In the realm of precision machining, CNC lathe operations stand out as a pinnacle of technological advancement. These computer-controlled machines have revolutionized the manufacturing landscape, allowing for unparalleled accuracy and efficiency. Let's delve into the intricacies of CNC lathe operations, from programming to quality checks, and explore the manifold advantages they offer.

In the dynamic world of manufacturing, CNC lathe operations have emerged as a cornerstone for achieving precision and efficiency in machining processes. This article unravels the layers of CNC lathe operations, shedding light on the programming intricacies, setup procedures, cutting-edge tools, and the myriad applications that make these machines indispensable in various industries.

|

|

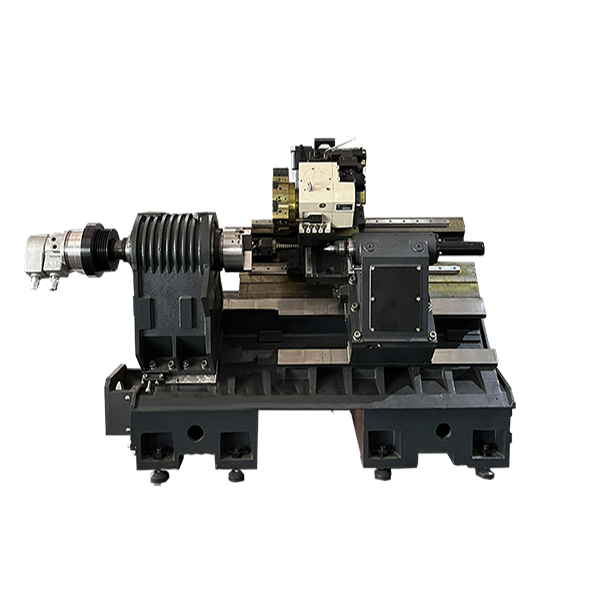

| CNC Horizontal Lathe Machine | Vertical CNC Lathe Machine |

| Contact Us | |

CNC, or Computer Numerical Control, lies at the heart of modern machining. It involves the use of computer systems to control the movement of tools and machinery. In the context of lathe operations, CNC brings a level of automation and precision that was once unimaginable.

Before delving into CNC specifics, understanding the fundamentals of lathe machines is crucial. Lathes have been a staple in machining for centuries, and with CNC integration, their capabilities have been elevated to new heights. These machines rotate a workpiece on its axis, allowing for the cutting, drilling, and shaping of materials.

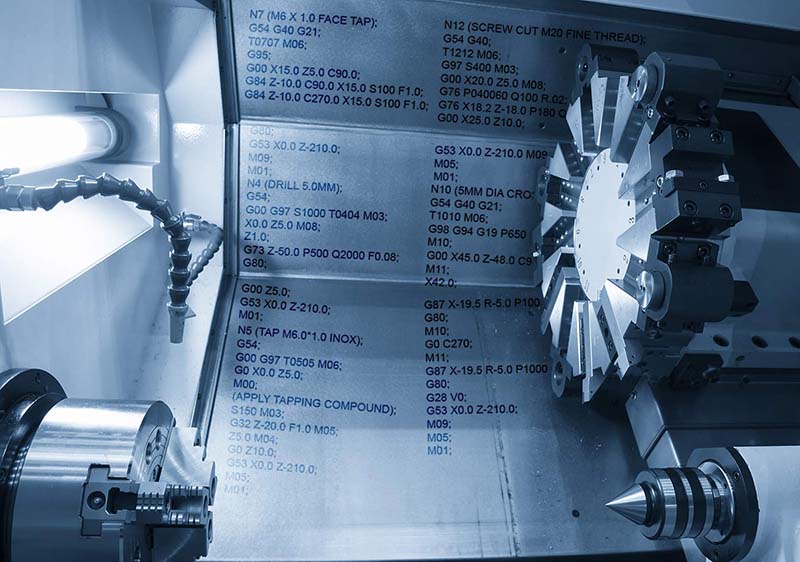

Main control G code

The core of CNC lathe programming lies in mastering G-code, a language that communicates precise movements and actions to the machine. This digital language determines every aspect of the machining process, from tool movement to spindle speed, acting as a conduit between the machinist’s vision and the machine’s execution.

Precise Language

G-code is more than just a set of instructions; it is the precise language for CNC lathe operation. Each code corresponds to a specific machining action, allowing machinists to control every nuance of the process. Whether it is a rapid positioning instruction (G00) or a linear interpolation instruction (G01), G code can transform design intentions into tangible results.

Write code

Writing G code is like creating a symphony of precise movement. Machinists carefully write every line of code with a deep understanding of design requirements, material properties, and tool capabilities. Every code is a stroke that contributes to the masterpiece of machined parts.

The art of precise programming

The success of CNC lathe operations depends on the accuracy of programming instructions. Precision programming is a multifaceted job that involves a deep understanding of materials, on-the-fly adjustments, and strategic planning of tool paths.

Material considerations

Materials affect machining parameters, and accurate programming requires a deep understanding of these effects. The machinist tailors the program to the specific characteristics of the material being machined, adjusting cutting speeds and tool path strategies accordingly.

Tool path planning

Strategic planning of tool paths is an art that distinguishes good programming. Minimizing tool changes, optimizing cutting efficiency and reducing unnecessary movements are hallmarks of precise programming. It's the subtle dance of the cutting tool that increases speed and precision.

