Delve into the world of machining. Understand the essence of Drilling, Boring, Milling, and Turning. Grasp key concepts, techniques, and applications. By the end, have a robust foundation in these core machining processes.

Drilling, Boring, Milling, and Turning refers to crucial machining operations. Each process serves unique purposes in manufacturing. Specifically, drilling creates holes using a rotating cutter. In contrast, boring enlarges these holes to precise diameters.

Milling, on the other hand, uses a multi-tooth cutter to remove material, shaping workpieces. Turning involves a lathe that rotates a workpiece against a cutting tool.

These operations, governed by parameters such as RPM, feed rate, and depth of cut, dictate the final product's quality. Selecting the right parameters proves essential.

In aerospace, precision matters. Drilling ensures accurate hole placements for aircraft components. Boring guarantees exact hole dimensions, vital for engine parts.

Milling shapes intricate components like turbine blades. Turning, meanwhile, crafts rounded parts like shafts. High-speed steel (HSS) and tungsten carbide tools dominate this sector, offering durability.

Cars rely on precise parts. CNC Drilling aids in creating bolt holes for chassis assembly. Boring perfects cylinder sizes in engines. Milling crafts complex parts like gearboxes.

Turning produces axles and rods. The use of Computer Numerical Control (CNC) machines streamlines production, ensuring consistency.

Medical instruments demand utmost precision. Drilling aids in crafting surgical tools. Boring ensures syringe needles have consistent bores.

Milling produces dental implants with complex geometries. Turning is crucial for prosthetics. Stainless steel remains a preferred material due to its sterilization properties.

Military equipment requires robust components. Drilling and boring craft gun barrels with high precision. Milling shapes armor panels.

Turning crafts artillery shells. Given the critical nature of defense applications, high-performance machines with advanced tooling are standard.

Miniaturization dominates the electronics sector. Drilling produces circuit board holes. Boring ensures connectors fit snugly.

Milling shapes semiconductor molds. Turning is less common but still vital for specific components. Given the small scale, micro-machining techniques are often employed.

Energy infrastructure stands tall due to machining. Drilling and boring craft pipes for oil and gas transport. Milling shapes turbine blades for wind energy.

Turning produces generator shafts for power plants. Given the large-scale operations, heavy-duty machines are often employed.

Machining plays a pivotal role in the agriculture sector. Tractors require precision components. Drilling ensures accurate holes in parts like gearboxes. Boring refines these holes for perfect fits. Meanwhile, milling crafts intricate shapes for machinery components.

Modern farms rely on equipment with parts made using these processes. CNC machines, with RPMs ranging from 1,000 to 4,000, dominate this sector. Such machinery ensures reliability, efficiency, and long-lasting performance.

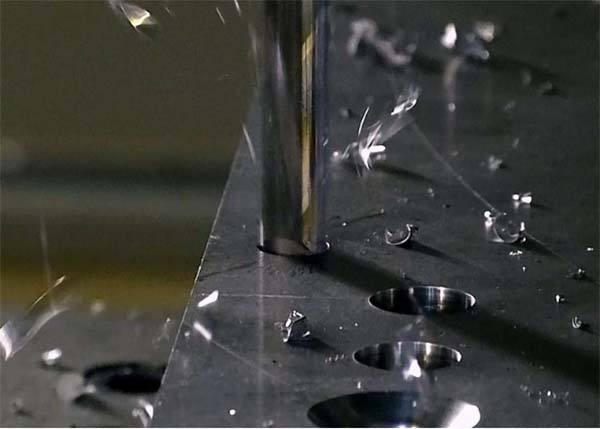

Drilling is a process where materials get pierced. A drill bit spins at high RPMs. HSS (High-Speed Steel) and carbide are common drill bit materials. Precision in hole diameter is crucial.

Different materials need specific drill bits. Metal requires robust, sharp bits. Proper alignment ensures accuracy. Too much pressure can damage bits.

In the drilling operation, chips form. Efficient chip removal is essential. Improper disposal can damage workpieces. Swarf auger and conveyor systems help.

Regular cleaning of the work area prevents buildup. Chips can affect the drilling process. Proper lubrication assists in chip removal. Adequate chip evacuation extends tool life.

The geometry of drill bits matters. Point angle, helix angle, and chisel edge are critical. The point angle is between 118-135 degrees.

Harder materials need larger point angles. The helix angle affects chip removal. A correct chisel edge ensures clean holes. Incorrect geometry can cause drill wandering.

Cutting speed refers to drill bit rotation. Measured in surface feet per minute (SFM). Material type determines optimal SFM. For aluminum, the SFM is around 250.

