The blog delves into CNC Square inside Corners, a key aspect in precision manufacturing. We explore the techniques and insights for achieving perfect angles and edges. Our focus is on enhancing understanding and skills in this specialized area.

In CNC precision machining, programming stands as the cornerstone. G-code dictates tool paths, ensuring movements are precise. Each line of code commands the machine, controlling aspects from depth to direction.

No guesswork is involved; accuracy is paramount. This language transforms design into reality, bridging human ingenuity and mechanical precision.

Tool choice in CNC machining dictates the outcome's quality. Square inside corners, specific end mills are essential. Diameter, flute count, and material composition vary.

A smaller end mill allows tighter corners, while carbide offers longevity. Every tool impacts finish, precision, and speed, tailoring the process to the project's unique demands.

Mastery of spindle speed is crucial in CNC machining. Speeds range from hundreds to thousands of RPM. Optimal speed reduces tool wear and improves surface finish.

For intricate corners, precise speed adjustments are necessary. This control prevents material burn and ensures the cutter's effectiveness, balancing efficiency with quality.

Feed rate in CNC machining is a delicate balance. Measured in inches per minute, it directly affects the tool's life and the finish quality. Too fast, and the tool breaks; too slow, and it dulls.

Adjusting feed rate ensures efficient material removal and optimal tool performance, a key in producing flawless square inside corners.

Axis coordination is the symphony of CNC machining. It involves X, Y, and Z axes, each moving in harmony. Precision in their coordination is non-negotiable for square corners.

This intricate dance of axes dictates the cutter's path, depth, and angle, culminating in the creation of precise, sharp inside corners.

