Turning Center vs Lathe serves as a crucial discussion in workshops. Today, you'll uncover insights into these machines. Deep dives into their working principles, structures, and operations await. Every detail provided guarantees expertise and authority.

Both machines rotate workpieces. In turning centers, precision is paramount, achieving up to 5,000 RPM, often higher. Standard lathes might hover around 2,500 RPM, depending on the model.

A turning center provides swift, automated tool movements. Conversely, traditional lathes rely more on manual adjustments. Hence, speed and efficiency diverge.

Continuous, accurate material removal is crucial. Turning centers offer enhanced consistency, while lathes might need more manual intervention.

Your turning center ensures consistent, uninterrupted cuts. Lathes, on the other hand, might necessitate periodic stoppages.

Lathes can achieve remarkable finishes, depending on the operator's skill. Yet, turning centers, with their precise controls, often surpass in uniformity and finish.

Effective chip formation minimizes tool wear. Lathes and turning centers use varied chip breakers, but turning centers often incorporate advanced chip management systems.

Turning centers boast automated feed systems. Lathes, while having power feeds, often require manual adjustments for optimal feeding rates.

In lathes, operators manually set tool angles. Turning centers utilize CNC controls, ensuring precise angle settings for optimal cutting.

Precision in depth control defines the turning center's advantage. Lathes demand meticulous manual calibrations.

While lathes offer RPM adjustments, turning centers provide granular control, adjusting to conditions in real-time for optimal performance.

Monitoring cutting forces prevents tool damage. Turning centers excel with built-in sensors. Lathes, being more manual, depend on operator experience.

Turret operation in turning centers is automated, housing multiple tools. Lathes, though possessing turrets, often require manual tool changes.

Turning centers, often multi-axis, synchronize movements seamlessly. Lathes, primarily 2-axis, require manual coordination for complex tasks.

Efficient coolant application ensures tool longevity. Turning centers provide targeted coolant delivery, whereas lathes might have generalized systems.

Turning centers adopt sophisticated clamping methods, ensuring workpiece stability. Lathes use more traditional methods, such as chucks and faceplates.

Turning centers sport automated tool posts. On lathes, tool posts are manual, requiring periodic adjustments.

Both machines offer forward and reverse operations. However, turning centers switch directions swiftly, optimizing operations.

Lathes use centers or steadies for support. Turning centers, with advanced tailstock designs, provide robust workpiece support and alignment.

Central to both machines, the bed frame supports and stabilizes. Made from heavy-duty iron, it provides firmness during operations. Without a sturdy bed frame, precision can't be achieved.

Located on the left end, the headstock holds the main spindle. High-quality bearings ensure its smooth rotation. The headstock houses the machine's drive components, vital for transmitting power.

Modern turning centers mostly employ this. Instead of single-tool posts, turrets hold multiple tools. Transitioning between operations becomes swift, optimizing workflow.

Positioned opposite the headstock, the tailstock provides additional support. Materials like long bars benefit from this structure. In advanced machines, tailstocks can also hold tools.

Situated atop the bed, the carriage moves tools longitudinally. Precision in this movement is paramount. Most lathes and turning centers prioritize this aspect to ensure accurate cuts.

A vital part, the lead screw drives the carriage. Its rotational movements translate into the carriage's linear motions. Every rotation must be exact, affecting the tool's positioning.

Essential for holding workpieces, the chuck system varies in design. Some use three jaws, others four. Regardless, firm grip and alignment are non-negotiable.

These ensure straight movement of the carriage. Precision-ground surfaces facilitate smooth transitions. Their alignment directly influences the end product's quality.

Perpendicular to the bed, the cross slide moves tools laterally. Lathes and turning centers both use this component for depth control in cuts.

Mounted on the cross slide, it allows angular tool movements. Versatility in cuts gets enhanced, especially in intricate designs.

Power transition occurs here. The gearbox changes the spindle's speed, allowing for diverse operations. Sophistication in design determines machine efficiency.

Spindle bore defines the maximum diameter of workpieces. Both machine types have varying spindle bore sizes. Workpiece compatibility depends on these dimensions.

