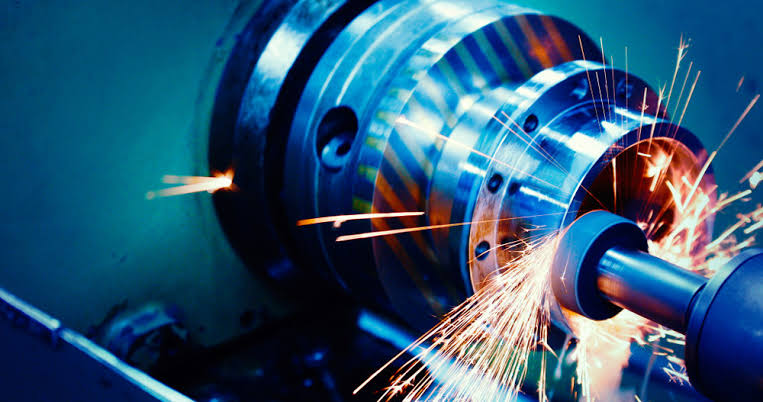

Are you looking to improve your manufacturing process and produce parts faster and with minimum waste? With technological advancements, mankind has developed sophisticated machines that can produce intricate and complex parts with high precision. The CNC vertical machining center is one such machine that has revolutionized the manufacturing industry. Its ability to produce precise and complex parts has made it a game-changer in the industry.

CNC centers are advanced machines used in the production of parts and components. These produced parts are used by various industries such as aerospace, automotive, medical, and energy. These machines operate on computer numerical control (CNC) technology, which enables them to perform various machining operations with great accuracy and consistency.

Vertical machine centers use cutting tools to remove material from a workpiece. First, the design of the part is created using CAD software. The machine is then programmed with the cutting path and other parameters. Once the workpiece is clamped in its position, the machine uses its cutting tools to remove material in accordance with the programmed instructions. This continues until the desired shape is achieved. Finally, the finished part is removed from the machine.

Now that you know what CNC is and how it works, it's time to explore the top 10 industries that benefit from vertical CNC machining center. These industries rely on CNC machining to produce high-quality parts and components quickly and more efficiently than traditional manufacturing methods.

The Aerospace Industry deals with the making of airplanes and spacecraft, which are used to travel long distances and carry people and goods. Precision is really important in this industry because every part of the airplane or spacecraft needs to be made accurately and carefully. This ensures that the machine functions correctly and doesn't put people in danger.

A few examples of things made using VMCs in the Aerospace Industry are engine parts, landing gear components, and space shuttle parts. These parts need to be strong and light so they can handle the stress of flying and save on fuel costs. Without VMCs and precision manufacturing, making these parts would be a lot harder and more dangerous.

Overall, precision is really important in the Aerospace Industry, and VMCs help to make sure that everything is made accurately and efficiently. This is important because it focuses on keeping people safe and makes sure that airplanes and spacecraft work properly.

Efficiency and accuracy are critical in the Construction Industry because the structures being built need to be safe, reliable, and long-lasting. To achieve this, manufacturers need to produce parts that fit together perfectly and work well. CNC machining centers are used to help make this possible by producing construction components quickly and accurately.

Some examples of construction parts made using CNC machining centers include steel beams, support brackets, and anchor bolts. These parts are critical to the stability and safety of buildings and other structures. Other parts, such as window frames, door frames, and decorative metalwork, can also be produced using this technology.

With CNC machines, construction projects can be completed more efficiently while ensuring that the final result is safe, reliable, and long-lasting.

Efficiency and accuracy are crucial in the Automotive Industry because the production of cars and other vehicles requires precision and consistency. Car manufacturers need to produce parts that fit together perfectly and work well in order to make a high-quality product. That's where CNC machining centers come in - they are used to make car parts quickly and accurately.

CNC machining centers use computer programs to guide cutting tools and shape metal into parts for cars. This process is known as CNC machining. By using this technology, manufacturers can make identical parts with extreme precision and consistency, reducing the chance of errors or defects. It also allows to create complex shapes that are hard to achieve with traditional machining methods.

Some examples of automotive parts made using CNC machining centers include engine blocks, pistons, and gears. These parts are critical to the function of a vehicle and require precise measurements and tolerances. Other parts, such as brake rotors, suspension components, and transmission housings, are also made using this technology.