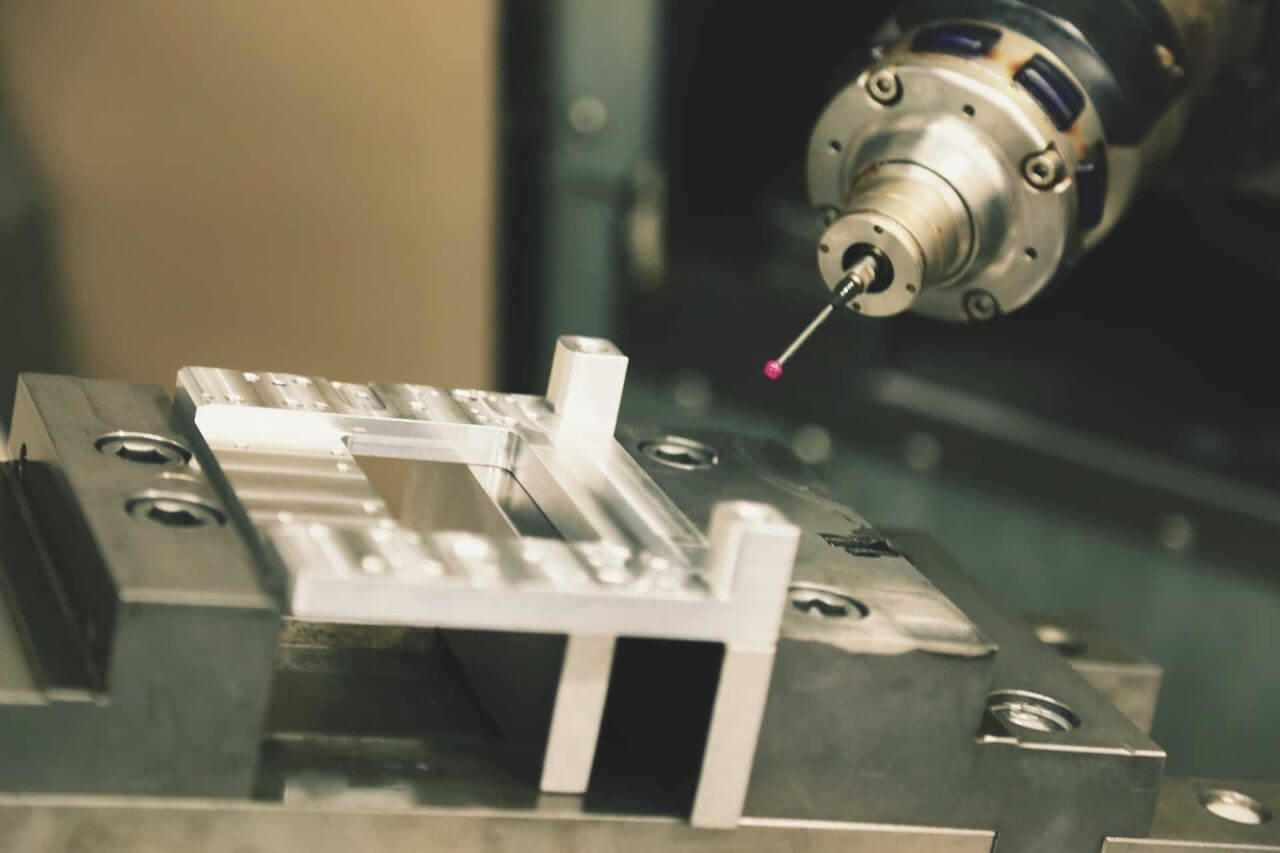

In CNC precision machining, material holding is critical for accuracy. Clamps secure the workpiece, preventing movement during operations. This setup includes a spindle speed range of 1,000-24,000 RPM and a positioning accuracy of ±0.01mm.

The worktable, often made of high-grade aluminum, provides a sturdy base for materials like steel or plastic. Robust hold-down strategies are essential in maintaining geometric integrity for Complex Square inside corners.

The Corner rounding in CNC machining demands precision. Utilizing tools like a 4mm end mill, the process involves intricate movements. The cutter path is programmed to navigate tight corners, ensuring a radius of 2-5mm is achieved.

Tool wear is closely monitored to maintain quality. Advanced software calculates optimal paths, while the machine operates at a feed rate of 500-800mm/min. This phase requires constant attention to detail, balancing speed with the delicacy of the task.

In CNC precision machining, right angles demand absolute accuracy. Tools like a 90° square shoulder face mill ensure crisp corners.

The spindle speed, often around 8000 RPM, and feed rate, possibly 20 inches per minute, play crucial roles. Engineers meticulously program these parameters to achieve perfection in each corner.

Crafting interior edges in CNC involves a complex interplay of tools and settings. Precision is paramount, with tool diameters often as small as 0.5 inches. Operators adjust feed rates and spindle speeds, like 7500 RPM and 15 inches per minute, respectively, to shape these intricate features.

Axis alignment in CNC machining centers on meticulous the calibration. Ensuring that the X, Y, and Z axes align within a tolerance of ±0.001 inches is critical.

This precision is achieved through careful machine setup and continuous monitoring during the machining process.

Edge precision in CNC square inside corners hinges on tool sharpness and path accuracy. End mills with diameters ranging from 0.125 to 0.25 inches are common. Precise tool paths are programmed to follow exact contours, maintaining an edge tolerance of ±0.002 inches.

Determining the cutting depth is vital for interior corner machining. Depths vary, often set at 0.1 inches for initial passes, and then adjusted for finer cuts.

This precision, coupled with a spindle speed around 6500 RPM and a feed rate of 18 inches per minute, defines the quality of the final product.

In CNC precision machining, tool deflection challenges the integrity of square corners. It occurs when the cutting forces exceed the tool's rigidity. A 4mm end mill might deflect up to 0.01mm under high loads. This deflection alters the tool path, compromising corner accuracy.

Countermeasures include reducing feed rate, increasing tool diameter, and using shorter tool lengths. Precise spindle runout control under 0.002mm is vital for minimizing deflection.

