Are you a beginner and eager to learn how to operate a VMC machine like a pro? Or are you a VMC operator and want to enhance your skill and increase your knowledge? If so, you've come to the right place.

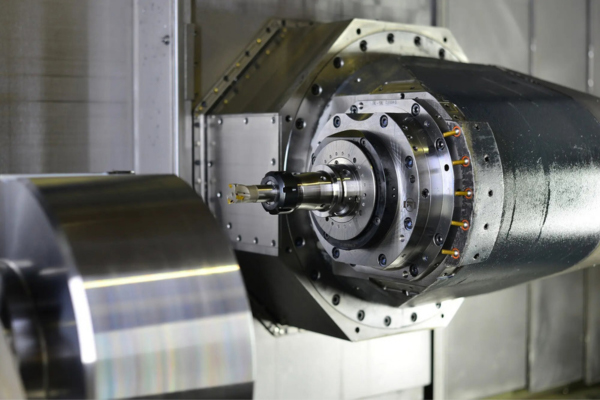

The vertical machining center, also known as VMC, has been integral to modern CNC technology for many years. A VMC is a specific type of machine tool equipped with a rotating cutter designed for drilling, slotting, and shaping metal workpieces.

VMC machining involves utilizing a vertically oriented machining center to perform various operations like milling and drilling on different materials.

With their ability to remove layers of material from a substrate and produce intricate features, VMC machines have revolutionized the milling process.

In a VMC, the cutting tool and workpiece can be precisely moved along their respective axes, with their movements controlled by a computer system.

From their initial development in the 1980s to the present day, Vertical Machining Centers have continuously evolved and incorporated new technologies.

So understanding their terminologies and operation has become essential for VMC operators. In this article, we will guide you on how you can operate a vertical cnc machine effectively.

Whether you are a beginner or looking to enhance your skills, this comprehensive guide will acquire your knowledge, and you can learn to operate a Vertical Milling Machine in simple terms.

So let’s get started!

Understanding the terminologies associated with VMC machines is essential for anyone who wants to operate vertical cnc machines, as it facilitates effective communication, proper setup, and optimal operation of these advanced machining tools.

Here are the terminologies you should know:

The computerized system that governs the operation of the VMC machine. It receives instructions from the operator, translates them into machine language, and controls the movement of the axes and spindle, ensuring precise and accurate machining.

The rotating component of the Vertical Machining Center that holds the cutting tool. It provides the necessary speed and power to perform cutting operations on the workpiece.

The VMC machine operates along three primary axes: X, Y, and Z. The X-axis represents the horizontal movement from left to right, the Y-axis represents the vertical movement from front to back, and the Z-axis represents the vertical movement from top to bottom.

The VMC machine is equipped with an automatic tool changer that holds a selection of cutting tools. It allows for quick tool changes during machining operations, reducing downtime and increasing efficiency.

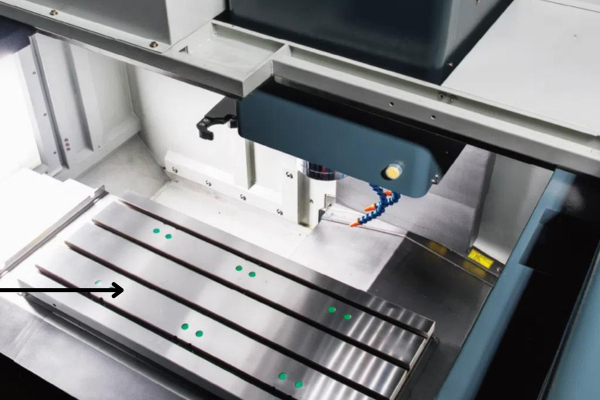

The work table is a flat surface on the vertical CNC machine where the workpiece is securely mounted and held in place during machining operations. It provides a stable platform for accurate positioning and cutting of the workpiece.

The coolant system is a vital component of Vertical Machining Center that helps to dissipate heat generated during machining and lubricate the cutting tool.

