5-axis CNC machines are capable of performing more complex and intricate machining operations than traditional 3-axis machines, which makes them ideal for improving precision machining. The advantages of using 5 axis CNC machine include greater flexibility and versatility, enhanced accuracy and quality, improved efficiency and productivity, and reduced Setup Time and Cost.

Precision machining plays a critical role in modern manufacturing, especially in industries where complex geometries, tight tolerances, and high surface quality are essential.

Traditional 3-axis CNC machines often struggle to meet these demands efficiently, requiring multiple setups that increase machining time and introduce positioning errors.

This is why 5-axis CNC machining has become a preferred solution for precision manufacturing. By enabling simultaneous multi-axis movement, 5-axis CNC machines deliver higher accuracy, greater flexibility, and improved productivity—making them ideal for advanced machining applications.

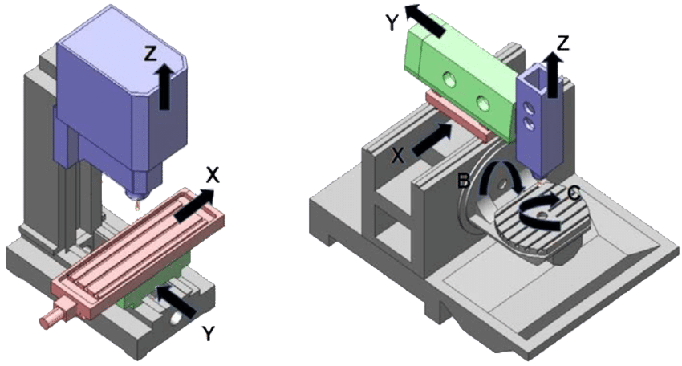

A 5-axis CNC machine allows the cutting tool or workpiece to move along five different axes simultaneously—three linear axes (X, Y, Z) and two rotational axes.

Unlike conventional 3-axis machining, which requires multiple repositioning steps, 5-axis machining enables multi-surface machining in a single setup.

This capability significantly reduces setup errors and improves dimensional accuracy, making 5-axis CNC machines particularly suitable for precision machining of complex parts.

Precision machining plays a critical role in modern manufacturing and engineering. It involves using computer-controlled machines to shape and cut materials with a high degree of accuracy and consistency, often to tolerances of just a few microns.

One of the main benefits of precision machining is that it allows for the production of complex and intricate parts that would be difficult or impossible to manufacture using traditional methods. This is particularly important in industries such as aerospace, defense, and medicine, where the performance and reliability of components can be a matter of life or death.

Precision machining also helps to improve the quality and consistency of finished products. By using computer-controlled machines, manufacturers can ensure that every part is produced to the same specifications, minimizing the risk of defects or errors. This is particularly important in industries such as automotive and electronics, where even small variations in part dimensions can cause significant problems.

5-axis CNC machines are capable of performing more complex and intricate machining operations than traditional 3-axis machines, which makes them ideal for improving precision machining. Here are some ways in which 5-axis CNC machines improve precision machining:

Greater Flexibility and Versatility

Enhanced Accuracy and Quality

Improved Efficiency and Productivity

Reduced Setup Time and Cost

As compared to standard 3-axis machines, 5-axis CNC machines provide much larger degrees of flexibility and variety, which is one of the primary benefits of employing such a machine for precision manufacturing. More adaptability and variety may be achieved via the use of 5-axis CNC machines in the following ways:

5-axis CNC machines are able to produce large and sophisticated shapes with better ease and precision since the cutting tool can move along five axes. In the aerospace and medical fields, for example, where accuracy is of the utmost importance, this is of paramount importance.

Areas of a component that are inaccessible with a 3-axis machine may be machined with a 5-axis machine. In order to mill inaccessible places with higher precision and accuracy, 5-axis machines may tilt and rotate the cutting tool.

As they are more adaptable and versatile, 5-axis CNC machines can process a bigger variety of materials than their 3-axis counterparts. Metals, polymers, composites, and precision ceramics of varied densities and hardness are all within their machining capabilities.

