Demystifying CNC Lathe Machine Programming is this blog's pivotal goal. Within these tutorials, a vast world unfolds, where mastery of the Spindle Motor, Tool Turret, Carriage Slide, and complex G-code operations is within reach. Learn to harness the full power of the lathe, program with precision, and optimize operations for peak efficiency. Gain insights that translate into real-world expertise.

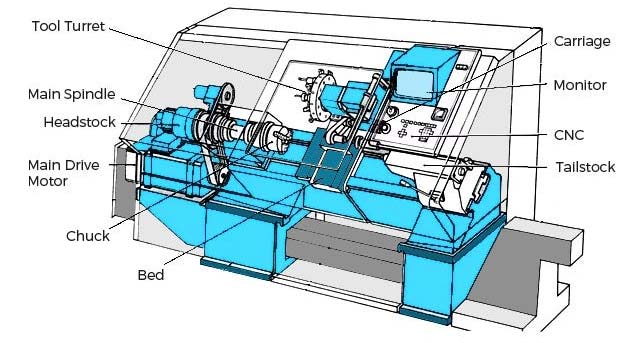

· Spindle Motor: Often considered the heart, drives the main spindle. Its RPM (revolutions per minute) defines the machine's speed capabilities.

· Tool Turret: Holds multiple cutting tools. It allows for quick tool changes, enhancing efficiency.

· Carriage Slide: Allows horizontal movement. Precisely positions the tool against the workpiece.

· Bed Rail: A sturdy foundation - ensures straight tool movement.

· Tailstock: Positioned at the end, provides support for long workpieces.

· Chuck: Holds the workpiece firmly, and ensures accurate, smooth operations.

· Tool Post: On the carriage, secures cutting tools.

· Lead Screw: Dictates the tool's motion, and converts rotary movement into linear motion.

· Control Panel: Your command center. From here, operators input essential data.

· Feedback Systems: Integral for precision. Continuously monitors, adjusts machine actions.

· Ball Screws: They convert rotary to linear motions. Ensure precise tool movement.

· Axis Motors: Drive the machine's axes. Define movement direction and speed.

· Coolant System: Dispenses cooling fluids. Prolongs tool life, ensures smooth cuts.

· Linear Guide: Assists tool movement. Reduces friction, maintains accuracy.

· Safety Shield: Protects operators from flying debris and accidental touch.

G code is the universal language for CNC operations. It dictates movement, speed, and direction. Each G-code number corresponds to a specific task, such as G01 for linear motion.

M code controls machine functions. Also, it activates coolant, changes tools, and more. For instance, M03 might start the spindle turning.

In CNC Lathe Machine Programming, linear interpolation plots a straight path between two points. Using G01 command, you direct the tool along X, Z axes.

Before carving, ensure the right tool position. Tool offsetting adjusts for deviations. With G10, corrections happen in real-time, ensuring precision.

Face turning addresses the workpiece end. G90 code aids in absolute positioning. Smooth finishes result from accurate face turning procedures.

Diameter turning shapes cylindrical workpieces. Rely on G92 for exact dimensioning. Always remember, precision ensures perfect parts.

Drilling creates holes. The G81 cycle initiates basic drilling. Depth, speed, and tool position determine successful drilling results.

Tapping creates internal threads. Using G84, synchronize spindle rotation with linear movement. Ensure taps match hole dimensions for fit.

These are predefined operational sequences. G73, G76, G89 are typical codes. Canned cycles simplify CNC operations, enhancing efficiency.

Crafting curves? Arc interpolation is crucial. Using G02 for clockwise arcs and G03 for counterclockwise ones simplifies curved paths.

Threads provide grip and connection. G76 command cuts threads efficiently. Proper synchronization and tool position give optimal results.

For deep holes, G83 is a savior. Peck drilling breaks chips, preventing clogging. Optimal peck depths prevent tool breakage.

G70 commands deliver a smooth finish. After rough cuts, G70 polishes workpieces. Every masterpiece deserves an impeccable finish.

Initial cuts need G71. It quickly removes material, preparing for finishing. Rough passes set the stage for perfection.

Parting cuts workpieces from the main stock. Use the T-tool with specific parameters. Proper feed rates and depths ensure clean parting.

Activation of the main spindle happens with M3. Correct RPMs matter. Smooth operation depends on correct spindle speeds.

Halting the spindle requires M5. Safety and maintenance underline its importance. Every operation needs a beginning and end.

After tasks, returning tools to origin is vital. G28 sends tools home. Always start from a known point for repeatability.

Different tasks need varied tools. Tool changers switch tools seamlessly. T codes, coupled with M6, execute flawless tool changes.