Facilitates rapid tool switches. In high-production environments, quick change mechanisms prove invaluable. Minimizing downtime is always a priority.

Mostly found in turning centers, the CNC panel guides operations. Pre-programmed instructions dictate tool movements. Automation results in heightened accuracy and repeatability.

Controls machine activation. Starting and stopping become effortless, enabling better control during operations.

Safety guard is a must-have for user protection. Safety guard encloses the moving parts for preventing potential injuries. Always ensure it's in place before starting.

Tool post holds the cutting tool on traditional lathes. Adjustability is its main feature, aiding in tool positioning.

Motor drive powers the entire setup. Motor specifications like horsepower determine machine capability. A balance between power and efficiency is essential.

Begin with the operation of facing. A turning center utilizes high-speed spindles, enabling rapid removal of material from a workpiece. Lathes, on the other hand, might have varied spindle speeds, affecting the quality and rate of the facing procedure.

Grooving on a turning center involves precise depth cuts. Often, CNC controllers govern the grooving process. Traditional lathes rely more on manual inputs, affecting groove accuracy.

When separating a piece from stock, employ parting. Turning centers offer enhanced precision due to their rigid setup. In contrast, lathes require an operator's expertise for this operation.

Thread creation becomes essential in numerous auto parts. Turning centers have advanced controllers, ensuring perfect thread pitches. Lathes demand an operator's skill to ensure thread consistency.

Introducing holes in materials demands drilling machine. Turning centers, with their automatic coolant systems, ensure optimal drill performance. Lathes might need manual coolant application, slowing the process.

For surface texture, turn to knurling. While turning centers can provide repeatable textures, lathes offer unique patterns, relying on operator technique.

Achieve inclined surfaces via taper turning. Turning centers use advanced algorithms, ensuring consistent tapers. Lathes need manual adjustments, introducing potential for variation.

Shape complexity demands form turning. Turning centers, with CNC capabilities, allow intricate shapes. Lathes, conversely, depend on operator expertise.

For off-center shapes, use eccentric turning. Turning centers with advanced feedback systems guarantee precision. Lathes require meticulous setup adjustments.

Reduce diameters at specific locations via necking. Turning centers benefit from automatic tool compensation. Lathes demand manual calibrations.

Removing material from beneath a workpiece is undercutting. Turning centers use high-speed tools, ensuring clean undercuts. Lathes need careful tool selection.

Enhance hole precision with reaming. Turning centers, boasting tool rigidity, offer consistent hole sizes. Lathes demand operator's vigilance for accuracy.

Achieve fine finishes with grinding. Turning centers with integrated grinding units promise superior finishes. Lathes necessitate separate grinding setups.

Remove material from inside objects via hollowing. Turning centers ensure consistent hollow depths. Lathes, however, might produce variations in depth.

Define workpiece profiles using contouring. Turning centers with adaptive control technology provide accurate contours. Lathes rely on operator's skill.

Smooth edges are achieved through filleting. Turning centers guarantee precise radius measurements. Lathes require manual adjustments for desired results.

|

Operation |

Turning Center |

Lathe |

|

Facing |

Automated, high precision, CNC controlled |

Manual operation, skill dependent |

|

Grooving |

Precise depth and width, CNC programming |

Manual control, depth may vary |

|

Parting |

Automatic tool change, accurate and fast |

Manual tool change, slower |

|

Threading |

Multi-point, accurate pitches, CNC controlled |

Single-point, manual pitch setting |

|

Drilling |

High-speed, auto-centering, tool variety |

Manual centering, limited speeds |

|

Knurling |

Uniform patterns, CNC precision |

Manual, pattern consistency may vary |

|

Taper Turning |

Automated angle setting, high accuracy |

Manual angle setup, operator skill dependent |

|

Form Turning |

Complex forms, CNC controlled |

Simple forms, manual operation |

|

Eccentric Turning |

Computer-controlled offsets, high precision |

Manual offsets, high skill required |

|

Necking |

Uniform reduction, CNC precision |

Manual, consistency can vary |

|

Undercutting |

CNC precision, repeatable |

Manual, requires skill for consistency |

|

Reaming |

High-speed, precise hole sizing |

Manual, depends on tool and operator |

|

Grinding |

Attachments available, high precision |

Limited to certain lathes, manual operation |

|

Hollowing |

Automated, consistent depths |

Manual depth checking |

|

Contouring |

Complex profiles, CNC controlled |

Manual following of template |

|

Filleting |

Precise radius setting, CNC controlled |

Manual, radius consistency can vary |

Table on Types of Operations of Turning Center vs Lathe!