5-axis CNC machines are capable of performing multiple machining operations in a single setup, which reduces the need for manual labor and improves overall efficiency. This can result in faster production times, lower costs, and higher-quality parts.

When it comes to precision machining, employing a 5-axis CNC machine has a number of critical advantages, one of the most important being the improved accuracy and quality it gives. The following are some of the ways in which 5-axis CNC machines provide improved precision and quality:

5-axis CNC machines are capable of positioning the cutting tool at more angles and orientations compared to 3-axis machines. This results in greater accuracy and precision when machining complex geometries, resulting in higher-quality parts.

The necessity for several setups and repositioning of the component is decreased with 5-axis CNC machines. This reduces setup mistakes, resulting in higher precision and uniformity across various components.

5-axis smaller tools and a greater range of motion made possible by CNC machines provide for a smoother surface finish on finished products. Aerospace, medical, and automotive sectors all benefit from the improved quality of the finished products that this process produces.

With the ability to position the cutting tool at more angles and orientations, 5-axis CNC machines can reduce the wear and tear on the cutting tools. This results in longer tool life and lower tooling costs, which can help to reduce manufacturing costs.

When it comes to precision machining, using a CNC machine with 5 axis offers a number of major benefits, one of the most important being an increase in both efficiency and production. The following are some of the ways 5-axis CNC machines provide better levels of production and efficiency:

As compared to conventional 3-axis CNC machines, 5-axis machines may drastically cut down on setup times. As 5-axis machines can manufacture many sides of a component in a single setup, they greatly reduce the amount of time spent setting up and moving the item.

Due to its capacity to place the cutting tool at more angles and orientations, 5-axis CNC machines may achieve faster machining rates than 3-axis machines. This leads to shorter cycle durations and greater production rates, which may enhance efficiency and productivity.

The capacity of 5-axis CNC machines to conduct numerous machining operations in a single configuration means less time and money spent on human labor. This has the potential to lower production costs and boost profits.

Parts may be manufactured with higher consistency and reproducibility because of the improved accuracy and precision provided by 5-axis CNC machines. This ensures that all parts satisfy the same high-quality requirements, which is critical in sectors such as aerospace, medical, and automotive.

5-axis CNC machines are an excellent option for precision machining applications due to their increased efficiency and productivity. They may shorten setup times, boost machining speeds, minimize labor costs, and enhance component uniformity, resulting in shorter production schedules, cheaper costs, and higher-quality products.

The decreased amount of time and money required for setup is another benefit of employing a 5-axis CNC machine for precision cutting. The following are some of how 5-axis CNC machines provide decreased time and costs associated with the setup:

5-axis CNC machines can machine multiple sides of a part in a single setup, which eliminates the need for multiple setups and repositioning of the part. This significantly reduces setup time and cost.

5-axis CNC machines have a lower rate of tool changes because the cutting tool may be positioned in a wider variety of orientations and positions. As a result, you spend less time and money on setup, and your tools have a better chance of surviving the machining process unscathed.

The potential for waste or reworked components is greatly reduced by the higher precision and quality afforded by 5-axis CNC machines. As a result, both manufacturing costs and material waste are reduced.

It may take more time to write the software for a 5-axis CNC machine than it would for a 3-axis machine, but after it's done, the milling time will be much shorter. The result is higher productivity and lower overall manufacturing costs.

It's crucial to differentiate between 3-axis and 5-axis CNC machines when talking about precision machining. Some parallels between the two are as follows:

Axis of Movement

3-axis machines can move the cutting tool in three directions (X, Y, Z) while 5-axis machines can move the cutting tool in five directions (X, Y, Z, A, B). The additional two axes allow for more complex geometries and greater precision in machining.

Setup Time

3-axis machines require more setups and tool changes for complex geometries while 5-axis machines can perform all operations in one setup, reducing setup time.

Part Complexity

3-axis machines are better suited for simpler geometries, while 5-axis machines excel in machining complex parts and shapes.

