CNC Machine Alarm plays a crucial role in modern manufacturing. Properly understanding these alarms ensures precision mold and quality in operations.

In this guide, every facet of these alarm systems will be unpacked. From their historical development to the anatomy and types, the aim is to give a complete understanding.

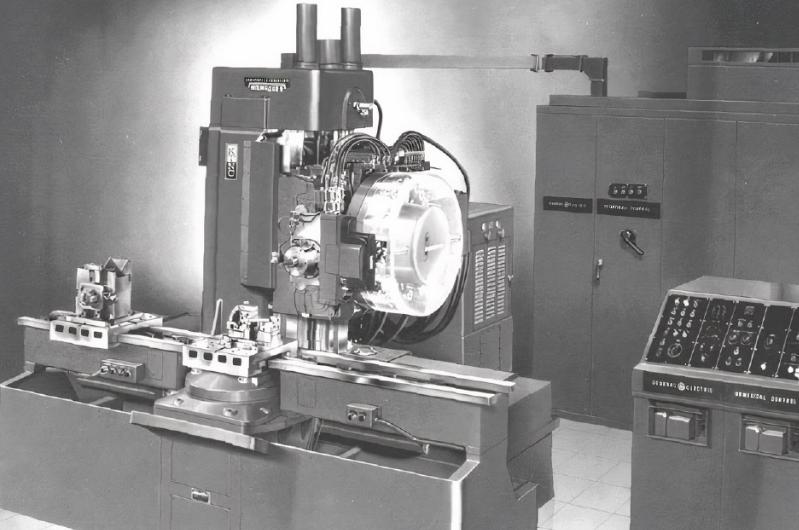

In the 1960s, CNC machines used basic alarm systems. Initially, parameters like G00 or G01 guided operations. Over time, advancements arrived.

By the 1980s, M-code changes resulted in more detailed alarm systems. Transitional shifts during the 1990s introduced multi-axis operations.

Subsequently, alarms had to monitor complex processes. Machine tool manufacturers, like Haas or Mazak, incorporated sophisticated alarm features.

Safety standards, like ISO 230, mandated these changes. Thus, alarms evolved, enhancing CNC operations' safety and efficiency.

In early CNC machines, operators used punch cards. Cards transmitted essential data. Mistakes in punch cards led to faulty operations. Alarms detected such errors, ensuring correct production.

Before advanced alarms, operators monitored machines manually. They observed and noted irregularities. Alarms then signaled deviations from set standards.

Modern CNC machines give error feedback. When a tool deviates from set parameters, alarms activate. Immediate feedback ensures minimal material wastage.

Before digitalization, analog systems ruled. Analog alarms relied on circuits. Their task detects and reports errors based on electrical signals.

By the 21st century, CNC operations shifted to digital platforms. Alarms became software-based. Their accuracy increased dramatically.

Advanced alarms now use predictive analysis. They forecast potential errors. Before an error occurs, corrective actions initiate.

Integration with software like Mastercam or SolidWorks is now common. Alarms communicate with these platforms. In case of deviations, the software auto parts-corrects or pauses the operation.