Turning centers offer CNC precision, ensuring consistent, repeatable results in each operation. Lathes might show variations over multiple tasks.

In turning centers, the tolerance can be as tight as 0.0001 inches. Lathes, being manually operated, can achieve a range of 0.001 inches if expertly used.

With turning centers, you achieve higher positional accuracy due to advanced feedback systems. In contrast, manual lathes depend heavily on operator skill.

Turning centers minimize surface roughness to levels below Ra 0.8 µm. On a lathe, results vary, and smoother finishes often need secondary operations.

Advanced turning centers use rigid tool holders. This minimizes tool deflection, ensuring precision cuts. Lathes might have more deflection, depending on tool quality.

Turning centers come equipped with coolants, maintaining thermal stability. Lathes may experience heat buildup, affecting precision.

Turning centers feature automated calibration mechanisms, ensuring consistent performance. Manual calibration on lathes requires experience and skill.

Advanced feedback loops in turning centers automatically correct minor errors. Lathes rely on operator adjustments.

Turning centers utilize complex feedback systems, ensuring tool and workpiece alignment. Lathes depend more on operator judgment.

CNC turning centers boast high-resolution capabilities, often achieving 0.0001-inch precision. Manual lathes offer less resolution, depending on operator expertise.

Turning centers often integrate digital measurement tools, facilitating accurate results. Lathes use external tools, like micrometers and calipers.

Automated systems in turning centers ensure perfect axis alignment. In lathes, regular checks by operators are crucial.

Turning centers have advanced mechanisms to eliminate backlash. Lathes require manual adjustments for backlash control.

With turning centers, spindle error remains minimal due to precision engineering. On lathes, periodic maintenance is essential to counter spindle errors.

Turning centers control runout effectively through superior engineering. Lathes can exhibit more runout, influenced by tool wear and setup.

Modern turning centers eliminate play using tight-fitting components and advanced bearings. In lathes, play can be an issue, often needing manual corrections.

Turning centers operate on real-time feedback loops, refining operations as they progress. Lathes lack this dynamic adjustment feature.

In the realm of precision machining center, cycle speeds denote the time required to finish a task. In general, Turning Centers offer faster cycle speeds due to advanced technology.

You prioritize shorter setup times to enhance production rates. Turning Centers generally boast rapid setup times compared to traditional lathes.

The time taken to load or unload parts can impact the production. Typically, Turning Centers optimize load/unload speeds, furthering operational efficiency.

While both devices handle batch processing, Turning Centers exhibit superior handling capabilities, especially for large batches.

Turning Centers, with their evolved design, incorporate higher levels of automation. As a result, human intervention decreases, leading to more consistent results.

Tool change speed plays a crucial role in minimizing downtime. Turning Centers, due to their advanced mechanisms, provide swift tool change capabilities.

Efficient program loading ensures seamless operations. In this arena, Turning Centers often outpace lathes with their sophisticated control systems.

Efficient job queuing is vital for streamlined operations. Turning Centers often have superior queuing systems, ensuring jobs line up without delay.

The ability to multi-task enhances productivity immensely. Turning Centers can simultaneously handle multiple operations, unlike conventional lathes.

Throughput rate, indicating the number of parts produced in a given time, is pivotal. Typically, Turning Centers exhibit higher throughput rates due to enhanced operational capabilities.

Minimizing idle times equates to increased productivity. Turning Centers, with their advanced systems, markedly reduce such unproductive intervals.

Turning Centers, equipped with automated systems, often require minimal operator intervention. Thus, consistent and error-free outputs are more attainable.

Turning Centers excel in redundancy management, ensuring that processes continue even when specific components fail.

The ability to recover swiftly from faults is essential. Turning Centers often have sophisticated fault recovery systems, ensuring minimal production hiccups.

