It goes unsaid that efficiency, accuracy, superior performance, and versatility are crucial in the modern manufacturing world. One such practice that particularly stands out as a solid solution is double column machining. Be it for automotive parts, durable machining tasks, aerospace components, or mold and die making, double column machining columns have always proven to be versatile.

Because of their versatility, double column machining centers are indispensable and play a crucial role in many different industries. This all-inclusive guide sheds light on the ins and outs of double column machining and its versatility, while exploring its most striking benefits, applications, proficiencies, and technological developments. So, keep reading to learn all about the versatility of double column machining.

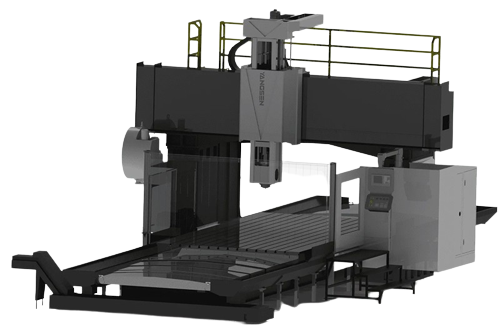

Double column machining (a.k.a., gantry mills or bridge mills) is one of the most effective kinds of machining process that incorporates the use of a firm and powerful structure. It typically consists of two columns that aid in ensuring stability and firmness.

The conventional machining center usually comprises one column. However, as the name implies, a double column machining is superior in terms of performance mainly because it features two columns.

The vibration damping and exceptional support you receive from double column machining centers makes them the perfect fit for machining gigantic heavy-duty workpieces with the utmost accuracy.

CNC double column machining centers are best suited for machining substantially large parts for heavy industries that mainly call for multifaceted structures that go far beyond boats, automobiles, and airplanes.

In fact, they are also applicable to the production and manufacturing of other machine tools. Put precisely, these heavy-duty dual column-machining centers simplify the machining of glued and solid laminated beams and wood panels.

Some of the tasks you can do using these substantial machine tools include milling openings, cutting extensive parts, and all kinds of milling and drilling for electrical work and plumbing.

Double column machining centers have a vast range of functions, advantages, and specific sizes to offer. Thanks to their superior automation levels, flexibility and versatility are the two main defining characteristics of machine centers.

It is because of these qualities that the machines are able to operate the same workpiece, which calls for numerous machining operations in one go. Additionally, you can obtain top-notch quality of results with exceptional finishes.

The versatility of machining centers is the most noteworthy feature of dual column machining centers. They are proficient enough to carry out an array of machining tasks and operations such as boring, drilling, contouring, milling, and tapping.

Furthermore, from composites to metals, double-column machining centers can effectively fit in an extensive variety of materials, proving how versatile and agile they are. Thanks to their versatility, double column machining centers serve as an ideal solution for a diverse set of manufacturing needs and processes.

By transitioning to a double column machining center, you can expect to observe a noteworthy progress in machining proficiencies for manufacturing processes and operations.

It is quite evident that not all orders will be alike. There will be some orders for smaller components and others for heavier and larger ones.

If you ever experienced any problems or limitations in accepting orders for large-size and heavyweight components, or find it challenging to machine materials, double column machines are ideal for this purpose.

Some components or parts that are challenging to machine are crucial and play a significant role in an array in applications and industries. These include shipbuilding, windmills, construction, aerospace, mold and die, commercial vehicles, power generation, machinery manufacturing, and semiconductor.

A good machining center should be able to reconfigure. This way, the operator can alter the settings without altering the process while the machining program is in operation.

The best thing about this form of machine toll is that it operates via automated numerical control. As a result, it is swifter and better able to produce bulk amounts of parts in series.

Ever since the CNC technology came into existence, machining centers can work parts in a relatively less amount of time. Moreover, they do not even require much human aid or involvement, ultimately minimizing the cost of labor, time, efforts, and production.

A dual column machining center is primarily designed to offer businesses optimum stability while reducing deformations during machining. It is relatively bigger in size and so it calls for sufficient space.

Transitioning to a double column-machining center can be beneficial for your business as it can increase the constraints on the sizes and types of components you can machine as well as multiply the machining competence. Ultimately, this will allow you to stand out and rise above your competition.

The thing about double column machining centers is that compared to the conventional C-Frame machines, they’re fashioned to serve exceptional stabilities and more significant part dimensions. As a result, they are able to machine bulkier, loftier, and more robust materials.