Precision and reliability are essential in the Medical Industry because the equipment used needs to be accurate and dependable to ensure patient safety and successful medical procedures. CNC vertical machining centers are used to help make this possible by producing medical components quickly and accurately.

Medical equipment made using CNC machining centers includes items such as surgical instruments, implants, and medical device components. These parts are critical to the success of medical procedures and require precise measurements and tolerances. Other parts, such as ventilator parts, oxygen concentrator components, and MRI machine components, can also be produced using this technology.

Overall, CNC machining centers have revolutionized the production process in the Medical Industry. By increasing efficiency and accuracy, they allow manufacturers to produce high-quality parts quickly and cost-effectively. This means that medical professionals can have access to the best possible equipment, and patients can receive the safest and most effective treatments. CNC machining centers play a crucial role in ensuring the success and reliability of medical equipment and procedures. Vertical Machining Centers YSV-855-5X. Used in the medical industry.

The Defense Industry demands the highest levels of precision and accuracy in manufacturing defense equipment. The equipment must be durable, reliable, and perform with high precision in a variety of environments. Vertical machine centers are one of the technologies that help meet these demands by producing defense components with exceptional precision and speed.

Defense equipment made using CNC machining centers includes items such as missile components, guidance systems, and armored vehicle parts. These parts require precise measurements and tolerances, and CNC machining centers are capable of producing these parts to exact specifications. Other parts, such as gun barrels, muzzle brakes, and grenade launchers, can also be produced using this technology.

CNC machining centers have revolutionized the production process in the Defense Industry. By increasing efficiency and accuracy, they allow manufacturers to produce high-quality parts quickly and cost-effectively. This means that military personnel can have access to the best possible equipment, and defense operations can be carried out with the highest levels of precision and accuracy. CNC machining centers play a crucial role in ensuring the success and reliability of defense equipment, which is essential to maintaining the safety and security of nations.

Precision is critical in the Energy Industry because the equipment used in this industry must perform accurately and reliably under harsh operating conditions. CNC machining centers are a technology that helps meet these demands by producing energy equipment with exceptional precision and speed.

The Energy Industry uses CNC machining centers to manufacture parts for a wide range of equipment, including turbines, generators, pumps, and compressors. These parts require precise measurements and tolerances, and CNC machining centers are capable of producing them to exact specifications. For example, CNC machining centers can create turbine blades that need to be precisely engineered to minimize vibrations and maximize efficiency.

Another example of energy equipment produced using CNC machining centers is pressure vessels. Pressure vessels are essential for storing and transporting gases and liquids safely. These vessels require precise machining and strict adherence to safety regulations, which CNC machining centers can help achieve.

CNC machining centers have revolutionized the production process in the Energy Industry. By increasing efficiency and accuracy, they allow manufacturers to produce high-quality parts quickly and cost-effectively. This means that energy equipment can be built with the highest levels of precision, which ultimately leads to more reliable and efficient energy production. CNC machining centers play a crucial role in ensuring the success and sustainability of the Energy Industry, which is essential to meeting the world's energy needs.

The electronics industry is constantly evolving and requires high-precision manufacturing to meet the demands of the market. Vertical machining are used to manufacture electronic components with high accuracy and efficiency.

One way in which CNC machining centers benefit the electronics industry is by providing the ability to produce intricate parts with a high level of precision. This is critical in the production of small electronic parts that are required for devices such as smartphones, laptops, and other electronic gadgets. CNC machining centers can produce these parts quickly and accurately, which is essential for meeting the production demands of the electronics industry.

Another advantage of using vertical machining centers in the electronics industry is that they allow for the production of custom parts. This means that the design and manufacturing process can be used to meet the special requirements of a product. This level of customization is essential in the electronics industry, where products are constantly changing and evolving.

Examples of electronic components that are made using CNC vertical machining centers include microchips, circuit boards, and connectors. These parts require a high degree of accuracy to function correctly, and CNC machining centers are well-suited to meet these requirements.

The tool and die industry plays a crucial role in the manufacturing sector by producing tools, dies, and molds that are used in the production of a wide range of products. The precision and accuracy required in this industry cannot be overstated, as even the smallest error can impact the final product. That is why CNC Vertical Machining Centers are widely used in this industry.

These machines can quickly cut and shape different materials like steel, aluminum, and plastics, allowing for fast turnaround times and high production rates. Moreover, they can perform a range of operations, including drilling, milling, and tapping, all in one setup.

