Welcome to an all-inclusive guide on CNC fixtures. In this guide, the aim is to delve deep into the design, types, and uses of CNC fixtures. The topic brings to light how CNC fixtures bring precision and efficiency to the world of machining. One will gain deep insight into the fixtures' indispensable role in CNC machining.

Proper positioning is key in CNC fixtures. It's the datum that starts every process. A CNC fixture holds a workpiece in a secure, specific spot for accurate machining.

CNC fixtures provide stability. They clamp down on the workpiece, keeping it steady. Without proper stabilization, precise cuts are impossible.

Consistency is critical. CNC fixtures ensure the same position for each workpiece. This results in identical parts, time after time.

CNC fixtures play a huge role in accuracy. With a set position and stability, each cut happens exactly as intended.

With CNC fixtures, production becomes faster. Once set, the fixture holds the workpiece, eliminating the need for manual adjustments.

Safety is paramount. Fixtures secure workpieces, reducing the chance of accidents. A secure workpiece means a safer workspace.

Fixtures help prevent damage. By holding the workpiece firmly, accidental slips or movements are avoided. A secure workpiece ensures a damage-free process.

CNC fixtures provide repeatability. With them, identical parts can be made consistently, time after time.

Rigidity is vital in CNC fixture design. A rigid fixture minimizes vibrations, leading to higher accuracy.

A well-designed fixture assures accuracy. It keeps the workpiece in the correct position, resulting in precise machining.

Compatibility is crucial in fixture design. The fixture needs to match the shape, size, and material of the workpiece.

Accessibility is key in fixture design. The fixture must allow the cutting tool to reach all necessary areas.

Fixtures should be easy to set up. Complex setups can slow down the process and cause errors.

A good fixture prevents damage. It holds the workpiece securely to avoid accidental slips or movements.

Fixture design should allow interchangeability. This feature allows the same fixture to hold different parts, increasing efficiency.

In the heart of a CNC Fixture sits the body. Built from hardened steel, its rigidity ensures stability during operations. Spanning from 200mm to 600mm, the body size adapts to various manufacturing needs. Durable, precision-engineered, the fixture body is a cornerstone in CNC operations.

Locating pins, integral to fixture design, guarantee exact workpiece placement. Made of HSS or carbide, they withstand high stress. Their diameters vary between 1mm and 20mm, allowing snug fit. Locating pins, indeed, make precision possible.

Clamping devices, crucial for firm hold, secure workpieces in place. Hydraulic or manual, these devices offer force from 500N to 5000N. Varied shapes - wedge, strap, swing, satisfy different needs. Without clamping devices, CNC operations face instability.

Supporting surfaces, usually flat, maintain workpiece stability. Their sizes align with the workpiece dimensions - as small as 50mm, as large as 500mm. Cast iron or steel made, their strength is unquestionable. These surfaces indeed offer solid support.

CNC fixtures house adjusting mechanisms for precision. From micrometers to lead screws, they allow changes as minute as 0.01mm. Aiding precise alignment, they reduce errors. Adjusting mechanisms, in essence, promote accuracy.

Guide elements direct workpiece movement. Often made of tungsten carbide, they tolerate wear. Ranging in diameter from 5mm to 50mm, they guide varied workpieces. Guide elements indeed streamline CNC operations.

A fixture base, typically flat, provides solid grounding. Cast from grey iron, it bears considerable weight. Sizes vary from 400mm to 1000mm to accommodate diverse fixtures. Undoubtedly, a fixture base sets a firm foundation.

Fixture plates offer a canvas for fixture configuration. Made of aluminium or steel, they resist deformation. Spanning 100mm to 800mm, they cater to varied needs. Fixture plates, indeed, offer the freedom of design.

Workpiece contacts touch the workpiece directly. Made from wear-resistant materials like carbide, they ensure longevity. Diameters range from 1mm to 50mm, fitting diverse workpieces. Workpiece contacts are integral to precise manufacturing.

Clamp actuators apply force, securing the workpiece. Manual or pneumatic, they provide up to 10kN of clamping force. Differing shapes accommodate unique needs. Clamp actuators, truly, keep things tight.

