In this serious guide, folks will uncover the amazing world of Boring and Facing Head (NCFP). This powerful machine tool part shapes metal. The blog will talk about how this tool grew over time. Readers will also learn how the tool works, types, and best ways to use it. Everyone will find out the right steps to make great metal pieces. The blog is full of expert secrets.

Centuries back, boring and facing heads made their debut. These tools were simple yet effective. They carved out precise hollows in wood or metal.

With diameters from 0.05 to 3 meters, craftsmen found them very useful. They enhanced accuracy, saved time, and ensured seamless operations.

Through the years, boring and facing heads evolved. With 1800s industrial revolution, technology offered new versions. By 2023, more than 20 types of boring heads were available.

Modern ones had digital readouts. They also boasted automatic diameter adjustments, accommodating up to 10 mm. Such advancements transformed industries. The introduction of the horizontal boring machine, in particular, revolutionized the way large workpieces are handled, providing new levels of precision and efficiency.

Cutting Action: Understand that a Boring and Facing Head (NCFP) commences with the cutting action. As the tool interacts with the material, removal occurs. The precision of the cut lies at a hundredth of a millimeter.

Tool Feed: The tool feed advances, controlling the cutting depth. On an average, the feed might progress between 0.02mm to 2mm per rotation.

Spindle Rotation: As for spindle rotation, it revolves at speeds ranging between 20 to 3000 RPM. The faster it spins, the finer the finish.

Diameter Adjustment: Users adjust the diameter to define the size of the hole being bored. Calibration lies within a range of 2.5 to 610 mm, providing flexibility.

Slide Movement: The slide moves in a radial path. Movement influences the cut's depth, ensuring an accurate finish. This system is particularly effective when implemented in a horizontal machining center.

Backlash Compensation: Backlash, an unwanted play, calls for compensation. A system within NCFP negates these effects, promoting smoother operation.

Balancing Mechanism: A good NCFP has a balancing mechanism. The distribution of weight leads to a smoother operation and extends tool life.

Damping System: To reduce vibrations, a damping system is in place. This addition lessens tool wear, promoting longevity.

Toolholder: The toolholder secures the cutting tool. Quality toolholders can withstand forces up to 10,000 Newtons, ensuring stability.

Slide: The slide is crucial. It provides linear motion, impacting the cut's depth and quality.

Adjustment Screws: Adjustment screws offer precision. These components enable fine-tuning of measurements to the nearest millimeter.

Drive Gears: Drive gears enable motion. With the average gear ratio of 2:1, these components ensure the machine operates smoothly.

Spindle: The spindle holds the toolholder. A robust spindle can rotate at speeds of up to 3000 RPM without damaging the tool.

Feed Mechanism: The feed mechanism controls the tool's forward movement. Rates between 0.02mm to 2mm per rotation are typical.

Locking Nut: A locking nut ensures stability. It fixes the toolholder in place, withstanding up to 20,000 Newtons of force.

Counterweights: Counterweights promote balance. A well-calibrated system can handle up to 50 kilograms of weight, ensuring a stable operation.

NCFP Series Flat Rotary Disk Performance

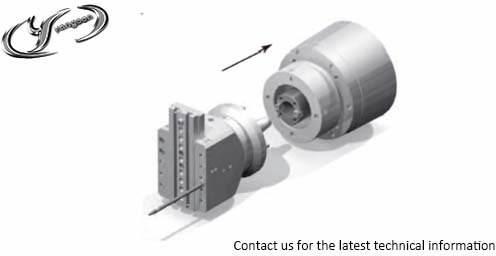

NCFP series flat rotary table, also known as variable-diameter boring tool, is an extended U-axis tool system installed on CNC boring and milling machines, floor-type boring machines, and horizontal machining centers with telescopic axes. Movement to realize extended U-axis turning within the radial stroke range, which makes up for the limitation that the CNC boring machine cannot complete turning. Through this flat rotary disc, the turning and milling compound function of a boring machine is realized, which enriches the processing capacity of the CNC boring machine. Cooperating with corresponding tools, it can realize the functions including variable diameter internal and external hole boring, internal and external thread processing, turning internal and external circles, grooving, groove, undercut, profiling, grooving and surface processing.

