Drill machines are vital tools. In this blog you’ll uncover how many types of drill machine are there? Dive deep into the world of drills. Understand their parts and functions. Learn how they differ and when to use them. Expert knowledge awaits you here.

|

|

|

| Contact us for the latest technical information | ||

A drill machine powers a rotating tool, the drill bit. Drill machines bore holes in various materials. Understand that RPM (Revolutions per Minute) measures drill speed. High RPM drills suit wood; low RPM drills work for metal. Remember, chuck size, often 1/4, 3/8, or 1/2 inch, indicates the drill's capacity. Drills vary by power source: electric, battery, or manual.

Cordless drills offer mobility but need battery recharges. Hand drills don't require electricity. Drills can be stationary, like bench drills, or portable, like pistol-grip drills.

Different jobs require specific drills, such as hammer drills for masonry or right-angle drills for tight spaces. By understanding drill specifications and types, one ensures the right tool selection for tasks at hand.

In the realm of drill machines, motors drive power. Different machines boast varied RPM (revolutions per minute). Handheld drills often utilize DC motors. Bench drills rely on AC motors. Hence, motor types hint at the machine's function. Always consider motor strength when selecting a drill.

A crucial component, the chuck holds drill bits. Typically, chucks come in three sizes: 1/4", 3/8", and 1/2". Larger chucks accommodate bigger bits. Locking mechanisms differ too. Some use keys, others offer keyless designs. Each type serves a specific drilling need.

Ergonomics matter in tool design. Drill machines present handles tailored for grip and comfort. Handles ensure user safety during operation. Materials like rubber offer better grip. A well-designed handle enhances the drilling experience, reducing user fatigue.

Central to drilling, bits do the actual work. Various materials and designs exist. For instance, HSS (High-Speed Steel) bits suit metalwork.

Masonry bits tackle concrete. Woodworking demands wood bits. Each material and design serves a unique purpose in the drilling world.

Control in drills, triggers start or stop the machine. Responsiveness is vital. Modern drills feature variable speed triggers. The harder you press, the faster the drill spins. Such precision aids in diverse tasks, from delicate to robust drilling.

Drills draw power in two primary ways. Corded drills need electrical outlets. Cordless variants rely on batteries, often Li-ion. Each source offers pros and cons. Cordless drills offer mobility, while corded ones deliver consistent power.

Drills come equipped with gearboxes to manage speed. Multi-speed gearboxes adjust RPM. Some drills feature two gears, others might have more. Proper gear selection ensures efficient drilling in different materials.

Precision in drilling depth is crucial. Depth gauges assist in maintaining consistency. Especially in repetitive tasks, gauges prove invaluable. They ensure each hole matches the desired depth, showcasing the drill's versatility.

|

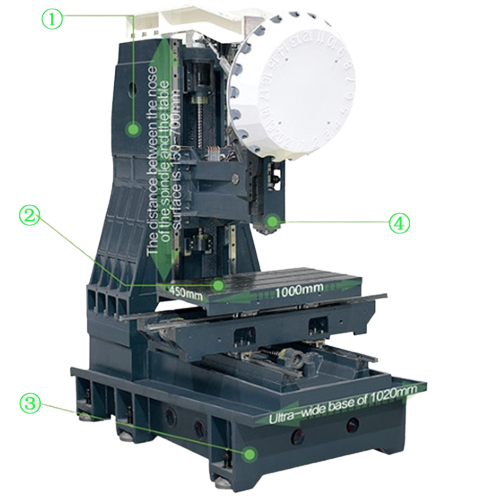

①. Higher Z-axis The effective stroke of the Z axis is 410mm, the distance between the nose of the spindle and the table surface is 150-560mm, four axes can be installed without additional raiser blocks, and the rigidity of the machine tool is not affected. ②. Large Table Table size:1000X450mm. The larger worktable allows bigger parts processing. Optical linear scales Optional Heidenhain, Fagor optical linear scales with an accuracy of under ±5um. ③.Stable Base Shared V8 base, 1020mm span, high rigidity, high precision bed. ④.Powerful Motor Standard 20000rpm BT30 high-speed motor, power 5.5kw; optional 12000rpm for large torque motor, power 7.5kw. Fast tool change speed Equipped with 21T servo tool magazine, tool change time is 1.8s; X/Y axis rapid traverse at 60m/min, Z axis rapid traverse at 48m/min. Powerful spindle YSV800 configuration BBT40 outer diameter 150mm with higher rigidity, and short nose spindle, five bearings, coolant nozzles. Upgrade Configuration German Rexroth roller linear guideway, Taiwan servo tool magazine, Taiwan spindle. Beautiful appearance European and American style sheet metal design, beautiful and practical |

Understanding various drill machines starts with power. Every drill requires energy. Electrical drills, for example, use volts (V) and amperes (A) for power. Cordless ones use batteries, often 12V or 18V. More volts mean more power. Such knowledge helps in choosing the right drill for tasks.

