Dive into the world of CNC Machining Precision. In this blog, find the core ideas of precision. Explore its importance in CNC operations. Discover the ways to control accuracy. Learn about the types of CNC machines and so on!

Precision in CNC machining is all about exactness. Numbers matter. Millimeters, micrometers, even nanometers count. Think of a part, say a gear. Now, visualize its teeth.

Their size, their shapes are all perfect. Each one is identical to the last. The goal is absolute precision, to make each part the same. Here, machine parts hold the utmost importance.

Even the machine bed matters. Everything must be exact. Abbreviations make the process easier. Instead of "Computer Numerical Control", just say "CNC". It's about simplicity and precision.

Tolerances set the precision boundaries. A fraction of a millimeter can make a difference. Each component has a range. Stay within that range, or it's no good.

Feed rate is crucial. It determines how fast the cutter moves. Too fast, the material might break. Too slow, time is wasted. Control is key.

Spindle speed defines how fast the tool spins. Higher speed, more cuts. But care is needed. Too fast can wear out the tool.

Cutting parameters influence precision. They set the speed, feed, depth. Each parameter contributes to the final product.

CNC machines follow paths. They guide the tool, cut by cut. The more precise the path, the better the end result.

Machines can make mistakes. Error compensation fixes them. The machine learns, adapts, gets better.

Calibration makes machines accurate. They're set, checked, rechecked. Nothing is left to chance.

How smooth is the part? Surface finish control decides. It checks, corrects, ensures perfection.

A stable machine is a precise machine. No shaking, no vibrations. Just clean, accurate cuts.

Clamps hold the workpiece. No movement means no errors. A firm grip leads to precision.

Heat can warp materials. Coolants keep the heat in check. Managed right, they improve precision.

Tools wear down over time. Monitoring keeps them sharp. Sharp tools, sharp cuts.

Measurements guide CNC machines. Metrology is the science of measuring. Integrated into the process, it enhances precision.

Robots can spot errors. Automated inspection keeps a check. It finds faults before they become problems.

CNC machines learn. They adapt. Control systems change based on past cuts. Every operation improves the next. Each cut brings more precision. Adaptive control makes it happen. It's the future of CNC machining precision.

Start by perfecting your code. Mistakes can cost time and resources. Precision comes with a flawless CNC program. Trust CAD/CAM software for complex projects.

Regular machine calibration is essential. Even a 0.001 inch deviation can make a big difference. Keep CNC machines in peak condition for optimum performance.

Before starting, preset your tools. Correct height and diameter settings improve accuracy. Eliminate trial runs by having tools ready.

Keep an eye on the operation. Real-time supervision helps catch mistakes early. Immediate actions save time and reduce wastage.

High speed can cause overheating. CNC machines need appropriate cooling. Temperature control safeguards against unwanted metal expansion.

Secure workpieces tightly. Poor fixture might result in errors. Robust clamping mechanisms ensure precise, consistent results.

Be ready to tweak settings on the go. Tiny shifts can improve the end product. Real-time adjustments keep CNC machining precision at peak.

Don't skip inspections midway. Frequent quality checks reduce final inspection load. A minor glitch, if not caught early, might ruin the whole batch.

After production, assess the workpiece. Any discrepancies call for immediate corrections. Maintain standards with rigorous post-processing inspections.

Record all relevant parameters. Data logging helps in troubleshooting and future improvements. Make informed decisions based on past records.

Learn from past mistakes. Error correction forms the basis of continual improvement. Each error rectified enhances your CNC machining precision.

Regular maintenance extends machine lifespan. Well-maintained machines deliver superior precision. Stick to your maintenance schedule religiously.

Invest in operator training. Skilled personnel increase productivity and precision. Encourage operators to continually upgrade their skills.

Proper use of cutting fluids ensures smooth machining. They reduce heat and prolong tool life. Use them wisely for accurate machining.

Sturdy machines withstand tough jobs. Rigidity matters in CNC machining precision. It maintains alignment and accuracy under high pressure.

CAD software aids in creating precise 3D models. High fidelity models are crucial for ensuring precision in CNC operations.

Before actual machining, tool path simulation forecasts potential errors. By identifying and rectifying issues early, CNC machining precision elevates.

Accurate part dimensions require precise coordinate measurements. Coordinate measuring machines (CMMs) offer this precision, ensuring parts meet exact specifications.

In CNC machining, feedback loops allow real-time adjustments. Quick detection and correction of deviations leads to enhanced precision.

Geometric error modeling predicts potential errors in the machining process. Thus, by minimizing errors, CNC machining precision improves.

Fine-tuning the machine movements through kinematic adjustments result in better precision. Smooth, controlled movements are key to high-quality auto parts.

In CNC machining, force control reduces tool wear and part damage. Reduced wear and damage contribute to enhanced precision.

