Computer Numerical Control is a cutting-edge manufacturing technique. It has completely changed how we manufacture complex, precision parts with unmatched accuracy. CNC machines have adjusted several sectors, including aerospace and automotive, as well as electronics and medical devices, through the convergence of computer technology and machining processes.

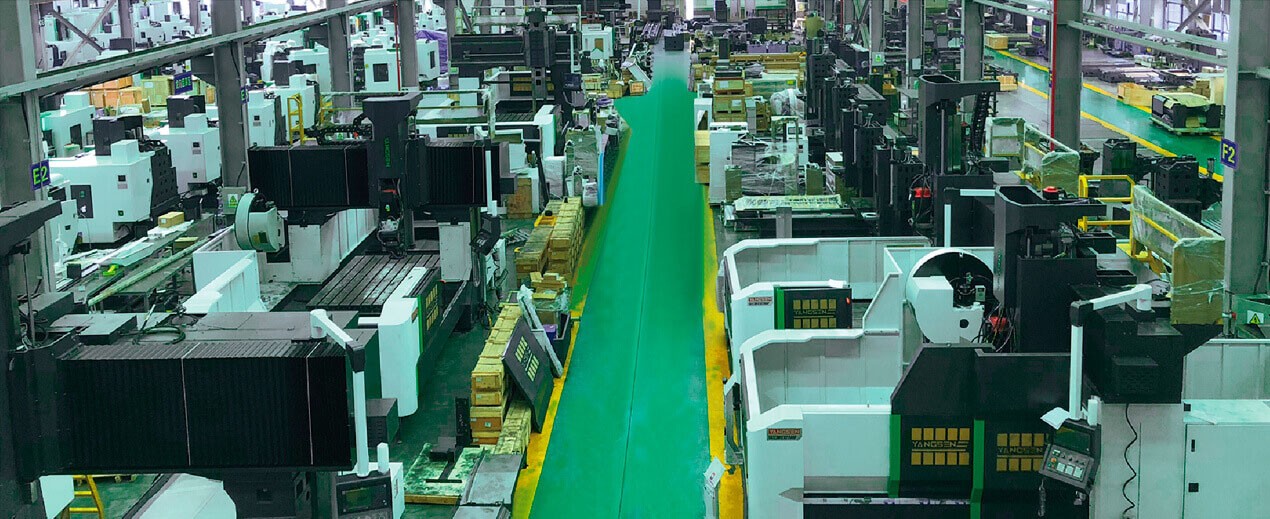

Traditional manual processes have been replaced by automated precision with CNC machining. Computer programs control the movement of cutting tools and material removal under sophisticated software guidance, producing consistent and error-free components.

The secret of CNC's power is its capacity to comprehend complicated geometries and complex designs, turning them into actual products with incredible reproducibility. This technology has encouraged innovation and pushed the envelope of engineering excellence by redefining what is feasible in contemporary production.

The art of determining machining costs for CNC machines will be covered in this tutorial, along with information on the variables that affect prices and tips for increasing productivity. Join me as we go through CNC machining, where potential meets accuracy and creativity has no limits.

Each machining procedure begins with the raw material that will be molded into the finished item. CNC machining costs impact material quality, accessibility, and unit cost. Premium materials may provide superior performance, but their price sometimes needs to be lowered. Manufacturers must balance material quality and cost-effectiveness to get the best outcomes without sacrificing quality.

Expertise and skilled labor are essential in the field of CNC machining. The time and energy used by machinists and operators to program, set up, and monitor the CNC machines during the production process are included in the labor cost. Although highly skilled workers with long experience frequently charge higher salaries, their skills can significantly impact the accuracy and effectiveness of the machining processes. Delivering excellent results under budget limits requires balancing labor expenses and qualified workers' requirements.

Time, a non-tangible yet priceless resource, is crucial to the cost equation. Machine time is the time a CNC machine spends creating a particular component. Increased expenses as a result of longer machining times have an impact on production capacity and turnaround times. Cutting cycle times down while keeping unwavering quality may be achieved using improved cutting processes and optimized tool paths like the Non-Slam Check Valve.