Vise fixtures, called VF in industry talk, hold workpieces tight. Solid metal makes them robust, durable. Use them for milling, drilling tasks. Two jaws squeeze the part. One stays put, the other moves.

Indexing fixtures, or IF, rotate workpieces with precision. One complete turn is 360 degrees, and offers accurate positioning for machining different sections. Use them in milling, drilling operations. A manual crank or automated mechanism spins the workpiece.

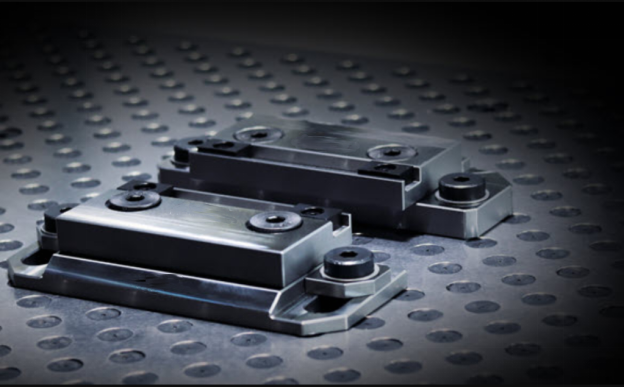

Modular fixtures are known as MF, offer flexibility. Assemble, reconfigure as per workpiece dimensions. Many components, like base plates, blocks, clamps. You can use for prototyping or small production runs. It’s easy to switch between different jobs.

Magnetic fixtures(Magnetic chuck), MF again, use magnetic pull. Switch them on, workpieces stick. Switch off, release. Use with ferromagnetic materials, like iron, steel.

Hydraulic fixtures, short HF, use fluid power. Clamps apply force, hold workpieces. Use in high-volume, high-precision manufacturing. It ensures quick, secure, consistent clamping every time.

Vacuum fixtures, VF, use air pressure. Workpiece stays put, sucked onto surface. No clamps, unhindered machining access. Use with non-magnetic, non-ferrous materials.

Custom fixtures, CF, are tailor-made solutions. Design them as per unique workpiece needs. Use with complex shapes, delicate materials. Customization ensures optimal machining efficiency, precision.

A CNC fixture's role is pivotal. Its function is to secure the workpiece during machining. Precise alignment is crucial, ensuring accurate cuts. No room for errors in tolerance; every millimeter counts.

Choosing the right material matters. Hardened steel stands out, boasting robustness. Yet, lighter materials like aluminum have merit too. Remember, the material's rigidity should withstand high machining forces.

Dimensions demand meticulous planning. There's a balance; fixtures must be small enough for machine tables, yet large enough to secure the workpiece. Sizes can range from 20 to 200mm, but each depends on the specific job.

The workpiece guides fixture design. A 50kg workpiece needs a sturdy fixture. Keep in mind, complex shapes may need bespoke fixtures.

Clamping plays a significant role in fixture design. Quick-release clamps offer efficiency. In contrast, toggle clamps provide high holding force. Therefore, factor in workpiece shape, size, and weight when selecting clamps.

Even stress distribution is essential. Improper stress can warp the workpiece, leading to inaccurate machining. So, proper placement of supports and clamps is crucial.

Safety remains paramount. A fixture should prevent workpiece movement during machining. Also, accidental release mechanisms are a must-have, protecting operators during unexpected machine shutdowns.

Before full-scale production, a fixture prototype is created. A three-axis milling machine might make the first model. Testing is rigorous, revealing any design flaws.

End-users provide invaluable feedback. Their insights drive continuous fixture improvement. From easy setup to improved clamp design, user experiences can reshape future CNC fixtures.

Precision matters in CNC fixtures. Before setup, cleanse the surface. Use industrial-grade cleaners, not solvents. Scrub the surface gently, removing particles. A clean fixture equals high precision work.

Straightness and alignment are crucial. Use a Dial Indicator for alignment checks. Record deviations, note the values. Precise alignment boosts workpiece accuracy. Always check alignment before operations.

