Lathe machines have drastically transformed the manufacturing industry by enabling the precision machining of multifaceted parts. In general, there are various types of lathes you will come across. However, CNC lathe machines, in particular, are quite renowned and stand out from other types of lathes due to their utmost precision, versatility, and efficiency.

Undoubtedly, CNC lathes offer superior control over the manufacturing process, and their tools play a crucial role in shaping and cutting materials. In this article, we will delve deeper into the different types of lathe tools, their functions, and their relevance to CNC lathe machining. Whether you are a novice or an expert, a deeper understanding of these tools can aid you in optimizing your machining process for better results.

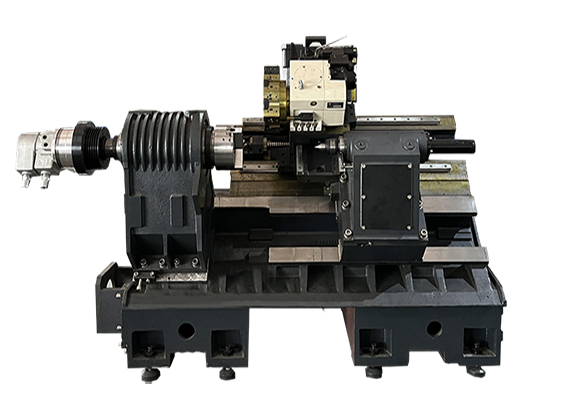

A CNC lathe is a computer-controlled lathe that uses Computer Numerical Control (CNC) technology to perform automated precision machining. The primary job of a CNC system is that it regulates the movements of machines with the utmost level of accuracy.

Due to this reason, CNC lathe machines are highly desirable and widely used in a vast array of industries. These mainly consist of the automotive, aerospace, electronics, and metalworking industries.

Some of CNC Lathes’ key features include:

One of the key defining features and benefits of CNC lathes is their extraordinary precision. These machines enable operators to create complex and precise cuts with extreme accuracy.

This ultimately makes them well-suited for applications that call for tight tolerances. The CNC lathe’s automated nature ensures that every movement is planned and controlled down to the minutest detail.

Consequently, this vastly eliminates any chances of human error that are likely to occurs with manual machining. For aerospace, automotive, and medical device manufacturing industries, even a slight deviation can result in major issues.

Luckily, CNC lathes offer you the reliability and precision required for high-quality production. Suffice it to say, CNC lathes enable you to achieve repeatable accuracy in every single part, even in more significant production runs.

CNC lathes are the most versatile of all and can handle a vast spectrum of materials, including metals, composites, plastics, and even wood. Rest assured, a CNC lathe accommodate a diverse range of materials without requiring significant modifications.

So, regardless of whether you are machining soft materials like aluminum and plastic, or harder metals such as steel and titanium, CNC lathes can do it all. In addition, they can carry out various functions such as turning, facing, drilling, and threading.

Altogether, a CNC lather is the ultimate solution for complex machining projects. This versatility can especially benefit manufacturers who have to produce components with diverse specifications and from different materials in a single setup.

CNC lathes are renowned for offering a high degree of automation, which makes them stand out from traditional manual lathes. After developing a program and inputting it into the machine, it can run continuously without requiring manual intervention.

With this remarkable feature, you can expect to see enhanced productivity as it allows operators to focus on other tasks while the machine performs its operations. Automation also results in reduced labor costs and minimizes the chance of errors associated with human input.

Additionally, CNC lathes can store multiple programs in the machine. Hence, this allows for quick switching between different production tasks, minimizing downtime and boosting flexibility.

CNC lathes can run round-the-clock because with minimal supervision. This makes them highly productive and cost-effective for both small and large-scale production.

Unlike manual methods, these machines operate at significantly high speeds that drastically cuts down production time.

Moreover, thanks to the precise control over cutting paths and material exclusion, CNC technology optimizes material usage by minimizing waste.

The increased efficiency also extends to energy consumption, as many CNC lathes are designed to consume less power while working. This efficiency expedites production and contributes to a more sustainable manufacturing process.

CNC Lathe tools are used to perform a wide array of operations such as facing, cutting, turning, knurling, threading, and drilling on workpieces. In a CNC lathe, choosing the right tool is essential in determining the machining process’s success.