Smooth, even surfaces are a mark of precision. Surface roughness assessment helps meet these quality standards.

Optical metrology uses light to measure dimensions and surface quality. By doing so, CNC machining precision gets a boost.

Machine learning algorithms predict and rectify errors. These techniques adapt and learn over time, improving CNC machining precision.

Lasers offer exact measurements. Laser calibration in CNC machining ensures parts match design specifications.

Vibration can cause errors in machining. Damping techniques minimize these vibrations, improving CNC machining precision.

Heat can warp materials. Compensation techniques help counteract this, preserving the integrity of the part.

Probing systems verify part dimensions. Precise measurements are crucial for maintaining CNC machining precision.

Dynamic tuning helps adjust machine parameters during operation. Continuous adjustments keep the machining process within acceptable accuracy ranges, thus ensuring precision.

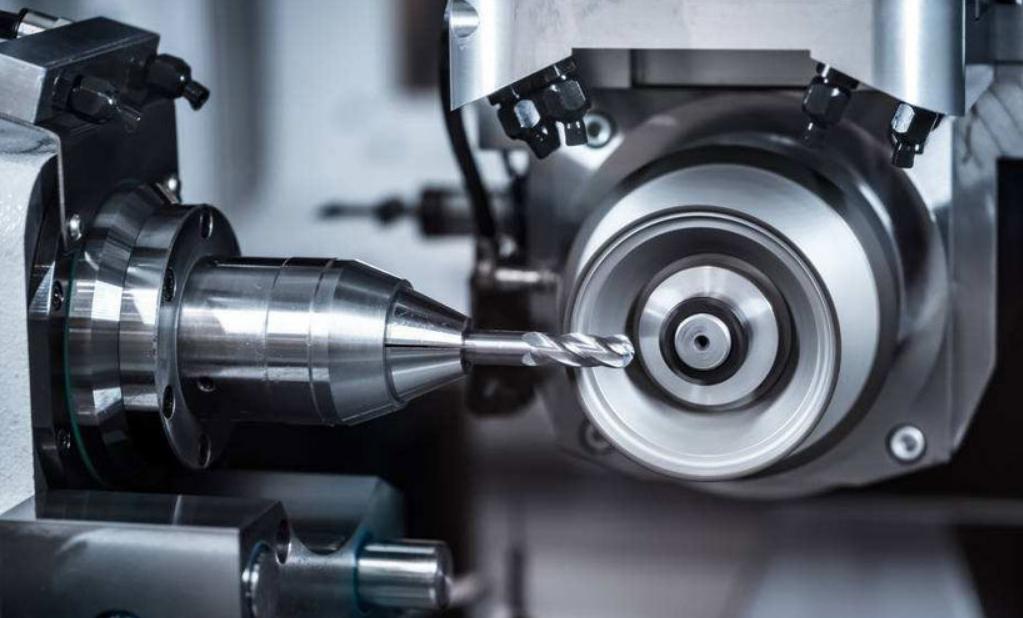

Known for versatility, CNC milling machines shape materials. Equipped with multiple tools, they execute different cutting tasks.

Involving rotation, turning centers shape objects. Employing a tool, they cut while the workpiece spins.

Surface smoothness is crucial. Grinding machines provide a polished, precise finish on metals.

The work of laser cutters defines precision. They slice materials with extreme accuracy, creating intricate designs.

Dealing with metals, plasma cutters slice through thick sheets. Their hot plasma stream leaves a clean, sharp edge.

On the other hand, routers handle softer materials. They carve intricate patterns with detail and precision.

Electrical Discharge Machining (EDM) shapes hard metals. Utilizing electrical discharges, EDM offers super-precise cuts.

Harnessing the power of water, these cutters slice. High-pressure water jets achieve clean, precise cuts, even in thick material.

Named after their origin, Swiss machines are distinct. They allow simultaneous operations, making them time-efficient.

Dealing with sheets, turret punches create holes. They handle complex patterns with speed and precision.

With additional flexibility, 5-Axis machines operate on five planes. They shape complex parts with enhanced precision.

Addressing minuscule parts, micro machines work with accuracy. Their small-scale operations cater to precise machining needs.

Tackling varied tasks, fabrication machines are versatile. They cut, bend, punch, and shape with impressive precision.

CNC drilling machines create precise holes. They deliver speed and accuracy, enhancing productivity.

Lastly, wire bending machines shape wires. Guided by CNC precision, they create intricate, precise wire forms.

Micrometers, a vital tool, let operators measure tiny lengths. They're essential for CNC machining precision.

In CNC machining, inches provide common length measures. Cutting paths are often planned in inches.

Like inches, millimeters provide a standard for distance. Their use guarantees precision in small parts.

Angles in CNC operations get defined in degrees. They guide tool orientation for perfect cuts.