Position clamps correctly on your fixture. Use the CAD/CAM software for exact coordinates. A millimeter's deviation can cause errors. A well-placed clamp ensures stability.

Fastening is vital for stability. Apply appropriate torque, use a torque wrench. Reference the manufacturer's instructions for exact values. The right force ensures secure fastening.

Every function must work as expected. Test the coolant flow, spindle speed, and feed rate. Verify each cycle time. Proper testing leads to accurate production.

Training yields better performance. Understand fixture setup, operation, and safety procedures. Know the software language and commands. Training promotes safe and efficient operations.

Regular fixture maintenance extends lifespan. Lubricate moving parts every 100 operational hours. Inspect wear and tear every 200 hours. Schedule repairs immediately if needed. Timely maintenance prevents unexpected breakdowns.

Fixing workpieces for drilling needs precision. CNC fixture holds parts at 90 degrees. Stability is vital in achieving exact holes. Drill bits vary from 0.05 to 75mm. Automated fixtures adjust as per the workpiece dimensions.

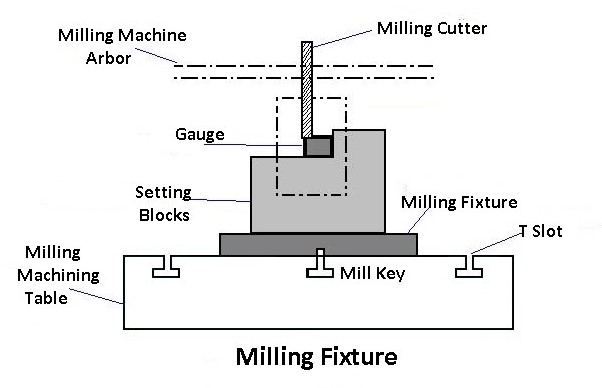

Milling jobs require distinct CNC fixture setups. Accurate placement of workpieces matters. Parameters like cutter size, speed (RPM), and depth play crucial roles. High-speed steel (HSS) or carbide cutters are common in milling.

CNC fixture in turning offers consistent results. Clamping forces must be balanced to avoid part deformations. The workpiece rotates at RPM between 1000 to 3000. Correct fixture setup can prevent tool crashes.

Fixturing in grinding operations demands precision. Holding workpieces rigidly reduces grinding errors. Abrasive wheels cut off material in microns. Wheel size, grit size, and speed parameters are critical.

EDM or Electric Discharge Machining uses CNC fixture for die sinking. Brass or copper electrodes remove material through sparks. The gap between workpiece and electrode is usually 0.01mm to 0.5mm.

CNC fixture setups in laser cutting ensure quality. Focused laser beams, usually 10-20 micrometers wide, cut through the material. The correct placement of workpieces enhances cutting precision.

Welding applications benefit from rigid CNC fixture. Consistent clamping forces help avoid weld distortions. Robotic welding fixtures can handle parts weighing up to 500kg.

In assembly, CNC fixture aids precision. Fixtures hold parts in exact alignment. Assembly parameters like part dimensions and torque settings guide fixture design. Use of CNC fixture makes the assembly process fast and efficient.

Your CNC Fixture may sometimes show signs of misalignment. Misalignment results when X, Y, or Z-axis offsets aren't set correctly. Accurate offsets assure precise production.

Common causes include worn-out screws or a damaged guide rail. Always inspect your machine and rectify any irregularities early. Early detection prevents potential breakdowns and improves machining efficiency.

In CNC machining, proper workpiece clamping is crucial. Failures may occur due to damaged clamping jaws or hydraulic pressure issues. Consider CNC fixture designs that ensure firm hold. Strong clamps safeguard against tool vibrations, thus ensuring smoother operations. Remember, well-maintained clamps are vital for product quality.

Fixtures need robust structures for optimal operations. Poorly designed fixtures might present defects, causing inefficient production. Common issues involve broken dowel pins, damaged base plates, or worn-out bushings. Hence, conducting regular checkups on fixture components is crucial. Structural integrity fosters quality, precision, and consistency in machining tasks.