This is because each tool has a specific application based on the shape and material of the workpiece. Now, we will take a more in-depth look at the most common types of tools used in CNC lathe machines:

Turning tools are one of the most prevalent tools in a CNC lathe. They are primarily designed to perform internal and external turning operations, and you can use a turning tool to remove excess material from the workpiece. Here are some examples of turning tools:

● Rough Turning Tools: These tools are essential in removing more significant amounts of material efficiently, in a relatively shorter period.

● Finish Turning Tools: After roughing, finishing tools are utilized to create a smooth surface finish on the workpiece.

Initially, you need to use a drilling tools for making holes in the workpiece. These holes can then be further enlarged or refined using boring tools, which is discussed next. In CNC lathe machines, drilling tools offer high precision and consistency. Here are some examples of drilling tools:

● Center Drills: They feature spiral grooves for efficient chip removal and are used to create pilot holes for more accurate drilling.

● Twist Drills: They establish a starting point for larger drill bits and are commonly used in CNC lathes for drilling a diverse range of materials.

Boring tools mainly help in enlarging holes that have already been drilled into the workpiece. These tools are important for achieving the most sough-after internal diameter and finish. Here are some examples of boring tools:

● Single-point Boring Tool: This is used for precise enlargement and finishing of holes.

● Fine Boring Tools: They provide a more accurate surface finishing for internal bores.

● Boring Bars: They offer superior stability for diameter holes that are larger in size.

If you need to create screw threads on the workpiece, a threading tool can be significantly useful. After all, these tools are designed to produce consistent and accurate threads in CNC lathe machines. Here are some examples of threading tools:

● Internal Threading Tools: They help in cutting internal threads within holes.

● External Threading Tools: They are primarily used to cut threads on the external surface of the workpiece.

● Die Head Threading Tools: These are best-suited for high-volume, rapid threading production.

● Single-point Threading Tools: They provide a precise threading option for custom profiles.

Grooving tools help in creating grooves on the workpiece’s surface. You can find them in an array of different sizes and shapes, depending on the type of groove required. Here are some examples of grooving tools:

● Internal Grooving Tools: They are used for cutting internal grooves in bores, holes or hollow areas.

● External Grooving Tools: They are explicitly created for making external grooves on cylindrical workpieces.

Sometimes you might need a knurling tool to create textured patterns on the surface of the workpiece. This is commonly used for improving the grip on items such as tool handles or knobs. Here are some examples of knurling tools:

● Straight Knurling Tools: You can use this to create linear patterns.

● Diamond Knurling Tools: This helps in creating cross-hatched patterns.

Parting tools are used for cutting off a portion of the workpiece. These tools are relatively thin and sharp, allowing you to create a narrow cut without hampering the remaining material’s quality.

● Insert Parting Tools: They provide versatility in parting operations.

● Blade Parting Tools: They are the most common type of parting tools and offer high rigidity.

Facing tools help in establishing a smooth surface on the face of the workpiece. This process is crucial for preparing the part for further machining. Here are some examples of facing tools:

● Side Facing Tools: They are used to remove material from the side of the workpiece.

● End Facing Tools: They smooth out the face at the end of the cylindrical workpiece.

|

Turning Tools |

● High material removal rate (MRR). ● Precisely shapes cylindrical parts. |

|

Drilling Tools |

● High-speed drilling with accuracy. ● Can be found in various sizes and shapes. |

|

Boring Tools |

● Precision in internal machining. ● Consistent bore diameter. |

|

Threading Tools |

● Accuracy in thread cutting. ● Ideal for assorted thread pitches and sizes. |

|

Grooving Tools |

● Flexibility for creating precise grooves. ● Available for both internal and external operations. |

|

Knurling Tools |

● Enhanced surface grip. ● Aesthetic surface finishing. |

|

Parting Tools |

● Accurate and clean cuts. ● Appropriate for narrow cut-off operations. |

|

Facing Tools |

● Guarantees a flat surface for further machining. ● Perfect for high-speed operations. |

The materials used in CNC lathe tools can significantly impact the lifespan, performance, and wear resistance of a tool. This is why it is important to have a proper understanding of the materials used in the manufacture of these tools.