Mirror Imaging in CNC Lathe Machine Programming offers precision. By flipping a workpiece's code, both left and right-hand parts get manufactured seamlessly. Transitioning between mirrored parts becomes efficient.

Helical Interpolation forms helical paths on materials. In CNC machines, programmers set precise X, Y, and Z coordinates. Such coordinates control the cutter's path, giving desired helical shapes. Your accuracy depends on well-defined parameters.

Groove Programming requires skill. The technique crafts specific depths and widths into a workpiece. Groove types vary, so setting correct tools and spindle speeds is crucial. Consistency is the key.

Opt for Multi-start Threads for enhanced lead distance. Multiple threads start simultaneously on a cylinder's circumference. Hence, each rotation results in a greater axial distance. Consider threads per inch (TPI) and the desired pitch.

During deep hole drilling, Variable Pecking proves beneficial. Instead of uniform peck depths, adopt varied depths. Such a strategy reduces wear on the tool and optimizes chip evacuation.

Rigid Tapping ensures synchronized spindle rotation with tool movement. By harmonizing the tool's RPM with its linear speed, tapping operations occur without hitches. A controller with synchronized tapping capability is indispensable.

Taper Turning creates conical sections on cylindrical parts. By altering the tool's angle or synchronizing the X and Z axes, desired taper results. Remember, tool offsets and axis feed rates influence outcomes.

For intricate thread profiles, G76 Fine Threading is pivotal. By defining P and Q parameters, you achieve precise pitch and depth. The G76 command offers control over every threading aspect.

Advanced Tool Paths enable cutting complex geometries. Utilizing CAD/CAM software, generate paths that reduce cycle time. Ensure correct inputs for flawless tool movement.

Sub-routine Programming aids repetitive tasks. Instead of rewriting code, call upon existing segments. The M98 command initiates such calls, simplifying repetitive tasks.

In situations demanding repeated operations, employ Multiple Repetition. Parameters like L in G-code denote repetition counts. Such techniques boost efficiency.

B-axis Operations introduce rotational capabilities. With a rotating tool, complex geometries become achievable. Ensure perfect alignment for accurate results.

Complex Profiles demand expert CNC programming. Crafting intricate designs requires understanding of advanced tool paths and precise parameters. Always recheck inputs.

Utilize the M98 Subprogram Call for executing external programs. This command calls upon predefined subprograms, enhancing program flexibility.

After the M98 call, the M99 command signals subprogram completion. It ensures smooth transitions between main and subsidiary programs.

|

Technique |

Application |

Machine Requirement |

Complexity Level |

Tooling |

Cycle Time Reduction (%) |

Industry Usage |

|

Mirror Imaging |

Symmetrical parts |

Dual-axis CNC |

Moderate |

Standard |

10-15 |

Aerospace |

|

Helical Interpolation |

Hole drilling, Arcs |

4-axis CNC |

High |

End Mills |

15-25 |

Automotive |

|

Groove Programming |

Recesses, Undercuts |

Lathe |

Moderate |

Grooving |

5-10 |

General Mfg. |

|

Multi-start Threads |

Faster thread engagement |

Multi-spindle CNC |

High |

Thread |

10-20 |

Hydraulics |

|

Variable Pecking |

Deep hole drilling |

CNC with peck cycle |

Low to Moderate |

Drills |

20-30 |

Oil & Gas |

|

Rigid Tapping |

Precise thread creation |

CNC with sync spindle |

High |

Taps |

10-15 |

Aerospace |

|

Taper Turning |

Conical shapes |

Lathe with offset |

Moderate |

Turning |

5-10 |

Metalworking |

|

G76 Fine Threading |

Precise threading |

CNC with G-code supp. |

High |

Thread |

5-15 |

Instrumentation |

|

Advanced Tool Paths |

Complex contours |

5-axis CNC |

Very High |

Multi |

20-35 |

Aerospace |

|

Sub-routine Programming |

Repeat operations |

Advanced CNC |

Moderate |

Standard |

10-20 |

General Mfg. |

|

Multiple Repetition |

Batch production |

CNC with memory |

Low |

Standard |

15-25 |

Mass Production |

|

B-axis Operations |

Angled machining |

Multi-axis CNC |

High |

Complex |

10-20 |

Tool & Die |

|

Complex Profiles |

Custom shapes & forms |

5-axis CNC |

Very High |

Special |

15-30 |

Mold Making |

|

M98 Subprogram Call |

Modular programming |

CNC with G-code supp. |

Moderate |

Standard |

10-15 |

General Mfg. |

|

M99 End Subprogram |

End of modular program |

CNC with G-code supp. |

Low |

None |

N/A |

General Mfg. |

Table on Advanced Programming Techniques!