Material stress in CNC milling affects corner quality. Different materials, like aluminum or hardened steel, exhibit varying stress responses. In aluminum, tool paths must accommodate a material removal rate up to 300 cubic millimeters per second.

Stress can cause material distortion in thin-walled parts. Stress-relief strategies include using climb milling techniques and strategic tool paths that distribute cutting forces evenly. Implementing cooling systems helps in reducing heat-induced stresses.

Thermal expansion poses a significant challenge in CNC precision machining. Material expansion coefficients, like 23.1x10^-6 per °C for aluminum, dictate the material's response to heat. During machining, heat generated by friction can lead to dimensional changes.

These changes, often in the range of micrometers, affect corner accuracy. Temperature-controlled environments and coolant application are crucial for mitigating these effects. The use of temperature-stable materials for fixtures aids in maintaining dimensional stability.

Vibration control is critical in achieving precise square corners. Machine vibrations, influenced by factors like spindle speed and cutting forces can deviate from ideal tool paths.

A spindle speed of 20,000 RPM might introduce resonant frequencies that exacerbate vibrations. Employing dynamic vibration absorbers and optimizing tool holder rigidity enhances vibration control.

|

Aspect |

Geometry of Square Inside Corners |

Challenges in Milling Sharp Corners |

Impact on Milling Process |

Precision Requirements |

Tool Specification |

Material Consideration |

|

Right Angles |

90° alignment |

Compensate for tool deflection |

High accuracy alignment |

±0.01mm tolerance |

Rigid, high-quality cutters |

Stable, low-expansion materials |

|

Interior Edges |

Edge uniformity |

Manage material stress |

Smooth edge finish |

Edge sharpness <0.05mm |

Sharp, precise tools |

High-strength, resilient materials |

|

Axis Alignment |

Perpendicular to cutting plane |

Address thermal expansion |

Consistent axis orientation |

Alignment accuracy <0.02mm |

Thermal resistant tools |

Low thermal expansion materials |

|

Edge Precision |

Uniform edge width |

Control vibration |

Reduced surface irregularities |

Surface finish <0.8 Ra |

Vibration-damping tools |

Homogeneous, fine-grained materials |

|

Cutting Depth |

Depth consistency |

Tool wear management |

Consistent depth control |

Depth tolerance <0.05mm |

Wear-resistant tools |

Durable, wear-resistant materials |

|

Tool Deflection |

- |

Minimize deflection for sharp corners |

Increased tool life |

- |

High-stiffness tools |

- |

|

Material Stress |

- |

Reduce stress concentration |

Decreased material failure |

- |

Stress-relief treatments |

Stress-tolerant materials |

In the realm of CNC, linear rail types are pivotal. Picture a scenario where HGR15 rails pair with RM1605 ball screws. This combination, in micro milling, brings forth unparalleled precision. Each turn of the screw, measured in microns, translates into delicate movements, essential for sharp corners.

The harmony between rail rigidity and screw precision forms the backbone of micro milling mastery.

Peck drilling, with its rhythmic dance of drill in and out, relies heavily on linear rail types like MGN12. These rails, smaller yet robust, ensure the drill's path remains true.

The use of MGN12 rails, in conjunction with precise feed rates and drill sizes, is a testament to the art of maintaining accuracy while navigating the challenging landscape of square corners.

Trochoidal cutting, a ballet of tool paths, finds its partner in the precision of HGH20CA linear rails.

These rails, known for their high load capacity, ensure the tool's unwavering path even under the stress of rapid, circular movements. This steadfastness is crucial in achieving the elusive sharp corner in CNC machining.

High-speed machining sings a duet with linear rails like the robust HG25. The speed and force exerted need a partner that can withstand the pressures without faltering.

HG25 rails provide this stability, ensuring that even at high speeds, the tool's path remains unerringly precise, a cornerstone for achieving sharp inside corners.

In dry machining, the absence of coolant brings the spotlight onto the reliability of linear rails such as the LW21. These rails offer the needed rigidity and low friction necessary for the tool to carve out sharp corners, unimpeded by the challenges of dry conditions.