For steel, it's approximately 100. Exceeding recommended speeds risks tool breakage. Proper speed ensures efficient material removal.

Feed rate is drill bit movement rate. Correct feed rate ensures smooth drilling. Too fast, and you risk tool breakage. Too slow, and it's inefficient. Harder materials require slower feed rates. Soft materials can handle faster rates.

Coolants reduce heat in drilling. They extend tool life and improve finishes. Water-based coolants are common. Oil-based coolants offer better lubrication.

Coolant type depends on the material. Aluminum needs specific coolants. Proper application ensures effective cooling. Regular coolant checks are vital.

Twist drills, often known as HSS drills, play a pivotal role in metalworking. With a diameter range of 0.2 to 20 mm, they ensure precise holes.

RPM values range between 1000-5000, depending on material hardness. Additionally, using coolant extends tool life. For optimal efficiency, replace or re-sharpen drills every 50-60 hours.

Step drills are versatile, allowing multiple hole sizes using one tool. Commonly, they feature 4-12 steps. Tool lifespan depends on material thickness.

With an optimal RPM of 2000, such drills are indispensable. Regular maintenance ensures extended tool longevity.

Countersink drills create a conical hole for screw heads. A 90-degree angle is standard. Materials like aluminum require RPMs around 2500. Harder materials, like steel, demand a slower 1000 RPM. Proper technique guarantees flush screw placement.

Center drills, vital for lathe work and start holes for larger drills. Often, they possess a 60-degree point angle. For steel, RPMs hover around 2000, whereas softer metals might demand 3000 RPM. Ensure the tool remains centered for optimal results.

Taper drills create conical holes, often for fittings. The standard taper is 1:16. RPM values can vary, but 1500-2000 is a common range. Too high RPM can damage the tool. Ensure consistent pressure during operation.

Core drills remove material from the center, leaving a cylindrical core. The cutting depth often reaches 4D. With RPMs around 2500, they're effective for materials like concrete. Use water to cool and lubricate the drill during operation.

Masonry drills, with carbide tips, tackle brick and concrete. The flute design aids in dust removal. A hammering RPM of 700-1200 proves effective. For safety wear eye protection. Lubrication is key for longevity and effectiveness.

In drilling processes, steel stands out. With a tensile strength of around 58,000 psi, steel's durability is unmatched. HSS (high-speed steel) bits work well. Additionally, coolant usage improves bit lifespan. Steel's high carbon content affects tool choice. Ensuring precision becomes crucial.

Drilling into aluminum requires care. Softer than steel, aluminum's melting point is lower, around 660°C. Using carbide-tipped bits proves beneficial.

Aluminum's thermal conductivity is 205 W/mK. Rapid heat dissipation is observed. Appropriate lubrication ensures smoother operations. Consequently, chip removal remains efficient.

Titanium presents unique challenges. Boasting a tensile strength of 63,000 psi, it's robust. Titanium's heat resistance demands attention. Carbide drill bits suit titanium.

Notably, the recommended RPM ranges between 50-110. Using coolants like TiCC (Titanium Carbonitride Coating) enhances tool longevity. Above all, consistent feed rates ensure optimal results.

Brass, a copper-zinc alloy, is distinct. Often, brass components have 65% copper. Drilling requires specific bits, preferably HSS. Considering brass's ductility, chips form easily.

An RPM range of 100-300 is ideal. Lubrication, although not mandatory, aids in smoother operations. Achieving precision becomes feasible.

Plastics vary in hardness. HDPE (High-Density Polyethylene) differs from PVC (Polyvinyl Chloride). Drilling demands sharp, wedge-angle bits. RPMs below 500 work best.

Since plastics are insulators, heat accumulation occurs. Ventilation and coolants can counteract this. Ultimately, feed rate adjustments optimize drilling outcomes.

In precision machining, achieving the right bore diameter is crucial. Bore dimensions range from 2mm to 100mm. A bore's diameter defines the part's function.

For optimal performance, adherence to specified measurements is vital. Errors beyond 0.01mm can compromise a component's functionality. Ensuring precision is non-negotiable in boring machine operations.

Selecting the appropriate tool determines machining success. Tools like Single Point, Twin-tip, and Adjustable reamers have distinct uses.

Each tool caters to a specific material: HSS for steel, carbide for harder metals. Tool lifespan varies based on material and usage. Understanding tool specifications and application ensures desired results in boring operations.

Feed rate impacts the efficiency and quality of boring. Feed rates range between 0.05mm/rev to 0.5mm/rev. adjusting the feed rate can influence the surface finish.

