Prepared to upgrade your machining? Go through our CNC Conversion Kits guide. Here, you will learn the secrets of selection, installation and performing of the upgrades, which will make your machine the true transformer. We will solve the riddles of the revolutionary kits together.

Stepper motors, control hardware and power supplies are used to upgrade manual machines with CNC conversion kits. Each component is critical. For example, the stepper motors regulate the spindle movement, which allows for the fine control of the machining process.

The hardware control, for example GRBL shields or Mach3 boards, communicates with computers for commands. Power supplies keep the whole system active and provide constant power to the machine for uninterrupted performance.

Installation of a CNC kit is in a form of a process that requires attention to detail and proper set up. Control board links up to the PC system, converting digital orders into mechanical movements of the machine. Wiring is critical here, linking motors to controllers with certain paths of routing to prevent interference. The software setup makes sure that all the components work in unison. Users should carry out tests of the connections over and over again until it needs to be operational and before full scale production begins.

The CNC system upgrade brings significant improvements. The speed control becomes much better, which makes it possible to reduce the time of machining without damaging the detail.

Finer motor control leads to improvement in cutting precision. The enhancement also provides more workable materials, which broaden operational facilities. Calibration is necessary for the upgrade of these systems to ensure that they perform optimally and stay reliable for the long run.

Some machines are not appropriate for CNC retrofit. Compliance is determined by the current hardware configurations and physical sizes. There might be some additional adjustments necessary for the older models to be able to accept new kits.

One should verify the axis moving range and attachment points of the motors. Consultation with kit manufacturers can give a lot of useful information about compatibility problem and solutions to them.

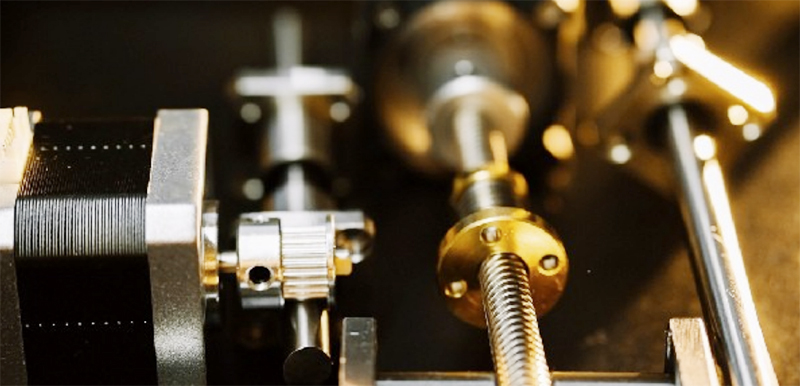

Accuracy holds an important position in CNC conversions. The set ought to contain high resolution motors and precise lead screws for fine work. Improved software algorithms aid in the achievement of finer details in CNC milling machine operations.

Testing after installation is thorough to ensure that the machine operates within set tolerances. This meticulousness to the detail ensures higher standard of the product and consistent production.

The selection of the proper kit starts with compatibility tests. It includes evaluation of machine dimensions, motor kinds, and interface needs.

It is vital to verify that the control system is consistent with the computer operating system. Others may require a lot of modifications. Relevance in such appraisals eliminates expensive blunders and equipment mismatches.

Features assessment includes motor performance, control software abilities, and other applications in automatic tool changers. Stepper motors of high quality guarantee smoother running.

Modern software can perform complicated tasks, thereby improving general productivity. Features must relate with desired manufacturing processes and complexity.

Needs assessment is about CNC kit abilities with production demands. High-volume production could need strong systems that have better efficiency and speed.

In precision craft, control features are placed above accuracy ones. These needs act as a guide in the selection process of the kit, hence making sure that the kit adds value to production.

The budgeting for a CNC conversion includes the costs that may be incurred at the beginning, the possible upgrades and the maintenance expenses.

Kits that are less expensive may provide basic features with a small room for growth. Even though premium kits are expensive they have a lot of functionalities and are more durable. The balance of cost with operational needs and future opportunities for growth is essential for an efficient budgeting.

The preparation of the machine for a CNC conversion includes the cleaning, inspection, and parts removal. Debris free surfaces are essential for easy and proper installation. Inspection of components such as gears and spindles, for wear and tear is important. Substituting worn parts prior to installation prevents future malfunctions and ensures smooth integration.

The installation steps are mounting of motors, setting up of control units and wiring of connections. The correct use of manufacturer’s recommendations will eliminate the typical mistakes.

The mounting of the motors secures stability in the process. Wire routing done properly prevents electrical hazards as well as interference with the working of the machine. Stepwise testing leads to a complete setup.

Preventing problems during installation demands anticipation and troubleshooting aptitude. General problems can be misalignment of elements, software setup faults and unstable power source.

Prompt resolution of these avoids operational hold ups. Periodic consultations with technical support personnel can bring to light the necessary solutions and adjustments for the trouble-free installation.