HSS tools are quite prevalent and can be used in general-purpose machining. They offer optimal sturdiness and good wear resistance and are versatile and cost-effective. However, compared to carbide tools.

In general, HSS is deal for general-purpose machining, including tasks such as drilling, turning, and light milling operations.

Ceramic tools offer excellent resistance to heat and wear, making them ideal for high-temperature machining, high-speed cutting, especially in applications where heat resistance is crucial, such as machining cast iron or hardened steels. However, they are brittle and prone to breakage under heavy loads.

Carbide tools are renowned for their unmatched wear resistance and hardness. This makes them ideal for high-speed machining of tough materials, particularly in operations involving the cutting of hard metals such as stainless steel, titanium, and alloyed steels.

Diamond tools are quite popular and provide the ultimate wear resistance and cutting precision. These tools are primarily used for ultra-precise finishing and cutting in non-ferrous metals and composite materials.

Choosing the most appropriate tool for your CNC lathe involves considering various critical factors to ensure optimal performance and precision. The choice of tool can significantly impact the quality of the workpiece and the efficiency of the machining process.

The hardness of the material you are working with plays is essential in determining the type of cutting tool needed.

For instance, harder materials, such as stainless steel or titanium, call for more durable and heat-resistant tools such as carbide or ceramic as they can effectively withstand the stress and wear during machining.

The speed at which the tool operates and the rate at which the material is fed into the tool are also worth considering.

Each tool is designed to function at its peak within a specific speed range. Hence, it is essential to opt for a tool that aligns with your machine’s capabilities for maintaining efficiency and extending tool life.

The nature of the machining operation also dictates the choice of tools. Roughing operations require robust, heavy-duty tools capable of withstanding high levels of force as they involve removing significant amounts of material.

On the other hand, finishing operations call for finer details and smoother surfaces, so they require precision tools that offer superior control and accuracy.

Many CNC lathe tools are coated with materials such as titanium nitride (TiN) or aluminum oxide that aid in boosting their wear resistance. These coatings enhance the tool’s lifespan and minimize friction, allowing for smoother cuts and better heat dissipation during high-speed operations.

The shape and design of the cutting edge, along with its sharpness and angle have a direct influence on cutting efficiency and the finish quality of the workpiece. For example, the sharper the edges, the cleaner the cuts.

However, they may wear out faster. On the other hand, more durable edges may be able to tackle tougher tasks but may not deliver the same level of surface smoothness.

By carefully evaluating each of these factors, you can select the CNC lathe tool that best matches your specific machining needs while ensuring both productivity and superior results.

Due to their versatility, CNC lathe tools can be used across various industries. Each industry has its own set of demands for CNC lathe tools that call for careful tool selection and management.

● Automotive: Best for producing precision engine components, shafts, and fasteners.

● Aerospace: Ideal for manufacturing critical components requiring high tolerances.

● Medical Devices: Good for creating small, intricate parts used in medical instruments.

● Oil and Gas: Suitable for producing drilling and exploration equipment.

● Electronics: Great for precise machining of small components like connectors and terminals.

Proper tool maintenance is critical to achieving consistent results and maximizing the lifespan of CNC lathe tools. For instance, it is important to sharpen tools regularly to ensure proper cooling during operations.

Moreover, you should continuously inspect for wear to extend the life of the tools and ensure high-quality output.

Additionally, CNC lathe operators must monitor the most important indicators such as surface finish degradation, tool chatter, and dimensional inaccuracies to prevent tool failure.

By replacing or repairing the tools before they fail, manufacturers can maintain the efficiency of their CNC lathe operations.

All in, CNC lathe tools play a crucial role in the world of precision machining and are indispensable for creating accurate, high-quality parts.

Whether you are cutting, drilling, boring, threading, grooving, facing, or parting, the right tool is critical to achieving desired results.

Hence, with an in-depth understanding of the different types of lathe tools available, along with their material composition, machinists can make the most of the longevity and performance of their CNC lathe systems.

With technology rapidly advancing, the role of CNC lathes is only expected to continue to grow in the future. Rest assured, it will provide manufacturers with the precision and efficiency needed to meet the demands of modern-day competitive markets.

Finally, by focusing on proper tool selection and maintenance, you can rest assured that your CNC lathe will deliver optimal performance for years to come.