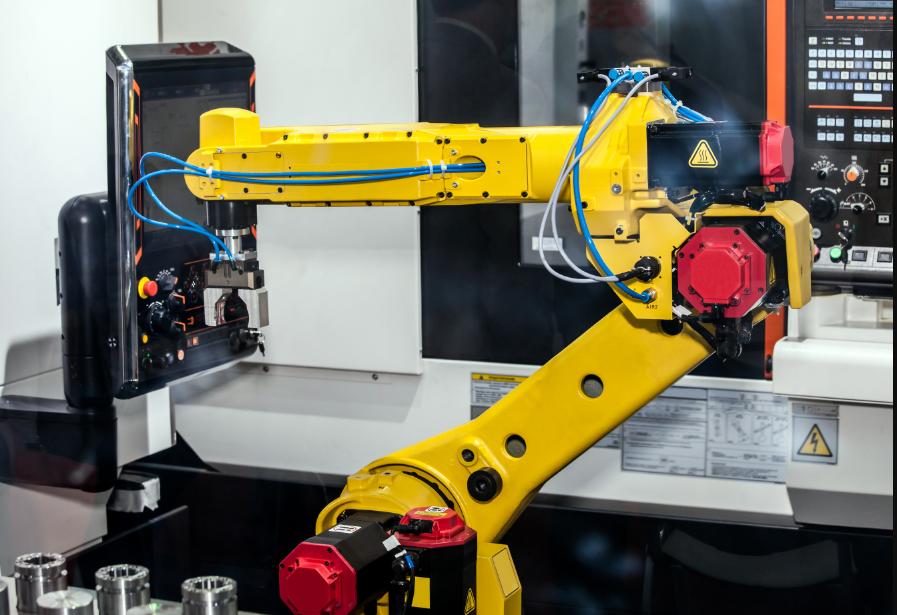

Internet of Things (IoT) transformed CNC operations. Machines connect online. Alarms, through IoT, send alerts to operators even remotely.

Artificial Intelligence aids in error detection. Alarms, with AI support, can understand complex patterns and alert about unnoticed errors.

Over time, alarms learn from repetitive patterns. Machine Learning enables them to predict errors better.

Now, alarms don't just alert. They trigger automated correction mechanisms. Tools auto-adjust, ensuring optimal performance.

Modern alarms offer real-time data analysis. They continuously assess machine operations. Any discrepancy results in instant alerts.

The inclusion of high-precision sensors enhances alarm accuracy. These sensors detect even minute deviations, ensuring top-notch product quality.

No more wired connections. Alarms now communicate wirelessly. Data transmission is faster, and error reporting becomes immediate.

Cloud-based platforms store machine data. Alarms, when detecting discrepancies, can retrieve past data for comprehensive analysis. Thus, error detection is more thorough and informed.

Machines generate heat. If too much, you'll get an alert. Overheat alerts protect from damage.

Electricity can spike. Power surges risk your machine's health. Safety measures are crucial.

Machines move in paths. When not aligned, errors happen. Axis checks keep precision.

Tools wear out. If broken, the machine stops. Regular checks maintain work quality.

Machines need oil. Low lubrication causes wear. Proper oiling enhances machine lifespan.

Overloading strains systems. Excessive loads trigger alarms. Monitor to avoid machine fatigue.

Circuits control actions. Errors disrupt operations. Immediate fixes prevent bigger issues.

Memory stores data. When full, operations halt. Periodic clear-outs maintain smooth running.

Corrupt data means wrong commands. Ensuring data integrity safeguards machine functions.

Steady power is vital. Fluctuations affect performance. Voltage monitors stabilize operations.

Machines talk to computers. Breaks in this talk mean stoppage. Regular checks ensure sync.

Movement is crucial. Halted motion disrupts work. Sensors detect and alert such issues.

Machines follow instructions. Wrong input disrupts. Input checks prevent these issues.

Drives power movements. Failures mean stoppage. Routine checks keep drives healthy.

Coolants reduce heat. Low levels risk overheating. Monitor levels to maintain temperature.

Spindles rotate tools. Variance affects tool performance. Precision checks are vital.

Machines feel through sensors. Detecting issues, sensors alert the system. They're the machine's eyes and ears.

It’s the brain of the alarm that processes signals and decides actions.

Display alerts. Visual or sound, they inform operators. Quick response hinges on clear indicators.

Store data and alarm history. Reviewing helps trace issues that are essential for diagnostics.

Trigger external actions. Can stop operations or alert other systems. Safety often relies on them.

Audible alarms notify staff. Different tones mean different alerts. It’s crucial in noisy environments.

Show status or issues. Quick glance aids operators. Visual clarity can hasten solutions.

Operators give commands. Buttons allow response to alerts. Immediate action can avert damage.

Systems check themselves. Feedback ensures all's well. Self-checks boost reliability.

Data loggers record activity over time. Reviews help spot trends. Vital for maintenance schedules.

Software drives the alarm. Updates improve performance. Regular checks ensure peak operation.

Power outages happen. Backup ensures alarms still work. Continuous protection is priceless.

|

Component |

Function |

Location |

Power Consumption |

Maintenance Requirement |

Connectivity Options |

|

Sensors |

Detects changes in environment (e.g., motion, heat) |

Various points |

Low |

Regular calibration |

Wired, Wireless |

|

Processors |

Analyzes signals from sensors & determines actions |

Central unit |

Moderate |

Firmware updates |

USB, Ethernet |

|

Indicators |

Conveys system status (armed, disarmed) |

Panel, Remote |

Low |

Periodic checks |

LED, LCD |

|

Memory Units |

Stores data, configurations, and event history |

Central unit |

Low |

Rarely replaced |

Flash, RAM |

|

Alarm Relays |

Transmits alarm signal to other systems or devices |

Central, Wall |

Low |

Periodic tests |

Wired |

|

Sound Modules |

Produces audible alerts or announcements |

Various points |

Moderate |

Rare replacement |

Analog, Digital |

Table on The basic components and functions of alarm systems!