Double column machining centers are usually grander and more heavy, but at the same time, they are also significantly stable and firm. Due to all this, they can minimize vibration drastically and provide a more enhanced part finish.

Naturally, all of this largely depends on the crucial things like the design specifications, construction quality, and the selection of materials used.

In addition to their versatility, there are some of the advantages that double column machining centers have over conventional single column ones.

The design of double column machining is better able to support more significant load capacities as opposed to the single column machining center.

This significantly broadens the variation of applications to be dealt with because dual column machining centers can deal with bulky workpieces without any hassle.

A double column machining center is known for having larger work envelopes, both in Z-axis clearance and X-Y travel. This permits several small parts and larger parts to be effectively machined in just one setup, resulting in enhanced efficiency and productivity.

The inherent stability of double column machining centers translates into superior accuracy and precision in machining operations. This is crucial for industries where tight tolerances and high-quality surface finishes are required.

The most striking feature about double column machining centers is their powerful and sturdy structure. The dual-column design can effectively support the bridge or crossbeam where the spindle is attached.

There is variation in their design, meaning dual-column machining centers are able to offer increased firmness and stability, ultimately resulting in superior surface finish and unmatched precision in machining.

The slant structure of the Y-axis aids in effective movement, ensuring brilliant stability and straightness while cutting. Moreover the bridge-type structure in double column machining centers is symmetrical, allowing the heat, load, and vibration to be equally dispersed to the dual columns.

All of this is essential for ensuring minimal deformations and precise and stable cutting. The movement with the work piece is solely in the direction of the X-axis. However, the Y and Z axis are free from altering weight condition and influence, ultimately delivering accuracy and stability in cutting.

Thanks to state-of-the-art features such as probing systems and tool changers and larger work envelopes, these two column machining centers can drastically minimize the overall setup time. In addition, they can boost the efficiency of your machine, which will ultimately save the overall cost significantly.

Several dual-column machining centers work harmoniously with automation systems like pallet changers, cohesive part measurement systems, and robotic loaders. This is effective as it streamlines the workflow of production and aids in machining even when the lights are out.

A machining center with two columns typically entails multiple tool changers or a large tool magazine. This helps in changing tools automatically while the machining of parts is in process. Moreover, this enhanced tool changer capability also contributes to enhanced productivity in general and lesser downtime.

Despite the plethora of advantages they offer, there are some limitations. For instance, these heavy-duty machines call for sufficient floor space mainly because of their extensive footprint.

As a result, dual column machining centers might be suitable for small operations. Additionally, these machines require a hefty investment and so, it is important to understand that these machines come at a substantial price.

But despite their cost and substantial size, dual column machining serves as an invaluable tool in applications and industries where efficiency and precision are fundamental.

As technology keeps advancing, so does their usage and relevance. This signifies that these machines will be continuously useful and relevant in modern manufacturing for a long time.

Here are some of the most common applications of double column machining that makes them so versatile and popular across a vast range of industries.

The mold and die making process is often signified by tight tolerances and use of complex geometries. Double column machining is suitable for such complex processes as it provides the accuracy and meticulousness one needs for producing dies, molds, and tooling inserts, all with unwavering consistency, repeatability, and superior quality.

Double column machining is widely used in an array of general engineering applications for manufacturing structural parts, heavy machinery fragments, and specialty gears.

From transmission housings to engine blocks, automotive components demand machining processes that ensure consistency and accuracy in the dimension. These machining centers help in producing these essential parts with optimum productivity and efficiency and very little configuration time.

Aircraft parts and modules like engine mounts, fuselage frames, wing ribs, etc., call for defined machining of towering structures. Luckily, dual column machining centers are efficiently able to fulfill all these requirements while also promising and delivery the maximum accuracy and superior surface finish that is imperative for such applications.

In shipyards, these machines play a vital role in producing components and parts such as engine mounts, propellers, bulkheads, etc. They are wells-suited for the shipbuilding industry because they can work efficiently on king-size parts.

There are various high-tech developments that follow with dual column machining. These include:

Top-tier spindle designs that include fully developed cooling mechanisms, heat compensation systems, and ceramic bearings vastly aid in boosting spindle accuracy, firmness and stability, and thermal stability.

Advanced CNC control systems are well-known for their exceptional in-built user interfaces. They vastly give operators the autonomy to program intricate machining tasks without any hassle and maximize machine performance for optimum efficiency.

