The choice between ball screws and roller screws is crucial in CNC machines, where accuracy drives productivity and efficiency. As a leading supplier of CNC machine components, we understand the significant effect this choice has on manufacturers and operators. This article explores the subtle differences between ball screws and roller screws, explaining their benefits and uses.

CNC machine performance depends on precision and efficiency. The decision between ball screws and roller screws is crucial in this complex terrain. Accuracy is essential for delicate machining. Thus each screw type's mechanical details must be considered. However, these screws must manage different weights and speeds smoothly to be efficient. As we explore this topic, we want to provide decision-makers with the information to make CNC-specific decisions.

Our CNC components expertise goes beyond providing; we design precision. CNC machine components affect everything from surface finishes to manufacturing speeds. The choice between ball screws and roller screws is significant. As precision engineers, we can advise customers on CNC settings based on our history of cutting-edge solutions.

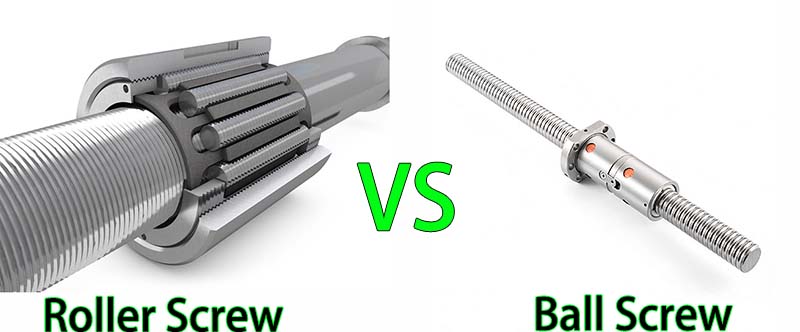

This investigation focuses on the complex dance of mechanical components. Ball screws use ball bearings for smooth action. Roller screws with rollers increase load-bearing capability and durability. Each mechanism's symphony echoes differently in CNC operations. We want to explain how these mechanisms improve CNC machine accuracy and efficiency by peeling back their layers.

This article goes beyond technical specifications to examine the practical ramifications of selecting one screw type over another. We will discuss accuracy, load capacity, speed, and application-specific concerns to highlight the advantages of ball screws and roller screws. We'll also display our precision-engineered components, allowing readers to examine our CNC machine performance-boosting options.

Ball screws vs. roller screws is a story in CNC machining. Join us as we discover accuracy, efficiency, and the seamless blending of technology and artistry.

In precision engineering, the ball screw mechanism combines simplicity and complexity. Ball screws have a screw shaft and nut, but ball bearings make them more useful. These microscopic, precision-engineered spheres travel inside the nut's helical grooves to bridge the screw and nut. Reduced friction and increased efficiency are the magic of this ball-bearing mechanism.

As the screw turns, the balls move between the grooves, smoothly transforming rotation into linear motion. Ball screws are helpful for precision-critical applications because of this trait. Without sliding friction, wear and tear are reduced, extending operating life. In CNC machines, where exquisite detailing is typical, the ball screw's unmatched accuracy changes everything from surface finishes to complex machining procedures.

In contrast, the roller screw mechanism shows strength and load-bearing ability. Roller screws use cylindrical rollers instead of ball bearings. Rollers in the threaded nut engage the screw shaft in a spiral pattern. A mechanism that handles enormous loads and wears well under pressure is the outcome.

Roller screws reduce stress concentrations and increase load-bearing capacity by spreading the load over a more excellent contact surface. Roller screws are essential in high-force, durable applications due to their design. The roller screw's durability is crucial in CNC applications that machine thick materials or perform high-force operations. It is a mechanical workhorse that ensures dependability and stability in difficult machining situations.

Both ball screws and roller screws are precise engineering yet serve different CNC niches. The ball screw excels at exact jobs due to its fineness and smooth motion. In pressure-sensitive situations, the roller screw's rugged construction and load-handling capabilities excel.

CNC machining accuracy benefits from ball screw mechanisms. Ball screws' ball bearings embody precision. The flawless interaction of these tiny spheres inside the nut's helical grooves yields unmatched precision. Ball screws are used in situations where even a millimeter may affect product quality.

Ball bearings' low friction promotes smooth motion and reproducibility. Complex CNC machining jobs demand repeated precision, making this trait essential. From delicate sculpted surfaces to micro-machining, the ball screw's sub-micron accuracy is necessary for perfect outcomes. Manufacturers and operators trust ball screws to offer accuracy.

