When you use CNC machines, you may face several problems. In order to help you solve the problem. Today we summarize and summarize most of the common CNC machining problems encountered in the use of machine tools, and make a Checklist. Let's get started.

Deterministic failure refers to the hardware damage in the control system host or the failure that will inevitably occur on the CNC machine tool as long as certain conditions are met.

This type of fault phenomenon is most common on CNC machine tools, but because it has certain rules, it also brings convenience to maintenance.

Deterministic faults are irreversible, so once a fault occurs and not be repaired in time, the CNC machines will not automatically return to normal and affect the CNC machining and production tasks. But as long as the root cause of the failure is found, the machine tool can return to normal immediately after the repair is completed.

Moreover, CNC machine tool operators play very important roles in CNC machine repair and maintenance, proper use and careful maintenance are important measures to eliminate or avoid failures. All machine operators should pay more attention to it. of course, improper maintenance CNC machines should be avoided by professional and conventional training

Random faults refer to accidental faults that occur during the working process of a CNC machine. The causes of such faults are relatively hidden, and it is difficult to find out their regularity, so they are often called "soft faults".

The cause analysis and fault analysis of random faults Diagnosis are more difficult. Generally speaking, the occurrence of faults is often related to many factors such as the installation quality of components, parameter settings, quality of components, imperfect software design, and the influence of the working environment.

Random faults are recoverable. After a fault occurs, the machine tool can usually return to normal by restarting the machine, but the same fault may occur again during operation.

Strengthening the maintenance and inspection of the CNC system, ensuring the sealing of the electrical box, reliable installation and connection, and correct grounding and shielding are important measures to reduce and avoid such failures.

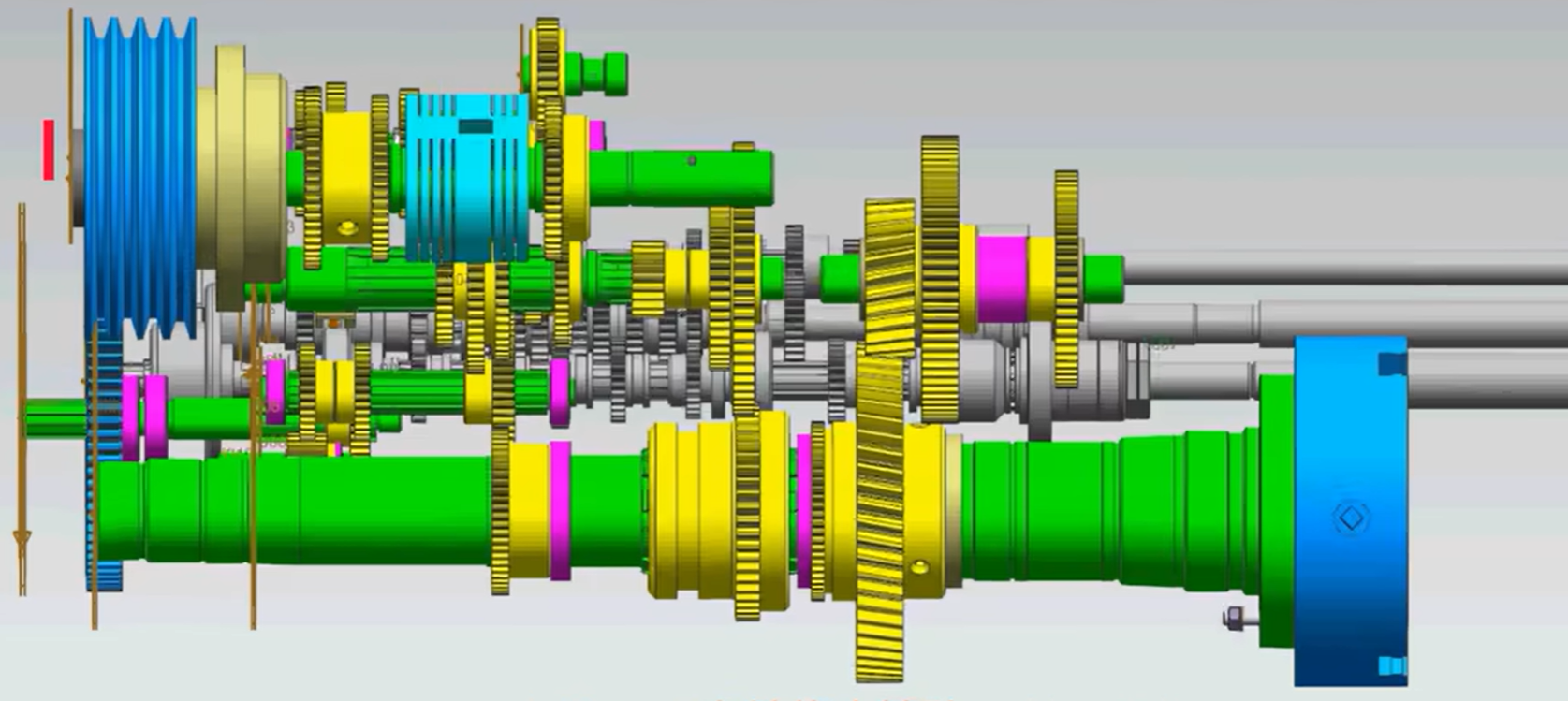

Due to the use of speed-regulating motors, the structure of the spindle box of CNC machine tools is relatively simple, and the parts that are prone to failure are the automatic tool clamping mechanism and automatic speed-regulating device inside the spindle.