In the heart of a drill lies its motor. RPM (revolutions per minutes) measures motor speed. Common drills have RPMs ranging from 500 to 2000. Higher RPMs enable faster drilling. Thus, knowing the motor's RPM aids in task efficiency.

Torque, measured in Newton-meters (Nm), represents a drill's strength. Drills with high torque can drill into harder materials. For instance, masonry drills need high torque. Understanding torque ensures users select drills suitable for their materials.

Modern drills come with multiple gears. Having 1 or 2 gears is standard. The first gear provides more torque but less speed. Conversely, the second gear offers higher speed but less torque. Selecting the appropriate gear optimizes the drilling process.

The drill bit does the actual drilling. Bits come in various sizes, typically measured in millimeters (mm). Depending on the task, users might choose a 5mm bit or a 10mm one. Knowing bit sizes and types enhances drilling precision.

Drilling isn't just about rotation. The type of material—wood, metal, or concrete—matters. Each material demands a specific drill type. For instance, metal requires HSS (High-Speed Steel) bits. Recognizing material types ensures effective penetration.

Drilling produces debris. Efficient drills eject this waste, preventing clogging. Flutes in the drill bit help in this evacuation. The more pronounced the flutes, the better the debris removal. Hence, observing the flutes can indicate a drill's evacuation capability.

A drill's clutch disengages its drive shaft at a specific resistance. This feature, especially in cordless drills, prevents over-drilling. Recognizing the clutch settings can help users avoid damaging surfaces.

Drills often come with speed settings. Users can adjust these settings for different tasks. Slow speeds suit screwing, while fast speeds suit drilling. Mastery of speed variation ensures optimal drill performance.

Most common among homeowners, battery-powered drills offer convenience. Equipped with lithium-ion batteries, these tools provide mobility. Modern models boast an average 18V power, ensuring optimal performance.

Cordless designs eliminate dependency on electrical outlets, increasing versatility on job sites. Remember; always ensure timely battery replacements for uninterrupted work.

Distinct for its pulsing mechanism, the hammer drill excels in masonry tasks. With RPM (Revolutions per Minute) ranging from 2,500 to 3,000, these drills penetrate hard surfaces.

The pulsating action combined with rotation delivers precise holes in bricks, concrete and stone. Professionals in construction frequently prefer the hammer drill due to its efficiency.

Primarily used for driving screws, the impact driver stands out with high torque. With torque outputs up to 1,500 inch-pounds, these devices secure fasteners swiftly.

An internal mechanism increases rotational force, ensuring screws penetrate without stripping. Typically, contractors and builders opt for impact drivers to hasten project completion.

Unique for its 90-degree angled head, the right-angle drill accesses tight spaces. Essential for plumbers and electricians, this tool simplifies tasks behind beams or inside cabinets.

While RPMs vary, most models offer speeds between 1,200 to 1,500. The compact design coupled with powerful rotation makes it an invaluable addition to toolkits.

General-purpose and versatile, the rotary drill suits various materials. From wood to metal, it offers consistent results. Standard models feature RPMs ranging from 600 to 2,500.

The adjustable clutch settings empower users to control torque, ensuring accurate drilling. Trades people across sectors recognize the rotary drill's adaptability and dependability.

Often used in workshops, the Drill Press offers precision. Spinning motor drives the drill bit. Many professionals prefer the Drill Press for accurate whole placement. Adjusting depth is simple, ensuring repeated accuracy.

The Radial Arm drill serves larger projects. It has a long horizontal arm. The drill head moves along this arm. Ideal for handling big materials, it ensures versatility in operation. Large industries often invest in Radial Arm drills.

A unique feature sets the Magnetic Base drill apart. The powerful magnet aids in positioning. Sturdy materials like steel are no match. The magnet ensures the drill stays in place. Workshops dealing with metals find the Magnetic Base invaluable.

Compactness defines the Bench top Model. Designed for small spaces, it sits on workbenches. Despite its size, efficiency remains top-notch. Light tasks benefit from the Bench top Model's capabilities.