In heavy-duty CNC applications, accuracy is essential, and roller screws shine. Rollers provide precision in heavy-load, high-force situations as well as accuracy. Roller screws transmit these powerful pressures across a greater contact area than ball screws, reducing stress concentrations and assuring accuracy even under challenging conditions.

Roller screws' cylindrical rollers are unusual in their precision under pressure. The roller screw's accuracy is unwavering, whether grinding thick materials or performing heavy operations. Roller screws are essential in situations where accuracy is not only necessary but also crucial to the structural integrity and quality of machined components. Roller screw accuracy is critical to performing heavy-duty CNC jobs smoothly and reliably.

However, numeric precision defined in terms of ball screws or roller screws is not only the numeric precision. Ensures that each step is executed accurately however small it may be. The ball screws are renowned for precise CNC machining work of the highest sensitivity. Roller screws, however, reinvent precision when operating under high loads of pressure, displaying toughness but not sacrificing exactitude.

Ball screws' load-bearing qualities make them effective in CNC machining. Ball screws are strong despite their appearance. Ball bearings help distribute the load, which is the key. As the screw revolves and the balls circle in the nut's helical grooves, they equally distribute forces, reducing stress. This gives the screw a load-bearing capability that contradicts its slim form.

The ball screw's capacity to bear axial and radial loads in CNC machining settings with dynamic forces shows its strong engineering. Equally impressive is ball screw durability. Smooth motion and reduced wear and tear are achieved by minimizing friction between the balls and grooves. They are highly recommended for accuracy and durability operations because they remain reliable under continuous running and variable loads.

Roller screws are meant for high-duty usage, which increases their load capacity and durability. Rather than using balls, roller screws employ cylinder rollers to spread loads across a more extensive surface area. Roller screws play a vital role in many CNC tasks, characterized by heavy forces and long-time operations.

Roller screws using cylindrical rollers yield high contact and good wear protection. This resistance spreads stresses uniformly over the broader surface of the screw shaft, thereby reducing localized wear. For example, roller screws are hardier and trustworthy for heavy-duty operations such as cutting relatively thick materials in CNC applications. Roller screws are more durable. Thus, they are less expensive in maintenance, leading to cheap setups for CNCs.

Ball screw versus roller screw – the applicability to CNC machining is proven by the load capacity and longevity differences." In high-accuracy applications, ball screws employ a highly evolved ball-bearing principle for carrying loads and durability. Although roller screws have cylindrical solid rollers, they define the load capacity and durability, particularly in extreme force uses.

The ball screws play a critical role in speed and efficiency for most fast-moving applications on CNC machines. Ball screws having ball bearings decrease friction when in operation. It also minimizes friction, thus moving the screw faster and smoothly. Ball screws help in facilitating high-speed machining and intricate chiseling where precision in alignment is required.

Low inertia and friction make ball screws very sensitive to dynamic changes in direction and speed. The crucial factor that defines the CNC machine's efficiency during critical times is the speed at which the machine performs motions correctly. High-speed operation with precision is currently aided by the use of ball screws in the CNC production line.

Roller screws are the best for high-speed operations required by CNC. The dynamic stress handling feature of a roller screw is enabled by its cylindrical rollers and nut design. Such a feature is essential for high-speed machining and cutting, where CNC machines must accelerate and decelerate fast.

Roller screws involve more area for transferring forces compared to ball screws providing higher speed capacity with precision and stability. It increases the productive efficiency of CNC machines and enables high-speed operations with good-quality products. Speed, accuracy, and reliability are unmatched by roller screws in high-speed applications.

The difficulty that lies in selecting the appropriate ball screws or roller screws depends on their speed and efficiency. Ball screws have minimum friction and reactivity, which makes them apt for fast, accurate motion. On the other hand, roller screws which can take on dynamic loads and keep stability at a high speed, are preferred in cases where the rate is equal to efficiency.

CNC machining's tapestry must be precise. The repeatability and accuracy are at their maximum in CNC machining operations where very exact moves are needed. As such, decision-makers should know how ball screws or roller screw affects precision-oriented programs when setting for CNC machines.

With its ball-bearing mechanism, ball screws are reliable in precise applications. The smooth motion and minimal friction of ball bearings provide precise movement control. This is useful for micro-machining, etching delicate designs, and making components with tight tolerances. The ball screw's clear and consistent rotations guarantee that the finished product meets all criteria.