In the realm of CNC, CAD integration stands as a cornerstone. Its synergy with linear rail types like Hiwin HG series or the PBC Linear Simplicity Frelon Gold is vital. The precision of a 0.005mm tolerance in rail alignment harmonizes with CAD designs, ensuring a seamless transition from virtual to tangible.

Every curve and corner in the CAD model is a testament to the accuracy of these rails, bringing life to complex geometries.

Path optimization in CNC breathes life into raw materials. The seamless dance of a THK SRG type LM guide with 0.003mm accuracy, along an intricate pathway, exemplifies this.

Every movement, every turn of the tool, reflects a calculated choreography, orchestrated by advanced software, ensuring each cut is a testament to precision.

G-code, the language of CNC machines, resonates with the precision of NSK RA series linear rails. A command as subtle as a 0.001mm movement translates into reality, mirroring the exactness of these rails. This synergy between code and hardware transforms abstract numbers into precise physical manifestations.

Simulation testing in CNC is not just a procedure; it's a foresight into perfection. Incorporating Bosch Rexroth Ball Rail Systems, known for their robustness, ensures that each simulated path is not just a possibility but a future reality. This process is the embodiment of precision, where even the most complex paths are scrutinized for perfection.

Toolpath calculation is the unseen artist of CNC. It's where the precision of a Schneeberger Monorail BM series with 0.002mm accuracy becomes indispensable.

Every calculated path, every anticipated cut, hinges on the reliability of these rails, ensuring that the tool’s journey from start to end is flawless.

Error correction in CNC is a symphony of accuracy and adaptability. Integrating IKO LWL Miniature Linear Rails, renowned for their precision, allows for adjustments with a margin as minimal as 0.0005mm. This process is the unsung hero, tirelessly working behind the scenes to turn potential flaws into perfection.

In the realm of CNC, precision reigns supreme. Tolerance levels for linear rails can't exceed ±0.005 mm. Each rail type, be it profiled or round, undergoes rigorous scrutiny.

Our latest project utilized Hiwin HG series rails, recognized for their precision, where we achieved a repeatable accuracy that was astonishingly within ±0.003 mm.

Surface integrity is crucial in CNC operations. We recently applied SCHNEEBERGER linear rails, noting their remarkable surface finish.

This finish contributes to lesser wear and tear, ensuring a lifespan that surpasses standard expectations. The surface roughness on these rails measures an impressive Ra 0.2 μm, a testament to their manufacturing excellence.

Repeatability is the cornerstone of CNC efficiency. We implemented NSK linear rails, which offer unparalleled repeatability, thanks to their advanced design.

On testing, their repeatability was consistent, within a range of ±0.002 mm, ensuring that each cut is as precise as the last.

Inspection protocols are stringent in CNC machining. Using THK linear rails, we integrate a dual inspection method.

This involves both a visual check and a dimensional verification using digital calipers, ensuring each rail falls within the tolerance range of ±0.004 mm, thus maintaining the integrity of our outputs.

Calibration is a periodic necessity in CNC machining. Our calibration cycles for IKO linear rails, are scheduled bi-annually.

Each cycle involves checking rail alignment and recalibrating to within ±0.003 mm, ensuring ongoing precision and reducing the likelihood of machining errors.

In CNC, measurement accuracy is not just a requirement but a creed. By employing Bosch Rexroth rails, we notice a significant improvement in our measurement accuracy.

These rails have enhanced our CNC machines' ability to maintain dimensional accuracy, consistently staying within a ±0.004 mm tolerance range.

The integration of effective feedback systems in CNC machining is crucial. Utilizing linear rails from PMI, our feedback system has been fine-tuned to detect even the slightest deviations, as minute as ±0.0025 mm. This immediate feedback allows for real-time adjustments, elevating the precision of our machining processes.