The series of flat rotary discs, also known as variable-diameter boring cutters, are extensions of CNC boring and milling machines, floor boring machines, and telescopic-axis horizontal machining centers installed on CNC boring and milling machines, floor-type boring machines, and telescopic-axis horizontal machining centers. Axis tool system, through the telescopic movement of the CNC boring spindle (W axis) of the machine tool, the extended U-axis turning process within the radial stroke range is realized, which makes up for the limitation that the CNC boring machine cannot complete turning. The turning and milling compound function of the boring machine enriches the processing ability of the CNC boring machine. With the corresponding tools, it can realize boring of inner and outer holes with variable diameter, machining of internal and external threads, turning of inner and outer circles, grooving, groove, undercut, and profiling. , cutting and surface processing functions.

NCFP series flat rotary discs are divided into two types: center water outlet type and without center water outlet type. The center water outlet type of flat rotary disc can cooperate with the existing high-pressure water outlet system in the spindle of the machine tool equipment, and can also be effectively combined with the external cooling device of the machine tool equipment. It can effectively reduce the local temperature generated by high temperature during turning and prolong the service life of the tool. Improve the surface finish of parts and improve the quality of parts. Increase cutting speed and tap greater productivity in production.

The Ncp series of flat rotary discs are divided into two types: center water outlet type and without center water outlet type. The center water outlet type of the flat rotary disc can cooperate with the existing high-pressure water outlet system in the spindle of the machine tool equipment, and can also be effectively combined with the external cooling device of the machine tool equipment. It can effectively reduce the local temperature generated by high temperature during turning processing, prolong the service life of the tool, improve the surface finish of the part, improve the quality of the part, increase the cutting speed, and tap greater productivity in production.

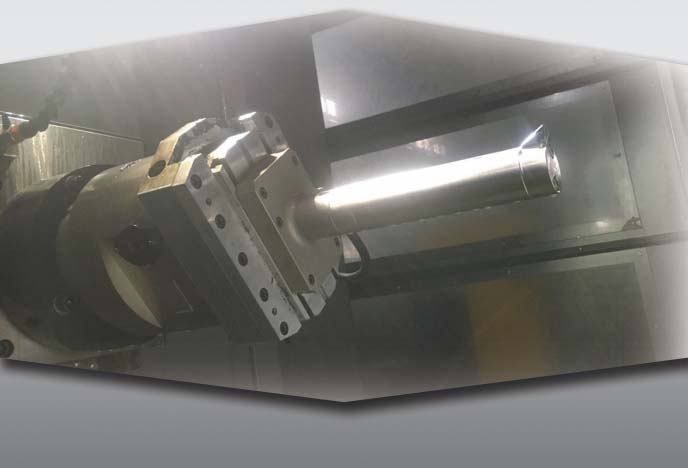

NCFP Series Flat Rotary Disc Installation

The spindle of the machine tool is stretched out and the tool handle of the head of the flat rotating disk is engaged with the taper hole of the spindle and the tool handle is clamped. locked on the machine.

The NCFP series of flat rotary cutters are powerful, and can be installed with various tool holders on its slide table, such as Capto, square shank, and cylindrical shank.

| Model | Single Trip(mm) | Max boring dia.(mm) | Min boring dia. (mm) | Internal Coolant | Boring Tolerance | Max Speed rpm | Transmission Ratio | Boring Axis Dia.(mm) | Processing Roughness | Weight(Kg) |

| NCFP-50 | 50 | 800 | 50 | optional | H7 | 500 | 2:1 | ≥110 | Within 1.6 | 120 |

| NCFP-85 | 85 | 1000 | 50 | optional | H7 | 400 | 1:1 | ≥110 | Within 1.6 | 130 |

| NCFP-120 | 120 | 1400 | 80 | optional | H7 | 400 | 1:1 | ≥110 | Within 1.6 | 150 |

Manual: A favorite among traditional machinists, the manual boring and facing head lets you control cuts. With exact adjustments, the perfect bore size becomes easy to achieve.

Automatic: Efficient and high-performing, automatic heads do the job without your constant guidance. For bulk jobs, they prove vital.

Roughing: For removing large amounts of material, use roughing heads. They hasten the machining process.

Finishing: Precision is the promise of finishing heads. After roughing, finishing heads refine the hole size for a perfect fit.

Modular: Flexibility defines modular heads. Change their components to fit various machining needs.

Adjustable: One size doesn't fit all in machining. Adjustable heads let you alter the cutting diameter.