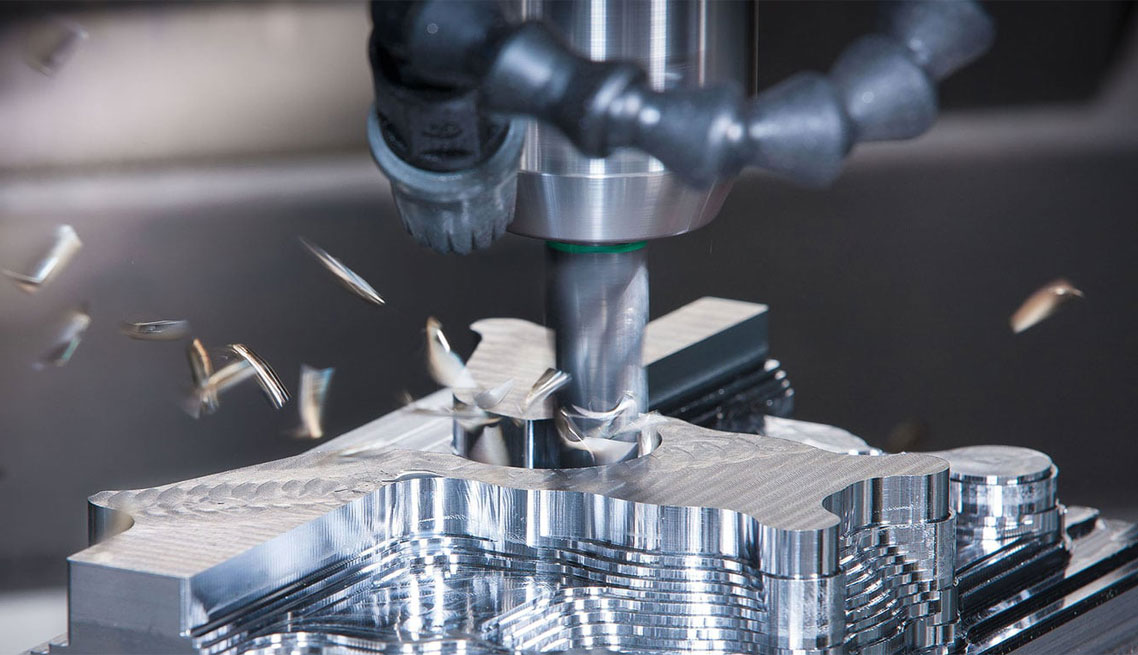

Precision machining requires cutting tools of the highest caliber and performance. The costs incurred with purchasing, maintaining, and changing different cutting tools, such as end mills, drills, and inserts, are referred to as tooling costs. Premium tools may perform better and have a longer tool life, but they are frequently more expensive. To establish the correct balance between tool durability and cost-effectiveness, manufacturers must measure the benefits of high-quality tooling against their expenses.

Overhead costs comprise the indirect costs necessary for successfully operating a machining process and the direct costs of materials, personnel, machine time, and tools. They cover things like the upkeep of the building, utilities, office bills, insurance, and other little expenses. While they might not directly relate to particular projects, overhead expenses significantly determine the company's profitability. To maintain a competitive advantage, overhead costs must be carefully managed and distributed.

The foundation for the machining trip is laid by a rigorous evaluation of the material amount before the hum of the CNC machine breathes life into the space. The machinist must calculate the material needed to create the desired masterpiece, such as the Pneumatic Piston Actuator. A surplus of materials not only raises the price but also causes waste and inefficiency. In contrast, insufficient supply causes the CNC machine to become hungry, interrupting the operation and upsetting the output flow.

The machinist must determine the precise amount of raw materials needed for each type of form by carefully planning and measuring while considering design requirements, density, structure, and material form.

The price tag attached to each material unit can be as unpredictable as the ocean waves in the ever-shifting tides of trade. The cost of the material per unit carries the weight of economic and market considerations, defining the amount spent on purchasing the fundamental components of the machining process.

A competent machinist must carefully evaluate vendors to find the best price/quality ratio, ensuring authenticity and industry compliance. Negotiating effectively and having a keen eye for detail can help find reasonable prices without sacrificing quality. -This leads to cost-effective and efficient machining procedures, as each material unit is purchased appropriately.

