In the fast-paced manufacturing world, efficiency and productivity are crucial for success. Computer numerical control (CNC) machines have become increasingly prevalent to meet the demands of modern production processes. These machines offer unparalleled precision, repeatability, and speed, revolutionizing the manufacturing industry.

This article explores the various aspects of CNC automatic tool changers, including their definition, functionality, benefits, selection factors, types, types of tool magazines, maintenance tips, and future developments.

Let's dive in and discover how these remarkable devices have become indispensable in modern manufacturing processes.

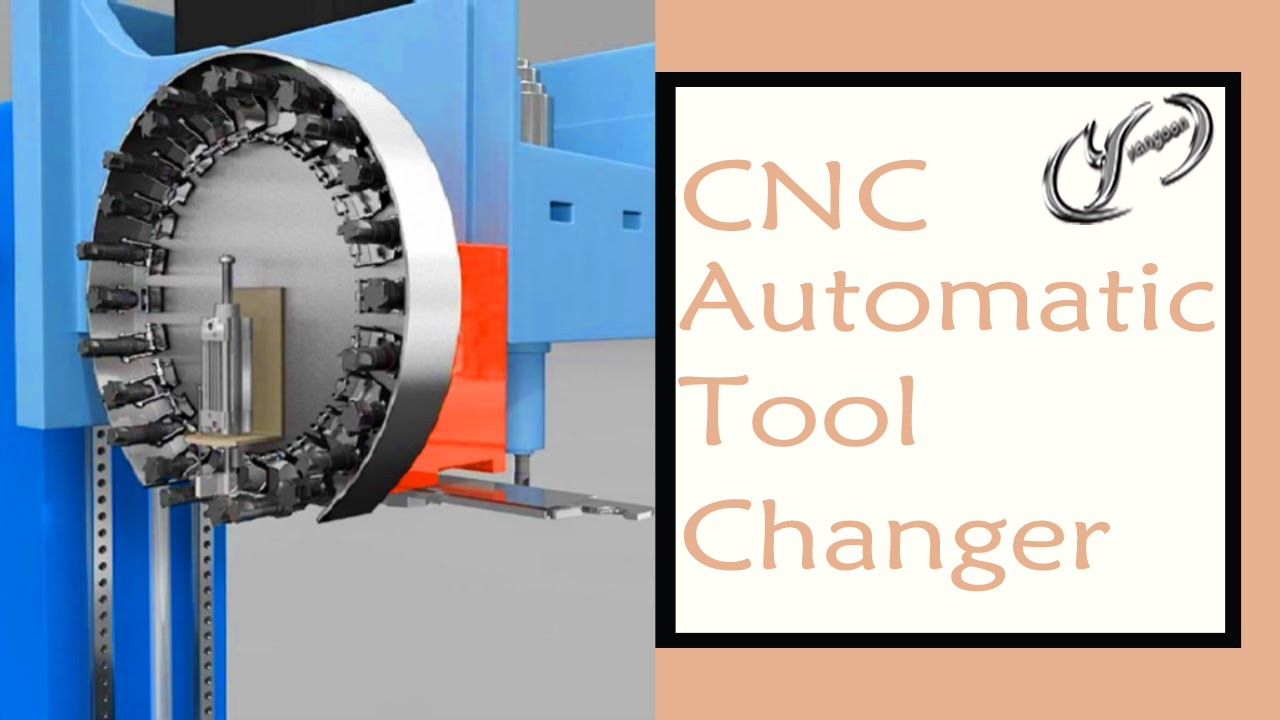

A CNC automatic tool changer, or an ATC, is vital to a computer numerical control (CNC) machine. It is responsible for automatically swapping cutting tools during the machining process, eliminating the need for manual tool changes.

By incorporating an ATC into a CNC machine, manufacturers can greatly enhance efficiency, reduce downtime, and achieve higher productivity.

CNC automatic tool changers utilize a sophisticated mechanism to store and retrieve tools quickly and accurately. They consist of a tool magazine or carousel with multiple tools, an arm or mechanism to position and exchange the tools, and a control system that manages the tool-changing process.

The ATC receives instructions from the CNC machine's program and executes tool changes seamlessly, ensuring uninterrupted machining operations.

Here's a comprehensive breakdown of the components that make up a CNC automatic tool changer:

The tool carousel or magazine serves as a storage unit for holding a collection of cutting tools. It is typically located close to the machine spindle and can feature multiple pockets or slots to accommodate a range of tool types and sizes. The carousel/magazine may rotate or index, allowing for quick tool selection.