Minimize the time a CNC machine takes from start to finish. Lower cycle times save valuable resources. By adjusting the RPM (revolutions per minute) and IPM (inches per minute), precision enhances.

Always execute dry runs. Before making actual cuts, run your CNC machine without material. Detect potential problems and correct them.

Unnecessary air cuts waste time. Program your CNC machine to eliminate or reduce them. Every saved second boosts productivity.

Feed rates determine how fast the tool moves. Ensure you select optimal feed rates. G01, G02, and G03 commands help in adjusting.

Short, direct paths mean less wasted motion. Employ CAD/CAM software to optimize these paths.

Tools wear over time. Adjust your program to compensate. Use G41 and G42 commands for efficient tool wear management.

Maintain a steady surface speed. Using the G96 command ensures even wear and optimal finish.

Every tool change consumes time. Strategically organize tasks to require fewer changes. For instance, use multi-tip tools.

Heat causes materials to expand. Consider thermal effects in your programming. Apply coolant to reduce excessive heat.

Secure workpieces properly. Employ chucks and fixtures for solid holding. Proper clamping prevents costly errors.

Adjust the cutting strategy based on material and tool. Adaptive clearing reduces stress on tools.

Too much lubrication isn't always best. Opt for minimal lubrication techniques. Ensure longevity and clarity.

CNC machines can operate at high speeds. Harness these capabilities for swift outputs. Remember, G05.1 Q1 sets the high-speed mode.

Maintenance is key. Regular checks ensure the machine operates without unplanned stops. Schedule a periodic maintenance for best results.

Errors cost money and time. Implement checks and validation steps in your program. Anticipate common mistakes and counteract.

Keep your code neat and simple. Uncluttered programs run smoother. Use G-code commands effectively for clarity.

Every machine setup values accuracy. With CNC Lathe Machine Programming, collision detection ensures safety. Monitoring tools, workpieces, and fixtures, you avoid potential damages. Probing and sensors, often integrated, catch the slightest deviations, saving both time and money.

Before any actual cutting begins, path visualization becomes critical. It allows viewing the exact path a tool takes. Any misalignment or potential hazard gets highlighted, prompting corrective action.

Think of this as a rehearsal. Virtual machining simulates the entire process on a screen. CNC programmers gain insights, detecting any possible issues in advance.

G-code, fundamental to CNC operations, requires meticulous verification. By validating the code, one ensures machine instructions align perfectly with the desired output.

Understanding how much material gets removed aids in achieving the desired shape. By monitoring tool depth and width, you maintain quality and precision.

Precision dictates the success of any lathe operation. Regular tolerance checks ascertain the product meets exact specifications. An even minor deviation, less than 0.001 inches, is a major matter.

Grasping the movement and operation of machine parts becomes essential. Observing rotations, pivots, and translations ensure flawless operation every cycle.

Before actual machining, a dry run tests the machine. It operates without cutting material. Such runs pinpoint any operational issues, ensuring optimal performance later.

Not all operations require the same speed. By tweaking RPM values, you achieve efficiency and precision, maximizing tool lifespan.

Occasionally, adjustments become necessary. Feed overrides allow alteration of the tool's movement speed, facilitating fine-tuning during operations.

Constant surveillance keeps operations smooth. Real-time data, like spindle load or temperature, offers insights, promoting timely interventions.

These involve making actual cuts on spare material. Through test cuts, one gauges tool performance and final product quality.

By generating a graphical representation, backplotting allows visualization of tool paths. It aids in verifying G-code execution without running the machine.

Using software, virtual probing assesses and measures parts without physical interaction. This offers another layer of precision and verification.

Analyzing the movement of tools ensures efficient and safe operations. Detecting unusual patterns or hesitations, you avert potential mishaps.

Finally, any program will communicate issues. Error messages guide operators, highlighting areas that require attention, be it software glitches or hardware malfunctions.

High-speed steel (HSS) and carbide rank as primary choices. Carbide excels in durability, whereas HSS offers flexibility. Both impact CNC Lathe Machine Programming directly.

It’s a vital parameter in machining. Different shapes like diamond, round, or square determine the finish and precision. Understand their distinct advantages.

Ensure you select the proper holder. BT30, CAT40, and HSK are common varieties. Compatibility with the lathe machine ensures efficiency.

RPM (Revolutions Per Minute) and IPM (Inches Per Minute) matter. Dialing in the correct values optimizes the cut. Improper settings can damage tools or materials.

Flood coolant and mist coolant stand out. Flood coolant submerges the tool, while mist uses fine droplets. Proper cooling extends tool life.

A concern every operator should prioritize. Regular inspections prevent unforeseen halts. Breakages compromise product integrity.