RPM denotes spindle speed. High RPM leads to efficient, precise cutting.

IPM signifies the feed rate. Correct IPM values uphold quality and precision.

Cutting speed gets measured in Surface Feet per Minute. Proper speed ensures smooth, accurate cuts.

Surface roughness, or Ra, indicates the texture of machined parts. Lower Ra values signal smoother, more precise finishes.

G-codes command CNC machine movements. Well-written G-codes secure precise manufacturing outcomes.

M-codes control machine states. Correct use of M-codes contributes to process precision.

This international standard outlines acceptable tolerances in CNC machining. Adhering to DIN ISO 2768 promotes high precision.

In CNC machining, force impacts tool wear and cutting efficiency. Optimal force application upholds precision.

Controlling temperature, measured in degrees Celsius, is critical. It prevents material deformation, ensuring precision.

Pressure regulation supports effective coolant application. Adequate pressure leads to precision by reducing tool wear.

Precision relies on machine accuracy. High-accuracy machines yield more precise parts.

Excessive tool wear compromises precision. Regular inspection minimizes wear, enhancing precision.

Different materials demand different machining parameters. Knowing material properties fosters precision.

Correct cutting speed boosts precision. Too fast or too slow hinders accurate machining.

The feed rate, or IPM, affects part dimensions. Right feed rates ensure precision.

Stable machines produce accurate results. Regular maintenance ensures stability, improving precision.

Proper fixturing secures workpieces. Solid fixtures eliminate unnecessary movements, boosting precision.

Coolants preserve tool life. Adequate coolant application fosters precision by reducing heat and wear.

Skilled operators run machines efficiently. Their expertise leads to precision in CNC machining.

Clean, stable environments enhance precision. Factors like temperature and humidity need controlling.

Accurate G-code and M-code programming is crucial. Precise commands result in precise outcomes.

Precise measurements confirm part dimensions. Advanced techniques, like micrometers, enable high precision.

Regular machine maintenance prevents unexpected downtime. Planned maintenance schedules protect machining precision.

Consistent quality control checks uphold precision. Stringent QC detects errors early, allowing for adjustments.

A crucial tool in precision CNC machining, end mills cut in all directions. End mills come in different shapes for varied uses.

You use drills to bore holes into the workpiece. Different sizes make precision drilling possible.

Taps create threads inside drilled holes. Precision is vital when threading.

For enlarging drilled holes, boring bars prove essential. With careful handling, boring bars ensure precision.

Insert cutters shape your workpiece. Different inserts exist for varied materials.

These tools flatten surfaces. Face mills guarantee precise, flat finishes.

Turning tools shape materials as they rotate. Precision is key in turning operations.

Threading tools shape external threads. Their use demands accuracy and precision.

Reamers perfect drilled holes. For exact hole sizes, reamers are indispensable.

Parting tools cut workpieces into sections. Accuracy during parting determines the end result.

For specific shapes, form tools are critical. CNC machining accuracy rests on form tool precision.

Grooving tools carve grooves into your workpiece. Depth and width precision is paramount here.

Broaches create complex shapes. Each broaching operation demands careful planning.

Fly cutters provide smooth finishes. For flawless surfaces, fly cutters are a must.

Slot cutters carve slots into workpieces. Precision dictates the slot's functionality.

Each tool must match your workpiece material. An improper tool-material match can compromise precision.

Regular tool maintenance extends tool life. Longer tool life equals consistent precision.

Tool selection impacts surface finish. A good finish signals precision in machining.

The shape of the tool influences machining precision. The right tool geometry ensures consistent, precise results.

Coating protects tools, extending their life. A longer-lasting tool maintains precision.

Cutting forces affect tool wear. Controlled forces equal longer tool life and enhanced precision.

Excess heat can warp your workpiece. Effective heat control guarantees precision.

Unwanted vibration causes inaccuracies. Vibration control is a must for precision CNC machining.

Broken tools ruin workpieces. Regular inspection prevents breakages and ensures precision.

Speed and feed rates impact tool life and finish. Balancing these rates ensures precision.

Coolants protect tools and workpieces from heat. The right coolant promises precision in CNC machining.

Overworn tools cause inaccuracies. Regular tool wear checks uphold precision.

Timely tool replacement prevents horizontal machining center errors. A well-followed schedule safeguards precision.

Proper tool storage prevents damage. Careful storage results in better tool performance and precision.

Correct tool handling minimizes breakages. Safe handling practices uphold tool integrity and machining precision.

Now, you grasp the essence of CNC Machining Precision. You have explored its role in CNC operations and the importance of maintaining accuracy. You now know different CNC machines and units of measure. You understand factors that affect precision and ways to manage errors.

You can select tools wisely for CNC machining. Most importantly, you see how these concepts apply to real life. For more, visit CNCYANGSEN to deepen your understanding.