Dynamic Adjustment

Real-time adjustments are a testament to the adaptability of skilled mechanics. The ability to make dynamic changes to a program based on changes in material properties or unexpected tool wear is critical to maintaining accuracy throughout the machining process.

The first step in CNC lathe operations is the setup of the workpiece. Whether using a chuck or collet, securing the workpiece with precision is paramount. Proper alignment ensures that subsequent machining operations are executed accurately.

Equally important is the selection of cutting tools. Machinists must consider the material being worked on and the desired features when choosing tools. CNC lathe machines often come equipped with tool changers, automating the process of switching between tools.

To achieve precision in CNC lathe operations, tool offsets must be set accurately. This process involves accounting for variations in tool lengths and diameters, ensuring that the cutting tool engages with the workpiece at the intended location.

Simultaneously, machinists set the workpiece zero, which serves as the reference point for machining. This establishes a consistent starting point, crucial for maintaining accuracy throughout the entire process.

Utilizing the CNC controls, machinists command rapid movements of the cutting tool to the starting position. This rapid movement occurs in the air above the workpiece, minimizing any unintentional cutting.

Starting with a clean slate is essential in CNC lathe operations. A clean starting point ensures that the first cut is precise and free from any material irregularities, setting the stage for subsequent machining.

At the heart of lathe operations lies turning, a process where the workpiece rotates, and the cutting tool removes material to create cylindrical shapes. This fundamental operation is the cornerstone of many manufacturing processes.

Whether producing shafts, components, or intricate details, turning operations on a CNC lathe allow for the creation of cylindrical forms with unparalleled precision. The machine follows the programmed instructions, chiseling away excess material to reveal the desired shape.

Facing operations involve cutting material from the end of the workpiece to create a flat surface. This is often one of the initial steps to ensure that subsequent machining operations occur on a level plane.

Beyond turning and facing, CNC lathe operations can seamlessly transition into drilling. The machine radially moves the cutting tool into the workpiece, creating holes or features along the axis. This versatility makes CNC lathes invaluable in diverse manufacturing scenarios.

Grooving is a specialized operation where the CNC lathe cuts a groove or channel on the surface of the workpiece. This can be instrumental in creating features that go beyond the standard cylindrical shape.

Parting operations involve cutting the workpiece off, creating separate parts. This capability allows for the efficient production of multiple components in a single machining cycle.

Threading is yet another feat achievable with CNC lathe operations. The machine follows precise instructions to cut threads on the workpiece, producing screws or other threaded components with unmatched accuracy.

While the initial cutting operations shape the workpiece, finishing operations are dedicated to achieving the desired surface quality. Specialized finishing tools are employed to refine the surface finish, ensuring that the final product meets the specified requirements.

Finishing tools, often with fine cutting edges, delicately polish the surface of the workpiece. This step is crucial for applications where aesthetics and precision are paramount, such as in the production of components for high-end machinery or medical devices.

One of the remarkable features of CNC lathe operations is the ability to automate tool changes. The machine, following the programmed instructions, seamlessly transitions between different tools based on the requirements of each machining step.

Automated tool changes significantly enhance the efficiency of CNC lathe operations. The machine can switch between cutting, facing, drilling, and other tools without manual intervention, reducing downtime and increasing overall productivity.

Periodic quality checks are integral to CNC lathe operations. Machinists use precise measurement tools to verify dimensions and surface finish, ensuring that the workpiece meets the specified tolerances.

Quality checks serve as a safeguard against deviations from the intended design. Machinists meticulously inspect each machined part, confirming that it adheres to the exact specifications outlined in the programming phase.

Regular cleaning and maintenance are essential for the longevity and optimal performance of CNC lathe machines. Machining processes generate debris, and proper cleaning prevents the accumulation of material that could affect the precision of future operations.

Scheduled maintenance checks involve inspecting the machine components, lubricating moving parts, and addressing any potential issues. Proactive maintenance ensures that the CNC lathe operates at peak efficiency, minimizing the risk of unexpected breakdowns.

One of the primary advantages of CNC lathe operations is the unparalleled precision and accuracy they offer. The machine faithfully follows programmed instructions, eliminating the variability introduced by manual operation.

Automation in CNC lathe operations results in a significant reduction in manual errors. The consistency of the programmed instructions ensures that each machined part is an exact replica of the digital design, minimizing the likelihood of human-induced mistakes.

CNC lathe operations find extensive applications in the aerospace industry. The ability to produce intricate and precisely engineered components makes these machines indispensable for crafting parts used in aircraft and spacecraft.

In the automotive sector, CNC lathe operations contribute to the production of engine components, gears, and other critical parts. The efficiency and accuracy of these machines play a pivotal role in the automotive manufacturing process.

The medical industry benefits from CNC lathe operations in the production of precision components for medical devices. The ability to achieve tight tolerances and high-quality surface finishes is crucial for applications in healthcare.

CNC lathe operations have become a cornerstone in general manufacturing, catering to a diverse range of industries. From producing bolts and nuts to complex components, these machines offer versatility and adaptability.

In the realm of machining, CNC lathe operations represent a technological marvel that has reshaped the landscape of precision manufacturing. From programming intricacies to automated tool changes, these machines embody efficiency, accuracy, and versatility. As industries continue to evolve, CNC lathe operations will undoubtedly remain at the forefront, driving innovation and setting new standards in precision engineering.