Ever wondered how an automated machine works miracles? Are you also amazed at how a giant machine makes even the most minor things of our daily use? You are here at the right place to get all the answers.

In this article, you will get to know what are lathe machines and how they are used in workshops to manufacture various products.

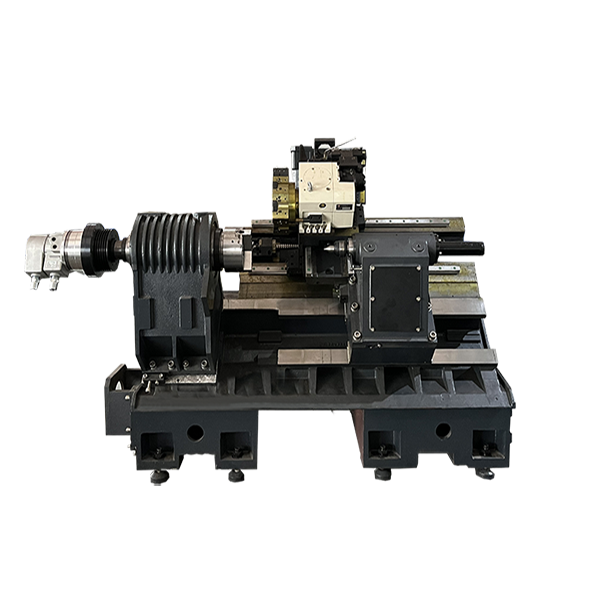

You are visiting a workshop and all of a sudden you see a generator-like machine spinning and rolling different materials. No wonder you encountered a lathe machine.

Generally, the lathe is a tool that helps in shaping metals and wood.

Now your brain processes how and when this machine was made. Its first use dates back to 1300 BC i.e., the Egyptian era, Ancient Romans then modified it to make it easy to use and now we have the most advanced form of lathes i.e

|

|

| Horizontal Lathe Machine | Vertical CNC Lathe Machine |

You are thinking that this machine has a resemblance with some of the small machines that are currently in your knowledge. Yes, you are right Lathe machine is known as the “mother of all machines”.

The next question that pops up in your mind is what is the purpose of all this spinning and rotation? The main function of the lathe machine is to rotate the workpiece on a spindle against the tool at a certain speed to remove excess materials to attain desired shape and size for the work.

Now moving into further details, you see some metal bed-like structures, screws, nuts, spindles, etc. These are the tools that you already know but why this machine has so many other elements? To get your answer, you will search for it, and here are the details for all your queries.

Bed: holds all parts of the machine together

Lead Screw: converts rotational movements to linear

Guideways: a medium that transmits forces to bed

Prime mover: provides energy

Headstock: transmits power to different parts of the lathe

Spindle: holds and rotates the chuck

Chuck: holds the workpiece, helps in rotations of both spindle and workpiece

Feed Gearbox: transmits power from spindle to lead screw

Thread Chasing Dial: thread-cutting operation

Split nut: helps in thread cutting

Carriage: holds the cutting tool at the desired angle and slides the tool in different directions during the machining operation.

Slideways with saddle: movement of the tool

Compound rest: taper turning operation

Toolpost: spins a block of material when abrasive, cutting, or deformation tools are applied to the block.

Tailstock: support and the secure free end of the workpiece

Quill: houses the spindle for movement

When you step forward to explore the workshop you see so many machines of the same structural composition but of different shapes and sizes. Now it strikes that this machine has various types. Yes, you are right.

· You came across a machine by which metal pieces were being drilled and bored by continuous rotation. That means you have just encountered an Engine lathe or center lathe

· Another machine was being operated at various speeds that’s a Speed lathe used in minor tasks like polishing, spinning, centering, machining of wood, removing burs, or finishing of an object.

· From another machine identical workpieces were being made it’s a Turret lathe that can hold several cutting tools that work simultaneously.

· On another machine various operations were being performed like parting, grooving turning, boring, drilling, threading, etc. this is a Capstan lathe

· Tool room lathes were making accurate cuts it also resembled engine lathes.

· The bench lathe was mounted on the workbench.

· In the Gap bed lathe machine beds were being removed or slightly slid to make larger diameters of workpieces.

· By Hollow spindle lathe cutting and chamfer, tubing was done efficiently

· In another lathe a workpiece was held vertically this is a Vertical turret lathe

· Then comes the most advanced and highly accurate lathe machine i.e CNC (Computer numerical control) lathe

After roaming around you are now wondering about the day-to-day use of lathe machines in workshops. Think and re-think about all the common materials that are of your daily use be it wood, glass, metals, coins, or automobiles. Every single thing of your routine use is made by using these lathe machines. Let’s discuss them in detail.

· Woodworking

50% of almost all the things we use are made up of wood. Have you ever thought about how a big wooden log is changed into various shapes to change it into a useful product? The furniture you use to sit or place things on, the bats you play with, the cupboards you put your stuff in, the spoons you use while cooking, different decorative items, doors you use every wooden thing that has been carved into the things of your personal use is a miracle of lathe machine.

This machine is used in wood chipping, carving, and shaping. Big wooden logs are first chipped and then shaped to make a desired product. All of this is possible using a wood-turning lathe.

· Pattern Making

The patterns you see on different furniture parts, ornaments, or coins make you wonder who did this. The answer is simple yet it keeps you in awe that how such a big lathe ends up giving such delicate patterns and designs on our daily use stuff. Lathe machines not only do the precise work of designing and pattern making it is also involved in the stamp and seal manufacturing process. First, a metal is carved using a lathe then the material of interest is made red hot and poured in that cast and after cooling the desired pattern is obtained.

