In the steadily developing scene of assembling, accuracy and effectiveness are central. Industries going from aviation to auto and past require apparatus that can deliver complex parts and parts with unmatched precision. One such wonder of present-day designing is the Bridge milling machine and bridge CNC machine. In this complete aid, we will dive into the universe of bridge milling machines, investigating their usefulness, applications, benefits, and the critical job they play in the world of manufacturing.

The Bridge Mills and Gantry CNC machines cater to a wide range of applications, offering multi-purpose solutions and large-capacity options that can be customized to ensure your success. Equipped with advanced CNC control systems, these machines offer precise control of the milling head's movements and cutting parameters, optimizing machining operations and reducing setup times.

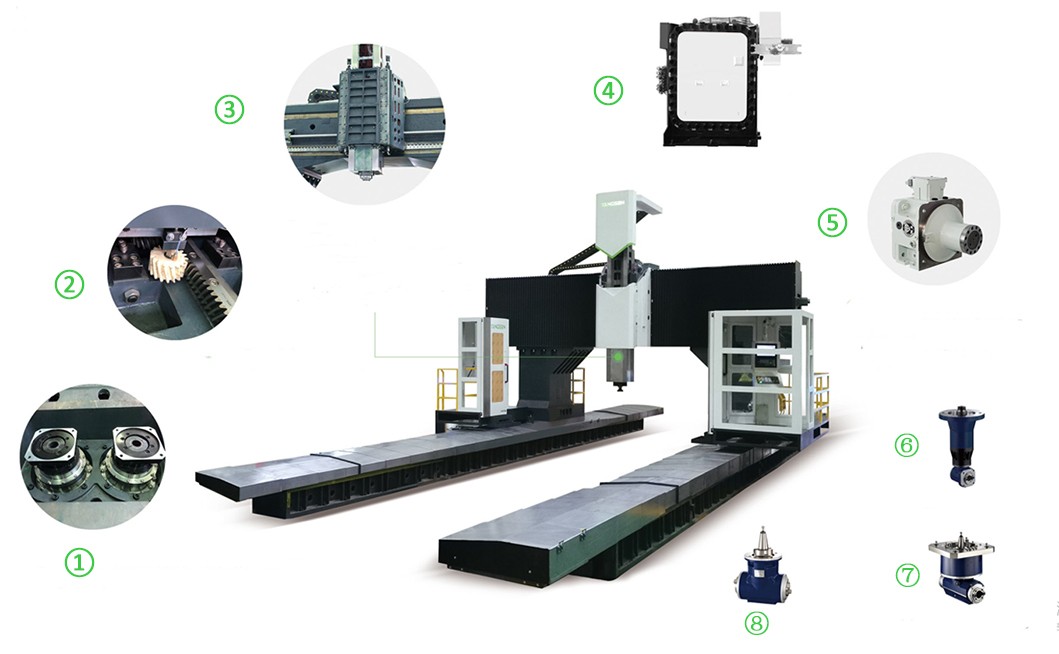

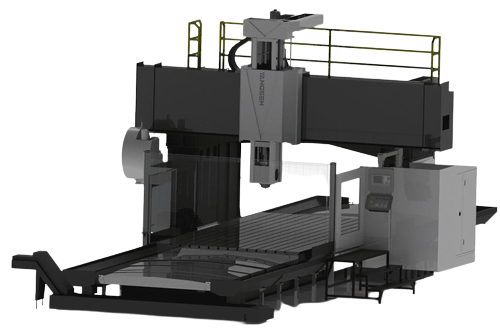

Bridge Mills, also known as portal mills, are advanced vertical milling machines with an adjustable cross rail that creates a "bridge" or "portal", allowing the spindle axis to travel end-to-end across large workpieces. Comprising a robust base/bed casting and a single-piece bridge structure bolted to the bed, Bridge Mills provides unparalleled stability and precision.

The name "bridge milling machine" originates from the unmistakable bridge-like structure, traversing the worktable and offering help for the cutting instrument. This design considers the machining of enormous workpieces and guarantees solidness during high-velocity cutting tasks.

A milling machine removes material from a workpiece by rotating a cutting tool (cutter) and moving it into the workpiece. Milling machines, either vertical or horizontal, are usually used to machine flat and irregularly shaped surfaces and can be used to drill, bore, and cut gears, threads, and slots.