In order to ensure that the tool holder will not loosen automatically during work or power failure, the automatic tool clamping mechanism adopts spring clamping and is equipped with a travel switch to send a clamping or loosening signal. If the tool cannot be released after clamping, consider adjusting the pressure of the tool release hydraulic cylinder and the travel switch device, or adjust the nut on the disc spring to reduce the amount of spring compression. In addition, the heating of the spindle and the noise of the spindle box cannot be ignored.

In addition, the main consideration is to clean the spindle box, adjust the amount of lubricating oil, ensure the cleanliness of the spindle box, replace the spindle bearing, repair or replace the spindle box gear, etc.

In the feed transmission system of CNC machine tools, ball screw pairs, hydrostatic screw nut pairs, rolling guides, hydrostatic guide rails, and plastic guide rails are commonly used. Therefore, there is a fault in the feed transmission chain, which mainly reflects the decline in motion quality. Such as the mechanical parts do not move to the specified position, the operation being interrupted, the positioning accuracy decreasing, the backlash increasing, crawling, the bearing noise increasing (after a crash), improper feed speed ratio, etc.

Such failures can be prevented by the following measures

Adjusting the pre-tightening force of each motion pair, adjusting the loose links, eliminating the transmission gap, shortening the transmission chain, and installing reduction gears in the transmission chain can also improve transmission accuracy.

Adjusting the pre-tightening force of the screw nut pair and supporting parts and reasonably selecting the size of the screw itself are effective measures to improve transmission rigidity. Insufficient rigidity will also cause crawling and vibration of the workbench or pallet, as well as a reverse dead zone, which will affect the transmission accuracy.

Under the premise of satisfying the strength and rigidity of the components, the mass of the moving parts should be reduced as much as possible, and the diameter and mass of the rotating parts should be reduced to reduce the inertia of the moving parts and improve the motion accuracy.

Rolling guides are sensitive to dirt, so good protective devices must be installed, and the preload of rolling guides should be selected properly. If it is too large, the traction force will increase significantly. The hydrostatic guide rail should have a set of oil supply systems with good filtering effects.

The failure of the automatic tool changer is mainly manifested in:

Movement failure of the tool magazines

Excessive positioning error

Unstable gripping of the tool handle by the manipulator,

Larger movement error of the manipulator.

When the fault is serious, the tool change action will be stuck, and the machine tool will be forced to stop working.

Wrong-cutting tools or settings are common problems in many precision processing companies, but they shouldn't be. For a successful production run, the proper cutting tools and settings must be selected before work begins. Failure to do so may result in damage to the finished product in the form of burn marks, rough edges, and corners, or visible cut marks, all of which are unacceptable.

If the coupling connecting the motor shaft and the worm shaft is loose or the mechanical connection is too tight due to mechanical reasons, the tool magazine cannot rotate. At this time, the screws on the coupling must be tightened. If the tool magazine does not rotate properly, it is caused by motor rotation failure or transmission error. If the current tool holder cannot clamp the tool, it is necessary to adjust the adjusting screw on the tool holder, compress the spring, and tighten the clamping pin. When the up/down of the knife cover is not in place, check the position of the fork or the installation and adjustment of the limit switch.

If the cutting tool is not clamped tightly or the tool falls off, adjust the spring of the clamping claw to increase its pressure, or replace the clamping pin of the manipulator. If the tool cannot be loosened after being clamped, adjust the nut behind the loosening spring so that the maximum load does not exceed the rated value. If the tool is dropped during the tool change, it is caused by the spindle box not returning to the tool change point or the tool change point drifting during the tool change. The spindle box should be re-operated to return to the tool change position and the tool change point should be reset.

On CNC machine tools, in order to ensure the reliability of automation work, a large number of limit switches for detecting the movement position are used. After the long-term operation of the machine tool, the movement characteristics of the moving parts change, and the reliability of the travel switch pressing device and the quality characteristics of the travel switch itself change, which has a great impact on the performance of the whole machine. Generally, it is necessary to check and replace the limit switch in time to eliminate the influence of such a switch on the machine tool.

(1) Hydraulic system

The hydraulic pump should adopt a variable displacement pump to reduce the heat generation of the hydraulic system. The filter installed in the fuel tank should be cleaned regularly with gasoline or ultrasonic vibration. Common failures are mainly pump body wear, cracks, and mechanical damage. At this time, it is generally necessary to overhaul or replace parts.