A slower rate often produces smoother finishes. Conversely, faster rates might expedite the process but compromise quality. Balancing speed and precision is essential.

Depth is pivotal in boring operations. Depths vary based on component requirements, often between 5mm to 500mm. The tool's length and rigidity influence achievable depths.

Achieving the correct depth ensures the component's fit and function. Constant monitoring and adjustments guarantee the desired outcome in depth-specific boring tasks.

The final surface's quality speaks volumes about the boring process. Surface roughness values (Ra) indicate finish quality. Lower Ra values, such as 0.2µm, signify smoother finishes.

Material type, tool selection, and feed rate directly impact the Ra value. By optimizing these parameters, achieving a superior finish becomes feasible.

Proper machine setup lays the foundation for successful boring. Parameters like spindle speed (RPM), usually between 1000 to 5000, play a role. Aligning the workpiece and tool correctly prevents errors.

Calibrating machines using micrometers and gauges ensures accuracy. Regular maintenance and calibration uphold the machine's performance and longevity.

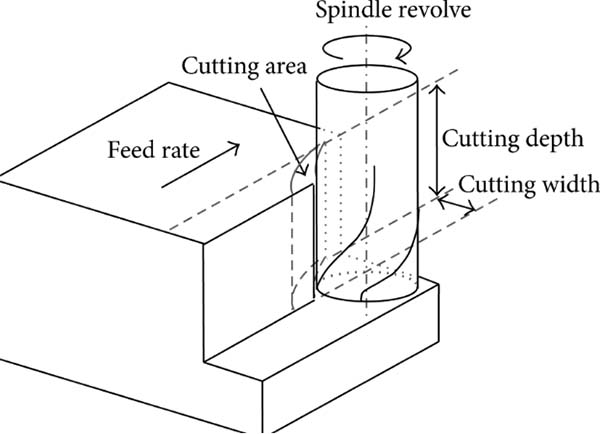

In milling, controlled material removal results in precise shapes. Machines utilize rotary cutters to remove metal. CNC machines automate the process, ensuring precision.

Determining the tool path is vital. The path follows a sequence, dictating the cutter's movement. Proper planning maximizes efficiency and minimizes tool wear.

Achieving a smooth surface finish is crucial. Factors influencing finish include cutter type, speed, and feed rate. Aim for a Ra value between 0.2 to 3.2 µm for optimal outcomes.

Various cutters cater to different tasks. End mills handle profiling and pocketing. Face mills ensure flat surfaces. Ball nose mills create contoured surfaces. Selecting the right cutter ensures the job's success.

Secure work holding is essential for safety. Vises, clamps, and fixtures hold the work piece. Proper work holding prevents movement, ensuring accurate cuts.

Depth of cut influences the final product. Too deep cuts strain the machine. Too shallow cuts waste time. A depth of 2-5 mm is standard for most materials.

Lathes transform raw materials. CNC (Computer Numerical Control) lathes aid precision. With RPM (revolutions per minute) set, turning begins. Next, inserts shape metal pieces.

Correct machine settings yield optimal results. Lathe operations, essential for Drilling, Boring, Milling, and Turning, offer industry precision.

Choosing tools is crucial. HSS (High-Speed Steel) remains popular. Carbide tools resist heat. Fact: Tool lifespan varies. Regularly, experts select tools based on material hardness. For optimum results, tool choice matters.

RPM matters in turning. High RPM ensures smooth finishes. Conversely, low RPM aids harder materials. Fact: Aluminum's optimal RPM is 2,500. Steel requires 1,200 RPM. Correct spindle speed enhances product quality significantly.

Angles impact material cutting. Rake angle, relief angle, and lead angle are vital. A 12° rake angle suits steel. Correct angles ensure smooth cuts, reduced wear, and extended tool life.

Depth directly affects material removal. Depth ranges between 0.2 mm to 6.5 mm. A 3 mm depth is common for roughing operations. Precise depths ensure desired finishes, maximizing efficiency.

