Struggling with Precision Manufacturing? It is common for many manufacturers and engineers to experience problems with quality fluctuations and organizational challenges. Such problems can increase costs of production and lead times, hence affecting competitiveness. CNC machines are a reliable solution, which is needed to achieve high accuracy and stability in manufacturing operations. Such technologies improve efficiency and quality of products hence enabling business organizations to meet market needs in the best way possible.

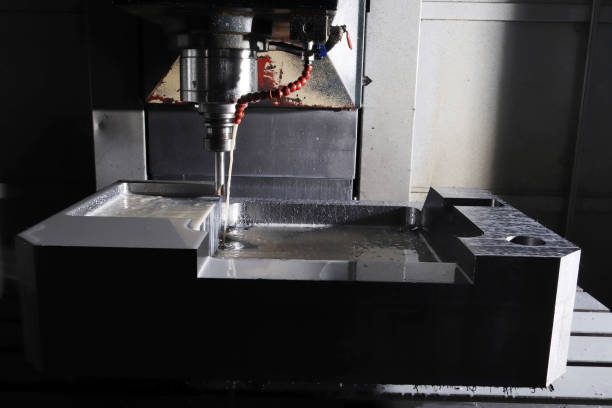

CNC is an abbreviation for Computer Numerical Control and means that we are dealing with computer-controlled manufacturing. This process incorporates superior software that commands the actions of a machine which enhances the shaping and slicing of materials. CNC is an abbreviation of Computer Numerical Control, which points to the application of a program for the operation. This technology helps cut down on cost, and time and minimizes mistakes made during production. CNC machining is widely used in industries as a way of cutting small and complex parts and components.

CNC machining follows a well-defined process that can only be initiated when a program has been created. First and foremost, the design is made in the form of a digital layout on a computer-aided design tool. After which, this design is fed to the CNC machine which breaks it down through G-code for interpretation of what has to be done. All these commands make the machine work after setup to cut materials to the required precision. It is important to comprehend this process to achieve improved levels of manufacturing effectiveness and product quality.

CNC machining is preferred in a production environment for several reasons. It provides high accuracy and reproducibility which is very effective in manufacturing quality parts. This technology also improves efficiency by cutting on physical work and consequently shortening the time taken in production. Since CNC machines can handle several materials, they can respond to different manufacturing requirements. In addition, they also permit the creation of designs that are difficult to manufacture, and thus it is easy to create many parts with a high level of detail.

Aerospace production relies on CNC machines to create accurate parts including turbine blades, fuselage frames, and landing gear parts. These components may demand extreme precision; dimensional control may be permitted to a range of plus or minus 0.0005 inches. The high-volume machining of such materials as titanium and carbon fiber composites is critical because these materials offer the high strength-to-weight ratio that is required for aircraft and fuel efficiency.

In the automotive industry, the application of CNC machining is critical for the production of intricate parts such as engine blocks and heads, as well as gears and housing. CNC machines have made it easier to produce geometries that have small tolerances hence making the assembly process easier. CNC machining also aids just-in-time manufacturing hence enabling quick production runs that can easily change to meet the ever-changing consumer needs hence minimizing inventory costs.

CNC technology plays an important role in the manufacturing of medical instruments and surgical instruments where accuracy is of immense importance. Products like orthopedic implants, dental instruments, and surgical robots have complex geometries that must conform to the requirements for biocompatibility. These components are easy to manufacture using CNC machines and with high surface finishes and accurate dimensions to function optimally in the human body.

Computer numerical control is used to shape the electronic housing enclosures that shield delicate parts from the physical conditions. Such enclosures may contain vent holes, mounting holes, and cable management systems among other parts. The flexibility in handling aluminum and plastics means that the company can provide lightweight enclosures that improve device sturdiness and ease of use.

The furniture industry more and more uses CNC machining for the fabrication of complex wood and composite parts. Machines can do more detailed designs than by hand, like the dovetails that often are used and curves, too. This technology improves product production by reducing wastage from poor cutting paths and allows the production of multiple products in one design.

CNC machining is a critical step in the development of a product prototype. It enables engineers to make accurate models that are based on CAD files to encourage rapid prototyping. This kind of fast-track approach fosters better integration between design functions and shortens the new product development cycle, thus improving time-to-market for radical innovations.

CNC machines are employed in making special tools, which include, jigs, fixtures, and molds in manufacturing sectors. These tools are meant for some particular operation that aids in enhancing the rate of production and precision. Special tools also eliminate time wastage that is usually spent when changing from one part to the other, which is very important, especially in quality control.

CNC machining is widely used in mold making for injection molding and casting. Accuracy is critical when using molds to form parts because the end product must meet a particular quality and surface finish. Mold geometries that are difficult for conventional machining techniques can be made using CNC machines, thus creating improved replicas in a high-volume production process.

In the marine industry, various parts like propellers, hulls, and the support structures of the boats are made by using CNC machines. These parts include Stainless steel and marine-grade aluminum that can endure tough marine conditions. CNC machining is used to mill precise and high-quality components required for performance criteria in marine vessels thus improving the safety of the vessels.

