Computer numeric control forms an anchor for modern manufacturing processes where, through complex operations, detailed parts are made. While CNC machining is more advanced than traditional machining, it uses computers to cut raw materials in perfect figures and measurements. This intro will examine the basic features and their importance in tomorrow's manufacturing world.

CNC machining is driven by precision and accuracy. Variability and errors were inherently present in traditional manufacturing processes due to their reliance on a human element. However, CNC machining is a paradigm in which complex geometry is converted to reality using unprecedented precision. Precision cannot be underscored as it leads to the quality of the end product besides enhancing efficiency and reducing costs.

Using software and modern machines enhances the precision and accuracy of CNC machining. Computer programs accurately control the movement of tooling. This gives very intricate parts having the best standards. However, in precision-sensitive industries like aerospace, medicine, and automotive, this level of precision proves vital with no error tolerance.

While undertaking this journey to CNC machining, one thing pops up – the technology can produce quality and complicated parts without error, hence becoming a stone upon which modern manufacturing is based. The following chapters shall reveal the secrets behind tolerance and allowance, outlining how CNC machining brings together precision and adaptability toward revolutionizing manufacturing.

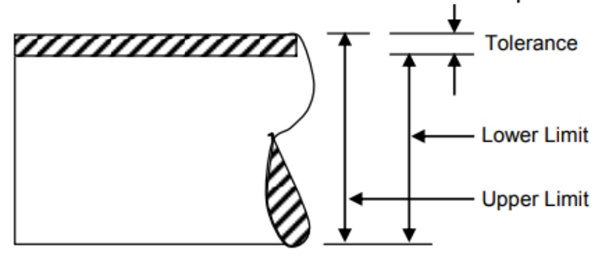

Tolerance is critical in CNC machining, defining the permissible disparity to the intended dimension. It reflects the allowable variance that can be included during a complex process like machining. Tolerance in CNC machining is an exquisite adjustment that differentiates the excellent from other machines.

Quality starts with tight tolerances for a product in CNC machining. Following strict tolerances as the industries require more complex parts is critical. Tight tolerances ensure accuracy during components' production for aerospace and medical device applications. It not only improves the functionality of the finished product but also facilitates work assembly, hence providing general.

For instance, consider the context of the aerospace industry, which requires perfect integrations of individual components for the best aerodynamics and avoiding accidents. Such deviations can affect the safety of an airplane if they go beyond specified tolerances. However, in medical applications where accuracy is vital for implants and prostheses, tight dimensional control minimizes misfits and maximizes biocompatibility.

Precision is essential in the complex world of engineering. Communicating design intent is paramount in ensuring a product correctly embodies a message. The only important part is tolerancing, which entails specifying permitted variations in dimensions to function correctly, be interchangeable, and easily install.

Geometric Dimensioning and Tolerancing (GD&T) are essential in contemporary tolerancing practices. GD&T is, however, more effective than linear tolerancing in communicating design intent. GD&T uses symbols and control frames to specify allowable form, orientation, and position variations for features. This makes it possible for the global engineering community to use a unified language to interpret the model's intended meaning.

Statistical tolerance was introduced in an age of dominant statistical principles in engineering. It considers the natural fluctuations in the production process and specifies tolerances through statistical calculations. The use of statistical methods such as Six Sigma enables the engineers to ensure quality while reducing wastage in production at the same time.

Worst-case tolerances are used when accuracy matters. This entails computing the total tolerance by summing up all individual dimensional tolerances and settling for a situation representing the worst case. Although it may appear strict, it ensures that the dimensions crucial to product function are achieved, minimizing the possibility of any future malfunctioning.

In turn, limit dimensioning is an easy but good tolerancing method. When an engineer states a value for a limit above plus tolerance or subtracts minus tolerance, this is known as specification limits, where they communicate that the actual measurement should be within a certain tolerance that can be accepted. This practice comes in handy when there is a need to strike a balance between accuracy and simplicity that remains applicable to numerous applications in engineering.

Bilateral tolerancing allows variations on both sides around nominal dimensions up to some limit. However, multilateral tolerancing allows for deviations from the nominal size in all directions, while unilateral tolerancing only allows for variations from the nominal size in one order. Therefore, engineers decide which approaches will be selected depending on the engineering design constraints and manufacturing capabilities. Using appropriate tolerances based on specific needs.

Although achieving narrow tolerances yields many benefits, it also gives rise to some problems—the improved quality and functionality of the final product evidences this. Nevertheless, complexities in machining processes pose more difficulties, sensitivities toward environmental issues, and possibly higher prices may be experienced. Navigating this delicacy is an art by fusing modern technology, talented manual labor, and knowledge about the composition of materials.

Therefore, allowance becomes a strategic and adaptive component in the ever-changing environment of CNC machining that enhances precision processes' flexibility. Allowance, in this case, means the addition of tolerances that allow deviations in dimensions and specifications. This is an intentional deviation from the rigidness of tight tolerances that provides for a practical approach to incorporate natural variants associated with machining.