Here’s a simplified breakdown of their operation:

At the core of every bridge milling machine is a CNC control framework. CNC innovation empowers exact command over the development of the cutting apparatus. Administrators program the machine by contributing a bunch of directions that characterize the toolpath, cutting paces, feed rates, and different boundaries. This degree of computerization takes into consideration remarkable repeatability and precision.

The slicing device is connected to a shaft that pivots at high rates. The decision of cutting device and its particulars rely upon the material being machined and the ideal result. Bridge milling machines are equipped to utilize different cutting instruments, including end mills, ball plants, and drills.

Workpieces are safely fixed to the machine's worktable utilizing tight clamps, or concentrated apparatuses. Appropriate fixturing is critical to guarantee that the workpiece stays stable during machining, preventing vibrations and errors.

The bridge-like construction of the machine conveys the axle and cutting device. This construction can move along numerous axes, regularly including the X, Y, and Z axes. The X-axis addresses even development, the Y-axis addresses vertical development, and the Z-axis addresses profundity or tool feed.

As the axle moves along the customized toolpath, it eliminates material from the workpiece. The CNC control framework precisely facilitates the bridge's development and the shaft's pivot to accomplish the ideal cuts, shapes, and surface finishes.

Modern bridge milling machines frequently incorporate sensors and checking frameworks to guarantee the interaction stays on target. These frameworks can recognize varieties in cutting powers, temperature, and device wear, making real-time adjustments to keep up accuracy.

The flexibility and accuracy of bridge milling machines make them essential in a large number of businesses and applications:

In aerospace production, accuracy is central. Bridge milling machines are utilized to deliver parts, for example, airplane wings, motor parts, and primary parts with tight resistances.

The assembling of molds and dyes for the plastic injection molding and metal projecting ventures requests high accuracy. Bridge factories succeeded in making unpredictable and complex shape holes.

Bridge milling machines are utilized to create basic parts for the automotive sector, including motor blocks, transmission parts, and suspension parts.

In device and die-making, where accuracy and solidness are essential, bridge mills assume an urgent part in molding and shaping passes on for metalworking and producing tasks.

Bridge milling machines find applications in overall machining assignments, where enormous and complex workpieces need exact machining, including parts for large equipment and modern hardware.

From assembling wind turbine parts to thermal energy station parts, bridge milling machines are associated with delivering essential parts for the energy sector.

There are numerous advantages of bridge milling machines

Bridge milling machines are inseparable from phenomenal accuracy and exactness, making them vital in ventures where tight resilience is non-debatable. Their high-level CNC control frameworks, fastidious adjustment, accuracy parts, and constant checking frameworks, on the whole, add to their uncommon accuracy. Whether in aviation, clinical gadget fabricating, or any industry where accuracy is vital, span processing machines keep on setting the norm for greatness in machining. As innovation propels, these machines are probably going to push the limits of accuracy much further, empowering new degrees of development and quality in assembling.

The flexibility of bridge milling machines to a wide range of materials is the main impetus behind their flexibility and applicability across ventures. Their accuracy, speed, and capacity to keep up with tight resistances while working with different materials make them essential devices for current assembling, whether in aviation, auto, clinical, or imaginative undertakings. As ventures proceed to develop and investigate new materials, span processing machines will stay at the very front, empowering advancement and creation greatness.

Bridge milling machines have changed assembling by conveying quick cutting and effective material evacuation abilities. Their capacity to decrease creation times is a distinct advantage in enterprises where time-to-market and cost-effectiveness are basic. From aviation parts to car parts and then some, these machines keep on driving development, efficiency, and seriousness in the advanced assembling scene. As innovation progresses, we can expect further refinements in span processing machines, making them much more imperative for fulfilling the developing needs of the present business sectors.

The multi-pivot abilities of scaffold processing machines are progressive in present-day production. They empower the creation of perplexing shapes and mind-boggling calculations with unparalleled accuracy and productivity. From aviation parts with streamlined forms to molds with complicated depressions, multi-pivot machining is at the front of making the creative and high-level items that characterize the present ventures. As innovation keeps on advancing, these capacities are probably going to extend considerably further, opening up additional opportunities for assembling greatness.

