Welcome to the incredible universe of 3-axis CNC machines, where accuracy and innovation unite! If you're eager to explore the thrilling world of CNC manufacturing, you've landed at the perfect spot. In this comprehensive guide, we'll explore the ins and outs of these versatile machines, helping you make informed decisions and optimize your production process.

But first, let's start with the basics. A 3-axis CNC machine is a computer-controlled cutting and shaping tool that precisely manipulates raw materials. These machines have revolutionized industries worldwide, offering unparalleled accuracy and efficiency in manufacturing. From crafting intricate components to carving out masterpieces, the possibilities are endless for CNC machining.

In the following sections, we'll delve deeper into the mechanics of these incredible machines, discussing their various components and how they work together in harmony. Additionally, we'll look at some inspiring examples of 3-axis CNC machines in action, showcasing their incredible capabilities and advantages over traditional manufacturing methods.

As we journey through this ultimate guide, we hope to inform and inspire you with the limitless potential of 3-axis CNC machines. So, buckle up and prepare to embark on an adventure into the fascinating world of CNC machining, where creativity meets cutting-edge technology.

In the dynamic manufacturing world, the 3-axis CNC machine has emerged as a game-changer, combining precision and efficiency to create intricate designs easily. But what exactly is a 3-axis CNC machine, and how does it differ from other CNC machines? Let's dive in and explore the concept further.

A 3-axis CNC machine operates on the principles of computer numerical control (CNC) technology, which uses computer software to control the action of cutting tools and workpieces. This advanced technology allows for precise, automated manipulation of raw materials, resulting in high-quality finished products.

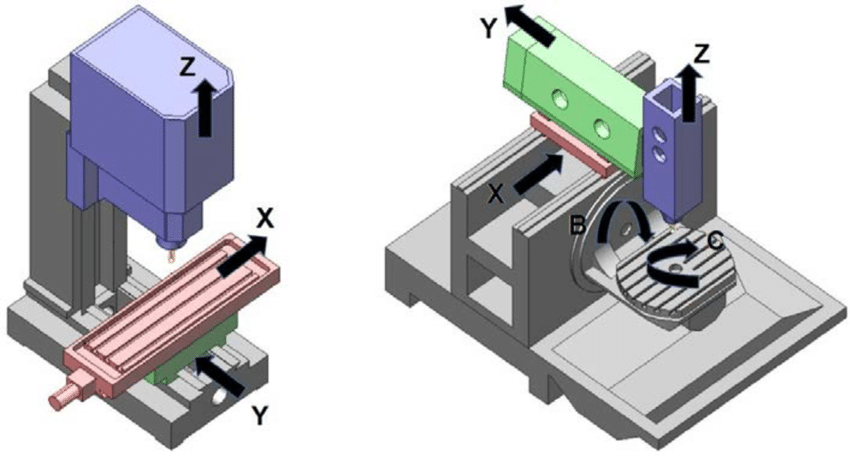

The term "3-axis" refers to the three linear axes (X, Y, and Z) along which the cutting tool can move. In other words, a 3-axis CNC machine can manipulate the workpiece in three directions, providing considerable flexibility and versatility in shaping and cutting operations. This capability makes them popular across various industries, including aerospace, automotive, and consumer products.

While 3-axis CNC machines offer impressive functionality, it's essential to understand that other types of CNC machines exist, such as 4-axis, 5-axis, and even 6-axis machines. These machines provide additional axes of movement, allowing for even more complex and intricate designs. However, they also come with a steeper learning curve and higher costs, making them less suitable for beginners or smaller-scale operations.

3-axis CNC milling is a popular machining process that utilizes 3-axis CNC machines to remove material from a workpiece, creating intricate shapes and designs. The cutting instrument travels along the X, Y, and Z directions while the workpiece stays still. This method enables accurate and effective elimination of material, using brief phrases and straightforward language.

3-axis CNC machine applications are vast and diverse, spanning numerous industries. Some key applications include creating complex geometries in automotive parts, crafting complex aerospace components, and producing intricate moulds for consumer products. With its remarkable precision and versatility, 3-axis CNC milling is pivotal in modern manufacturing, driving innovation and efficiency across various sectors.

In the world of manufacturing, efficiency and precision are paramount. One way to achieve both is by using a 3-axis CNC machine. These versatile machines offer numerous benefits that can create all the difference in your production process. This section explores the advantages of using a 3-axis CNC machine, showcasing how they can elevate your manufacturing capabilities.

One of the most notable 3-axis CNC machine benefits is the significant boost in efficiency and productivity. With their ability to execute complex operations with remarkable speed and accuracy, these machines allow you to complete projects faster than ever. Consequently, you can produce more units in less time, ultimately increasing profits.