It involves the circulation of a coolant, such as water or oil, to cool down the workpiece and tool, improve cutting efficiency, and flush away chips and debris.

The reference point or origin used to establish the position of the workpiece on the VMC machine. It allows for consistent and repeatable positioning of the workpiece during machining operations.

The enclosure of a vertical CNC machine is a protective housing or cover that surrounds the working area of the machine. It serves multiple purposes, including operator safety, by preventing accidental contact with moving parts, containing coolant and chips, and reducing noise and environmental contamination.

A chip conveyor is a mechanism used to remove chips and swarf (metal shavings or waste) generated during the machining process.

It helps to maintain a clean working environment by continuously collecting and transporting the chips away from the work area to a designated collection point or bin.

So these are the basic terminologies. Understand them before operating a VMC machine. Now let’s begin with the control panel interface below to learn more!

The control panel of VMC (Vertical Machining Center) machines serves as the interface between operators and the CNC (Computer Numerical Control) controller, allowing them to input commands and monitor the machine's operations.

Here are some key features and functions of the control panel:

Display Screen: The control panel typically features a display screen that provides visual feedback and information about the machine's status, such as tool positions, spindle speed, program execution, and error messages. Operators can easily navigate through different screens and access various functions.

Keypad/Keyboard: The control panel is equipped with a keypad or keyboard for operators to input numerical values, program codes, tool offsets, and other commands. It allows for precise and efficient data entry and editing.

Function Buttons: Dedicated function buttons are available on the control panel for quick access to commonly used commands and functions. These buttons can include start, stop, pause, reset, spindle control, feed rate adjustments, and tool changes.

Emergency Stop Button: A prominent emergency stop button is prominently located on the control panel to immediately halt machine operations in case of any unforeseen emergencies or safety concerns.

Mode Selector Switch: VMC machines often have a mode selector switch on the control panel, allowing operators to switch between different modes of operation, such as manual mode, automatic mode, and jog mode. Each mode offers specific functionalities and control options.

Program Storage and Retrieval: The control panel may have built-in storage or memory capabilities to store and retrieve CNC programs. This allows operators to easily access and load pre-programmed instructions for different machining tasks, saving time and effort.

Diagnostic and Maintenance Functions: The control panel may provide diagnostic and maintenance functions, enabling operators to perform checks, troubleshoot issues, and perform routine maintenance tasks.

Now you understand the terminologies and know about control panel functions; it’s time to learn how to operate a Vertical Milling Machine.

Operating a VMC (Vertical Machining Center) machine requires careful attention.

So here is a step-by-step guide on how to operate a vertical CNC machine:

Before operating the Vertical Machining Center, make sure that you are familiar with all the safety procedures and precautions. Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and safety shoes.

Make sure the machine is properly connected to a power source, and then turn on the main power switch. Wait for the machine to initialize and perform its self-check routine.

Securely mount the workpiece on the machine table or vice. Make sure that it is properly aligned and clamped to prevent any movement during the machining process.

Choose the appropriate cutting tool for the machining operation you want to perform. Consider factors such as the material of the workpiece, desired cutting parameters, and tool availability. Install the tool securely in the machine's spindle.

You need to input the machining program if the VMC machine uses CNC (Computer Numerical Control). Use a compatible programming language such as G-code or conversational programming. Load the program into the machine's control system either via USB, network connection or by typing it in manually.

Before running the program, set up the machine by specifying various parameters. This includes setting the work coordinate system, establishing tool length offsets, and selecting the appropriate cutting speed, feed rate, and depth of cut.

Establish the work coordinate system by referencing specific points on the workpiece or using an edge finder or probe. This step helps the machine know the exact location and orientation of the workpiece, allowing for accurate machining.

Perform a dry run or program verification to check for any errors or potential collisions. Some machines have built-in simulation capabilities to visually represent the tool's path and check for any issues. This step helps avoid damage to the machine or workpiece.

Start the machining process once you are confident that the program is error-free and the machine is properly set up. Activate the spindle and initiate the program using the machine's control panel or software interface.

