Welcome, seekers of knowledge! The goal of our blog is to answer the question, 'What Can a Milling Machine Do?’ This journey will shed light on the vast abilities of milling machines. The quest will lead us from basic tasks to complex operations. This blog aims to broaden your understanding, taking you closer to these remarkable machines.

A milling machine holds a powerful spot in the world of machines. Unique in function, these devices shape metal. With a spinning cutter, the machine can carve out parts of metal, making 3D shapes. Turning blocks into intricate parts becomes simple.

Milling machines create gears, slots, and grooves, aiding many industries. A milling machine’s precision exceeds human hands, making pieces to a thousandth of an inch. This accuracy breathes life into complex designs and blueprints.

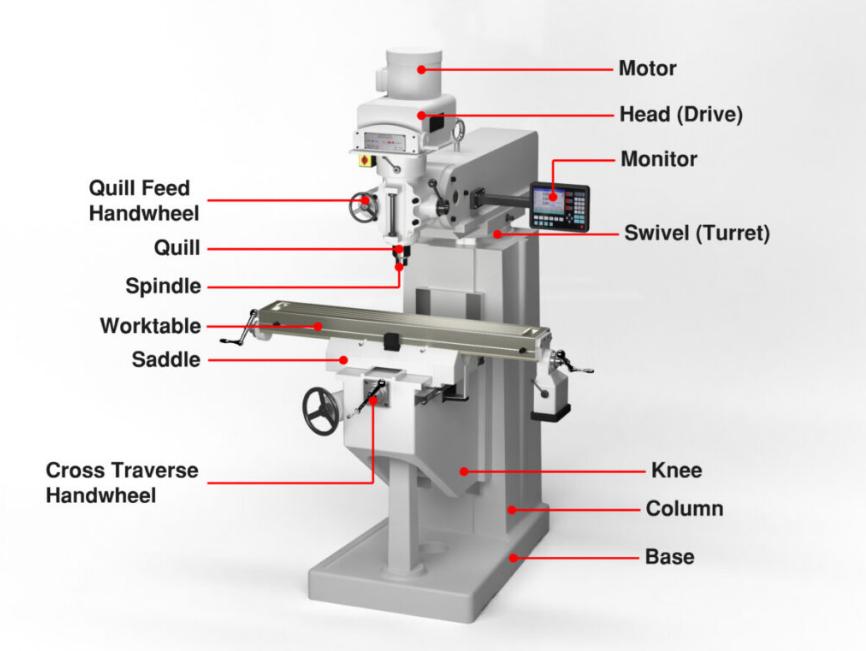

• Base: The base supports the machine, providing stability during operation. It houses coolant, lubricant, and swarf.

• Column: A vertical component, the column holds the machine’s driving motor and gears. It’s the backbone of the milling machine.

• Spindle: The spindle is crucial. Here, the rotating cutter finds its home. The spindle controls cutter speed, and by extension, the precision of cuts.

• Table: Resting on the saddle, the table holds the workpiece. It can move in all directions, giving the machine versatility.

• Knee: The knee supports the saddle and table, allowing vertical adjustments for depth of cut.

• Overarm: The overarm, extending from the column, provides extra support to the spindle, enhancing stability.

Though small, a mini milling machine offers great possibilities. Its compact size means easy storage and portability. Despite its size, this machine boasts accuracy, cutting up to a thousandth of an inch.

With a maximum 2500 RPM speed, it's ideal for light-duty tasks. Hobbyists and DIY enthusiasts often prefer mini milling machines for their convenience.

Unlike the mini version, vertical milling machines are for heavy-duty operations. They stand tall, with a spindle axis oriented vertically.

Known for versatility, these machines can perform various cuts. From simple to complex tasks, their RPM range of 60 to 4200 covers it all. Workpieces move on the vertical axis, creating precise shapes.

• Power Source: Milling machines start with an electrical source. This energy powers the motor, starting the process.

• Drive System: The drive system transfers power to the spindle. By controlling the speed, it helps deliver precise cuts.

• Cutting Process: The machine's spindle starts spinning the cutter. With the workpiece secure, the machine begins its task.

• Material Removal: The milling machine, moving in set directions, starts to shape the workpiece. It removes excess material, revealing the desired shape.

• Coolant Application: To prevent overheating, coolant gets applied during operation. It keeps the cutter and workpiece at optimal temperatures.

• Finished Product: Once the milling machine completes the task, a finished, precise workpiece emerges, ready for use.

• Maintenance: After operation, regular maintenance ensures the machine stays in peak condition. Lubrication and cleaning are key steps.