Time is a river that flows constantly in the world of CNC machining, and work hours are its currency. Finding labor hours is similar to seizing fleeting moments that sand past one's fingers. Every step of the machining process, including setting up the CNC machine and monitoring its rhythmic dance, must be thoroughly tracked in terms of the number of hours spent on it by the machinist.

The machinist keeps an eye on each production stage with vigilant eyes and a steady presence. Cutting tools slash through the material, converting undeveloped potential into skilled creativity while the clock ticks. The machinist painstakingly records his labor hours in the productivity ledger as each second passes.

Labor rate orchestrates machining efforts, assigning value to each hour of toil, reflecting a machinist's skill, experience, and dedication.

The labor rate, however, involves a delicate balance between bargaining and just remuneration. It combines the commercial realities with the goals of the craftsman. For the artisan, the labor cost reflects their proficiency with the CNC machine; for the business, it represents an investment in accuracy and perfection.

Machinist wants a labor rate that respects their craft while aligning with customer expectations and the market competition via uncompromising dedication to their trade. It needs the skill of a tightrope walker to strike the right balance between vanity and pragmatism.

CNC machining uses cycle time as a rhythmic measure, ensuring efficient production and harmony in the machinist's meticulous calculations.

The machinist breaks the machining process into primary phases with meticulous attention to detail. Every action, from the CNC machine's initial configuration through the cutting tool's final stroke, is carefully watched. The time spent changing means, moving materials, and doing other auxiliary tasks is precisely tracked.

Cycle time calculations necessitate a complex dance between the computer's algorithms and the machinist's knowledge. The mechanical components of the CNC machine are controlled by the code that composes a digital symphony. With the same talent, a maestro has to fine-tune their ensemble and make adjustments and improvements. The goal of the machinist is to find the ideal rhythm when productivity is mesmerized by the rhythmic convergence of efficiency and accuracy.

The tool-wielding machine, a dependable ally in CNC machining, persistently transforms raw materials into wonders. The machine's hourly wage mirrors its contribution to the manufacturing symphony, much like the machine's heartfelt music does.

The machinist calculates the machine's hourly rate by analyzing maintenance, depreciation, and energy consumption. It represents the essence of the CNC machine, highlighting its craftsmanship and promoting economic prudence.

CNC machining involves tools as virtuoso instruments, transforming raw materials into precision-crafted components, requiring unique assessment and performance.

The machinist analyzes the intricate details of the machining project with a keen eye. They interpret the blueprints for the designs and reveal the hidden geometry. Each tool's function is shown, from the resounding drilling of an end mill to the delicate dance of a lathe. Precision is required in the tool selection procedure since making the wrong pick might cause problems with the machining operation. The machinist must decide which material—high-speed steel, carbide, diamond-tipped—is best for the job. Variables, including material hardness, cutting speed, and tool life, are considered in this orchestration of effectiveness and economy.

The machinist is now faced with the task of the financial conductor - the tooling expense estimate – as the symphony of tooling needs takes shape. Each tool has a price to pay for its knowledge and experience in creating the machining masterpiece.

The machinist searches supplier inventories and catalogs for the best balance between tool quality and cost-effectiveness. Superior tools are expensive but offer prolonged tool life and flawless performance. Economical options could be less expensive initially but must be more durable and accurate.

The machinist must consider maintenance and replacement costs for a tool's performance. Regular maintenance and timely replacements ensure peak performance and prevent unexpected breakdowns. Achieving a balance between precision and budget constraints is crucial, as cost-effectiveness and performance form a harmonious duet.

CNC machining cost reduction entails streamlining several process components to increase effectiveness and reduce waste. The following are some tactics you may use to cut costs:

● Design for manufacture: Begin with an optimum plan considering CNC machining's potential and constraints. Use common tools and materials whenever possible and steer clear of complicated, complex forms that may demand lengthier machining periods.

● Material selection: Choose affordable materials that meet your project's needs. In certain cases, switching to a new material with comparable qualities might result in considerable cost savings without sacrificing the finished product's performance.

● To minimize material waste, make your cutting and nesting designs as effective as possible. Effective nesting software may increase material efficiency and minimize scrap.

● Manufacturing in batches: Where possible, make parts in larger quantities. CNC machines can be configured to process numerous parts at once to spread setup expenses across more components and lower the per-unit cost.