● Tool Gripper/Clamp:

This is responsible for securely grasping and holding the cutting tool. It ensures the tool remains stable during machining to maintain accuracy and minimize vibration. The gripper/clamp mechanism utilizes pneumatic, hydraulic, or electric actuators to exert the necessary gripping force on the tool.

● Tool Release Mechanism:

The tool release mechanism facilitates the smooth removal of the current tool from the machine spindle. It typically involves unlocking the tool and disengaging any retention systems. The release mechanism allows for swift and effortless tool exchange, reducing downtime between tool changes.

● Tool Exchange Arm:

Also known as the tool changer arm, it is a robotic or automated mechanism that physically transfers tools between the tool carousel/magazine and the spindle. Controlled by the CNC system, the tool exchange arm moves with precision and speed to accurately position the selected tool.

● Tool Presence/Identification Sensors:

Tool presence or identification sensors verify the presence of a tool in the carousel/magazine or confirm that a tool has been successfully loaded into the spindle. These sensors provide feedback to the CNC system, ensuring that the correct tool is in place before initiating machining operations. They help prevent tooling errors and promote process reliability.

● Tool Presetter:

A tool presetter is a measurement device used to precisely measure and record the dimensions of cutting tools. It enables accurate tool length and diameter information to be stored in the CNC system's tool library. This data is crucial for tool selection, tool path calculations, and optimizing machining processes.

● Coolant and Air Supply:

CNC automatic tool changers often incorporate integrated coolant and air supply systems. These systems deliver coolant or compressed air to the cutting tool during machining operations, aiding in heat dissipation, chip evacuation, and improved cutting performance.

● Control System Integration:

The CNC automatic tool changer seamlessly integrates into the overall control architecture of the CNC system. The control system manages the tool change sequences, monitors tool positions, and communicates with the tool carousel, gripper, sensors, and other components. It ensures precise coordination and synchronization of tool changes with the machining process.

At the heart of a CNC automatic tool changer lies a complex system that coordinates the tool-changing process seamlessly. When a machining operation requires a different cutting tool, the ATC retrieves the designated tool from the tool magazine or carousel and replaces the current tool. This automated process enables uninterrupted machining, minimizing human intervention and maximizing productivity.

The tool magazine or carousel is designed to store and organize various cutting tools, such as drills, end mills, and taps. Each tool is assigned a specific location within the magazine, making it easy for the ATC to locate and retrieve the required tool efficiently.

The tool exchange is performed precisely and quickly, allowing the CNC machine to resume the machining process without significant delays.

Please watch the following video about Yangsen CNC machine automatic changer

There are several common methods used to change tools in a CNC automatic tool changer. Each method offers its own advantages and may be preferred depending on the specific machine and application requirements. Let's explore some of these methods:

The umbrella type tool changer is a popular method used in CNC machining centers. It features a circular or semi-circular tool magazine mounted on the side or back of the machine.

The tool grippers or clamps are attached to a rotating arm, resembling an umbrella. This arm swings out to access the desired tool and brings it to the spindle for tool exchange. The umbrella type changer allows for a large number of tools to be stored and provides quick tool change times.

This type of ATC utilizes two arms for tool changing. While one arm holds the current tool, the other arm retrieves the next tool from the magazine and swaps them. The double-arm ATC reduces tool change time by concurrently performing tool exchange operations.

In advanced CNC systems, a robotic arm may be employed for tool changes. The robotic arm is equipped with a gripper or tool-changing mechanism that can grasp and exchange tools. The robot arm is controlled by the CNC system and follows programmed instructions for tool changes.

The carousel type tool changer features a rotating tool carousel or magazine, similar to a carousel on a merry-go-round. The carousel holds the tools in individual pockets or slots, and the selected tool is brought to the spindle by the tool exchange arm.

This method allows for a large number of tools to be stored and provides quick tool change times. It is commonly used in high-production machining centers.

The random access tool changer is a versatile method where tools are stored in a fixed location within the tool magazine. The tool exchange arm moves in multiple axes to access any tool in the magazine and bring it to the spindle.

This method offers flexibility in tool selection and can handle a variety of tool sizes and types. Random access tool changers are commonly found in advanced CNC machines and machining centers.