A cohesive tool management system typically features adaptive machining competences, tool wear compensation, and tool life monitoring. All these exceptional features aid in ensuring industries can benefit from an extended tool life, superior tool performance, and a drastic reduction in tooling costs and downtime.

Sensor-operated monitoring systems on top of data analytics tools are able to provide valuable in-depth insights regarding machine performance, and that too in real-time. As a result, this significantly aids in the ability to identify inconsistencies, enhance machining duties for peak efficiency, and foresee maintenance requirements.

Thanks to dual column machining’s cutting-edge workpiece clamping solutions like magnetic chuck technology and modular fixturing methods that allow the workpieces to be positioned securely, firmly, and swiftly, the machining accuracy can be twofold and the setup time is drastically cut down.

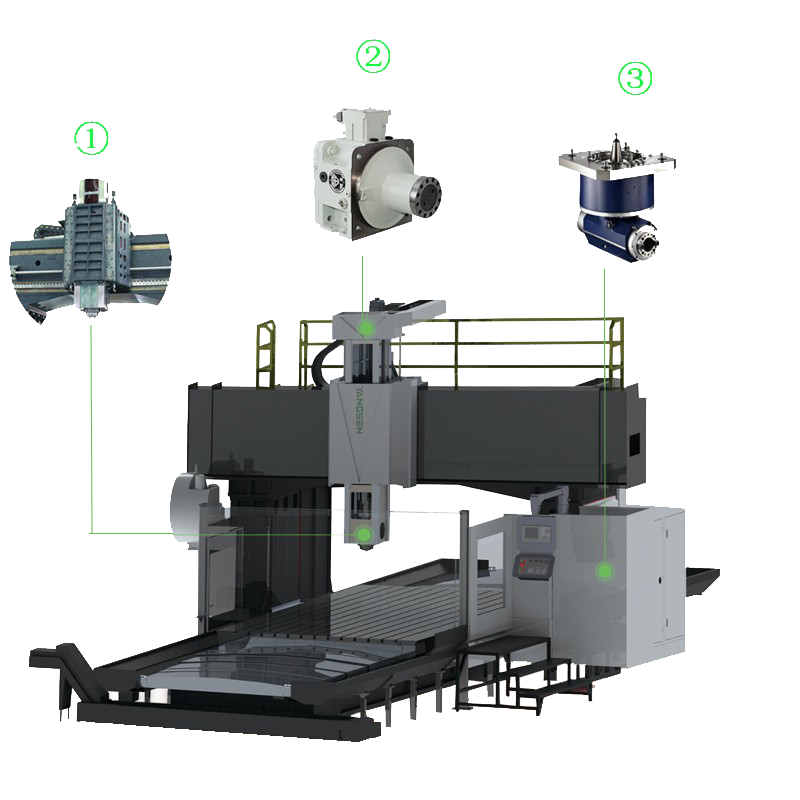

① Square ram structure 500X500MM

The machine installs a four-sided restraint quenching guide guideway and double-cylinder nitrogen balance device. The overall rigidity is strong. It has the strong cutting ability and stable precision.

② Italy BF gearbox

High-performance speed, low noise, expandable motor constant power range with easy installation. It can be used in conjunction with multiple series of motors and adapt to high-strength tension.

③ Fully automatic side milling head

The transmission gear is a Gleason spiral bevel gear. The transmission is stable and accurate. It has a long service life. The internal transmission key of the milling head is a quenched part with minimal backlash.

Dual column machining has largely emerged and grown as a key technology, and they play a crucial role in the realm of contemporary manufacturing. They signify the combination of conventional manufacturing operations and cutting-edge technology, giving users versatility and accuracy in machining gigantic workpieces.

It goes unsaid that these machines provide exceptional power, unmatched accuracy and stability, and superior performance across several applications and industries. Over the course of the years, double column machining has undergone multiple developments in control systems and system design.

Moreover, thanks to their versatility and the innovative technologies they are equipped with, these machining centers tend to be at the front of industrial settings.

Suffice to say, dual column machining centers are the most effective way to give manufacturers the autonomy and freehand they need to swiftly and confidently fulfill the industry’s ever-rising demands.

Nonetheless, before you transition to double column machining centers, it is important to consider things like meeting the floor requirements, covering the startup investment costs, and catering to the tailored requirements of your production operations.

Furthermore, your personnel must have adequate programming proficiency and training to be able to fully leverage the efficiencies of such state-of-the-art machining systems.