In CNC operations, overheating emerges as a top alarm trigger. Constantly monitor machine temperature. Elevated levels compromise machine accuracy. Use coolants. Consider integrated temperature regulation.

Motors drive CNC machinery. A stall indicates rotation hindrance. Causes include electrical imbalance or mechanical obstructions. Regularly inspect motors. Ensure timely maintenance.

When tools don't move as planned, you have a tool jam. Dust, debris, or misalignment can cause this. Regular cleaning is essential. Also, check tool paths for smooth operations.

CNC operations rely on precise data. Incomplete or absent information can halt production. Always double-check program inputs. Ensure a stable data transfer method.

Any unexpected shutdown is harmful. CNC machines need a constant power supply. Invest in uninterrupted power sources (UPS). Regularly check electrical connections.

Sometimes, software causes problems. Erroneous instructions lead to malfunctions. Regularly update your software. Consult with technicians for troubleshooting.

Machines operate in sequences. Disruption in any step can cause faults. Sequence checks are paramount. Ensure all operations align in the correct order.

Precision is vital in CNC operations. Incorrect settings can produce flawed results. Regularly calibrate machines. Cross-reference parameters with established benchmarks.

Too fast or slow feeds disrupt operations. Consistency in feed rates ensures optimal performance. Use sensors to monitor rates. Adjust speeds as required.

Damaged tools compromise quality. Integrated sensors detect such failures. Replace tools promptly. Always have backups ready.

Machines have operational boundaries. Exceeding these limits can trigger alarms. Establish clear boundaries. Adherence prevents potential damages.

Controllers guide CNC machinery. Any dysfunction disrupts production. Periodic checks are crucial. Stay updated with the latest firmware.

Environmental factors impact CNC operations. External interferences like radio frequencies can cause alarms. Ensure machine placements are optimal. Consider shielding techniques.

Machines, though robust, can fail. Hardware issues can range from circuitry to mechanical parts. Implement regular diagnostic tests. Maintain a log of all maintenance actions.

Most machines provide error messages using numbers. Numeric codes, like 012 or 231, specify distinct alarm issues. Understand each number to tackle problems swiftly.

Some alarms combine letters and numbers. Codes like F12 or E3B indicate unique issues. Alphanumeric mixes give more specific information than numeric ones.

Often, CNC machines have colored lights for alarms. Red might indicate a critical issue. Green can suggest minor hitches. Always consult your manual for exact color meanings.

Machines can produce beeps or other sounds for different problems. A continuous beep might mean one thing, while intermittent beeps might mean another. Sound patterns help in quick selection troubleshooting.

Specific issues might cause LED lights to flash in distinct patterns. Observe the flash frequency and consult the guidebook for details.

Sometimes, alarms present in sequences. Sequence 1-3-2, for instance, could represent a specific module malfunction. Knowing sequences aids in faster problem identification.