• Safety Measures: Lastly, observing safety measures, such as using safety guards and eyewear, is essential during operation.

|

Criteria |

Horizontal Milling Machine |

Vertical Milling Machine |

|

Orientation |

Horizontal spindle |

Vertical spindle |

|

Movement |

Parallel to the workpiece |

Perpendicular to the workpiece |

|

Versatility |

Limited versatility |

High versatility |

|

Workpiece |

Large/Heavy |

Small/Medium |

|

Operations |

Slab, Grooving, Gang milling |

Drilling, End milling, Pocket milling |

|

Complexity |

More complex |

Less complex |

|

Maintenance |

Higher |

Lower |

Table on How a Milling Machine Works?

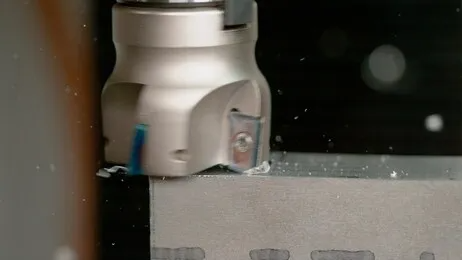

• Cutting and Shaping a Range of Materials: A milling machine is your ideal tool for cutting metal. Imagine a giant scissors slicing through steel.

With sharp, spinning tools called cutters, a milling machine can trim metal down to the perfect size. From metal blocks to thin sheets, the machine makes easy work of metal cutting. Always remember, safety first!

• Creation of Detailed and Precise Parts: With a milling machine, you can make detailed parts like gears. Think of it as molding clay into shapes, but with metal.

The machine can cut curves, straight lines, or complex designs. So, creating things like clock gears or car parts becomes an easy task.

• Surface and Gear Milling: A milling machine is not just for cutting. It can also make surfaces smooth and flat. It's like using sandpaper on wood but with metal.

Additionally, it can create teeth on gears. Like making a comb from a piece of plastic, the machine can shape metal into gears.

• Crafts and Small Project Capabilities: Mini milling machines are great for small tasks. With them, you can create jewelry or small parts.

Imagine making your own silver necklace or toy car parts. These machines are the perfect tools for craft projects or even small manufacturing tasks.

• Perfecting Precision with the Mini Milling Machine: A mini milling machine gives precise results. Like drawing a straight line with a ruler, the machine can cut perfect shapes.

You can adjust the settings to get the right size and shape. It's like having a personal metal workshop in your garage.

√ Conventional milling moves against the workpiece, while climb milling moves with it. Picture two swimmers: one swimming against the current, the other swimming with it. That's the difference between these two milling techniques.

√ In conventional milling, the cutter enters into the workpiece. It's like diving into a pool.

√ In climb milling, the cutter exits the material. Think of it as climbing out of the pool.

√ Climb milling gives a better finish. Imagine sanding wood until it is silky smooth.

√ Conventional milling is more stable. It's like standing on solid ground.

√ Conventional milling is great for heavy cuts. It's like using a chainsaw to cut a thick tree.

√ But, there is more wear and tear on the machine. Think of how your car tires wear out after many miles.

√ The workpiece needs to be clamped down firmly. Imagine securing a box before opening it with a knife.

√ Conventional milling gives rougher finishes. Picture a block of wood after the first sanding.

√ It's best for older machines. Imagine using a typewriter instead of a computer.

Milling machines perform face milling for smooth, flat surfaces. Cutting tools like rotary cutters swiftly remove excess material. Notably, cutter diameters can reach 10 inches.

Vertical, horizontal, or angled orientations enable diverse designs. Resultantly, precise machining of 3D shapes happens efficiently. Hence, face milling is crucial.

In gang milling, numerous milling cutters work together. Each cutter operates on different shafts for simultaneous machining. Typically, the process yields several identical slots, grooves, and profiles. A 0.001 inch precision level is achievable.

Consequently, complex components become simpler to manufacture, illustrating gang milling's importance.

Straddle and side milling enhance manufacturing versatility. With straddle milling, two side milling cutters perform simultaneously on opposite sides. Side milling, conversely, cuts workpieces' sides. Cut depths up to 2 inches are possible.

Notably, creating channels and slots becomes more manageable. Therefore, straddle and side milling offer notable operational advantages.

Computer Numeric Control or CNC greatly elevates milling precision. CNC utilizes digital templates to guide tool paths. Errors reduce to less than 0.005 inches.

Plus, automatic adjustments happen in real-time, making intricate milling tasks simpler. Therefore, CNC contributes significantly to milling accuracy.

Digital Readout (DRO) systems optimize milling accuracy. DROs provide precise measurements, usually within 0.0001 inches. Real-time readouts enhance adjustments and decision-making.

Reduced manual measurements mean less room for errors. Consequently, DRO systems make a critical difference in milling precision.

Metal milling is a key milling machine function. Hard materials like stainless steel require strong carbide or cobalt cutters. Speeds range from 2,000 to 3,000 RPM, depending on metal hardness. Achieving accurate, smooth finishes on metal parts is hence possible.

Plastic milling requires unique care. Overheating can distort or melt plastic. Therefore, low spindle speeds, typically below 1,000 RPM, are necessary. Using sharp tools minimizes heat generation. Thus, plastic milling remains an essential, yet delicate operation.