The allowance is paramount in traversing the inbuilt variation in CNC machining. Tight tolerance serves as a basis for the standard of precision, while allocation is aware of the practicalities of machine manufacturing, such as tool wear, material variability, and environmental issues. This idea acts as a friend in helping to minimize the negative influence of such factors, enabling production with expected quality. However, some imperfections will undoubtedly be faced during the process.

Allowance is essential in CNC machining processes as it enhances productivity and lowers costs. The necessity of ultra-precise tooling and constant recalibration is minimized by admitting and catering to anticipated fluctuations. It also improves the machining process by reducing expensive tolerances that must be maintained closely. Accordingly, allowance is pragmatic by giving the best possible efficiency in manufacturing while maintaining the proper quality of parts.

To show how an allowance can work with CNC machining, let us imagine parts that are very complex and manufactured for car transmissions. Some elements must have strict tolerances for perfect functioning, while others will benefit from some degree of indulgence while in manufacture. The strategic employment of allowances does indeed speed up production while at the same time ensuring efficient allocation of resources balancing on precision and economy.

An example could be a project on producing consumer electronics with various aesthetic parts that may need careful attention to detail. In this context, the allowance may form part of a strategy for handling differences in finishes and consequently delivering on appearance specifications and cost savings, among other objectives.

Precision in CNC machining comes at a great price, the delicate balance of tolerances and allowances. This has little to do with specifying rigid limits of variation and nothing to do with entirely open interpretation but rather knowing how these two relate. Tolerance is the prerequisite for accuracy, and allowance makes working with various machining conditions possible. Understanding this interaction among them, that is, recognizing how to conduct a production symphony with each note providing input into manufacturing superior parts, is critical.

Therefore, the strategy to strike an equilibrium between specificity and adaptability is crucial. Another method involves separating design into critically essential features, which use tighter tolerances at places that matter most and with reasonable allowances on parts where variation doesn't matter as much. Such an approach targets the limited resources and allows precision for what counts with the required control variation to help seamlessly make the goods.

Also, sophisticated sensing and surveillance systems offer instant information during machining. This allows adjustment, accounting for variations, and ensuring the finished product meets the desired standards. Innovative machining provides an active approach to balancing the minimum allowances and small tolerances.

However, material selection is vital in the equilibrium between tolerance and allowance. The response of materials varies towards tooling and environmental conditions because each material has distinct characteristics when machined. Knowing these material subtleties allows the makers to adjust tolerance and allowance dimensions properly. For example, for brittle materials, more liberal allowances should be provided to avoid cracking or other damage and tight tolerance in the case of ductile material.

More so, the suitably matching material properties concerning machine properties greatly determines the possible attainment of required specifications. Hence, to come up with the best combination, care has to be taken to select suitable materials that will match stipulated tolerance and allowance standards.

Analyzing practical cases of successful CNC machine jobs demonstrates the craftsmanship of balancing tolerances and allowances. For example, think of a high-performance automotive component manufacturing project. Critical engine parts are manufactured with tight tolerances to maintain perfectionism and efficiency. At the same time, allowance is planned into unimportant elements, promoting smooth production without affecting final artistry.

In medical device manufacturing, some connection exists between allowance and tolerance while producing highly complex implants. The critical dimensions maintain precise tolerance while allowing the inherent variation for those biocompatible materials to improve the final product's safety and effectiveness.

When we talk about our commitment to precision, we refer to the concept of tolerance that includes allowance. While different, these terms have other functions in realizing the desired objective. How about we consider discrimination between payment and acceptance regarding CNC machining?

|

Aspect |

Allowance |

Tolerance |

|

Definition |

The deliberate gap or extra allowance for free clearance and fit during assembly of the mating parts with slight dimensional differences |

The tolerance level permits variation from a stated dimension or specification to achieve the end item within the prescribed limits. |

|

Purpose |

It helps the assembly process and ensures all parts match appropriately for size and form differences. |

It considers natural deviances in production processes, creating errors within permissible limits. |

|

Role in CNC Machining |

They are used for a well-planned purpose of smoothing up throughputs within productions, maximizing performance while being cost-effective but not at the expense of quality provision. |

Given variations may occur during machining, it is very significant for maintaining the precision of the final product. Further, this will ensure that it meets specifications. |

|

Application Example |

Allowances serve a strategic purpose in auto-body engineering, where they help facilitate manufacture with relatively better engine operation and fuel efficiency. |

Such tolerance considerations are employed in producing medial implants with conforming components that achieve biocompatibility and a functionally satisfactory product. |

|

Outcome |

Improves cost-effective and efficient production while maintaining quality. |

Assures a high-quality standard at specific points, such as those needed in the health sector, by ensuring it is precise. |

It is on the cutting edge of technological advancement and professionalism in the highly delicate field of CNC machining, where precision and flexibility in the strategic developmental process are concerned. This exploration of tolerance and allowances has defined the quest for perfection.

The appropriate combination of tolerance and allowance is an art in itself. Precision demands tight tolerances, requiring every part to measure up to specific standards. At the same time, allowing for some flexibility that enables variations to be expected along the machining path is known as systematic allowing.