· Duplicating

When you win any competition, you are given a medal as a reward, ever wondered who made this? Or take the example of luxurious ornaments usually made up of metals, bones, or ivories, all of these masterpieces with fine details who is their creator? Or whenever you visit any historical place, the art pieces the heritage they have carved from where does it come from? Who made these minor details?

All of this is possible using a duplicate lathe or copying lathe.

· Glass working

Ever wondered about glassware and how neatly and precisely they are made?

Be it be the apparatuses you use in the laboratories, mirrors you use to get dressed up, glass or bottles you use to enjoy your drinks in, or the bangles you wear. All are glassware made with fragile glass. These different forms of glass that we use daily are made by using glass-making lathes. These lathes are used to make glass malleable and then different products of various shapes and sizes are made.

· Metal working

Metal-working lathe work wonders. Every single thing that you use in your routine comprises metallic products that are synthesized by metalworking lathes. Starting with the smallest yet strongest nut and bolts you use to fix almost everything, hammers, pliers, screwdrivers, lamps, rings, spinning tops, Turner’s tube, ink pens, screw jacks, magic tubes, pistons, scribes, or whatnot. Every single metallic item is made by molding metals into useable products.

· Metallic sheets

Have you ever keenly observed the tins you get your stored items in or the tins of cooking oils? From where did they come from? All such storage tins are made from metallic sheets molded into cylinders to make such storage boxes.

The shades that are usually made in mountainous areas all are made up of iron or bronze sheets, they too are made from lathe machines by pressing metals.

· Ornament designing

When you will focus on minor details of the jewelry you wear occasionally or daily basis, or the decoration items you place to beautify your living area, these are all the finest examples of ornaments made by using lathe machines. Every pattern, design, curve, or cut is made from lathe machines. Such lathes used for ornamental turning were first made in the 19th century.

· Watchmaking

One of the finest fashion statements is the watches. Wearing watches never gets old. Have you ever thought who made such a delicate and precise tool to monitor time? How are such masterpieces designed? From its gears to the arms all is made possible by using lathes. All of its parts are designed with high precision in the workshops using watchmaking lathes.

· Recording

Sound recorders are one of the classics. Hearing music through such recorders never gets old. Here you must be thinking what’s the connection between recordings and lathe? Sound recording lath utilizes an audio signal that is sent through a cutting amplifier, this signal is then transmitted to the cutter head, which controls another part i.e. cutting stylus. The cutting stylus then engraves a modulated spiral groove that corresponds to the audio signal into the lacquer coating of the master disc.

· Coin making

Looking at the penny you have in your hand, or the coins you get to play games in a playland, have you ever thought where all the carved stuff on these came from? All these minor details have been made possible by using a lathe machine.

· Making of engine parts

Cars or any other automobiles are the things of our daily use. If they lack the engine, they won’t work. The engine possesses a complex structure made by molding metals into various shapes and sizes. All of this is attained using lathe machines.

· Tools designing

All the mechanical tools you use to make your life sorted be it a little nail or hammer, pliers or nuts and bolts, each and every tool is made using lathe machines to mold metals into useful tools.

· Aerospace products

The planes that fly over your head, rockets, or shuttles launched in space all of the aerospace products are synthesized using CNC lathe.

· Medicinal products

Talking of the medical field can you believe that lathe machines also work here too but how? CNC machines are used to make high-performance machines used in diagnostic or treatment tools.

· Robotic parts

Various robotic parts have been designed using a CNC lathe. Yes, science does wonders.

· Automotive parts

Lathe machines are ideal for making automotive parts including gearbox and engine cylinder heads.

Selecting suitable lathe machine tools is important for assuring the quality of your work and the efficacy of your procedures, whether you're a skilled machinist or a passionate hobbyist. In this article, you will be guided on how to select the perfect lathe machine tools for your workshop.

· First of all, it is very important to Understand Your Requirements for the process whether it will be a small-scale or a large-scale project, the type of work you will be doing, or the materials you will need.

· Then your main focus should be on the Types of Lathe Machine Tools. It can be any of the tools mentioned below:

Turning Tools: For shaping the workpiece.

Boring Bars: To enlarge existing holes in a workpiece.

Thread Cutting Tools: To create threads on the workpiece.

Parting Tools: To separate the workpiece from the remaining materials.

Knurling Tools: To add texture to the workpiece.

Drilling Tools: To create holes in the workpiece.

· After this you need to Consider Material Compatibility

· Then you have to consider the Quality and Durability of tools that can withstand the rigors of machining.

· Do ensure the Tool Holder Compatibility

· Then prioritize the Functional design and Safety of the tools you are going to use

Now that you have gained a lot of knowledge about lathe machines you can get an idea about the advantages of lathe machines that they are:

· Speedy: it is a fast-working machine that saves time and energy

· High productivity: produce accurate and high-quality products

· Saves money: less machining and labor cost

On the other hand, it does have some disadvantages that it requires:

· Highly skilled operators: though it requires fewer operators they must be highly trained

· Constant supervision: lathes require constant supervision for high precision

· Spacious machinery: Heavy machinery that needs a lot of space

· Constant maintenance: these machines require timely maintenance to keep them in good condition

Hope this article will be useful for all the new learners of lathe machines. Now that you have explored all about lathe machines you can easily contact us because Yangsen is a smart choice for CNC machines.