Having a CNC machine sure feels great, especially since you may now create any products or parts using different types

of materials. In order to perform properly, you need to take a proper look inside it to understand its essential parts, especially the spindle.

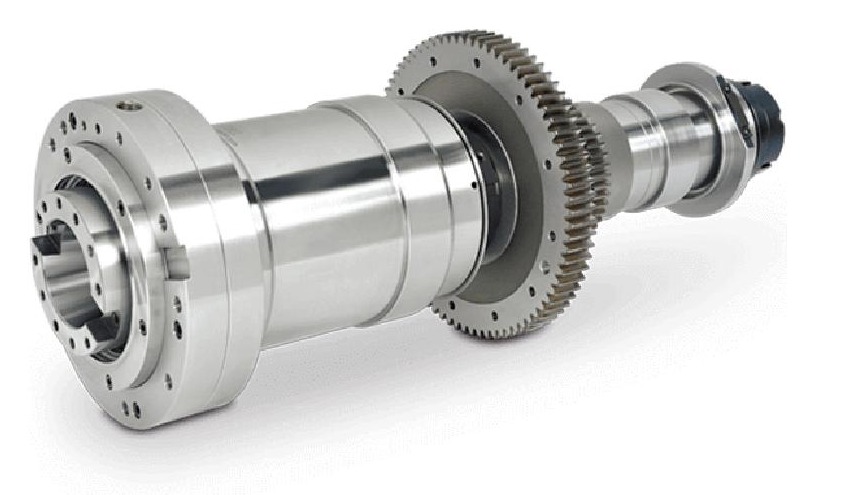

The spindle is the shaft located at the center of rotating machine tools. There are various kinds of spindles you can find in the market, and each comes with different purposes and functionalities. These spindles are crucial in CNC machines as they can maintain the efficient and fast process as precise as possible.

Our team at Yangsen wants to help customers to understand the spindle better. Thus, in this article, you can find a lot of information about CNC spindles, starting from understanding what it is, knowing how it works, and finally listing the different types of spindles in CNC machines.

Without further ado, let us start by understanding what a CNC spindle actually is.

As mentioned above, the spindle is the shaft placed at the center of the machine’s rotating axis. The spindle is actually not only the shaft itself but also the other components installed in it.

It’s a really important part of a CNC machine as it determines how precise and accurate a CNC machine can be. These spindles will rotate on the axis that’s “controlled” by using the CNC controller.

Usually, a machine consists of more than one spindle, with the big one, called the main spindle. As there are different needs to be applied to various industries, there are various kinds of spindles available in the market, and each comes with different specifications and even structures.

The spindles in CNC machines are generally used to work on various kinds of materials, like wood or metal in order to create a certain product in the most precise way possible. Many would refer spindle as the material-removal component.

As materials do have different characters and densities, various spindles can be used to cut into those materials. So yes, you can’t just have one spindle and expect it to work on anything. Thus, if you want to create products more precisely, it’s better to invest to those high-speed spindles that may work miraculously.

The way it works is pretty simple, actually. When looking into a spindle shaft, you’re not only looking at the shell, as there are so many components inside it. The shafts hold those components together so they don’t simply break off when the rotation happens.

Generally, the structure is as simple as this: a shaft then added with motor, plus a taper. The taper here functions as a controller for various tools. When the machine is turned on, the spindle then rotates on the axis. The axis movement is set by either a computer command or a human.

As the machine rotates the tool, the spindle rotates so fast, reaching around 8,000 rpm to 15,000 rpm to slice, cut, or refine.

The way the spindle rotates may differ depending on what kind of spindle type is used. If you use a motorized spindle, then it’s pretty clear that the internal motor is what drives it. For the non-motorized types, the spindle may be “powered” by using a belt, gear, or other means.

The machine’s precision is highly determined by the spindle. If you use a broken spindle, the result will be terrible. In order to do a certain machining task, a spindle should meet the required speed, torque, and accuracy.

CNC spindle generally has a rotating shaft, motor (external or internal), and housing to nicely fit all of them. However, there’s a lot more than just those three main components if you look closer. Check each of them below:

As the name implies, these are the bearings used to support the spindle. As you might know, bearings are usually used for various machine tools that have a high precision level. As the spindle needs to be precise, these bearings are installed.