Over time, your CNC Fixture can show signs of wear. Constant friction between the workpiece and fixture causes deterioration. Check for worn surfaces on fixture clamps, base plates, and locators. Regular maintenance can extend fixture life and maintain its functional efficiency.

Precision is the cornerstone of successful CNC operations. However, fixtures can lose accuracy over time. Misalignment, wear, or structural defects may cause this. Regular recalibration using CNC coordinate measuring machines can enhance accuracy. Precise fixtures guarantee high-quality final products.

CNC fixtures, like any industrial equipment, need routine cleaning. Accumulated debris and coolant residues may compromise fixture performance. Use approved industrial cleaning solvents to remove stubborn grime. Regular cleaning ensures fixture longevity and operational efficiency.

CNC fixtures must match the workpiece material. Wrong material pairing can cause production challenges. For example, using a steel fixture for an aluminum workpiece might present problems. Compatibility ensures smoother machining processes and higher quality outcomes.

Correct fixture installation is key for efficient CNC operations. Mistakes may occur due to incorrect positioning or wrong assembly. Following the manufacturer’s manual can guide correct installation. Always ensure that fixtures align correctly with the CNC machine axis. Correct installation promotes precision and efficiency.

Fitted with A-Axis and B-Axis, rotary fixtures give precise results. They handle parts with circular patterns with ease. CNC machining gains speed and accuracy. Versatility is their strength, allowing varied machining on a single setup.

Air power runs these fixtures. Main parts include valves, cylinders, and FRL units. Fast clamping and unclamping do result in high productivity. Safety increases as hands stay away from the clamping area. Ruggedness is another upside, ensuring longevity.

Trunnion fixtures boost CNC capabilities. These fixtures hold parts between two angled plates. Both plates pivot around a central axis. Such an arrangement allows for complex operations. Precision is their hallmark in five-axis machining.

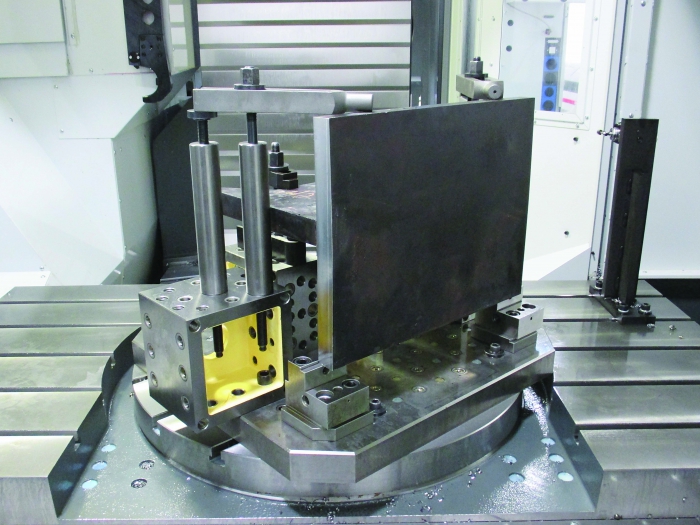

Tombstone, or column fixtures, maximizes workspace utility. Standout features include verticality and multiplicity. They hold multiple parts on various faces. Vertical machining center arrangement means gravity assists chip removal. The result: smooth, uninterrupted CNC machining.

For batch processing, multi-station fixtures are key. Each fixture holds different parts simultaneously. Operations like cnc milling machine, cnc drilling machine, and tapping happen in one go. The fixtures move from one station to another. Efficiency and time-saving stand out here.

These fixtures work under intense pressure. High-pressure coolant channels clear out chips from deep holes. The upside is better surface finish and longer tool life. High-pressure fixtures excel in handling tough materials.

Having unraveled the intricate world of CNC fixtures, the takeaway is clear. Fixtures, through their design and types, underpin CNC machining's efficiency and accuracy. From positioning workpieces to maintaining consistency, they are integral to smooth operations.

To explore further, visit CNCYANGSEN for a closer look at these remarkable tools that boost productivity in machining. The adventure in the dynamic world of CNC fixtures waits. Be part of it.