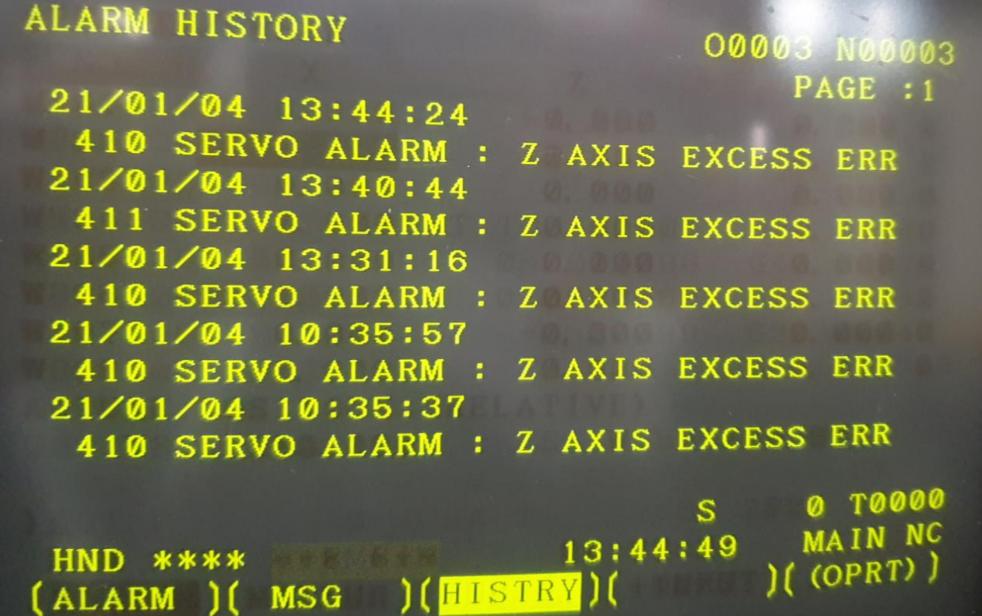

Different manufacturers have unique codes. Siemens might use a different code system than Fanuc. Hence, always have the manufacturer's manual handy.

Some alarms have priority levels. A priority level 1 might be urgent. A priority level 5 might be less pressing. Addressing high-priority alarms first ensures smoother operations.

Modern CNC machines provide a time stamp with alarms. A time stamp, like 14:30, tells when the alarm occurred. Keeping track of timestamps helps in maintaining machine health logs.

Alarms can refer to specific machine modules. A reference to the X100 module, for instance, points to a particular part's issue. Knowing the module aids in focused troubleshooting.

CNC machines often provide a brief description of the alarm. Phrases like "spindle malfunction" give operators a clear idea of the issue at hand.

Alarms can also show fault zones, guiding technicians to the exact machine area needing attention. Zone C2, for instance, might refer to the machine's lower left quadrant.

When a CNC Machine Alarm signals immediate shutdown, your machine ceases operation. Often, such shutdowns relate to grave internal problems.

A triggered alarm can indicate a looming safety hazard. Addressing these risks protects both equipment and operators.

Some alarms highlight component failures. Spindle motors or control panels might malfunction, demanding immediate attention.

Alarms warn of potential data corruption. Sudden data loss can disrupt intricate milling or lathing processes.

External or internal physical harm may activate an alarm. Such issues jeopardize your machinery's lifespan.

These alarms indicate irreversible errors. Such situations require expert intervention and possibly parts replacement.

Here, the operator must intervene. Manual adjustments or resets become necessary, delaying operations.

Critical alarms might entail financial ramifications. Unscheduled downtime or defective parts replacements cause monetary losses.

A halted production line stems from alarming issues. Rebooting and troubleshooting become mandatory.

Alarm-triggered operations often produce sub-par components. Such degradations affect overall product integrity.

Alarms may signify altered machine parameters. Feed rate or axis movement deviations need swift rectification.

Interruptions in rotary or linear motion cause operational inefficiencies. Address such alarms promptly.

Overheating machinery is a red flag. An alarming temperature surge demands immediate cooling or shutdown.

Non-critical alarms point out slight irregularities. Yet, they don't typically hamper overall functionality.

Alarms of this nature hint at manageable problems. A simple reboot or parameter reset can address them.

Here, alarms merely log the discrepancy without demanding action. Review logs periodically to discern patterns.

These alarms heighten operator awareness. They signal potential concerns without halting operations.

Addressing these alarms isn't immediate. You can schedule interventions during downtime.

Even when triggered, production remains unaffected. Such alarms serve as advisory notes.

These alert operators about factors influencing product quality. Immediate action might not be necessary, but vigilance is.

Cosmetic concerns, like surface scratches, might set off alarms. Address at discretion; functionality remains intact.

Parameters nearing threshold values cause these alarms. Before a significant deviation occurs, recalibration might be needed.

Maintenance reminders often activate these alarms. Schedule a timely servicing to prevent major issues.

Alarms of this type indicate amendable discrepancies. Operators can opt to rectify or continue as is.

These alarms remind operators about daily or periodic tasks. They include oiling or cleaning components.

Regularly update the CNC's firmware. Older versions often contain unresolved issues. Updated firmware brings solutions, enhancing the machine's performance.

Sometimes, the system shows unpredictable behavior. In such cases, always consider the possibility of a software bug. Contact software providers for patches.

Modern CNC operations need adequate memory. An overflow indicates that storage is beyond capacity. Regularly check memory consumption, and delete unnecessary files.