Calibration before installation is necessary. It also includes setting tool positions, checking axis movements and altering speed settings. Calibration makes the machine function with the required exact specifications. Calibration at regular intervals promotes accuracy over time, correcting for wear and environmental changes. This stage is very important as the result remains at the high level.

|

Category |

Machine Prep |

Installation Steps |

Challenge Mitigation |

Tool Calibration |

|

Main Objective |

Prepare the equipment and workspace |

Execute the setup procedure |

Address potential issues during setup |

Ensure precision of machinery |

|

Key Activities |

Cleaning, space allocation |

Assembling parts, connecting systems |

Troubleshooting, adjusting strategies |

Measuring, adjusting tools |

|

Tools Required |

Cleaning supplies, measuring tape |

Wrench set, screwdrivers, pliers |

Diagnostic software, manuals |

Calipers, micrometer |

|

Personnel Involved |

Technicians, facility manager |

Technicians, engineers |

Quality assurance, risk management |

Calibration specialists |

|

Time Required |

2-4 hours |

4-8 hours |

1-3 hours (varies by issue) |

1-2 hours |

|

Common Challenges |

Inadequate space, unclean environment |

Incorrect part assembly, misalignment |

Equipment failure, delays |

Inaccurate measurements, drift |

|

Success Metrics |

Area readiness, safety compliance |

System functionality, component fit |

Issue resolution rate, downtime reduced |

Precision rate, tool accuracy |

Table on The Installation Process Simplified!

User training on the improved CNC machine includes operational skills and safety performances. Comprehensive training guarantees user’s ability to utilize the full potential of the machine safely and productively. Practice sessions enable users to get acquainted with the subtle aspects of the software and hardware. An effective training eliminates mistakes and reduces time of work.

The maintenance of CNC conversion, the software updates, and the workflow optimization ensure maximizing efficiency. Pre-scheduled maintenance eliminates the chances of abrupt breakdowns.

The purpose of software updates is to improve functionalities as well as to bring in new features. When tools and materials are organized, the setup time is decreased and cycles of production are increased.

A systematic approach is required to troubleshoot common problems, allowing quick and timely resolution of issues. The obvious problems are unpredictable machine performance, output inaccuracy and software bugs. Logging in details of operations facilitates the detection of repeating issues. Fast solution reduces downtime and sticks to production programs.

The use of CNC software properly requires that you understand the features and capabilities of it. Modification of settings for particular tasks improves productivity.

Advanced software provides the opportunity for simulating operations prior the actual machining, which enables reducing material waste as well as detecting possible errors. Unceasing education about software update and improvements increases operational efficiency and product quality.

The process of optimizing CNC operations is linked with adjustment of machine parameters for speed, accuracy, and material manipulation. Feeding rates and spindle speeds are frequency changed depending on hardness of material for optimum tool life and finish quality. CNC software automation features minimize manual adjustments, what improves overall throughput.

Development of advanced features of CNC kits can greatly improve the functionality of machines. The capabilities of multi-axis rotation, automated tool changers, and advanced cooling systems are among the features that enable the expansion of the type of operations that can be performed.

Maximum utilization of these features can convert simple machining setups into flexible manufacturing stations.

Optimizing machine settings and streamlining processes make increase operational speed achievable. Tool change times are shortened and path planning is optimized to decrease non-cutting time.

Improved motor characteristics enable working with higher cutting speeds preserving the quality of the work and, the overall production efficiency rises.

Achieving the accuracy in CNC machining requires tight tool calibration, optimal motion control systems, and good machine setup. High-accuracy motors and close feedback loops ensure that the machine moves follow the programmed paths precisely. Regular inspections and repairs of mechanical components preserve this accuracy over lengthy periods.

The monitoring of the performance of a CNC machine ensures that optimal operations are maintained. Sensors and software analytics monitor machine effectiveness, tool wear, and product quality.

Real-time data analysis enables the observance of choice adjustments and maintenance schedules, ensuring progression in the performance and progressions.

Demonstrating success cases of CNC conversions showcase their advantages in different industries. The examples are reduced cycle time in automotive part manufacturing, improved precision in aerospace components and higher customization enablement in the cons. These examples show the revolutionary effect of CNC technology.

Range of industries makes use of CNC conversion kit. Ranging from woodworking and metal fabrication to plastics and composites, these kits take manufacturing capabilities to the next level.

Different industries benefit at different levels, depending on the specific needs and problems they have.

Showcasing innovations in CNC conversions features advancements such as AI driven predictive maintenance, IoT-device integration, and adaptive control systems.

These innovations result in smart manufacturing processes that decrease cost and improve product quality. Displaying these advancements triggers more invention and use.

Capability growth from CNC conversions comprises the addition of new capacities and technologies. The enhancements, such as laser cutting heads, 3D printing modules, and robotic arms, are sought to be integrated with the current configuration, giving multifunctional abilities. This extension widens the scope of products to be manufactured as well as operational agility.

Idea generation for CNC converted machines projects makes the person think creatively and in practical terms. Projects may vary from complex jeweler models to strong mechanical parts.

The projects make use of the machine’s abilities and tests out its capabilities, showing us what can be done, and, in essence, bringing versatility of CNC technology to our attention.

The further stretching of capacities following the initial conversion implies constant improvements and learning. The software of a machine is developing by adding more sophisticated programs, trying new materials, and integrating more automation features, and the new parameters make a prototype more and more universal. This continuous progress maintains the system up-to-date and competitive.

CNC conversions improve production flexibility, permitting faster adjustments to market fluctuations. Rapid prototyping competencies, variable production volumes, and multi-material handling are the competitive advantages. This adaptive environment allows the operations to quickly react to new opportunities and demands.

To sum up, CNC Conversion Kits provide a way of improving machine performance in many industries. In conclusion, this guide has broken down the steps of kit selection, installation, and utilization to the last detail. Are you making your machining ready for the next level?

For expert consultation and top quality kits that will meet your needs perfectly, visit CNCYANGSEN. Boost your manufacturing capability today!