Surface Finish

5-axis machines can maintain a consistent tool angle throughout the machining process, resulting in smoother and more uniform surface finishes than 3-axis machines.

Cost

5-axis machines are generally more expensive than 3-axis machines due to their increased complexity and capabilities.

When choosing a 5-axis CNC machine for precision machining, there are several key considerations to keep in mind. These include:

The size of the machine and its work envelope should match the size and complexity of the parts you will be machining. It is important to consider the largest part size you will be machining and ensure that the machine can accommodate it.

The accuracy and repeatability of the machine are crucial for precision machining. Look for machines with high-quality components and features such as real-time tool position monitoring and collision detection.

The control system should be user-friendly and offer advanced features such as 3D simulation and programming capabilities. Look for machines with a reliable and well-supported control system.

Spindle speed and power are important factors that affect the machine's performance and the types of materials that can be machined. Consider the types of materials you will be machining and ensure that the machine has the necessary spindle speed and power.

The tool changer capacity determines how many tools can be loaded into the machine at once. Consider the complexity of the parts you will be machining and ensure that the machine has a sufficient tool changer capacity.

Look for machines from reputable manufacturers with good maintenance and support programs. Consider the availability of spare parts and technical support in your region.

Yangsen can be your smart CNC machine partner. It also serves you with a complete range of machines such as drilling machines, horizontal boring machines, CNC vertical machining centers, horizontal machining centers, and many more.

1. What is the main advantage of 5-axis CNC machining compared to 3-axis machining?

The biggest advantage of 5-axis CNC machining is the ability to machine complex geometries in a single setup.

By allowing the tool or workpiece to move along five axes simultaneously, 5-axis machines reduce repositioning errors, improve accuracy, and significantly shorten machining time compared to traditional 3-axis CNC machines.

2. How does 5-axis CNC machining improve precision machining accuracy?

5-axis CNC machining improves accuracy by minimizing multiple setups and maintaining consistent tool orientation during cutting.

This reduces cumulative alignment errors and enables tighter tolerances, making it ideal for high-precision components with complex contours or angled features.

3. Is 5-axis CNC machining suitable for small-batch or prototype production?

Yes. Although often associated with complex parts, 5-axis CNC machining is highly efficient for small-batch and prototype production because reduced setup time and faster cycle times offset the higher initial machine cost.

4. What types of parts benefit most from 5-axis CNC machining?

5-axis CNC machining is especially beneficial for:

Aerospace components with complex surfaces

Medical implants and surgical instruments

Mold and die components

Precision automotive and mechanical parts

Any part requiring multi-surface machining, deep cavities, or angled features benefits from 5-axis capability.

5. What materials can be machined using a 5-axis CNC machine?

5-axis CNC machines can process a wide range of materials, including:

Aluminum alloys

Stainless steel

Titanium

Hardened steel

Engineering plastics

The ability to optimize tool angles improves machining stability across different materials.

6. What is the difference between 3+2 machining and true 5-axis simultaneous machining?

3+2 machining positions the workpiece using two rotary axes before cutting, but machining occurs with only three axes active.

True 5-axis simultaneous machining allows all five axes to move at the same time, enabling smoother toolpaths, better surface finishes, and higher accuracy on complex geometries.

Many benefits, such as increased adaptability, precision, quality, efficiency, productivity, and decreased setup time and cost, can accrue to manufacturers who invest in a 5-axis CNC machine for precision machining. For these reasons, industries like aerospace, medicine, the auto industry, and others that rely on high-quality, precise parts should look into 5-axis CNC machines.

A 5-axis CNC machine may need a larger outlay of capital than a 3-axis machine, but it may save money in the long run by reducing labor expenses, saving money on tools, and speeding up production. The capacity to machine more complicated geometries and create components with higher-quality surface finishes may also increase a manufacturer's marketability.

By increasing accuracy, quality, and efficiency, a 5-axis CNC machine may help producers keep up with the dynamic nature of the industry.