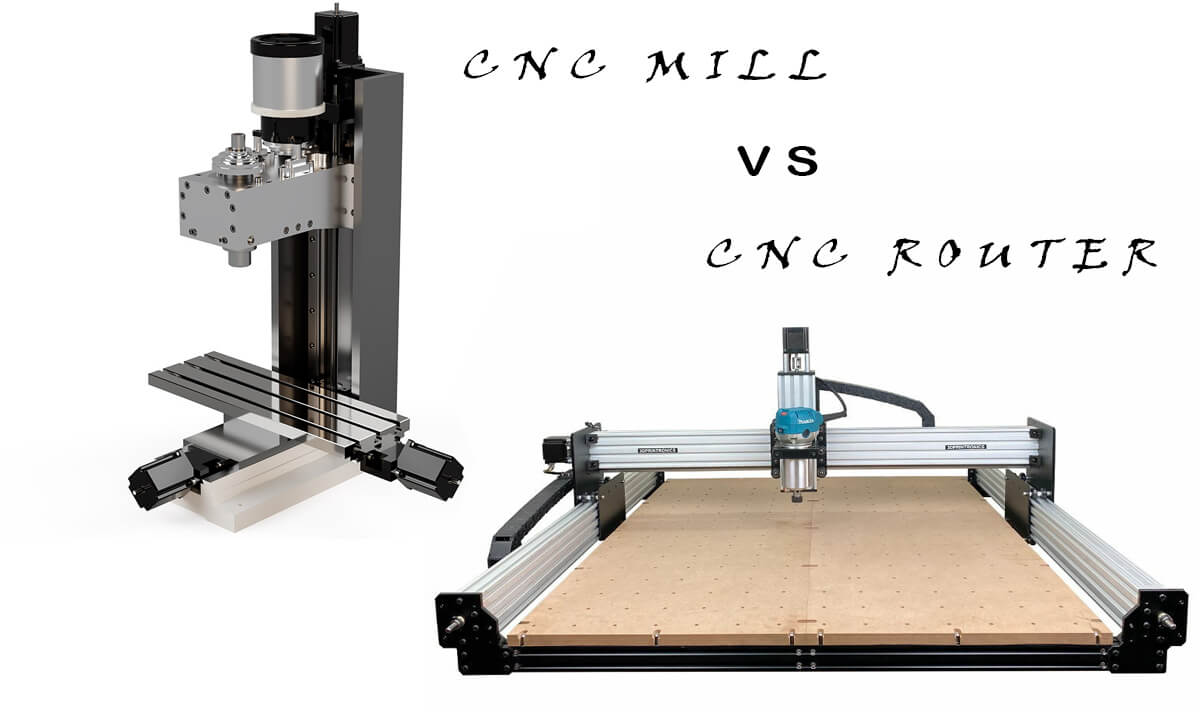

Both routers and mills are popular in the machinery industry, but how do they differ? Both have similar jobs: to cut materials, but they differ significantly in their application and functionality.

Gantry routers are used to cut softer and lighter materials like wood and plastic. On the other hand, mills are used to cut harder and tougher materials like metals and alloys. Gantry routers are faster, while mills are more accurate in their application.

Interesting, right? Let’s learn more about gantry routers vs mills in the guide below!

Routers and mills are part of the machinery but with different purposes. Both are used to cut materials, but a router can cut softer and lighter materials, while mills are used for tougher materials like metals.

When a router uses a gantry structure (a bridge-like configuration), it is called a gantry router. It is versatile and suitable for tasks requiring intricate cutting, engraving, and shaping. On the other hand, a mill is a machine that crushes a material into a powder or into very small pieces.

There are also other differences between the two, like mills are faster than routers and achieve higher precision in machining.

To save you the time, here is a table to help you quickly understand the key features and differences between the two.

|

Feature |

Gantry Router |

Mill |

|

Primary Function |

Cutting, shaping, and engraving various materials |

Precision crushing of materials |

|

Motion Control |

3-axis or more for multi-directional movement |

Typically 3-axis (X, Y, Z), with optional rotary axes |

|

Material Types |

Suitable for a wide range of materials, like wood, plastic, and composites |

Can crush tougher metals, plastics, and various materials |

|

Precision Level |

Good for general precision tasks |

High precision than gantry routers |

|

Speed |

Typically faster for tasks like cutting large patterns |

Variable speed, can be optimized |

|

Machine Size |

Can be large, especially for industrial models |

Compact to large size, depending on the purpose |

|

Cost |

Generally more affordable than precision mills |

Can be more expensive, especially for high-precision models |

|

Versatility |

Versatile for various creative and woodworking tasks |

Specialized for precision machining, less versatile for artistic projects |

|

Applications |

Sign making, woodworking, and artistic projects |

Metalworking, precision engineering, and production machining |

Now, let’s quickly dive into each feature to better understand the differences between a gantry router and a mill.

Here is a detailed insight into the key differences between gantry routers and mills.

The primary function of both gantry routers and mills is to cut materials. But a gantry router deals only with softer and lighter materials like wood or plastic. On the contrary, mills are designed to handle heavier and tougher materials like metals, alloys, and hard plastics.

Both machines have their specific functions. If a router is used to cut tougher materials, it can result in inefficient cutting or increased wear on the machine. Likewise, a mill can overcut and ruin the machining quality if it is used for lighter materials.

Gantry routers are versatile; they feature a 3-axis motion control (or more) for multi-directional movement. This flexibility allows them to perform intricate cutting, shaping, and engraving in various directions.

In contrast, mills also come with 3-axis motion control (X, Y, Z), but they have optional rotary axes. This configuration is necessary for precision machining and allows mills to navigate through complex geometries.