CNC computerization addresses a groundbreaking jump forward in assembling by limiting the bet of human mistakes. Its accuracy, repeatability, and capacity to handle complex undertakings with steadfast exactness have made it a crucial apparatus in different enterprises. Makers can depend on CNC machines to reliably create top-notch parts, lessen squandering, improve well-being, and at last stay serious in the present worldwide commercial center. As innovation keeps on progressing, CNC computerization is probably going to assume a much more essential part in forming the fate of assembling.

The accessibility of different sizes and plans of extension processing machines is a unique advantage for makers. It permits them to fit their machining abilities to suit their ongoing necessities while giving them the adaptability to extend as their business develops. Whether an organization is simply beginning or is a deeply grounded industry pioneer, the versatility presented by these machines guarantees that they can adjust and flourish in a steadily changing assembling scene. This flexibility is an essential component in excess serious and satisfying the needs of a powerful market

While bridge milling machines offer various advantages, they are not without challenges:

Getting an extension processing machine can address a significant upfront investment, which might be an obstruction for more modest producers. A cost-benefit analysis will need to be done which has its problems since technicians and specialists who are well-versed in this can only present an accurate cost-benefit analysis.

The viable activity of these machines requires gifted administrators who are capable of CNC programming and machining. To efficiently operate a bridge milling machine, skilled operators who understand the difficulties of machining huge components are required. Operator training and expertise are required to overcome a variety of obstacles.

Normal upkeep and tooling substitution can add to the by and large working expenses of a bridge factory. Large workpieces frequently necessitate the use of heavy-duty tools, which can be costly. Furthermore, tool wear is an issue, and frequent tool changes may be required, resulting in downtime and increased operating expenses.

These machines frequently require a significant measure of floor space, which might be a restricting variable in some assembling offices. The critical floor space necessities of extension processing machines represent a genuine test for the majority of producing offices. The choice to put resources into such a machine ought to be painstakingly thought to be one, considering the accessible space, creation needs, foundation costs, and the likely effect on existing work processes. While these machines offer unrivaled accuracy and flexibility, the reasonable items of incorporating them into an assembling climate should be entirely assessed to guarantee an effective and proficient execution. It can be difficult to hold and secure huge and complex workpieces. Inappropriate fixturing can cause workpiece movement or distortion during machining, lowering the quality of the final item.

Stiffness and Stability: Maintaining the stiffness and stability of the machine and workpiece is critical in bridge milling. Vibrations, deflections, and other forms of instability can result in poor surface finishes and dimensional mistakes in the final product. To meet this difficulty, proper machine setup and maintenance are required.

Safety: When working with huge bridge milling machines and heavy workpieces, safety is of the utmost importance. The dangers involved with this equipment are high, and accidents and injuries can occur if sufficient safety precautions, training, and attention to safety regulations are not implemented. Here's a more extensive explanation of bridge milling safety considerations. Bridge milling machines should have safety features such as emergency stop buttons, interlocks, and protective barriers. These safeguards are intended to limit access to risky regions of the machine while it is in operation and can be activated in the event of an emergency. Operators and staff participating in bridge milling activities must be thoroughly trained. They should be familiar with the machine's operation, safety procedures, and emergency procedures. Certification programs can help guarantee that operators possess the skills and knowledge they need to perform safely. It is vital to handle large workpieces safely. To transport and position heavy components, adequate equipment such as cranes, forklifts, and hoists should be used. To avoid back problems, proper lifting techniques should be used. It is critical to examine cutting tools and workpieces regularly. Damaged or outdated tools should be changed as soon as possible to steer clear of severe damage to the tools. Workpieces should also be inspected for flaws or possible concerns that could cause machining complications.

Bridge milling machines have upset the universe of assembling by empowering the exact creation of complex parts and components. Their CNC-controlled computerization, combined with multi-pivot abilities, has raised the guidelines of precision and effectiveness in different ventures, from aviation to car. While they accompany their difficulties, the benefits they offer concerning accuracy, adaptability, and versatility make them essential apparatuses for current assembling.

As innovation keeps on propelling, we can expect further refinements and advancements in bridge milling machines, improving their abilities and expanding their applications. In our current reality where accuracy and proficiency are key drivers of progress, the extension processing machine remains a demonstration of the creativity of human design and its continuous journey for perfection in manufacturing.

CNC Milling Machines provide the technology, precision, accuracy, and consistent flow of procedures for a high production rate. They have features that make them fast, with low to zero human errors. You can save time and money and lessen the risk of wastage of materials.