The spindle bearings usually have narrow tolerance, making them suitable for any kinds of work that requires a higher degree of precision.

The next important spindle part is, undoubtedly, the shaft. Many people even consider the shaft as the spindle as it’s the one that spins. When the machine works, the shaft will rotate while holding all the tools within, including the spindle itself.

So, you can refer to the shaft as the part that holds the piece together, while offering great support for the rotary drive.

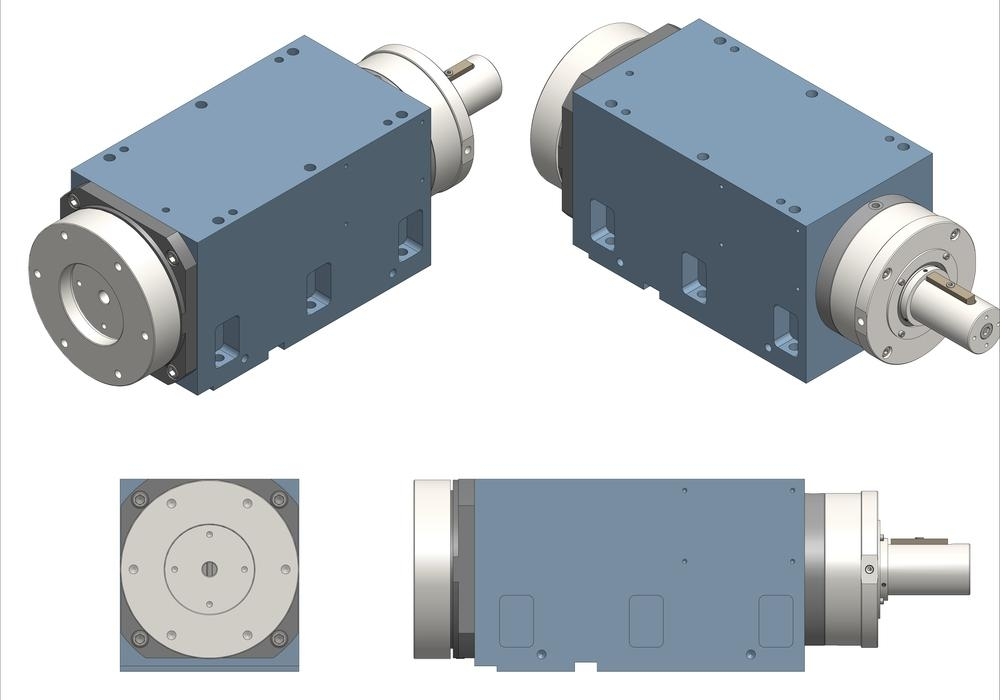

If the shaft holds the smaller components together, where does it get stored? The answer will be in the spindle housing. It’s the place where you can put the spindle shaft nicely, along with all the other functional components.

The spindle ring encoder, which is magnetic, is usually applied directly to the CNC spindle. It’s used generally for automation control. The spindle encoder works by sending the synchronous pulses to the CNC system, which is then directly sent to the motor to do the rotation motion.

These are not the same as the rings for the encoder. You can easily find these types of rings in various equipment, including connectors, pumps, or valves. These rings offer great protection to prevent any leaks by covering the gaps that are often found between the parts. The O-rings are versatile solutions to prevent the common, and most troubling issues in machine engineering.

To completely secure the spindle in the CNC machine, a spindle taper is needed. It usually comes in as a male connector that fits the female socket, which generally matches the taper. Taper is actually one of the most common components founds in most machine tools. Some power tools spindles even use to attach some tools together, for example, the chuck in drill presses.

Now let’s talk about the actual main topic here, the different types of spindles. When it comes to spindles, a lot of time, we’re talking about dealing with either a motorized spindle or a non-motorized spindle. The non-motorized spindles come in different forms, like block, gear-driven, belt-driven, and in-line spindles.

Differentiating between the two types of spindles often sparks misconception because many people thought that a spindle that’s powered by AC/DC motor.