Surface quality is paramount. RA (Roughness Average) measures finish quality. A lower RA denotes smoother surfaces. Factors like RPM, tool angles, and depth affect RA. Achieving a perfect surface requires expertise and precision.

|

Criteria/Parameter |

Lathe Operations |

Tool Selection |

Spindle Speed |

Tool Angles |

Depth Of Cut |

Surface Finish |

|

Precision |

±0.001 mm |

Carbide tips |

1500 RPM |

60° angle |

2.5 mm |

Ra 1.6 µm |

|

Material Compatibility |

Steel, Aluminum |

HSS, Carbide |

Steel: 1200 RPM |

Aluminum: 80° |

Aluminum: 1 mm |

Steel: Ra 0.8 µm |

|

Wear & Tear |

Low on brass |

HSS: Moderate |

Lower: Less wear |

Acute: Faster wear |

Deeper: More wear |

Rough: Ra 2.8 µm |

|

Application |

Drilling, Facing |

Roughing, Finishing |

High: Polishing |

Roughing: 55° |

Thick: Roughing |

Fine: Decorative |

|

Maintenance |

Regular oiling |

Sharpening |

Belt check |

Resharpening |

Regular check |

Regular buffing |

|

Efficiency |

High for metals |

Carbide: Fastest |

Consistent: Best |

Optimal: 60° |

Moderate |

Smooth: High demand |

A Table On Turning: Giving Shape To Raw Materials!

In Drilling, Boring, Milling, And Turning, optimal cutting speed is paramount. Metals like aluminum require higher speeds, around 400 RPM (Revolutions per Minute), whereas tougher materials like steel might operate around 125 RPM. Adjustments to cutting speed directly impact the quality of the machined part.

A longer tool life denotes efficiency. By monitoring wear and degradation, tool replacements become predictable. High-speed steel (HSS) tools, offer a balance between longevity and cost. Carbide tools, though pricier, extend tool life substantially in many cases.

This parameter determines how much material gets removed in one pass. During milling, a depth of 0.020 inches might be used for fine finishes, while rough cuts might employ a 0.100-inch depth. Adjusting this depth ensures precision and reduces tool wear.

The rate at which material advances towards the tool is crucial. For turning operations, feed rates between 0.002 to 0.006 inches per revolution often yield optimal results. Correct feed rates prevent tool breakage and improve surface finish.

Every machining process aims for a smooth finish. Surface roughness values, often measured in Ra (Roughness Average), help in quantifying this smoothness. A Ra value of 32 indicates a standard machined finish, but specialized operations can achieve values as low as 16.

Coolants serve dual purposes: temperature regulation and debris removal. Water-soluble oils are common, offering good cooling and lubrication. Synthetic coolants, on the other hand, resist bacterial growth, extending their usability.

In machining operations, tool degradation remains paramount. High-speed actions cause rapid tool wear. Even the most robust tools, such as carbide or HSS, face degradation.

Prolonged tool use affects the quality of cuts, leading to increased operational costs.

During drilling and milling processes, machinery often encounters unwanted oscillations. Excessive vibration compromises the integrity of the final product.

Using modern CNC machines with better stability can somewhat mitigate this. Machine operators need to constantly monitor and adjust settings to ensure minimal vibrations.

High-speed turning and milling produce significant heat. Excessive temperatures can deform the workpiece. Cooling methods, such as using cutting fluids, are essential.

These fluids reduce temperatures, but selecting the right one for each material is crucial.

Every machining process results in material loss. Inefficient milling or turning operations can lead to increased waste. Modern techniques, like CAD/CAM software, aid in optimizing cutting paths. Even with technology, achieving zero waste remains a challenge.

The demand for ultra-precise components is on the rise. Traditional drilling or boring methods might not achieve the desired accuracy. Advanced machinery with micron-level precision is available. Still, they come at a high cost and require specialized training.

HSM, or RPM, reaches up to 30,000 RPM. High-speed cutting of metals, especially aluminum and titanium, proves efficient. Precise tools and rigid machines ensure quality in HSM processes.

Cryogenic cooling uses liquid nitrogen at -196°C. Cooling rates surpass traditional methods. Tool life extends by 50% with cryogenic treatment. Such cooling enhances surface finish, reducing wear.

Laser beams cut, engrave, and shape materials. Beam intensity reaches 1,000 watts. Lasers achieve accuracy within 0.005mm. Metals, plastics, and ceramics benefit from laser precision.

USM employs high-frequency vibrations. The tool vibrates at 20,000 Hz. Hard, brittle materials like glass and ceramics undergo USM. Minimal heat generation ensures material integrity.

ECM removes metal via controlled anodic dissolution. Voltage between tool and workpiece stays between 5 to 25V. Material removal rate (MRR) depends on applied current. Achieving complex shapes becomes feasible.

Plasma reaches temperatures of 30,000°C. Conductive materials undergo plasma cutting. Depth of cuts reaches up to 50mm. The process offers speed and efficiency for thick materials.

Machining encompasses diverse processes. Drilling, Boring, Milling, and Turning stands out as core concepts. Each offers unique advantages in the manufacturing realm. Seek further knowledge and mastery. For advanced equipment and expertise, visit CNCYANGSEN. Trust in precision, quality, and efficiency.