Dive into the world of engraving. Explore CNC and laser methods. Both are unique. Both have strengths. You'll learn their history, principles, precision, and uses. By the end, you'll grasp CNC engraving VS laser engraving advantages and challenges.

Milling and engraving, both vital in manufacturing, differ fundamentally. CNC milling machine involves cutting material using a rotating tool. Operators use it for shaping metals and plastics. Precise control of the cutting tool carves out parts. It's a process known for its accuracy.

CNC stands for Computer Numerical Control, highlighting the role of computers in guiding the tool's path. Engraving uses either a pointed tool in CNC engraving or a laser beam in laser engraving. It's a technique for adding details like text or images to a surface.

CNC engraving removes material with a spinning cutting tool, creating designs. Laser engraving employs concentrated light to vaporize material. This method is precise and efficient for detailed work. Both techniques transform various materials, but their applications and methods show clear distinctions.

In CNC engraving, CAD design plays a pivotal role. You design on CAD software. Milling uses rotating tools to cut material. Engraving, carves designs onto surfaces.

Both differ in terms of depth, precision, and tool use. CAD software helps in achieving both processes efficiently. Tools like CAM (Computer-Aided Manufacturing) further aid the process.

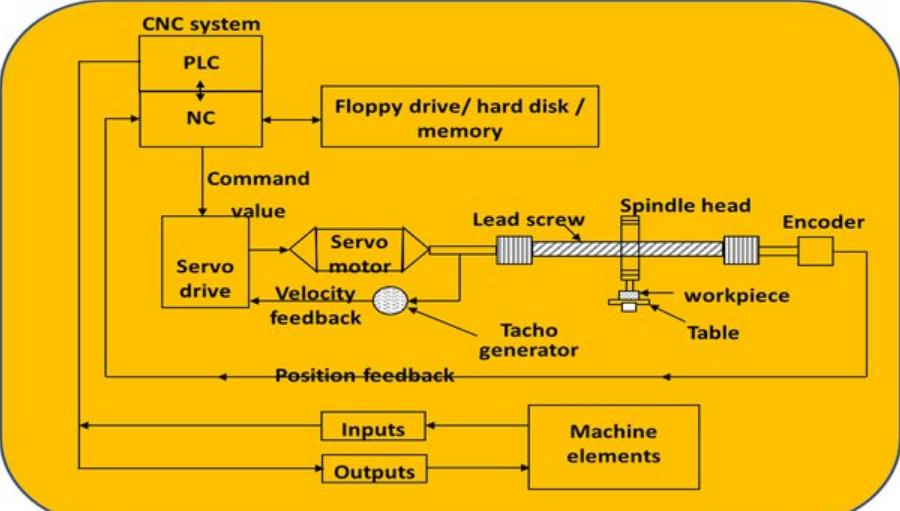

Post CAD design, G-code enters the scene. G-code instructs CNC machines. It dictates tool movement, speed, and path. Without G-code, CNC machines remain directionless.

CNC engraving relies heavily on accurate G-code. CAM software translates CAD designs into this G-code.

The spindle holds the tool in CNC machines. For engraving, spindle rotation speed is crucial. Speed varies between 8,000 RPM (Revolutions per Minute) to 30,000 RPM.

Correct RPM ensures clean engraving. Too fast or too slow affects quality. Adjusting spindle rotation thus becomes imperative.

The tool's route on the material is the tool path. Precision in this path is vital. CNC engraving demands meticulous tool paths. CAM software aids in setting these paths.

Depth control defines engraving quality. Too deep may damage the material. Too shallow won't make an impact. CNC machines allow precise depth settings. Engraving metal might need a depth of 0.005 inches. Depth varies with material and design.

CNC engraving is subtractive. Unlike additive methods like 3D printing, it removes material. You start with a block or sheet. The machine then carves out your design. The end result is your desired engraved piece.

Central to CNC engraving is material removal. The process carves out material. Be it wood, metal, or plastic, removal rate matters. Tools like end mills or engraving bits do this job. Selecting the right tool ensures optimal material removal.

In milling, tools cut into materials. In engraving, tools carve designs. CNC engraving uses computer-guided tools. Laser engraving uses light beams.

Both methods have distinct advantages. CNC engraving is precise. Laser engraving offers speed. Industries choose based on project needs.

Milling involves rotating tools. Engraving uses sharp tools. CNC engraving is about precision. Laser engraving focuses on beam control. Different projects require different methods. Consider material type and desired finish.

Milling machines use strong spindles. Engraving tools create detailed designs. Laser beams focus on small points. This makes laser engraving faster. CNC engraving provides depth control. Choose wisely for your project.

Milling removes material layers. Engraving creates fine details. Lasers produce heat. This heat changes material surfaces. CNC engraving doesn’t produce much heat. Material choice impacts the result.