(2) Pneumatic system

In the air pressure system used for tool or workpiece clamping, safety door switch, and spindle taper hole chip blowing, the water separator air filter should be regularly drained and cleaned regularly to ensure the sensitivity of the moving parts in the pneumatic components. Faults such as spool action failure, air leakage, pneumatic component damage, and action failure are all caused by poor lubrication, so the lubricator should be cleaned regularly. In addition, the airtightness of the pneumatic system should be checked frequently.

(3) Lubrication system

Including the lubrication of machine tool guide rails, transmission gears, ball screws, spindle boxes, etc. The filter in the lubricating pump needs to be cleaned and replaced regularly, usually once a year.

(4) Cooling system

It cools the tool and the workpiece and flushes chips. The coolant nozzles should be cleaned regularly.

(5) Chip removal device

The chip removal device is an accessory with independent functions, which mainly ensures the smooth progress of automatic cutting and reduces the heat generation of CNC machine tools. Therefore, the chip removal device should be able to remove chips automatically in time, and its installation position should generally be as close as possible to the cutting area of the tool.

Because the faults of CNC machine tools are relatively complicated, and the self-diagnosis capability of the CNC system cannot test all the components of the system, it is often a single alarm number that indicates many faults causes, making it difficult for people to start. The following describes the troubleshooting methods commonly used by maintenance personnel in production practice.

The visual inspection method is for maintenance personnel to determine the scope of the failure based on the observation of various abnormal phenomena such as light, sound, and smell when the failure occurs. The scope of the failure can be narrowed down to a module or a circuit board, and then eliminated.

Under normal circumstances, for system alarms caused by transient faults, the faults can be cleared by hardware reset or by switching on and off the system power supply in sequence. If the working storage area of the system is confused due to power failure, circuit board insertion, or battery Undervoltage, the system must be initialized and cleared, and data copy records should be made before clearing. diagnosis.

The CNC system already has a strong self-diagnosis function and can monitor the working status of the hardware and software of the CNC system at any time. Using the self-diagnosis function, on the CNC machine tool's display screen, it can display the state of the interface information between the system and the host computer, so as to judge whether the fault occurs in the mechanical part of the numerical control part, and display the general part of the fault (fault code).

The functional program test method is to program the functions of the CNC system into a functional test program and store it on the corresponding media, such as paper tape and magnetic tape. Running this program during fault diagnosis can quickly determine the possible cause of the fault. Functional program testing method is often used in the following occasions: machine tool processing produces waste products, and it is impossible to determine whether it is caused by improper programming or CNC system failure; random failures in the CNC system make it difficult to distinguish whether it is external interference or poor system stability; CNC machine tools that have been idle for a long time are before they are put into use or when the CNC machine tools are regularly overhauled.

Replace the diagnosed bad circuit board with good spare parts, that is, after analyzing the approximate cause of the failure, maintenance personnel can use spare printed circuit boards, integrated circuit chips, or components to replace suspicious parts, thereby narrowing down the scope of the failure to the printed circuit board or chip level. And do the corresponding initialization start, so that the machine tool can be put into normal operation quickly.

For the maintenance of modern CNC, more and more cases use this method for diagnosis and then replace the damaged module with spare parts to make the system work normally and shorten the downtime as much as possible.

Notice

(1) When using this method, be sure to operate in a power failure state, and carefully check whether the version, model, various marks, and jumpers of the circuit board are the same. If they are inconsistent, they cannot be replaced. Marks and records should be made when the stitches are removed.

(2) Generally, do not easily replace the CPU board, memory board, and battery, otherwise, the program and machine parameters may be lost and the fault may expand.

System parameters are the basis for determining system functions. Wrong parameter setting may cause system failure or invalid function. When a failure occurs, the system parameters should be checked in time. The parameters are generally stored in the magnetic bubble memory or in the MOSRAM that needs to be kept by the battery. The machine tool is not working properly. At this point, the fault can be eliminated by checking and correcting the parameters.

According to the composition principle of the numerical control system, the logic level and characteristic parameters of each point can be analyzed logically, such as voltage value and waveform, and instruments and meters can be used to measure, analyze and compare, so as to determine the fault location.

In addition to the above commonly used fault detection methods, you can also use the plug-in board method, voltage bias method, open-loop detection method, etc. In short, according to different fault phenomena, several methods can be selected at the same time for flexible application and comprehensive analysis, so as to gradually narrow the fault range and quickly eliminate the fault.

There are many reasons for machine tool failures. For more complex faults, several methods need to be used comprehensively to correctly determine the cause of the fault and diagnose the specific location of the fault, so as to solve the fault in time, reduce the loss caused by the CNC machine tool to production, and effectively improve the efficiency of the machine tool. Use efficiency.

Yangsen is one of the leading machine suppliers with 20 experience in China. Besides the price competitiveness and quality control, we still pay our top priority on our after-sales service and maintenance and training for our clients and supply comprehensive user manuals.

Please contact us for enquiry now!