Another key advantage of using a 3-axis CNC machine is its unparalleled precision. These machines operate with computer-guided controls, ensuring that each cut, drill, or mill is accurately executed. This level of consistency means that every product manufactured will meet the highest quality standards, reducing the likelihood of defects and waste.

3-axis CNC machines' adaptability is a key reason why they are a top choice for manufacturers.

These machines can handle various materials, including metal, plastic, and wood, making them suitable for various industries. Moreover, their flexibility allows easy reprogramming, enabling you to switch between different projects without requiring extensive setup time.

By automating many tasks traditionally performed by human operators, 3-axis CNC machines can significantly reduce labour costs. With fewer manual operations, you can allocate resources to other business areas, such as sales and marketing, to further grow your company.

Using 3-Axis CNC machines can help create a safer work environment. Automated operation of the machines means there is less risk of accidents caused by people, keeping workers safe and minimizing time off due to workplace injuries. It's an essential step in providing a secure workspace for your staff.

When considering an investment in manufacturing equipment, evaluating its performance capabilities and cost-effectiveness is crucial. This is particularly true for 3-axis CNC machines, which offer numerous benefits but can come with a significant price tag. In this section, we'll assess the 3-axis CNC machine price and discuss factors that influence it, ultimately helping you determine whether it's a worthy investment for your business.

When evaluating the cost-effectiveness of 3-axis CNC machines, it's essential to consider the long-term value they bring to your operations. Although the initial investment may be high, these machines can significantly reduce labour costs, minimize waste, and increase productivity – all of which contribute to a healthier bottom line over time.

Several factors can impact the 3-axis CNC machine price, so understanding what drives these costs is essential. Some of these factors include:

● Machine size and capabilities: Larger machines with more advanced features are more expensive than smaller, more basic models.

● Quality and brand: Well-known brands with a reputation for quality and reliability often command higher prices.

● Software and control systems: More sophisticated software and control systems can add to the overall cost of the machine.

● Accessories and tooling: Additional components, such as work-holding devices or specialized cutting tools, can increase the required investment.

Selecting the suitable 3-axis CNC machine for your manufacturing needs can be daunting, given the vast array of options available in the market. However, finding the perfect fit is essential to maximizing the benefits of this technology. This section provides a 3-axis CNC machine buying guide to help you choose the best 3-axis CNC machine for your specific requirements.

To make a decision when selecting a 3-axis CNC machine, consider the following factors:

● Determine your requirements: Before diving into machine specifications, take the time to know your needs. Consider the materials you'll be working with, the complexity of the parts you'll be producing, and the level of precision required.

● Machine size and workspace: Assess the available space in your facility to determine the maximum size of the machine you can accommodate. Remember that larger machines typically offer more excellent capabilities but may come at a higher cost.

● Spindle speed and power: The spindle speed and power of a 3-axis CNC machine directly impact its cutting capabilities. Higher spindle speeds enable faster cutting, while more powerful spindles can handle more demanding materials. Choose a machine with the appropriate spindle specifications for your needs.

● Tool capacity and tool-changing system: Consider the number of tools the machine can hold and the efficiency of its tool-changing system. A larger tool capacity and a faster tool changer can significantly boost productivity.

● Software and control system: Ensure that the machine's software and control system is user-friendly, compatible with your existing systems, and capable of handling your production requirements.

● Budget and cost-effectiveness: Set a budget for your 3-axis CNC machine purchase and weigh its capabilities against its cost. Remember to factor in ongoing expenses such as maintenance, tooling, and software updates.

● Customer support and warranty: Choose a reputable manufacturer with reliable customer support and a comprehensive warranty. This will ensure you have access to assistance when needed and protect your investment in the long run.

Investing in a 3-axis CNC machine can be a game-changer for many small businesses. However, finding affordable 3-axis CNC machines that suit your needs can be challenging. This section discusses some options and considerations for small businesses looking to benefit from this technology.

When searching for an affordable 3-axis CNC machine for small businesses, consider the following:

● Used machines: Purchasing a used machine from a reliable source can save you significant money while still providing exceptional performance.

● Compact models: Smaller, more compact machines are often less expensive than larger ones. These models can still offer impressive capabilities, making them suitable for small-scale production.

● Financing options: Explore financing options offered by manufacturers or third-party lenders to make the investment more manageable.

When investing in a 3-axis CNC machine, it's essential to understand the key features that contribute to its performance and the software needed for efficient operation. This section covers the most critical 3-axis CNC machine features and discusses the essential software for 3-axis CNC machine operation.

Features to consider when evaluating a 3-axis CNC machine include the following:

● Spindle speed and power: Higher spindle speeds enable faster cutting, while more powerful spindles allow the machine to handle more challenging materials effectively.

● Tool capacity and tool-changing system: A larger tool capacity and a quick tool-changing system can boost productivity by minimizing downtime during tool changes.