The choice of right tool changer method depends on factors such as the machine size, tool capacity, tool variety, and the specific machining requirements of the application at hand.

Using a CNC automatic tool changer (ATC) offers a wide range of benefits that enhance efficiency and productivity in manufacturing.

Let's explore some of these advantages:

● Increased productivity:

With an ATC, tool changes are executed swiftly, minimizing machine idle time and maximizing production output. The automated tool-changing process eliminates manual intervention, reducing downtime and enabling continuous machining operations.

● Enhanced efficiency:

The automation provided by an ATC eliminates the need for manual tool changes, reducing human error and ensuring consistent and accurate machining. The CNC machine can seamlessly switch between tools, maintaining precision and achieving desired machining results.

● Versatility and flexibility:

CNC automatic tool changers enable a wide range of tools to be used in a single machining operation, expanding the capabilities of CNC machines and accommodating various manufacturing requirements. This versatility allows manufacturers to efficiently produce complex components with different tooling needs.

● Time and cost savings:

By automating tool changes, manufacturers can optimize their machining processes, reducing labor costs and increasing overall profitability. The quick and precise tool exchange provided by the ATC minimizes idle time and maximizes production throughput, improving efficiency and cost-effectiveness.

Several factors should be considered when selecting a CNC automatic tool changer for a specific application. It is necessary to consider these factors because you would like to put your capital in a safe place.

● Tool Capacity:

Consider the tools required for your machining operations and choose an ATC with an appropriate tool storage capacity. The tool capacity of an ATC determines how many tools can be stored and accessed during a machining process. Ensure the ATC can accommodate the tools needed for your specific manufacturing requirements.

● Tool Change Time:

Evaluate the tool change speed of the ATC to ensure it aligns with the desired production cycle time. The time taken to swap tools can significantly impact overall machining efficiency. Look for an ATC that offers fast and reliable tool change capabilities, minimizing the time required for tool exchange and maximizing productivity.

● Compatibility:

Verify the compatibility of the ATC with your CNC machine, as different machines may have varying requirements. Consider the interface, communication protocols, and mounting options to ensure seamless integration between the ATC and the CNC machine. Compatibility issues can lead to operational challenges and hinder the smooth functioning of the machining process.

● Precision and repeatability:

Consider the precision and repeatability of the ATC in positioning and aligning the tools. Accurate tool positioning is crucial for achieving high-quality machining results. Look for an ATC that offers excellent repeatability, ensuring consistent and precise tool placement with each change.

● Ease of maintenance:

Evaluate the maintenance requirements of the ATC. Look for features such as easy access to cleaning and lubrication and clear documentation and support from the manufacturer. Regular maintenance ensures optimal performance and extends the lifespan of the ATC.

By considering these factors, manufacturers can select the most suitable CNC automatic tool changer for their specific machining needs, optimizing productivity and enhancing the overall efficiency of their manufacturing processes.

In CNC automatic tool changers, the tool magazine is the component that houses and organizes the cutting tools. Different tool magazines are available, offering varying capacities and storage mechanisms.

Let's explore some common types:

The chain tool magazine utilizes a linear chain-like structure to hold the cutting tools. In this type, the chain moves linearly to bring the desired tool to the tool exchange position. Chain tool magazines are often used when a linear tool arrangement is preferred or when space is limited. They offer flexibility in tool selection and can accommodate various tool lengths.

The tool capacity of a chain tool magazine depends on the length of the chain and the spacing between the tools. These magazines can hold a range of tools, from a few (e.g., 10-20) to larger quantities (e.g., 50 or more). The linear arrangement of tools on the chain allows for efficient storage and retrieval, enabling quick tool changes during machining operations.

The disk style tool magazine features a rotating disk with tool pockets or slots arranged in a circular pattern. The disk rotates to present the selected tool to the tool exchange position. Disk style tool magazines are known for their compact design and efficient use of space. They are commonly used in machines with limited space availability.

The tool capacity of a disk style tool magazine varies depending on the size and design of the disk. These magazines can hold a moderate number of tools, typically ranging from around 10 to 30 or more.

The choice of tool magazine type depends on factors such as the number of tools needed, available space in the CNC machine, and the specific requirements of the machining operations.

Manufacturers should consider these factors when selecting the appropriate tool magazine for their CNC automatic tool changer.

The drum tool magazine features a cylindrical drum that rotates to present the tools for tool exchange. The drum is divided into tool pockets arranged in a circular pattern. Each pocket holds a single tool.