Milling creates chips. Engraving produces finer particles. Lasers vaporize materials. The vaporization process is quick. CNC engraving offers material versatility. Check material compatibility.

Milling depth depends on tool size. Engraving depth varies by design. Laser focus is crucial. A sharp focal point ensures clean engraving. CNC engraving allows depth adjustments. Precision is key in both methods.

Different materials need different lasers. Milling tools come in various sizes. Engraving tools have specific designs. Laser wavelength determines engraving quality. CNC engraving uses tool paths. Both methods require expertise for optimal results.

CNC engraving uses a spinning tool. Laser engraving employs a laser beam. CNC can achieve accuracy up to 0.01 mm. In laser, you might see 0.05 mm precision. Both methods provide high detail. CNC relies on physical contact. Laser works with light energy.

Laser engraving gives smooth finishes. CNC engraving offers textured surfaces. Laser engravers use heat, affecting the material's look. CNC machines carve out material, leaving behind distinct textures. Different tools in CNC give varied textures.

CNC engraving depth depends on tool size. Laser engraving's depth is about the laser's power. CNC can carve deep grooves. Laser tends to make shallower marks. Depth in CNC is controllable. In lasers, depth varies with material type.

Edges from CNC engraving are sharp and clean. Laser engraving can leave slightly rounded edges. Heat from lasers can affect edge quality. CNC provides consistent edges across materials. Choice depends on desired finish.

CNC machines offer resolutions like 600 dpi. Laser engravers can reach 1200 dpi. Higher dpi means finer details. CNC's resolution relies on tool sharpness. Laser's resolution depends on beam diameter.

CNC engraving boasts tolerances of +/- 0.005 inches. Laser engraving might achieve +/- 0.001 inches. Tighter tolerances mean more precision. CNC's mechanical nature dictates its tolerance. Lasers' non-contact method offers tighter tolerances.

CNC machines maintain consistent repeat rates. Laser engravers offer rapid repetition due to light speed. CNC's repeat rate depends on the machine's speed. Lasers repeat at a constant, fast rate, ensuring efficiency.

Understand that CNC engraving finds use in creating detailed jewelry patterns. Precision ensures intricate designs on gold, silver, and platinum.

Transition to laser engraving and you'll find gemstone marking without damaging the material. The preciseness of both methods ensures stunning jewelry outcomes.

For circuit boards and device casings, CNC engraving provides depth. Small components require accuracy, and CNC excels here.

Laser engraving, on the other hand, marks serial numbers on devices. Both techniques guarantee durable marks on electronics.

Woodworkers prefer CNC engraving for depth and detailed carvings. Machines carve complex designs on hardwood and softwood. Laser engraving gives a burnished finish, especially on veneers.

In industries, CNC engraving carves steel, aluminum, and bronze. The depth achieved is commendable. Laser engraving ensures surface marks, especially on anodized aluminum. For tools, parts, and machinery, these methods prove beneficial.

For decorative purposes, laser engraving stands out. Fragile glass materials need a non-contact method, and lasers provide that. Engravings on wine glasses, mirrors, and windows showcase craftsmanship.

Brands rely on CNC for deep imprints on leather goods. Belts, bags, and wallets with embossed designs owe their elegance to CNC. Laser engraving gives a charred finish, ideal for branding logos and patterns.

Precision is paramount in the medical field. CNC engraving ensures instrument parts fit perfectly. Surgical tools and prosthetics benefit from this. Laser engraving marks instruments for traceability. Patient safety remains uncompromised.

Car components need markings for identification. CNC engraving gives depth to these marks on engine parts. Laser engraving offers quick, efficient marking on VIN plates. Durability ensures longevity in tough conditions.

For intricate patterns on fabrics, CNC engraving molds are created. These molds then imprint designs on textiles. Laser engraving, in contrast, creates patterns directly on fabrics.

CNC engraving molds shape plastic products. Toys, containers, and household items benefit. Laser engraving offers identification marks on plastic goods. Both methods ensure products meet industry standards.

Delicate ceramic items need careful handling. CNC engraving provides detailed patterns on tiles and pottery. Laser engraving gives surface designs without compromising structural integrity. Both methods guarantee elegant ceramic artifacts.

CNC engraving uses spinning tools. Laser engraving uses light beams. CNC machines carve materials. Lasers burn or melt them. You'll see CNC takes longer but gives depth.

Lasers are fast but surface-level. CNC might use RPM (revolutions per minute) to work. Lasers use wattage power. So, choose based on your need for speed or depth.

CNC engraving works on metals, woods, and plastics. Laser engraving shines on glass, leather, and paper. CNC uses different tool bits for materials.

Lasers adjust power and speed. Not all materials suit lasers. Metals need special lasers. Match method to material for best results.

Engravings from CNC machines last longer. They carve deep into materials. Laser engravings, though precise, are surface-level. Surface engravings can fade.

CNC engravings, with their depth, stand against wear. Especially in materials like steel or hardwood.