● Axis travel and work envelope: The machine's axis travel and work envelope determine the maximum size of the parts it can produce. Ensure that these specifications align with your production requirements.

● Rigidity and stability: A rigid and stable machine frame helps maintain precision and accuracy during machining operations, ensuring consistently high-quality results.

● Coolant and chip management systems: Efficient coolant and chip management systems are crucial for maintaining optimal cutting conditions, prolonging tool life, and minimizing cleanup time.

The essential software for 3-axis CNC machine operation typically consists of the following:

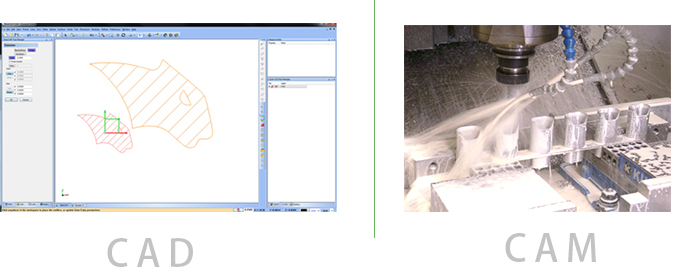

● Computer-aided design (CAD) software: CAD software is used to create 3D models of the parts you plan to manufacture.

● Computer-aided manufacturing (CAM) software: CAM software converts the CAD model into a set of machine-readable instructions called G-code, which guides the CNC machine during the machining process.

● Machine control software: This software interprets the G-code and controls the CNC machine's movements, ensuring accurate and efficient operation.

Proper maintenance and troubleshooting are essential to ensure the longevity and optimal performance of your 3-axis CNC machine. In this section, we'll provide tips for maintaining your 3-axis CNC machine and guidance on troubleshooting common 3-axis CNC machine issues.

Regular maintenance is crucial for keeping your 3-axis CNC machine in top working condition. Here are some key maintenance tips to follow:

● Clean the machine: Regularly clean all exposed surfaces, removing chips, dust, and debris to prevent buildup that could interfere with the machine's operation.

● Lubricate moving parts: Follow the manufacturer's recommendations for lubricating the machine's moving parts, including the spindle, ball screws, and linear guides. Proper lubrication reduces friction, prevents wear, and prolongs the life of these components.

● Inspect and replace worn parts: Regularly inspect the machine for signs of wear or damage, such as worn cutting tools or damaged belts. Replace any worn or damaged parts promptly to avoid further problems.

● Check alignment and calibration: Periodically check the machine's alignment and calibration to ensure it operates with the highest precision and accuracy.

● Schedule preventive maintenance: Establish a preventive maintenance schedule based on the manufacturer's recommendations. This may include changing filters, checking coolant levels, and inspecting electrical connections.

If you encounter problems with your 3-axis CNC machine, consider these troubleshooting tips:

● Inaccurate cuts: If your machine produces inaccurate cuts, check for worn or damaged cutting tools, incorrect tool offsets, or issues with the machine's alignment and calibration.

● Poor surface finish: A poor surface finish could be caused by dull cutting tools, incorrect cutting parameters, or insufficient coolant.

● Unexpected machine behaviour: If your machine is behaving unexpectedly, check for errors in the G-code, issues with the control software, or electrical problems.

● Excessive noise or vibration: Excessive noise or vibration could indicate worn or damaged components, misalignment, or improper machine levelling.

Upgrading from manual to 3-axis CNC machining can significantly benefit your manufacturing process. Transitioning to a CNC milling machine streamlines production increases efficiency, and improves precision. The process typically involves the following steps:

● Assess your needs: Determine the specific requirements of your production process and identify the suitable CNC milling machine that meets your needs.

● Invest in equipment: Purchase or lease a 3-axis CNC machine that aligns with your budget and production goals.

● Train employees: Provide training for your team to ensure they can operate the new equipment effectively and safely.

● Implement the new technology: Integrate the 3-axis CNC machine into your production process, replacing manual operations where applicable.

In summary, choosing the ideal 3-axis CNC machine tailored to your specific requirements is vital for unlocking its potential and enjoying this technology's many advantages. From heightened efficiency and productivity to improved precision and uniformity, 3-axis CNC machines can transform your manufacturing process and elevate your enterprise to new levels.

As progress in CNC machine tool technology persists, staying updated and adapting to these innovations is crucial to retain a competitive advantage in the manufacturing sector. Investing in a suitable 3-axis CNC machine and ensuring your team possesses the required knowledge and skills, you'll be primed to address contemporary manufacturing challenges and seize emerging opportunities.

In the end, comprehending and selecting the appropriate 3-axis CNC machine optimizes your production workflow and lays the foundation for stable growth and success within the constantly evolving manufacturing environment.