Wood milling machines shape wooden components efficiently. High spindle speeds, often above 1,000 RPM, ensure clean cuts. Wood types, like pine or oak, dictate tool sharpness and cutting speed. Thus, wood milling plays a critical role in woodworking industries.

• Cleaning Your Milling Machine: Milling machines do lots of hard work. Just like a busy bee, they need cleaning. Wipe off dirt and oil daily. Use a soft cloth, and be gentle.

This care keeps the machine in tip-top shape. Precision work stays sharp with a clean machine. Remember, a clean milling machine is a happy one.

• Regular Lubrication: Milling machines love oil. Oil makes the machine parts move smoothly. Think about a slippery slide at the park. That's what oil does for the machine.

Lubricate regularly for smooth operations. Your milling machine will thank you with precise cuts and no hiccups.

• Sharp Cutting Tools: Keep the cutting tools sharp. Dull tools slow the machine down. Sharp tools cut cleanly and precisely. Think about a sharp kitchen knife slicing a tomato. That's how your milling machine should work.

• Regular Inspections: Inspect the milling machine often. Look at all the parts carefully. Check belts for wear and tear. Are all bolts tight? Regular checks keep the machine running smoothly. It's like a doctor check-up for your machine.

• Professional Servicing: Sometimes, a milling machine needs a pro. Just like you go to the dentist, machines need professional check-ups too. Regular service keeps the machine running at its best. Make it a habit. Your milling machine will thank you.

• Proper Training: Running a milling machine needs skill. Get the right training before using it. It's like learning to ride a bike. Once you know, you can do amazing things.

A trained operator keeps the machine in good shape. Remember, a good machine needs a good operator.

• Metal Fabrication: Milling machines play a crucial role in metal fabrication. They shape metal parts with perfect precision. High accuracy makes them a must-have in industries like automobile and aerospace.

• Creating Complex Shapes: These tools can create complex shapes. CNC milling machines can handle circles, slots, gear teeth, and even 3D designs. With the right setup, anything is possible.

• Rapid Prototyping: Milling machines facilitate rapid prototyping. They enable fast and accurate production of physical models from computer-aided design data.

• Medical Industry: In the medical industry, milling machines prove vital. They help produce precision components such as dental crowns and orthopedic implants.

• Woodworking: In the realm of woodworking, milling machines reign supreme. These devices enable craftsmen to shape, cut, and finish wood with unrivaled precision.

• Engraving: For detailed engraving work, engraving and milling machines are indispensable. They deliver intricate designs on materials, setting the standard for quality engraving.

• Plastic Molding: In the plastic industry, milling machines shape and cut precision molds. The machines offer a high level of accuracy, crucial for manufacturing plastic products.

• Educational Purposes: Lastly, milling machines help in teaching engineering principles. Students learn about machining processes firsthand, enriching their understanding.

• Accuracy: Milling machines stand for precision. Accuracy within a few micrometers ensures quality standards. With a milling machine, every cut counts.

• Consistency: The consistency of milling machines sets them apart. They can reproduce identical parts, ensuring standards in mass production environments.

• Versatility: Milling machines offer unmatched versatility. They can work on diverse materials. This adaptability makes them a standard in multiple industries.

• Efficiency: Milling machines deliver efficiency. They cut down production times, raising industry standards for productivity.

• Durability: The durability of milling machines underscores quality. These tools withstand intense operations, ensuring long-term performance.

• Safety: Safety matters in milling. High-quality milling machines feature protective measures. These safeguards protect operators from potential accidents.

• Customization: Milling machines support customization. They adhere to specific industry standards by shaping materials to exact measurements.

• Regulatory Compliance: Quality milling machines comply with regulatory norms. This compliance ensures products meet the required industry and safety standards.

• Time-saving: Milling machines cut down on production time. Their swift operations enhance overall productivity.

• Low Maintenance: High-quality milling machines require less upkeep. This low maintenance contributes to higher productivity.

• Energy Efficiency: Milling machines save energy. They consume less power compared to other tools, boosting productivity while reducing costs.

• Scalability: Milling machines offer scalability. They handle large-scale production with ease, making them perfect for boosting productivity.

• Reduced Labor: Milling machines reduce manual labor. This reduction increases output while saving on labor costs.

• High Output: The high output of milling machines enhances productivity. They can manufacture hundreds, even thousands, of parts each day.

• Automation: Modern milling machines support automation. Automated milling processes increase efficiency and productivity.

• Waste Reduction: Milling machines minimize waste. By using materials effectively, they increase productivity and reduce costs.

After this deep dive into 'what can a milling machine do?’ you surely appreciate their power and versatility. From shaping materials to intricate parts creation, the capabilities seem limitless.

As you continue exploring, remember, every discovery begins with a single step. Visit CNCYANGSEN and start your milling adventure today.