Initial costs for CNC machines are high. Lasers can be more affordable. But, operational costs vary. CNCs need tool bits, which wear out. Lasers have fewer parts, but replacements are costly. Consider long-term costs, not just the initial price.

CNC machines require regular upkeep. Oiling, cleaning, bit changes are common. Laser engravers need lens cleaning. Recalibration is vital. Maintenance ensures the machine's longevity. Proper care avoids unexpected breakdowns.

Operating CNC machines demands skill. You must understand tool paths, speeds, feeds. Lasers need knowledge of power, speed, materials. Both require software understanding. Training is crucial for both, but CNC might be more challenging initially.

CNC machines use motors, demanding high power. Lasers, especially high-power ones, also need significant energy. Lasers might be more efficient for quick jobs.

CNCs can run for longer periods, consuming more electricity. Check the machine's power rating before deciding.

In CNC engraving, tools carve patterns on surfaces. Laser engraving uses beams to etch designs. CNC tools remove material layers, making deep cuts. Lasers burn or melt surfaces for fine lines. CNC machines have spindles; lasers use diodes.

Each method uses different RPMs, wattages, and feed rates. For precision, CNC may use 18,000 RPM, while lasers operate at 40W. CNC works with metals, lasers prefer softer materials.

CNC machines and lasers have modules for tasks. CNC uses end mills, ball nose, and V-bits. Lasers use varying lens types. Switching between milling modules optimizes results.

For intricate details, CNC might use a 0.1mm V-bit. Lasers might adjust focus with a 2-inch lens. Different jobs require module swaps. Understanding module types boosts efficiency.

Hybrid hmc-machine merges CNC and laser processes. Some jobs need both engraving methods. By combining, one machine handles diverse tasks.

A project might start with CNC carving, followed by laser detailing. Combining processes saves time and enhances quality. Such synergy yields unmatched results.

Hybrid machines speed up production. By housing CNC and laser functions, transition between tasks is swift. No need for separate machines.

Time spent on tool changes reduces. In a 3-hour project, a hybrid might save 30 minutes. Time savings result in more projects completed daily.

Hybrid machines work on varied materials. CNC excels on hardwoods, plastics, and metals. Lasers shine on paper, leather, and acrylic.

Some materials, like softwood, benefit from both methods. Knowledge of material compatibility ensures optimal results. Using the right process for the material enhances the outcome.

Modern hybrids integrate with design software. Programs like CAD or CorelDraw link directly. Designers create in software, and then send to the machine.

Direct integration streamlines the workflow. No manual inputs needed. Software integration leads to fewer errors and increased consistency.

Hybrid machines boast advanced features. CNC might offer automatic tool changers. Lasers could have adjustable beam widths. These features push boundaries of what's possible.

Auto-tool changers allow continuous work without pauses. Adjustable beams mean lasers can switch between fine etching and broad marking. Each feature enhances machine capabilities, delivering superior results.

|

Feature |

Description |

Advantages |

Limitations |

Applications |

Key Innovations |

Industry Trends |

|

Dual-Head Design |

Two machining heads for different tasks |

Flexibility in operations; Reduced tool changeover |

Higher initial cost; Complex maintenance |

Aerospace, Automotive, Textiles |

Modular designs |

Growing adoption |

|

Switchable Modules |

Interchangeable parts for varied operations |

Customizable for specific tasks; Easy upgrades |

Potential for increased downtime; Cost of modules |

Medical, Electronics, Jewelry |

Quick-release mechanisms |

Shift towards modularity |

|

Combined Processes |

Integration of multiple manufacturing processes in one |

Space-saving; Cost-effective |

Complexity in programming and control |

Signage, Toy Manufacturing |

Multi-axis machining |

Efficiency optimization |

|

Increased Productivity |

Enhanced output rates |

Time savings; High volume production |

Higher energy consumption |

All industries |

Automation, AI integration |

Focus on lean production |

|

Versatile Materials |

Capability to work with a range of materials |

Broadens market scope; Diverse product creation |

Need for specialized tooling |

Textiles, Automotive, Medical |

Advanced material handling |

Material innovation |

|

Software Integration |

Use of integrated control software |

Simplified operation; Improved precision |

Dependency on software reliability |

Electronics, Aerospace |

Cloud-based platforms |

Digital transformation |

|

Enhanced Features |

Additional capabilities like 3D printing, AI, etc. |

Increased functionality; Innovation |

Higher costs; Training requirements |

Jewelry, Signage, Toys |

IoT, Smart sensors |

Rapid technological evolution |

Both CNC Engraving Vs Laser Engraving hold vast potentials. CNC focuses on material removal, while lasers use light intensity. They serve industries like jewelry, automotive, and medical. Their precision is commendable. Yet, each has its learning curve and costs. Want to explore more? Visit CNCYANGSEN for in-depth insights.