices" at different Z-levels. It is highly effective for complex 3D surfaces, allowing for precise control over the depth of cut and ensuring a consistent finish. Z-level milling is often used for finishing operations on intricate curved surfaces.

● 3+2 Axis Milling: This advanced strategy uses three linear axes and two rotational axes to orient the workpiece in the optimal position for each cut. It allows for more complex and efficient toolpaths, reducing the need for multiple setups and improving accuracy. 3+2 axis milling is ideal for parts with complex geometries and undercuts, providing greater flexibility and precision.

Proper fixture and workholding methods are essential for stability and accuracy in milling:

● Clamping Methods: Visces and clamps are commonly used to secure the workpiece. Evenly distributed clamping force is crucial to prevent deformation, especially for delicate curved surfaces.

● Vacuum Fixtures: These use suction to hold the workpiece, ideal for thin or delicate parts. Vacuum fixtures provide uniform holding force and can be customized to fit the workpiece contours, ensuring stability and precision.

● Custom Jigs: Specifically designed for the workpiece, custom jigs offer tailored support and alignment. They are especially useful for complex or irregularly shaped parts, maintaining consistent and accurate machining.

Before milling curved surfaces, proper machine setup is crucial to ensure accuracy and efficiency:

● Calibration and Alignment: Machines must be calibrated to ensure all axes are correctly aligned. This prevents errors in toolpath execution and ensures the dimensions of the milled part are accurate.

● Tool Setup and Offsets: Tools must be correctly installed and aligned with the spindle. Tool offsets are set to compensate for tool dimensions and ensure precise cutting depths and contours during machining.

Optimizing milling parameters is essential for achieving desired surface finishes and maintaining tool longevity:

● Spindle Speed: The rotational speed of the spindle affects cutting efficiency and tool life. Higher speeds are generally used for smaller tools and softer materials, while lower speeds are suitable for larger tools and harder materials.

● Feed Rate: Feed rate determines how quickly the cutting tool moves through the material. It impacts machining time, surface finish, and tool wear. Adjusting the feed rate optimally balances material removal rates with tool life and surface quality.

● Depth of Cut: The depth of cut refers to the thickness of material removed in each pass. It influences cutting forces, tool wear, and surface finish. Optimizing the depth of cut ensures efficient material removal without compromising part integrity or tool performance.

In a nutshell, CNC milling is integral to modern manufacturing, enabling precise fabrication of complex components essential across industries like aerospace, automotive, and medical fields.

Milling curved surfaces presents distinct challenges requiring specialized techniques and careful planning for achieving precise contours and optimal finishes. This article provides practical insights to enhance proficiency in CNC milling of curved surfaces, emphasizing the importance of advanced tools, software, and meticulous process optimization.

● Achieving precise toolpaths

● Maintaining surface finish quality

● Managing tool wear.

Ball nose end mills for smooth finishes, bull nose end mills for roughing and finishing, and tapered end mills for deep cavities.

Optimise cutting parameters like spindle speed, feed rate, and depth of cut, and use appropriate toolpath strategies.

CAD software like SolidWorks and AutoCAD for design, and CAM software like Mastercam and Fusion 360 for toolpath generation.