Moreover, a router has a workpiece that remains stationary while the spindle moves in X, Y, and Z. On the other hand, the workpiece moves in X and Y in a mill while the spindle moves in Z.

A router works with softer and lighter materials, that include:

● Wood

● Plywood

● MDF (Medium-Density Fiberboard)

● Particleboard

● Soft plastics (like PVC, acrylic, etc.)

● Foam

● Composite materials

● Aluminum (for light-duty cutting)

● Corian (solid surface material)

● Corrugated cardboard

While a mill can handle tougher materials, such as:

● Metals (aluminum, brass, steel)

● Hardwoods (oak, maple)

● Engineered woods (plywood, laminates)

● Plastics (ABS, polycarbonate)

● Composite materials (fiberglass, carbon fiber)

● Hard plastics acrylic, nylon)

● Ceramics

● Hardened steel

● Titanium

● High-performance alloys (like Inconel, and titanium alloys)

Both gantry routers and mills are precise in their cutting, but mills are more accurate than routers. Because they are engineered for tougher materials, mills have specialized cutting tools to achieve higher accuracy in machining.

However, gantry routers are also a good option if you are dealing with cutting, shaping, and engraving of softer materials. Tasks like woodworking use gantry routers because mills can be overpowered, leading to unnecessary wear and tear. The lighter touch of gantry routers is more suitable for achieving finesse, unlike the robust precision of mills that can damage the material.

Gantry routers can complete tasks with faster speed, especially when cutting large patterns. It's because their design and motion control (featuring 3-axis or more) allow them to quickly cut materials.

As for mills, they offer variable speed options, allowing for optimization based on the specific requirements of precision machining. While they may not match the sheer speed of gantry routers in some applications, they can cut a wide range of materials. Also, thanks to their adjustable speed settings, they can cut according to the hardness and characteristics of the material.

Gantry routers usually have a larger size, especially for industrial models. They have a more robust structure to support the machining of sizable workpieces.

In contrast, mills have a more diverse size range, as they come in both compact models for smaller workshops as well as larger models for industrial-scale operations. The size of a mill depends on its purpose, as smaller models are better for precision tasks in limited spaces, while larger models can do heavy-duty machining applications.

Gantry routers are usually more affordable than mills. It's because the design and functionality of gantry routers make them accessible to more users, like hobbyists or artists. They are also popular among small businesses looking for cost-effective solutions for cutting, shaping, and engraving softer materials.

However, mills can be more expensive, especially if they are used for achieving high precision in machining tougher materials. Because they have specialized components, cutting tools, and enhanced precision features, they are more pricey than gantry routers. The price can increase even more in the case of advanced models designed for industrial-level accuracy and durability.

The price difference between the two is one reason why mills are more suited for industrial work, and gantry routers are the first choice of hobbyists and small business owners.

Gantry routers are remarkably versatile. They are popular and well-suited for a wide range of creative and woodworking tasks. As they work with softer materials like wood, plastic, and composites, they excel in applications where artistic projects demand complex cutting, shaping, and engraving. And because they have a lighter touch and flexibility in motion control, there is minimal risk of damaging the softer materials.

However, the same is not the case with mills, as they are designed for industrial work. Though they are less versatile for artistic work, their primary focus is on high-precision tasks, like cutting tougher materials like metals and alloys. They come with specialized cutting tools to achieve higher accuracy and thus can cater to the requirements of different industrial tasks.

Gantry routers are popular in many applications like:

● Sign making

● Woodworking (crafting furniture, carving designs, and shaping wooden components)

● Artistic projects

● Prototyping (iterating and refining designs in softer materials)

● 3D Modeling

On the other hand, mills are more used for tasks such as:

● Precision machining in industries such as aerospace, automotive, and medical

● Metalworking

● Production machining

● Prototyping of hard materials like metals and alloys

● Tool and die making (production of molds, dies, and tooling used in various manufacturing processes)

Confused if you need a gantry router or a mill? Here are some considerations to help you make the right choice for your specific machining needs and projects.

Whether or not you need a gantry router depends on two factors:

● Type of material

● Cost considerations

If you are dealing with materials like wood, plastic, and composites, a gantry router will be an ideal option. With its higher precision and milder speed (though still fast for softer materials), you can easily do tasks like cutting, shaping, and engraving. The router will be lighter on material, making it safer for delicate projects.

Moreover, gantry routers are an affordable option compared to mills. If you are an artistic person who occasionally creates art pieces, investing in a gantry router will be better than mills. Likewise, small businesses can get gantry routers to finish tasks without breaking the bank.

Gantry routers are more useful for occasional (if you are a hobbyist) and lighter tasks, but mills are all about serious precision. They are tough, highly powered, and designed for industrial-level machining.

Investing in a mill would be a better idea if:

● You are dealing with tougher materials that require a robust and heavy-duty approach. Mills are specifically designed for hard metals, alloys, and other resilient materials.

● You have a higher budget. Mills are constructed with specialized components, cutting tools, and enhanced precision features, all adding to their price.

● You have enough space to keep the mill as they are larger in size. Mills generally do not come with the flexibility of space, unlike gantry routers that have more compact designs and can fit in smaller workshops or spaces.

In a nutshell, both gantry routers and mills are efficient and precise, yet they cater to different machining needs. Gantry routers can handle softer materials, have a smaller size, and are more affordable. Thus, they are more suitable for personal hobbyists or smaller businesses looking for a cost-effective option. Mills, on the other hand, are designed to handle tougher materials, have a much larger size, and come with additional features that add to their price. They are more suitable for industrial use and applications with high precision requirements.