Spindle uptime indicates the duration a spindle remains operational. Turning Centers generally offer superior spindle uptimes, a testament to their efficiency.

Engaging in parallel operations significantly boosts production. Turning Centers, with their evolved design, can perform several operations simultaneously.

Efficient workholding ensures that parts remain secure during machining. Turning Centers generally offer advanced workholding mechanisms.

Preparation before the actual machining process is vital. Turning Centers usually simplify job prep, making the overall process more efficient.

Steel, known for its impressive tensile strength, often demands precision in both Turning Centers and Lathes. Moreover, CNC Turning Centers, with advanced tooling options, handle intricate steel projects.

Aluminum, lighter than steel, gets machined swiftly. Both machines manage aluminum well, but Turning Centers often offer quicker cycle times.

Brass, a soft metal, requires consistent speed for a fine finish. Lathes are traditionally favored; however, modern Turning Centers provide impeccable brass finishes.

Titanium's high strength-to-weight ratio presents challenges. Even though Turning Centers excel in controlled titanium machining, traditional Lathes might struggle without specialized tooling.

Plastics vary in hardness and brittleness. While Lathes handle most plastics, Turning Centers dominate when intricate designs on plastics are needed.

Handling hardened materials is no trivial task. Turning Centers, with robust tool holders and coolants, perform better in machining these materials.

Alloys blend multiple metals, yielding diverse machining needs. Both machines handle common alloys, but specific alloy grades might favor one over the other.

Non-ferrous metals, like copper, don't contain iron. Such metals often find a better match in Turning Centers due to their precision.

These metals are rare and costly, demand utmost care. Turning Centers, armed with cutting-edge technology, ensure minimal waste.

Machining cast iron produces fine chips. Lathes can handle cast iron well, but for bulk production, Turning Centers often win.

Metals expand with heat. Turning Centers, equipped with thermal compensators, ensure consistent machining despite temperature variations.

Harder surfaces can reduce tool life. Both machines adjust tools, yet Turning Centers often provide better tool life management.

Brittle materials risk breaking. Turning Centers, with their controlled environment, often handle these materials more safely than Lathes.

Proper lubrication ensures smooth machining. Turning Centers come with automated lubrication systems, whereas Lathes might need manual application.

Ensuring material stability is vital. Turning Centers, featuring advanced clamping, excel in holding materials more firmly than Lathes.

Different materials produce varied chips. Turning Centers, with advanced chip conveyors, manage chip disposal more efficiently.

Prolonged machining can wear down tools. Turning Centers generally boast of tools with enhanced wear resistance, ensuring longevity.

Feed and speed impact finish quality. Turning Centers provide real-time adjustments, optimizing output.

Turning Centers usually have a more compact footprint. In contrast, traditional lathes can span a wide area, often requiring up to 15 feet in length.

For overhead operations, Turning Centers demand around 9 feet. Lathes, especially older models, can require as much as 11 feet.

Lathes typically have minimal built-in tool storage. Turning Centers, on the other hand, offer integrated tool storage solutions, accommodating up to 20 different tools.

Utility connections in Turning Centers are typically at the back, requiring clear space. Lathes have side utility ports, needing side clearance.

Most Turning Centers come with wheels for easy transport. Traditional lathes lack this mobility, often fixed in a location due to their weight.

Turning Centers, given their closed nature, necessitate effective ventilation systems. Whereas, lathes, being more open, have fewer such requirements.

While Turning Centers can handle up to 2000 lbs, lathes often have weight limits of 3000 lbs or more due to their robust structure.

Lathes usually sit on heavy-duty bases, ensuring stability. Turning Centers have reinforced platforms, guaranteeing both stability and performance.

For future additions, Turning Centers need a reserved space of around 4 feet. Lathes often need more, sometimes up to 6 feet.

Lathes, because of their open structure, necessitate a safety buffer of 3 feet. Turning Centers, with enclosed operations, demand only 2 feet.

Turning Centers feature multiple access doors for ease of operation. In contrast, lathes usually come with a singular entry point.

For optimal operator comfort, Turning Centers need a 5-foot radius. Lathes demand a bit more, around a 7-foot radius.