The thing is, that’s not entirely the case. One character that’s pretty apparent from the motorized spindle is the motor that’s actually placed inside the housing, not outside. As for the non-motorized spindles, there are a few types you can find.

The first one is the motorized spindle, the one that’s commonly found and used by most engineers today. As it’s motorized, the motor is placed inside. It has the highest speed of 60,000 rpm, which is amazing. And thanks to its capabilities, the motorized spindle is generally versatile for various kinds of uses.

However, as the rotation is quicker, you may expect some overheating. Thus, the housing should be really taken care of and optimized to maintain the torque and power.

Now, we’ll mention the non-motorized types of spindles, starting from the first one, the block spindle.

One of the basic spindle types in the industry. Block spindle really up to its name as it’s really blocky in form. Many would consider it to be old tech, and that’s probably the reason why you wouldn’t find many of them anymore.

However, these are upgradable, and a lot of professionals love them due to their simplicity.

The next one on the list is the gear-driven spindle. The unit is known to be the most versatile, and it can engage in various tasks. Users are able to have more control of it. Gear-driven spindles are also known to have a great metal removal rate in different torque values.

Due to its capabilities, so many people are using it, making it one of the most popular spindle types in the industry.

Another popular choice is a belt-driven spindle. As you can see from its name, this unit is powered up using the belt that’s located between the two pulleys that are powered by a motor that is installed vertically above the spindle.

People love it for its simplicity and affordability.

The inline spindles, better known as direct drive spindles, are the units created by combining the spindle and the motor directly in an inline. The unit typically has two shafts, the motor and the spindle shaft.

If you take the pulley of the belt-driven spindle and put a servo motor behind it, you basically have the inline spindle.

Many people in the business are always looking for CNC spindles that may perform quickly. And yes, they’re not completely wrong. The highest-speed CNC spindles may offer various benefits, especially in terms of versatility, accuracy, and cost.

The high-speed spindles are some of the ones we can consider the most accurate. With proper adjustment, these spindles may have greater durability for temperature changes.

As the high-speed spindles are precise in nature, you may also have great benefits in terms of cost. Using them can be cost-effective as you don’t need to have excessive materials to work on.

CNC spindles offer great uses for so many industries. It includes the tools used in automotive, manufacturing, or even agriculture. What’s great is that the spindles may work on different kinds of materials as well, making the production process a lot more effective.

However, there are some spindle types that may be suitable for specific kinds of projects. So, if you want to seek the best spindle type to support your business, feel free to contact our expert team at Yangsen!

We know that it might be really confusing for beginners to understand what a spindle actually is, or even know the aspects to think of when getting one.

Well, in the explanation above, we’ve mentioned that the spindle is a critical part, especially in CNC machines. Without it, creating high-precision creations is nearly impossible.

So, when choosing a CNC spindle, you need to think about several factors beforehand to avoid spending too much money on something that may not feed your business needs. These factors are the CNC machine you have, its application, and also the types of materials.

Not all spindle types may work on all kinds of CNC machines. For example, you can’t just use a spindle shaft for a motorized spindle to block the spindle. Other than it looks really awkward, it won’t function as properly as well. So, picking a suitable spindle for your CNC machine is surely a must.

If you need to work on a certain material, make sure that the spindle is actually capable. Again, not all spindles may be used on all materials. So, check the specification first, and see some videos of it if you have to for more proof.

Now, if you’re looking for a CNC machine that may support your business greatly, you also need to think about the spindle. Spindles are made to work on different kinds of materials. But, you can just use one type of spindle to deal with them all.

The type of CNC spindle you want to use highly depends on the materials you’re working with. So, if you want to find the most suitable one, feel free to contact our team at Yangsen!

Maintenance is very important if you want to get the maximum potential of your CNC machine. Why? Because most problems in the spindles are generally coming from human error. Thus, it’s really important to find specialists that really understand how it works and deal with the problem to find the best solutions. And you can find just what you need at Yangsen.

Yangsen offers quality CNC machines for all kinds of industries. For more than 20 years, Yangsen is always available to give the best service to customers and is willing to give 100% care to communicate with them to deal with their problems.