While the machine is running, closely monitor the machining process. Pay attention to any unusual sounds or vibrations. If necessary, adjust the cutting parameters, coolant flow, or tool position during the operation to optimize the results.

Once the machining operation is complete, stop the program and turn off the spindle. Clean the work area, remove any chips or debris, and safely remove the workpiece from the machine. Power off the machine and perform any necessary maintenance or tool changes.

When operating a vertical CNC machine, it is crucial to follow specific safety precautions to ensure the well-being of the operator and prevent accidents because safety comes first. That is why keep these key safety measures in mind while operating VMC machines:

Before using a VMC machine, thoroughly read and understand the manufacturer's manual. Gain proper training and knowledge about the machine's operation, controls, and safety features.

Wear appropriate personal protective equipment, such as CSA-certified safety glasses, and any additional equipment required for the specific task, such as footwear or hearing protection. PPE should be worn at all times during machine operation.

Ensure that all machine guards are in place and secure. Check that the workpiece is properly secured and mounted before starting the machine. Verify that bolts holding down the workpiece do not interfere with the tooling.

Familiarize yourself with the location and functionality of the emergency stop (e-stop) button and the start/stop button. They should be within easy reach of the operator in case of an emergency or to quickly stop the machine.

Ensure the workpiece and cutter are securely mounted before starting the milling process. Check that the workpiece is mounted squarely and use proper hand tools to make adjustments. Hold milling cutters with a cloth to avoid accidental cuts.

Keep hands, brushes, rags, or any other objects away from the rotating milling cutter. Move the table as far as possible from the cutter while setting up the workpiece to prevent hand injuries.

Keep the working surface clear of scraps, tools, and materials to maintain a safe and organized environment. Use a vacuum, brush, or rake to remove cuttings only after the cutters have come to a complete stop. Regularly change cutting compounds and ensure that cutters are properly sharpened and in good condition.

Keep the milling machine and the surrounding floor free of oil, grease, and other substances that could cause slips or falls. Use appropriate lifting equipment when handling heavy workpieces or moving them to or from the machine.

Always remain at the machine and stay vigilant while it is in operation. Do not leave the machine unattended while it is running.

Never forget to use these safety precautions even if you are experienced in operating VMC machines. Just make sure of a safe working environment before operating these machines.

Yangsen, renowned as a leading CNC machine provider, offers an outstanding array of CNC machine solutions that guarantee excellent quality at competitive prices.

With over 20 years of industry experience, this pioneering CNC Machine manufacturer offers state-of-the-art machinery that has made it the number one brand in Fujian and one of the top 20 in China.

Boasting a professional production management system, stringent quality control, and on-time delivery, Yangsen's commitment to top-notch service is unrivaled. Their continuous strive for improvement, understanding of industry trends, and dedication to serving the global high-quality manufacturing industry set them apart.

A customer's investment in Yangsen isn't just for a machine; it's for the consistent online technical support, rigorous confidentiality, and comprehensive after-sales service that Yangsen provides.

To boost your production efficiency, consider Yangsen's CNC Machine Tools, offering an array of products from CNC Vertical Machining Centers to Engraving and Milling Machines.

You'll join their global customer base, enjoying not just their superior machinery but also the passion, honor, and responsibility they invest in every single piece of equipment.

Learning how to operate a Vertical Milling Machine can greatly benefit both beginners and experienced operators. VMC machining offers numerous advantages over manual methods, including automation, increased accuracy, and higher productivity.

These machines are essential for modern manufacturers seeking to remain competitive in today's fast-paced manufacturing industry.

By mastering vertical CNC machine operation, you can create precise parts with minimal effort and enjoy the benefits of improved efficiency and reduced downtime.

You have to understand the terminologies and use of a control panel to operate a VMC machine effectively.

By following the step-by-step guide provided in this article, you can easily grasp the knowledge needed to operate a Vertical Machining Center effectively.

With practice and adherence to safety precautions, you can confidently operate a Vertical Milling Machine and achieve excellent machining outcomes.