Turning Center panels average 2x1.5 feet, intuitive and compact. Lathe panels can be larger, up to 3x2 feet.

Turning Centers necessitate a 4-foot clearance for maintenance. Lathes often require a wider area, up to 6 feet.

Integrated chip disposal systems are present in most Turning Centers. Lathes need separate bins, adding to the footprint.

Turning Centers boast of inbuilt coolant mechanisms. Lathes often need external systems, demanding additional space.

Turning Centers come equipped with specialized loading bays. Lathes, due to their structure, rely on external loading mechanisms.

Power connections for Turning Centers are typically centralized. Lathes, being diverse, may have multiple power source positions.

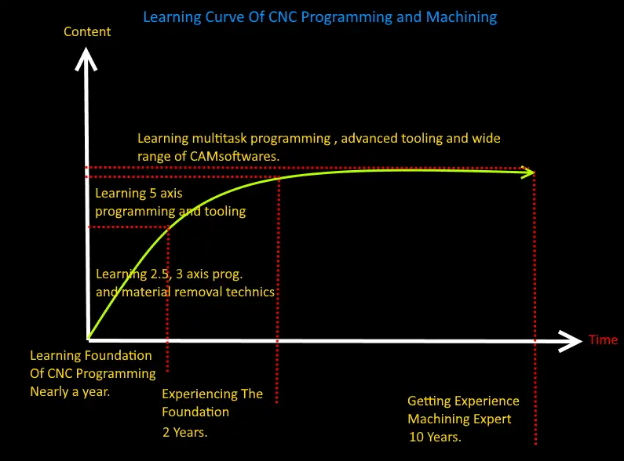

Turning Centers typically require specialized operator training. In contrast, Lathes, especially manual ones, depend on traditional machining knowledge.

Turning Centers boast advanced controls. Lathes, mainly manual types, operate with direct mechanical controls, emphasizing simplicity.

Most Lathes fall under the manual category, operated hands-on by machinists. Turning Centers, conversely, predominantly use Computer Numerical Control (CNC) for precise operations.

CNC-equipped Turning Centers feature user-friendly touch screen interfaces. Older Lathes, however, often lack such interactive interfaces.

CNC Turning Centers offer real-time error feedback. Such features are absent in most manual Lathes, where operators rely on firsthand experience.

For Turning Centers, proficient CNC programming skills become essential. Manual Lathes skip programming, focusing solely on mechanical adjus

Both devices demand tool setup, but Turning Centers often need more sophisticated setups due to complex operations.

Modern Turning Centers embed advanced safety mechanisms, reducing workplace hazards. Safety in Lathes comes mostly from operator vigilance and manual safety devices.

Turning Centers provide detailed, often digital, documentation for operations. Lathes, older ones, come with printed manuals, emphasizing basics.

Operating a Turning Center demands specific CNC experience. Operating a Lathe, however, builds on foundational machining skills.

Turning Centers, due to their digital nature, offer in-depth troubleshooting guides. Lathes, particularly older models, often lack these guides, placing reliance on operator knowledge.

Manufacturers of Turning Centers often offer comprehensive support, given the machine’s complexity. Lathes, being simpler, might have limited support, especially for older models.

Turning Centers’ digital interfaces provide clear, concise responses to operator inputs. Manual Lathes, on the other hand, require operators to understand the machine's tactile feedback.

Turning Centers incorporate visual aids, such as diagrams, for more comfortable operation. Most Lathes lack these aids, pushing the operator to depend on instinct.

Turning Centers, given their CNC nature, might include simulation options for training. Such simulation capabilities are typically absent in Lathes.

Both devices mandate on-job training, but the depth and length can vary. Turning Centers demand understanding complex CNC operations, while Lathes emphasize basic machining techniques.

Mastery of a Turning Center ensures proficiency in advanced CNC operations. In contrast, mastering a Lathe refines core manual machining techniques.

Turning Center vs Lathe showcases diverse strengths and features. From working principles to energy consumption, every aspect matters. Equip your workshop wisely. Your tasks and projects will thank you.

For top-tier equipment and guidance, trust CNCYANGSEN. Your pursuit of excellence starts now.