Digital Readout: In the digital era, machining adapts too. Digital readout heads provide real-time measurement data.

CNC-Compatible: For modern machines like CNCs, specific heads are needed. CNC-compatible heads deliver high precision and speed.

Engine Blocks: Crafting engine blocks requires accurate boring. Facing heads deliver the precision that your car's heart demands.

Manifolds: For efficient airflow in engines, manifolds need perfect boring. Boring and facing heads make that possible.

Flanges: Connecting pipes or valves often involves flanges. Achieve a secure fit with the accurate boring of these tools.

Gearboxes: Every gear in a gearbox needs to fit just right. Boring and facing heads ensure that perfect fit. The cnc vertical machining center has a significant role in these applications.

Hydraulic Components: For hydraulic systems to function, their components require precision boring. These heads make the task possible.

Mold Making: Molds need to be exact copies. Achieve this with precise boring and facing heads.

Aerospace Components: The aerospace industry demands high accuracy. For their components, these tools offer unparalleled precision.

Couplings: Connecting shafts rely on couplings. A precise bore ensures a tight fit. Use boring and facing heads for that job.

Cutting Speed: Precision matters in metalwork. The cutting speed, typically measured in feet per minute (FPM), greatly impacts the result. To ensure smooth operations, control the cutting speed in boring and facing head (ncfp) operations.

Feed Rate: When setting up a machine for boring or facing, remember that feed rate counts. A slow rate, denoted in inches per minute (IPM), maintains tool longevity.

Tool Geometry: Here, the angle of the cutting tool plays a major role. A wrong angle might cause the tool to wear out quickly.

Depth of Cut: A parameter to consider, since it determines the quality of the final product.

Material Type: Different materials need different strategies. Optimum machine settings depend on whether you're working with steel, aluminum, or something else.

Coolant Flow: Sufficient coolant flow prevents heat buildup. Protect your tooling and achieve a finer finish.

Spindle RPM: A high spindle RPM might make work faster, but could harm your tooling. Balance speed and tool lifespan for the best results.

Tool Overhang: Longer overhangs might cause vibration, resulting in inaccurate work. Strive for minimal overhang.

Plunge Boring: This technique, characterized by the tool's straight movement into the workpiece, provides excellent efficiency.

Step Boring: As the name suggests, it involves boring in stages or steps. This technique is suitable for creating different diameters within the same bore.

Contouring: Using this method, achieve a specific shape within the bore, beneficial when a straight bore is not ideal.

Back Boring: A valuable method when access to the opposite side of the workpiece is restricted. These techniques are vital, especially in the aerospace engineering sector where precision is paramount.

Micro Boring: For achieving precise bores of small diameters, this technique excels.

Taper Boring: Use this method to create tapered holes. The diameter of the hole changes along the length.

Facing: When you need to smooth the end of a workpiece, facing becomes your go-to technique.

Chamfering: Use this technique to remove sharp edges. A crucial step in preparing a workpiece for further operations.

Carbide Inserts: Carbide inserts offer a cutting edge for a Boring and facing head (ncfp). With high hardness and heat resistance, 80% of these inserts contain tungsten carbide.

High-Speed Steel: High-speed steel (HSS) is another tool material. By virtue of toughness, HSS endures higher forces compared to carbide.

Boring Bars: Boring bars, crucial for internal diameters, come in lengths from 6 to 40 inches. Rigidity ensures precision.

Toolholders: Toolholders support boring bars. Secure clamping enhances stability, reducing errors to mere thousandths of an inch.

Coolant Systems: Coolant systems prevent overheating. Targeted jets maintain a temperature below 200°F, optimal for machining.

Tool Presetters: Tool presetters measure tool geometry. Precise measurements, within 0.0001 inches, ensure machining accuracy.

Cutting Fluids: Cutting fluids reduce friction. A blend of oils and additives prolongs tool life by 50%.

Anti-Vibration Bars: Anti-vibration bars counteract chatter. Dampening vibrations translates to smoother finishes, down to 8 microinches.

Dimensional Checks: Dimensional checks ensure exact sizes. Calipers and micrometers measure to an accuracy of 0.0001 inches, maintaining critical dimensions.

Surface Finish: Surface finish defines the texture. A surface finish range of 1 to 3.2 micrometers is common for machined components.

Tolerance Analysis: Tolerance analysis assesses size variations. Aiming for a tight range, such as ±0.0002 inches, heightens product consistency.