The tool capacity of a drum tool magazine can vary depending on the size and design of the drum. Generally, these magazines can hold a range of tools, starting from a few tools (e.g., 6-8) up to larger capacities (e.g., 30 or more). The rotation of the drum brings each tool into position for tool exchange, providing quick and efficient access to the desired tool.

The arm-style tool changer utilizes a swinging arm mechanism to access and exchange tools. An arm swings out or rotates to bring the selected tool to the tool exchange position in this type. This type of tool changer is known for its compact design and efficient use of space.

The tool capacity of an arm-style tool changer can vary depending on the number of tool pockets or slots it incorporates. These magazines typically range from a few tools (e.g., 6-8) to larger capacities (e.g., 30 or more), depending on the design and size of the arm-style magazine.

Regular maintenance and troubleshooting are essential to ensure the optimal performance and longevity of a CNC automatic tool changer.

Here are some tips to keep your ATC running smoothly:

Clean the tool magazine, gripper mechanism, and tool pockets regularly to remove any debris or contaminants that could affect the performance of the ATC.

The manufacturer recommends applying lubrication to the moving parts to minimize friction and ensure smooth operation.

Periodically inspect the tool retention and clamping mechanisms to ensure they function properly. Loose or improperly clamped tools can lead to machining errors and tool damage.

Ensure the clamping mechanism is tightened securely to hold the tools in place during machining operations.

Regularly check the accuracy of tool changes to ensure that the ATC is properly aligning and positioning the tools.

Verify that the tools are securely held in their designated positions and that there is no interference during the tool change process.

Any inaccuracies should be addressed promptly to maintain machining precision.

Organize the tool magazine or carousel efficiently to prevent tools from getting stuck or damaged. Ensure that the tool pockets are clean and free from obstructions. Proper tool storage minimizes the risk of tool collisions and facilitates smooth tool changes.

Monitor the performance of the ATC during machining operations. Watch for unusual sounds, vibrations, or errors in the tool-changing process.

If any issues arise, consult the manufacturer's documentation or contact their technical support for troubleshooting guidance.

As technology advances, the future of CNC automatic tool changers holds exciting possibilities. Here are some developments to look forward to:

Integrating sensors in CNC automatic tool changers will enable real-time monitoring of tool conditions and performance. Sensors can detect tool wear, temperature, and vibrations, providing valuable data for predictive maintenance and optimizing tool life.

This proactive approach will minimize tool failures and improve overall machining efficiency.

With the advancements in AI and automation, CNC automatic tool changers will become even smarter and more autonomous.

AI algorithms can analyze machining data and make real-time decisions regarding tool changes, optimizing tool selection based on material type, cutting parameters, and desired surface finish.

This level of automation will further streamline manufacturing processes and increase productivity.

Future developments in CNC automatic tool changers will reduce tool change time and enhance pnrecision.

Innovations in mechanism design, control systems, and robotics will enable faster and more accurate tool changes, increasing productivity and minimizing downtime.

Future CNC automatic tool changers may offer customizable tool magazines, allowing manufacturers to tailor the storage capacity and configuration to their needs.

This flexibility will accommodate diverse machining requirements and enable rapid adaptation to changing production demands.

As these advancements come to fruition, CNC automatic tool changers will play a vital role in enhancing manufacturing efficiency, productivity, and competitiveness.

In modern manufacturing, CNC automatic tool changers have revolutionized the way machining processes are carried out. These remarkable devices enable efficient and seamless tool changes, resulting in increased productivity, enhanced precision, and cost savings.

By understanding the functionality, benefits, types, and maintenance tips associated with CNC automatic tool changers, manufacturers can make informed decisions to optimize their machining operations.

As technology progresses, the future of CNC automatic tool changers holds even more promising developments, such as advanced sensors, increased automation, and integration with Industry.

These advancements will further improve tool change speed, precision, and customization options, leading to heightened efficiency and productivity in the manufacturing industry.

Yes, it is possible to retrofit a CNC machine with a CNC automatic tool changer, depending on the specific machine model and compatibility.

The tool capacity of a CNC automatic tool changer can vary depending on the type and model. It can range from a few tools to several dozen tools or more. The tool capacity should be chosen based on the specific machining requirements and the variety of tools needed for the manufacturing processes.

CNC automatic tool changers require regular maintenance to ensure optimal performance and longevity, like any other mechanical component.