A horizontal boring machine stands as a stalwart in the realm of machining, exhibiting a set of distinctive features that render it indispensable for a myriad of industrial applications. From its unique spindle orientation to its precision-driven capabilities, let's delve into the key features that make a CNC horizontal boring machine a powerhouse in the machining world.

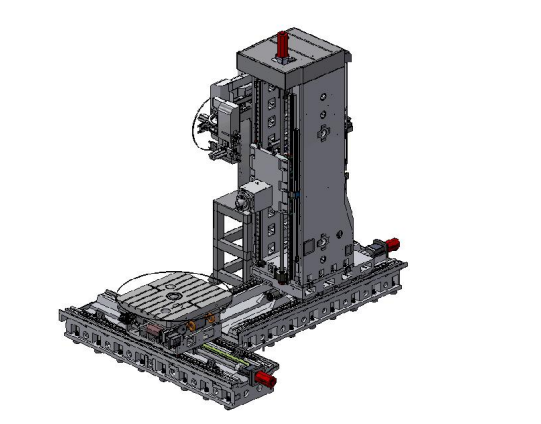

The horizontal spindle orientation of a boring machine enables it to work effectively on large and heavy workpieces. This positioning provides stability and facilitates the machining of components that might be challenging to handle with a vertical orientation. It ensures uniform force distribution, contributing to the overall accuracy of the machining process.

The versatility of horizontal boring machines lies in their ability to perform a wide array of machining operations. Boring, drilling, milling, and threading are seamlessly executed, making these machines adaptable to the diverse needs of different industries. This versatility is particularly advantageous for manufacturers dealing with complex and varied components.

The robust construction of horizontal boring machines is a key factor in their durability and reliability. The sturdy bed and column provide a solid foundation, minimizing vibrations during machining. This stability is crucial for achieving precision in cutting, especially when working on large workpieces that demand structural integrity.

The inclusion of rotary tables enhances the functionality of horizontal boring machines. The ability to rotate the workpiece during machining allows for multi-sided operations without the need for repositioning. This feature is especially beneficial for intricate work that requires precise angular adjustments, improving overall efficiency and accuracy.

Horizontal boring machines are engineered with a keen focus on accuracy and precision. Tight tolerances are achievable due to the machine's rigid structure and advanced control systems. This precision is vital for industries such as aerospace and automotive, where components must meet strict specifications to ensure optimal performance.

The integration of CNC technology brings automation and precision to horizontal boring machines. CNC systems allow for programmable and repeatable operations, minimizing human error and ensuring consistent results. This feature significantly enhances the efficiency and productivity of the machining process.

The spacious work envelope of horizontal boring machines accommodates the machining of large workpieces. This generous working space is essential for industries that produce sizeable components, such as engine blocks and gearboxes. It provides flexibility and convenience in handling diverse projects.

Horizontal boring machines incorporate efficient chip removal mechanisms to maintain a clean working environment. Rapid evacuation of chips and debris during cutting operations prevents interference and ensures uninterrupted machining. This feature contributes to prolonged tool life and sustained machining accuracy.

The adaptability to various tooling options allows horizontal boring machines to handle a range of cutting tools. This flexibility enables operators to choose the most suitable tools for specific applications, enhancing the machine's versatility and performance across different materials and machining tasks.

Horizontal boring machines demonstrate powerful cutting capabilities, thanks to robust spindles and high-powered motors. This strength is particularly advantageous when working with tough materials or undertaking deep hole drilling. The machine's ability to deliver substantial cutting power ensures efficiency in machining various workpieces.

The design of horizontal boring machines prioritizes ease of accessibility, simplifying setup procedures and tool changes. Quick and straightforward access to key components reduces downtime and contributes to a more user-friendly experience. This feature is essential for maintaining a seamless workflow in manufacturing environments.

Horizontal boring machines offer customization options to meet specific manufacturing requirements. Industries can tailor the machine to their unique needs, incorporating additional features or adjustments. This customization capability ensures that the machine aligns perfectly with the specific demands of diverse applications and industries.

Some modern horizontal boring machines address environmental concerns through eco-friendly features. Energy-efficient components, advanced cooling systems, and sustainable manufacturing practices contribute to reducing the machine's environmental impact. This consideration aligns with the growing emphasis on sustainability in industrial processes.

In conclusion, a horizontal boring machine emerges as a formidable machining tool due to its unique features. Its horizontal spindle orientation, versatility in operations, robust construction, incorporation of rotary tables, emphasis on precision, integration of CNC technology, and spacious work envelope collectively position it as a cornerstone in the manufacturing and machining landscape.