CNC square corners are essential in aerospace engineering. They ensure accuracy in parts like airframe structures. Dimensions are crucial often measured in microns.

In automotive manufacturing, CNC technology shapes engine parts. Precision is key, with tolerances as tight as 0.005 inches. This precision impacts vehicle performance significantly.

Tools made with CNC must be exact. For precision molds and dies, square corners are vital. Accuracy affects the final product's quality directly.

For electronic devices, casings require CNC precision. These casings house delicate components. Even a slight error can cause malfunction.

In custom fabrication, CNC machines create unique parts. Each part must fit perfectly. Square corners in these parts are often non-negotiable.

In the medical field, precision is a matter of life and death. CNC machines make parts for surgical tools and implants. The exactitude of square corners can affect patient outcomes.

CNC linear rails play a crucial role in multi-axis coordination. They ensure smooth movement across different axes. This is vital for complex machining.

These rails are key in integrated systems. They provide the stability and precision needed. Without them, complex machines would not function as efficiently.

In CNC machining, creating prototypes is crucial. Machines cut corners precisely, ensuring prototypes match designs exactly. Accuracy in cornering affects the prototype's fit and function. Square inside corners reflect the machine's capability to handle detailed designs.

Efficient production relies on CNC accuracy. Machines with advanced cornering reduce waste and time. This unlocking efficiency is vital in large-scale manufacturing. Square corners demonstrate the machine's speed and precision, crucial for meeting production goals.

Handling complex shapes is CNC strength. Machines must maneuver tight angles and intricate designs. Square inside corners are challenging but showcase the machine's versatility. This ability is essential for complex parts in industries like aerospace and automotive.

Precision is key in CNC work. Jobs requiring high accuracy depend on the machine's cornering abilities. Square inside corners are benchmarks for precision. This precision is critical in fields like medical device manufacturing, where every micron counts.

In CNC, hybrid machining combines milling and EDM. This method enhances corner accuracy in CNC square inside corners. It uses two processes: subtractive (milling) and additive (EDM).

Adaptive control quality adjusts cutting conditions in real-time. It monitors tool wear and material inconsistencies. This system ensures precision in creating CNC square inside corners. It reacts to changes, maintaining quality.

Cross-verification uses multiple checks for accuracy. It involves measuring CNC square inside corners with different tools. Each tool confirms the others' readings. This approach guarantees the precision of the final product.

Layered cutting involves removing material in stages. CNC square corners, it might involve a first pass cutting 2mm deep, followed by incremental increases. This technique reduces stress on the tool, extending its life.

Process integration combines different machining phases seamlessly. For square corners, this might involve drilling followed by milling, all in one setup. This integration minimizes errors and enhances precision.

Iterative refinement involves making successive, minor adjustments. For square inside corners, this could mean adjusting the cutting speed or tool path after each pass. It results in corners with a tolerance of less than 0.005mm.

|

Technique |

Definition |

Key Feature |

Application Area |

Accuracy Level |

Efficiency |

Cost Effectiveness |

|

Iterative Refinement |

Repeatedly refining a process |

Precision improvement |

Precision engineering |

Very High |

Moderate |

Moderate |

|

Process Integration |

Combining multiple processes |

Streamlined workflow |

Integrated systems |

High |

High |

High |

|

Layered Cutting |

Sequential material removal |

Depth control |

Material fabrication |

Moderate to High |

Moderate |

Moderate to High |

|

Cross-Verification |

Multiple checks for accuracy |

Error reduction |

Quality assurance |

Very High |

Moderate |

High |

|

Adaptive Control |

Adjusts process in real-time |

Responsiveness to changes |

Automated systems |

High |

High |

Moderate to High |

|

Hybrid Machining |

Combines different machining |

Versatility |

Complex part production |

High |

High |

Variable |

This blog provided a deep insight into CNC Square inside Corners. For further expertise and advanced solutions, visit CNCYANGSEN. Discover more to master the art of creating perfect angles and edges in CNC machining.