Choose the right insert for the material. CNMG, WNMG, and DNMG are popular shapes. Each serves distinct turning operations.

Critical for interior cuts. Ensure the bar's diameter matches the project. Sturdy boring bars reduce vibration, promoting precision.

Integral for milling operations. Flat, ball, and corner radius mills have specific applications. Select wisely to achieve the desired surface finish.

Determine the right drill for hole-making. Twist drills and spade drills offer variations. Each drill type has a specific depth and diameter range.

Perfect for achieving exact hole sizes. Use it after drilling to enhance accuracy. Size selection is paramount.

Create internal threads effortlessly. Spiral and straight-fluted taps exist. Each offers unique threading capabilities.

Essential for CNC Lathe Machine Programming, tool libraries store and recall tool parameters. Efficient libraries streamline the production process.

Cutter compensation adjusts tool paths in real-time, and recognizes tool wear and diameter changes. Thus, ensuring products remain within tolerance.

Tool wear is inevitable, yet manageable. Regular monitoring reduces unwanted stops. Sharp tools deliver quality cuts.

Initiate by importing your CAD design into CNC software. Use formats like DXF, DWG, or IGES for seamless integration.

Before further action, ensure your design's dimensions match your material size. Scale models appropriately within the software for precise execution.

Next, determine the path your tool will follow. M06 (tool change) or G01 (linear move) might be common G-code commands seen here.

Before real-time execution, run a simulation. Check for any potential errors, overlaps, or inefficiencies in tool movement.

Once satisfied, generate the G-code. This set of instructions tells the CNC lathe machine how to turn raw material into your desired part.

Using a post-processor, you can convert the G-code into a language compatible with your specific CNC machine. Ensure G-code commands, like G28 (return to home), align with machine requirements.

Within the software, select the CNC lathe machine type. Different lathes have different capabilities, hence choose wisely.

Always run an error-check. Ensure the code's compatibility with the selected machine, avoiding potential damage or wasted material.

After error-checking, export the program. Use a USB or direct connection for efficient machine communication.

Load the program into the CNC lathe machine's controller. Ensure proper data transfer for uninterrupted operations.

Incorporate feedback loops. Monitor machine performance in real-time and make necessary adjustments for optimal results.

Leverage your software's tool library. Select appropriate cutting tools, such as HSS (high-speed steel) or carbide, based on the material and desired finish.

Always save your program. Backup the file on external drives or cloud storage to prevent data loss.

Lastly, prioritize the order of operations. Efficient sequencing reduces production time, ensuring faster product delivery.

Recognize that varying materials present different hardness levels. When programming for a CNC Lathe Machine, ensuring correct tool paths based on hardness becomes paramount.

Successful chip formation results from accurate cutting depths and angles. Those settings stem from the material's unique characteristics.

Each material has distinct thermal properties. Understanding how a material behaves under heat aids in optimizing cutting parameters.

Desired surface finishes demand attention to detail. Different tools and settings yield variations in surface roughness.

Varying feed rates and spindle speeds ensure efficient and safe machining. Specific materials necessitate unique adjustments.

Harder materials accelerate tool wear. Thus, frequently inspect tools for wear, especially when working with materials like titanium or stainless steel.

Coolants play a role in temperature control and chip evacuation. Using the right coolant type enhances tool life and part quality.

After machining, parts might retain internal stresses. Stress-relieving processes aid in prolonging the life of the machined component.

Beware of material stretching during machining. Proper programming and fixturing prevent undue material deformation.

Some jobs require adhesive workholding. Such methods work well for thin or complex parts.

Excess vibrations harm part accuracy. Utilize fixtures and strategies to reduce or eliminate them.

Secure clamping ensures part stability. Yet, excessive force may deform the material. Thus, balance becomes essential.

Post-machining heat treatment alters part properties. Always factor in potential material changes when programming.

Secondary processes, like deburring, ensure parts meet specification. Acknowledge potential needs for post-machining steps in your planning.

Annealing can soften materials. If a part requires annealing, adjust your programming approach accordingly.

Surface treatments like anodizing or plating change part dimensions slightly. Factor in these changes when programming.

Familiarize yourself with a material's machinability index. A higher index denotes easier machining, guiding tool choice and settings.

Mastering CNC Lathe Machine Programming becomes an attainable goal with these comprehensive tutorials. Navigate through the essentials, from understanding spindle motors to intricate multi-start threads and advanced programming techniques.

Efficiency and optimization emerge as central themes, guiding professionals to minimize downtime and boost productivity. Every stage of the process, including tool selection, error handling, and adapting to material differences, is meticulously detailed. Explore, learn, and elevate your skills at CNCYANGSEN where the depth of knowledge meets the precision of application.