Tool Wear Monitoring: Tool wear monitoring detects tool degradation. Regular checks extend tool life, and timely replacement wards off inaccuracy.

Temperature Control: Temperature control maintains consistent heat. Sensors keep temperatures under 180°F, safeguarding dimensional stability.

Part Inspection: Part inspection utilizes probes and lasers. Exact measurements, within 0.0005 inches, secure compliance with engineering standards.

Calibration: Calibration guarantees measurement tools are precise. Annual calibration reduces deviation to as little as 0.00005 inches.

Documentation: Documentation tracks quality data. Rigorous logs reinforce conformity with ISO 9001, reinforcing process integrity and accountability.

Vibration Issues: Sudden, harsh vibrations can mean imbalance in your boring and facing head (ncfp). Balanced tools give precise cuts. An imbalance can lead to poor results.

Tool Breakage: Broken tools damage your workflow. Regular checks prevent unexpected breakdowns. Use the right material for your tools.

Poor Surface Finish: A bad finish can mean dull tools. Regularly sharpen the tools for smooth cuts.

Dimensional Inaccuracy: Measurements that are off by even a millimeter can ruin work. Accurate calibration is crucial.

Overheating: Machines that run hot risk breaking down. Regular cooling intervals keep temperatures in check.

Excessive Tool Wear: Worn-out tools give poor results. Routine replacement ensures peak performance.

Feed Marks: Unwanted marks spoil the finish. Proper tool feeds avoid unwanted grooves.

Workpiece Damage: Damaged workpieces lead to wasted resources. Correct tool use prevents unnecessary damage.

CAM Software: Computer Aided Manufacturing software guides your tools. Precise instructions lead to superior results.

Toolpath Generation: Defining tool paths accurately optimizes the machining process. It's a vital step for success.

CNC Programming: Correct programming of your CNC machines ensures optimal performance. It's a crucial skill in this industry.

Simulation Tools: Simulations provide insights without wasting material. Use them to foresee potential issues.

Collision Detection: Collision detection prevents costly machine damage. It's a safeguard in your production line.

Offline Programming: Offline programming allows for workflow continuity. It prevents machine downtime due to on-the-fly programming.

Tool Management: Proper tool management extends the life of your equipment. Well-kept tools provide better results.

G-Code: Mastering G-Code programming optimizes your machine's potential. It's the language of your CNC machines.

Versatility: A boring and facing head (ncfp) excels in versatility. You can work with a vast array of parts, from engine cylinders to gear boxes.

Accuracy: With its unrivaled precision, ncfp outshines other methods. Tolerance levels are generally 0.005 inch, supporting precise measurements.

Speed: Compared to manual methods, ncfp allows faster production, speeding up assembly lines by approximately 20%.

Tool Life: Although ncfp components are durable, they are outlasted by hard tools, reducing replacement frequency.

Material Variety: Ncfp is adaptable, capable of machining various materials like steel, aluminum, and brass.

Scalability: When it comes to mass production, ncfp stands out. Large scale projects become simpler and more cost-effective.

Setup Time: Ncfp setup demands time, which might delay operations. Other methods like milling may save setup time.

Complexity: Ncfp operates intricately. Expert operators can achieve superior results, yet this complexity presents a learning curve.

High Precision: Ncfp offers unmatched precision, generating exact measurements that bolster product quality.

Flexibility: The inherent flexibility of ncfp allows complex machining tasks to be performed with ease.

Improved Surface Finish: By eliminating manual errors, ncfp provides a finer surface finish.

High Cost: Despite the benefits, ncfp demands considerable capital investment. The advanced technology raises the initial costs.

Operator Skill Required: Running an ncfp requires skilled personnel, adding to the operational cost.

Maintenance Demand: Regular maintenance is essential to keep ncfp in optimal condition, adding to overall costs.

Limited Material Types: While versatile, ncfp has its limits. Harder materials may prove challenging.

Complexity in Setup: Setting up ncfp is intricate, requiring time and expertise, which can potentially delay operations.

In the guide, experts spilled secrets about Boring and Facing Head (NCFP). Readers learned the history and saw how the tool evolved. People also found out how the tool works.

There are different types, and each has a special job. This tool makes perfect metal pieces. To shape metal like a pro, always follow the best steps. To get a great Boring and Facing Head, the place to go is CNCYANGSEN.