CNC machining is becoming more popular in the architectural field, where many intricate parts such as molding, façade, and customized structures are manufactured. The use of technology in construction ensures that intricate designs are well-copied to improve the appearance and functionality of structures. CNC machines are versatile and can cut stone, wood, metal, and others making it possible to design and create interesting shapes for use in architecture.

CNC machines are vital for creating defense and military products because accuracy is vital in such a sector. Things like gun barrels and parts of armored vehicles have to have exact conformity to be deemed reliable enough and to work as intended. CNC technology is useful in manufacturing these delicate parts since it increases operational readiness. Also, the ability to rapidly prototype allows the defense sector to provide new designs and changes to meet the changing needs of the military quickly. Another advantage of CNC machines is flexibility in the application of materials as well as the application of improved materials when operating under challenging conditions.

The energy sector is another industry where CNC machining is critically important for manufacturing parts for renewable energy solutions. Components like wind turbines, photovoltaic structures, and conducting tools must be made of materials that can effectively prevent deformation due influence of one or the other. Large components can be molded with a better finish with the help of CNC machines and this is very important. Such geometries are also useful in ensuring that energy such as that in systems like wind turbines is used efficiently. In addition, CNC technology helps producers expand production capacity, addressing the increasing need for renewable energy solutions while providing only high-quality products.

CNC machining has made the jewelry and watchmaking industries undergo a major rethink by making designs that were thought impossible to be created to be created possible. They revealed that through the use of machines, people can engrave, cut, and polish precious metals and gemstones in the best manner possible with a lot of consideration for quality. This capability makes it possible for manufacturers to meet the consumers’ demands for customized jewelry conveniently. CNC technology also helps to improve the repeatability of production runs, thereby minimizing the production of parts with defects, and to maintain the accuracy of the design in use. CNC machines help present new collections frequently so that jewelers can meet the fashion industry’s rate.

CNC machines are particularly important when it comes to aerospace and defense industries due to prototyping. They allow engineers to develop and simulate an aircraft part or a military system quite effectively. The actual fine-tuning of designs during the prototyping phase helps designers work on improvements in subsequent cycles to make final products conform to high-performance standards. Computer numerical control makes it possible to make parts from CAD designs within a short duration of time thus reducing development time. Also, high accuracy and material compatibility are vital to achieving the quality of the work that is demanded by aerospace and defense industries.

CNC machining is one of the most prominent technological advancements in modern manufacturing as it is highly accurate, highly productive, and highly flexible cutting across most industries. From the aesthetics of the designs in the jewelry and watch industry to the essentials of the defense and aerospace industries, CNC technology is highly significant. As industries grow and the need for higher quality and precision in products is valued, CNC machining will be the key focus of future manufacturing. Any firm that adopts this technology will not only improve its production processes but also keep abreast with market changes.

Q1: Which industries get the most value from CNC machining applications?

CNC machining is implemented in almost all sectors of the economy, such as aerospace, automotive, defense, medical, energy, electronics, and consumer goods industries. All the sectors use CNC technology to obtain accuracy, speed, and consistency in creating intricate parts in manufacturing.

Q2: How does CNC machining enhance the production process?

CNC machines are used to generate different products, which minimizes the chances of human interference as well as the time taken in the process. As these machines can be run for lengthy periods, many parts can be manufactured with little interruption. This efficiency is important especially for delivering in a short time and being competitive.

Q3: What kind of materials are suitable for use in machining through the use of CNC technology?

CNC machining can work with metals such as aluminum, steel, and titanium and plastics such as ABS, nylon, and polycarbonate as well as wood and composite material. CNC machines enable the manufacturers to choose materials depending on the need of the application ranging from strength, weight, and resistance to corrosion.

Q4: In what way does CNC machining help in the process of rapid prototyping?

CNC machines make it easy to develop prototypes in a short span because one is in a position to make changes to the CAD models easily. This makes the process of testing and convergence relatively faster which is very necessary in industries such as aerospace industries and the automotive industries where many changes are expected.

Q5: How does CNC machining fit into the quality control chain?

Quality control is achieved through the precision and repeatability which are inherent in the use of CNC machining. Modern CNC machines come equipped with measurement systems that enable the pro-active control of part dimensions and hence the quality of the final product and minimization of time spent on inspection of the manufactured products.

Q6: Is it possible to CNC machine special designs and make limited quantities of the products?

CNC machining is perfect for such products since it can produce designs with high precision and accuracy even for small quantity production. CNC technology is also very versatile enabling the manufacturer to change from one project to another easily depending on the customer’s specifications, thus, CNC technology is especially suitable for the bespoke manufacturing environment.

Q7: Which technological advancements are making a difference in future development of CNC technology?

CNC technology has advanced in the following ways; the incorporation of artificial intelligence and machine learning for the prognosis of machines, the creation of multiple-axis machining, and the development of better software for design simulation. These innovations are widening the usage areas of CNC machining and improving manufacturing performance.