Ball screws are used in precision-centric applications where errors might affect product quality. Their ability to reduce backlash—the play or clearance between the screw and nut—ensures precise translation. Ball screws are essential in precision-intensive sectors, including aircraft, medical device production, and electronics.

Ball screws excel in precision-centric applications, although roller screws are essential, particularly in heavy-load applications. Roller screws' cylindrical rollers retain precision under heavy loads, giving them an edge in applications that need accuracy and durability.

Roller screws excel at high-speed machining and cutting dense materials under dynamic stresses. The ability to spread pressures across a broader contact surface reduces stress concentrations, guaranteeing accuracy even in difficult situations. Roller screws excel in precision-focused applications that need precision and durability.

In precision-centric CNC machining, ball screws or roller screws are essential choices. However, this is not simply selecting between two mechanical parts; it determines machined component quality and reliability. It is critical to the decision-making process because it allows decision-makers to make better choices between using exact accuracy or precision.

Our mission is to provide state-of-the-art CNC machining services at CNC YANGSEN. We supply high-quality precision screws from reliable suppliers, so our product will make CNC machines better for various uses.

This shows you how accurate and reliable are our "ball screws." All our ball screws meet unique CNC machining specifications, and they are manufactured under high standards—ball screws designed for micromachining, speedy compound motions, and high-speed, accurate performance.

Features of Our Ball Screws:

● The precision of each move is unparalleled in our ball screws. The ball-bearing system is free of backslash and precise in sensitive applications.

● Their ball screws are ideal for any CNC application that ranges from delicate engraving to high-speed machining. This attribute makes them perfect for focused precision sectors.

● Our ball nuts are long-lasting and require deficient maintenance. These characteristics increase operating life and reduce downtime and maintenance costs due to low friction and wear.

● Customization Options: Our ball screws are made to suit your CNC system, depending on its requirements.

We have a large variety of ball screws that show our superior engineering.

For Special Applications: Roller Screws

The quality of our roller screws reflects this when such a product requires strength and tremendous loads, among other things. The accuracy and durability of our roller screws are what make them successful in high-performance CNC applications.

Our roller screws demonstrate our commitment to quality for applications that need strength and severe loads. Our roller screws thrive in heavy-duty CNC applications due to their accuracy and endurance.

Our Roller Screw Features:

● Their roller screws reshape what is possible with CNC machining in terms of load capacity. Rollers offer better stability and are dependable for situations that are high on forces because they distribute forces over an area.

● Precision Under Pressure: Roller screws from CNC YANGSEN are solid and precise under dynamic stresses. This makes them perfect for applications requiring precision and strong forces.

● Our roller screws are built to resist demanding CNC jobs. This durability enables constant performance, eliminating replacements and maintenance.

● Application-Specific Solutions: Our roller screws vary. We know industries and applications have diverse needs. CNC-specific roller screws are available in our assortment.

Our roller screws [link to roller screws product page] demonstrate our dedication to redefining heavy-duty CNC machining.

CNC machining involves a delicate balance of accuracy, load capacity, speed, and efficiency. Ball screws or roller screws are key. After exploring the subtleties of these mechanical components, we realize that the selection procedure is a strategic choice that affects CNC machine performance.

● Precision is Variable: Ball screws and roller screws provide varied precisions for CNC applications. Ball screws are great for precise work, while roller screws redefine accuracy for large loads.

● Performance Depends on Load Capacity: Ball screws and roller screws' load capability determines their applicability. Roller screws prove their durability in heavy-duty applications, whereas ball screws excel in precise applications.

● CNC machines are fast and efficient thanks to ball screws and roller screws, although their benefits vary. Ball screws thrive at quick, accurate motions, whereas roller screws excel at high-speed, dynamic loads.

● Application Matters: Ball screws and roller screws are not interchangeable. Understanding the CNC application's needs is essential to choosing a selection that meets the task's needs.

As a trustworthy provider, [Your Company Name] offers outstanding creative solutions. Precision-engineered ball screws and customized roller screws show our commitment to CNC machining innovation. We provide components that redefine possibilities for micro-machining, high-speed milling, or heavy-duty applications.

Visit www.cncyangsen.com to learn more about CNC machine components. Browse our wide selection of ball and roller screws, each engineered for performance and dependability.

We created a visually attractive chart comparing ball and roller screw qualities to help you choose. This thorough resource lets you understand each component's intricacies, enabling you to choose one that meets your CNC machining needs.

CNC YANGSEN provides components and solutions to improve CNC system performance. Start your accuracy, efficiency, and innovation journey here. Choose CNC YANGSEN CNC components that expand options.