A sudden power surge can corrupt your CNC's data. Always maintain a backup. Restoration becomes simple with backup data on hand.

You feed commands into the CNC. An invalid input error signifies a command that the system can't recognize. Review the entered parameters for accuracy.

Different machines accept different G-Codes. Ensure the G-Code suits the specific machine model. Otherwise, errors become inevitable.

A system crash can halt operations. Restart the machine, and if problems persist, consult a technician. Timely intervention prevents long downtimes.

CNCs store vast amounts of data. A database error implies trouble accessing this storage. Regular maintenance and updates often prevent such issues.

Ensure your CNC software has a valid license. An expired or invalid license can halt operations. Renew or update as necessary.

Restrict system access to authorized personnel only. An unauthorized entry might change crucial settings.

Software components need to match versions. Discrepancies can cause operational issues. Always install compatible software versions.

CNC machines communicate with other devices. Failed communication might lead to operational errors. Ensure cables and wireless setups are in optimal condition.

Operations follow sequences. A mismatch suggests commands are out of order. Reorder sequences as needed for smooth operations.

The CNC operates on algorithms. A malfunction suggests algorithm issues. Reach out to software providers for solutions.

Long inactivity can trigger a timeout. Reactivate the machine. Regular use and timely shutdowns can avert such issues.

Different beeps convey varied messages. Know the machine's beep codes. Each pattern indicates specific conditions or errors.

A continuous buzz often signifies an urgent issue. Address promptly.

Regular pauses between beeps might suggest minor issues. However, don't ignore them.

Rising tones can represent increasing threats or problems. Regularly consult the user manual.

A tone that descends often signifies decreasing power or resources. Recharge or refill resources as necessary.

Change in beep frequency signals varying error intensity. Always monitor.

No sound means no power. Check power sources and connections.

Complex messages get conveyed through Morse patterns. Refer to manuals for translation.

Multiple tones signify multiple issues. Prioritize based on the machine's user manual.

Modern machines speak. Voice warnings provide direct error messages.

Some alarms convey errors through melodies. Understand each tune's meaning.

Tap patterns might indicate mechanical issues. Consult technicians.

Unique tunes for specific errors. Familiarize yourself with each melody.

Fanuc, a dominant CNC brand, provides alarms for operational deviations. Examine the operator’s manual. Pinpoint the alarm number and remedy immediately. Monitor G and M codes for discrepancies.

Siemens controllers deliver specific error codes. Recognize the numeric values. Address spindle and axis errors swiftly. Remember, the PLC section holds most remedies.

With Mazak machines, errors indicate system misalignments. Delve into the machine parameters. Identify turret mispositions or tool life overages.

Heidenhain systems employ explicit feedback loops. Should deviations arise, consult the TNC report. Scrutinize encoder values and linear measurements.

Haas machines present clear warnings. Check the pop-up messages on the control screen. Act on servo overloads or coolant interruptions.

Okuma’s OSP system showcases vibrant indicators. Assess the alarm page for rapid solutions. Tackle temperature variations or power fluxes.

Fadal CNC units give real-time notifications. Navigate to the user interface. Address any mismatch in settings or unexpected stoppages.

Mitsubishi CNCs are unique. Their alarms distinguish subtle system nuances. Gauge parameters like spindle rotation or tool change cycles.

Hurco controllers emit discernible signals. Seek the WinMax system alerts. Rectify feed rate issues or memory overflows.

Brother machines convey breakdowns with precision. Dive into the maintenance mode. Rectify any programming errors or operational lags.

On Sodick machinery, alarms alert of system anomalies. Observe the wire feed rates. Take note and adjust settings for EDM functions.

Doosan's CNC systems are adept at diagnostics. Screen the alarm list. Remediate tool offsets or axis travel over-extensions.

Romi machines assist in precise interpretations. Analyze the control panel's readouts. Resolve issues related to hydraulic pressure or chuck alignment.

Makino systems signal distinct malfunctions. Engage with the Pro control suite. Adapt to situations like tool breakage or pallet change errors.

CNC Machine Alarms safeguard quality, efficiency, and safety in machining center operations. Their intricate designs span from simple alert mechanisms to complex software-driven notifications.

By understanding their codes, triggers, and responses, operators optimize machine performance and mitigate risks. To further delve into CNC machine intricacies and solutions, explore CNCYANGSEN. Your path to mastery in CNC operations awaits.