● Tooling optimization: To save downtime and produce precise cuts, use the appropriate tooling for the work and ensure that tools are kept in excellent condition. While initially expensive, high-quality tooling can save costs over time thanks to better performance and extended tool life.

● Cut down on machining time by making your toolpaths as efficient as possible while retaining the requisite precision. You can use sophisticated CAM software to create effective toolpaths.

● Shop scheduling: Optimizing the production schedule reduces energy use and idle machine time. A good schedule also helps avoid pricey expedited orders.

● Eliminate complicated fixturing: Streamline the setup and fixturing procedures to save time and money while setting up the CNC machine.

● Improve your machining operations continuously by identifying potential areas for improvement. To cut waste and simplify processes, apply Lean and Six Sigma methods.

● Partner with an established CNC machining company: If you need in-house CNC capabilities, working with an established CNC machining company can help you access their knowledge, effective procedures, and economical methods.

CNC machining faces overhead expenses, resembling sun shadows. These hidden indirect costs significantly impact every step of the production process. Understanding overhead expenses is like looking into the ocean's depths; hidden intricacies exist.

The machinist must understand the intricacies of overhead expenses like facility rent, utilities, insurance, and administrative salaries to determine their impact on the final cost of a machining project. Accurate tracking and record-keeping are crucial for precisely allocating and understanding these expenses.

Machinists must carefully choose overhead allocation methods to effectively manage projects and impact the economic landscape of CNC machining. Different ways exist, with some offering simplicity and others involving intricacy. Standard metrics include direct labor hours, machine hours, and material usage. The machinist must weigh the implications and make a choice that aligns with the business's objectives and captures the impact of overhead expenses on final costs.

Inspection and quality control act as watchful sentinels to ward against flaws in CNC machining, where accuracy rules supreme. The price spent for each component to fulfill strict requirements and be free from faults and defects is inspection and quality control charges.

As a skilled artisan, the machinist carefully examines every component, using fine-tuning tools like calipers and micrometers to measure tolerances to the last nuance. Quality control is a constant dance of testing and retesting to ensure that each invention is the epitome of perfection.

Inspection and quality control costs are not just figures on a ledger but investments in quality and client happiness. Each component is produced as a tribute to the artistry of CNC machining thanks to the high cost of specialized machinery, expert labor, and thorough testing.

The machinist, now a logistical coordinator, must orchestrate the delivery process of a finished CNC machine. Shipping and handling charges encompass packaging, insurance, and efficient transportation, ensuring the component arrives intact and ready for its new home.

The contingency margin is a crucial safety net in CNC machining, acting as a buffer against unforeseen circumstances like material shortages, machine breakdowns, or design changes. It is an insurance policy against cost overruns and project delays, ensuring a machinist's commitment to excellence.

The machinist calculates the final machining cost by combining cost elements like a master conductor, ensuring precision and harmony. Each component plays a role in shaping the ultimate figure.

● Cost of Materials: Total project cost, including unit and material quantity.

● Labor Cost: hours worked multiplied by labor rate, calculating knowledge and work.

● Calculated by dividing the cycle time by the machine's hourly rate, the machine time cost reflects the time the CNC machine used.

● The cost of purchasing, maintaining, and replacing the essential cutting tools to ensure accurate and effective machining.

● Facilities maintenance, utilities, office expenditures, and other indirect costs are all considered overhead expenses and are distributed following the proper overhead allocation technique.

● Including additional quality assurance and inspection costs, shipping and handling fees, and a contingency margin to account for unforeseeable circumstances.

|

Cost Element |

Cost ($) |

Project A ($) |

|

Material Cost |

$1000 |

$1500 |

|

Labor Cost |

$800 |

$1200 |

|

Machine Time Cost |

$600 |

$900 |

|

Tooling Cost |

$300 |

$450 |

|

Overhead Expenses |

$250 |

$375 |

|

Additional Costs |

$150 |

$225 |

|

Total Cost |

$3100 |

$4650 |

The final machining cost calculation is a complex tapestry of financial acumen and artisanal craftsmanship, reflecting the machinist's dedication to delivering flawless results while optimizing efficiency and cost-effectiveness.