The Pedestal Drill stands tall. Mounted on a floor stand, stability is a given. Tasks requiring depth and precision find an ally in the Pedestal Drill. Workshops and garages commonly employ this tool.

Core drills, often abbreviated as CD, delve deep into materials. Essential for extracting samples, CDs possess diamond tips. Industries highly value CDs for their precision.

Ground drills, termed GDs, suit earthy terrains. GDs aid in creating holes for posts or plants. Construction and agriculture sectors predominantly deploy GDs. Their spiral design aids in soil penetration.

Submersible drills, or SDs, function underwater. Oil industries employ SDs for seabed exploration. Comprising stainless steel parts, SDs resist corrosion. Their high-pressure design ensures effective underwater operation.

In the medical realm, surgical drills, termed SDs, prove crucial. Surgeons use SDs for precise bone operations. Composed of medical-grade stainless steel, these drills ensure patient safety.

Milling machine drills, abbreviated as MDs, serve in metalworking. MDs differ from typical drills; they cut in all directions. Manufacturing sectors prefer MDs for their versatility. Typically, MDs have tungsten carbide tips for enhanced durability.

Traditionally, drilling began with hand-operated crank systems. These systems rely on human strength. In carpentry workshops, craftsmen favored them. Now, modern industries prefer more efficient methods.

Drills progressed from manual to electrical. Electric drills use motors. Motors convert electrical energy into mechanical energy. This enhancement increased efficiency, precision, and speed.

Advanced drills now incorporate computer systems. Such systems offer precision. For example, in manufacturing units, computer-controlled drills ensure product uniformity.

Modern drills can follow pre-set patterns. Users input these patterns. The machine then follows the set sequence. Such programmability reduces errors in repetitive tasks.

Accuracy remains a top priority. To address this, some drills come with laser guidance. The laser points where the drill should operate. It ensures the drill bit hits the target.

In high-tech environments, robotic arms play crucial roles. These arms can hold and operate drills. They offer flexibility and increase safety.

CNC stands for Computer Numerical Control. CNC machines follow exact instructions. They drill precise holes in specified locations. Such machines dominate industries requiring high precision.

Automated feed systems save time. Once set, the drill bit moves automatically. It adjusts based on material thickness. This feature eliminates manual adjustments, enhancing productivity.

Despite advancements, some tasks need human touch. Manual alignment allows users to position the drill. Users can make micro-adjustments. Such control is vital for custom jobs.

Understand the delicate nature of wood. Machines tailored for wood have RPM (Revolutions Per Minute) ranging from 600 to 4,500. Such machines prioritize torque over speed. The chuck, often 13mm, securely grips the bit.

Metal demands precision. Metal-specific drills operate at a lower RPM, between 50 and 2,500. The torque in these devices surpasses that of wood drills. Carbide-tipped bits and a 10mm chuck often accompany them.

Masonry materials require force. Consequently, drills designed for masonry boast an RPM between 100 and 1,000. A hammering function, combined with a rotating action, ensures effectiveness. SDS (Slotted Drive System) chucks, typically 20mm, provide a tighter grip.

Ceramics are brittle. Drills suitable for ceramics maintain an RPM range of 200 to 1,200. Diamond-tipped bits are a common choice. The machine's steady pressure ensures clean holes without cracking.

Glass, a fragile material, needs caution. Drills for glass operate between 200 and 800 RPM. Diamond-encrusted bits guarantee precision. Consistent, gentle pressure is vital to avoid shattering.

For plastic, a standard twist drill suffices. Lightweight plastic requires a 118-degree drill point. High-speed steel (HSS) drills offer precision. Remember, RPM (Revolutions per Minute) settings impact the outcome. Adjusting RPM ensures no melting occurs.

When dealing with drywall, specific drills shine. The screw gun remains the top choice. With variable speed and depth settings, optimal results emerge. Precision remains paramount, especially with thin drywall sheets.

Drilling into concrete demands power. Hammer drills equipped with carbide-tipped bits excel here. Rotary hammer drills offer even more force. With BPM (Blows per Minute) metrics, efficiency rises. Always wear safety gear, given the debris produced.

Stone demands specialized equipment. Masonry bits made of cobalt stand out. Diamond-tipped core drills also make a difference. RPM adjustments and coolant use prevent overheating. Always ensure the drill remains steady for best outcomes.

Tiles, especially ceramic, can be tricky. Carbide-tipped spear point drills prove effective. Low RPM settings and water cooling’s aid in precision. Avoid excessive pressure to prevent cracking.