Some of the tool and die components made using CNC Vertical Machining Centers include cutting and forming tools, molds, dies, and fixtures. These are used by different industries, from the automotive, mold, and aerospace industries to the medical and electronics industries.

CNC vertical machining centers have revolutionized the mold-making industry by making the process faster, more precise, and more efficient. These machines can produce molds with complex geometries that would be nearly unimaginable to create using traditional methods.

Some examples of molds that can be made using CNC vertical machining centers include injection molds, blow molds, and compression molds. These are used for various items, from toys and household items to automotive and aerospace components. By using CNC vertical machining centers, mold makers can produce these molds more quickly, accurately, and cost-effectively than ever before.

CNC Vertical Machining Centers have revolutionized the job shop industry by allowing for more precise and efficient production of custom components. These machines offer a range of benefits, such as faster production time, improved accuracy, and decreased waste, which make them an ideal choice for job shops.

Job shops can benefit from CNC Vertical Machining Centers for producing custom components, such as engine parts, brackets, and housings, among others. These machines can handle plastics, metals, and composites, allowing job shops to offer their customers a wider range of services.

A CNC vertical machining center (VMC) is a powerful machine tool capable of performing various machining operations with high accuracy and precision. Several factors must be considered when choosing a VMC to ensure the machine suits the required applications and meets the desired performance specifications.

One of the most critical factors to consider when choosing a VMC is the spindle speed and power. The spindle speed determines the maximum cutting speed of the machine, while the spindle power influences the cutting force that the machine can apply. The cutting speed and force are essential for achieving high-quality surface finish and material removal rates, making choosing a VMC with suitable spindle speed and power for the intended application critical.

The size of the machine should be determined by the size of the workpieces that will be machined. The machine's capacity, which includes the maximum weight and size of the workpiece, should also be considered to ensure the machine can handle the intended workload.

Another critical factor to consider is the type of control system used in the VMC. The control system determines the machine's accuracy, speed, and versatility and can significantly impact the machine's performance. Advanced control systems with multi-axis control and adaptive machining capabilities can increase the machine's efficiency and precision.

The tool changer capacity determines the number of tools that can be loaded onto the machine, impacting the machine's versatility and productivity. The machine's rigidity influences its accuracy and precision, making choosing a machine with sufficient rigidity critical. Support and service availability is also essential to ensure the machine can be serviced and maintained properly.

Choosing a CNC vertical machining center requires careful consideration of several critical factors. By considering these factors, selecting a VMC that meets the desired performance specifications and is suitable for the intended application is possible.

The future of CNC vertical machining centers (VMCs) looks promising, with numerous advancements and developments paving the way for new applications and possibilities. One of the most significant trends in the VMC industry is the integration of automation and robotics, which can significantly increase productivity and reduce costs.

Another development area uses advanced sensors and analytics to monitor and optimize machine performance. These sensors can provide real-time data on machine conditions, enabling operators to identify potential issues before they occur, reduce downtime, and optimize cutting parameters for maximum efficiency.

The integration of additive manufacturing and subtractive machining is also a growing trend, allowing for the production of complex geometries and shapes that were previously impossible. Combining these technologies can reduce waste, increase material utilization, and improve manufacturing.

Additionally, advancements in software and control systems are enabling VMCs to perform more complex and precise operations, such as 5-axis machining and adaptive machining. These capabilities can increase the machine's versatility and expand the range of applications that can be performed.Overall, the future of CNC vertical machining centers is exciting, with new technologies and capabilities emerging regularly. As the industry continues to evolve, the possibilities for VMC applications will only expand, providing greater opportunities for innovation, productivity, and efficiency in the manufacturing sector.

CNC vertical machining centers have proven to be essential in various industries, including automotive, medical, defense, energy, electronics, tool and die, mold making, and job shops. The precision, accuracy, and efficiency provided by CNC machining centers have improved manufacturing processes, resulting in high-quality products and reduced production costs.

Companies looking to implement CNC vertical machining centers should consider the requirements of their business and choose a reliable and efficient machine tool distributor. They should also invest in proper training for their employees and prioritize maintenance and regular inspections to ensure optimal performance of their CNC machining centers.

As a distributor of CNC machine, we understand the importance of providing efficient, accurate, and reliable solutions to our customers. Contact us today to learn about CNC vertical machining centers and how they can benefit your manufacturing processes.