Fiberglass, being composite, needs care. Brad point drills with HSS materials prove valuable. Clamping down the material prevents splintering. Remember, clean cuts ensure the longevity of the fiberglass.

Laminate cutting, popular in homes, demand precision. Down-cut spiral bits prevent chipping. RPM settings and steady hands ensure clean cuts. Aim for continuous motion to prevent burn marks.

Used primarily for general-purpose drilling into metals, plastics, and woods. High-speed steel (HSS) twist bits rank among the most common. You'll notice a helical flute running up the bit's length, assisting in chip removal.

Masonry bits Designed specifically for drilling into hard material such as brick, stone and concrete. Typically, these bits have a tungsten carbide tip. A hammering action, in conjunction with rotation, optimizes performance.

Often employed in cabinetry and woodworking, Forstner bits provide clean results, even on irregular surfaces. Carbide-tipped versions extend longevity.

Recognize their broad, flat blade, an ideal for drilling large holes in wood. The pointed machining center aids in positioning, ensuring accuracy during tasks.

The screw tip ensures the bit pulls through the material, enhancing efficiency. These bits often feature a hexagonal or SDS shank.

Allow for screws to sit flush with or below the surface of the material. After drilling, a conical hole results, ready for countersunk screw heads.

Crafted for drilling into hard tiles, including porcelains, ceramics, and glass. The spear-shaped tungsten carbide tip provides precision, minimizing the risk of cracking or breaking tiles.

Unique in design, these bits enlarge existing holes in metal sheets or create new ones of varying diameters. The conical shape, marked with multiple diameter levels, ensures versatility.

|

Type of Bit |

Material Best Suited For |

Typical Sizes (in mm) |

Ideal RPM |

Cutting Angle |

Common Uses |

Price Range ($) |

|

Twist Bits |

Wood, Metal, Plastic |

1-13 |

1,000-3,000 |

30° |

General drilling |

5-20 |

|

Masonry Bits |

Brick, Stone, Concrete |

3-16 |

700-1,200 |

45° |

Construction & masonry work |

10-30 |

|

Forstner Bits |

Wood |

10-50 |

600-800 |

90° |

Flat-bottomed holes & cabinet work |

7-35 |

|

Spade Bits |

Wood |

6-38 |

600-1,500 |

45° |

Boring large-diameter holes |

5-25 |

|

Auger Bits |

Wood |

4-25 |

250-1,000 |

30° |

Deep holes & timber framing |

20-50 |

|

Countersink Bits |

Wood |

6-19 |

600-1,200 |

45° |

Creating countersunk screw holes |

8-28 |

|

Tile Bits |

Ceramic, Glass |

3-10 |

1,000-2,500 |

60° |

Drilling tiles without cracking them |

10-40 |

|

Step Bits |

Thin Metal, Plastic |

4-30 (Steps) |

500-1,500 |

35° |

Enlarging holes in stages |

15-45 |

Table On Drill Bits: Matching The Job To The Tool!

Select the right drill bit for optimal performance. For wood, HSS (High-Speed Steel) bits work best. For masonry, use carbide-tipped bits. Metal projects often require cobalt bits. Your choice directly impacts the efficiency of the machine.

Apply uniform pressure when drilling. Too much force damages the material and the bit. Conversely, too little force results in inefficient drilling and wears out the bit prematurely.

Adjust the drill's RPM (Revolutions per Minute) based on material hardness. Hard materials like steel need lower speeds, typically 1,200 to 1,500 RPM. Soft materials like wood can handle speeds up to 3,000 RPM.

Regularly lubricate drill bits to reduce friction. Lubrication prevents overheating, prolongs bit life, and ensures smoother cuts. WD-40 or cutting oil serves well for most materials.

For thick materials, pre-drilling a smaller hole aids the main drilling process. The pre-drilled hole guides the main bit, reducing chances of error and enhancing precision.

After each drilling operation, remove debris from the work area. Accumulated debris not only hampers visibility but also poses a safety risk. Use a brush or compressed air to clear the area.

Set depth stops to ensure uniform whole depths. Depth stops prevent over-drilling and provide consistency across multiple holes.

Drills come in many forms and uses. Now you have learned how many types of drill machine are there.

You've also explored stationary, portable, and specialized drills. They vary based on power and purpose. Remember each drill's unique function. For top-notch drills, consider visiting CNCYANGSEN. Equip yourself with the best.