Peek into the world of precision manufacturing! Here's an enlightening blog about "What is CNC in Bed". Together, we'll explore its mechanism, types, uses, and importance.

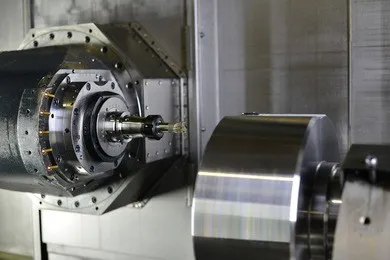

"CNC in Bed" stands for Computer Numerical Control in bed-type milling machines. Precision is paramount here. With CNC, computers guide the process. Machines execute commands flawlessly. Fine details, complex shapes, and accurate measurements - everything is possible. Experts deem this technology invaluable for its precision and reliability.

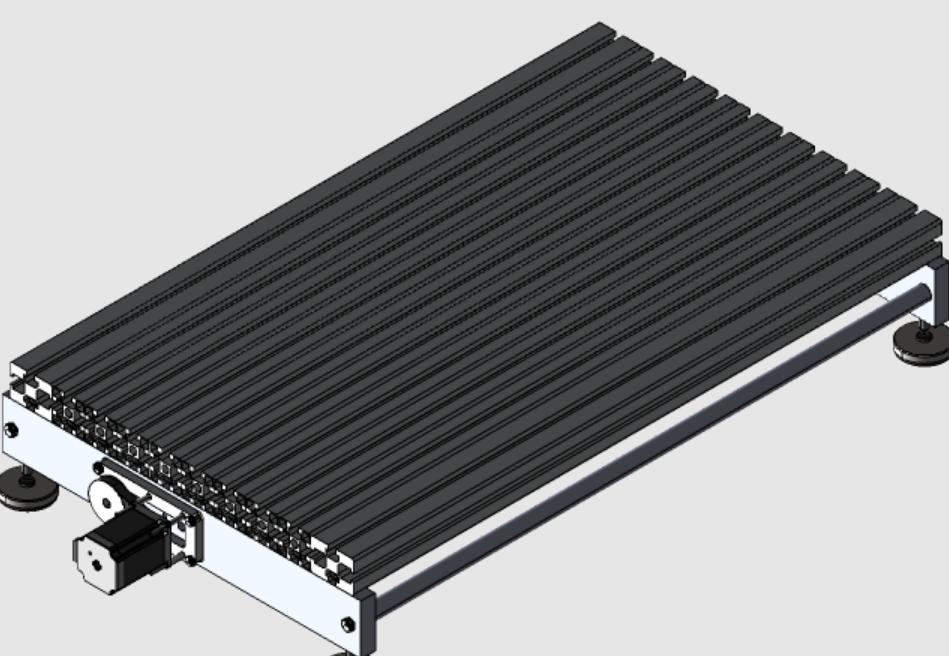

Next, a 'bed' in this context refers to the fixed structure where workpieces sit. The structure is immovable, offering stability during milling operations. Milling machines carve out auto parts and others from the workpiece, guided by a CNC system.

In a CNC bed system, the motor controller plays a vital role. The device directs the motors by interpreting G-code commands. Sending precise signals, the controller adjusts speed and direction. It's the brain behind a CNC bed system, ensuring smooth operations.

The machine bed is a stable platform for the entire CNC setup. Comprised of hard materials like cast iron, the bed resists vibrations. Its durability ensures accurate cuts and longer tool lifespan.

At the heart of a CNC bed system is the spindle motor. High rotation speeds, often exceeding 12,000 RPM, allow the spindle to drive cutting tools. Thus, it plays a crucial role in CNC vertical machining center, determining the cutting speed and finish quality.

Essential for CNC bed systems, the axis drive moves the machine along its X, Y, and Z-axes. Through lead screws or ball screws, it provides precise control over the machine's movement, critical for achieving accurate machining results.

A variety of cutting tools, such as drills and mills, are employed in CNC bed systems. Each tool has a unique function. For example, drills make holes while mills remove material from the workpiece.

The machine table holds the workpiece securely. It may have clamps or a vacuum system for this purpose. The table ensures the workpiece stays steady during machining, aiding in accurate results.

The control panel is the user interface of the CNC bed system. With buttons and displays, operators can input commands and monitor the machining process. Thus, it serves as the primary communication bridge between the operator and the machine.

The positioning system in a CNC bed helps move the cutting tool with precision. Encoders and sensors track the tool's position, contributing to the accuracy of the machine.

The coolant supply reduces heat and friction during machining. Water-based coolants or oils are used. By maintaining optimal operating temperatures, they help in achieving higher machining speeds and extending tool life.

Power supply units feed electricity to all CNC bed components. Typically, industrial-grade power supplies are used to ensure the system runs efficiently without interruptions, thus providing a reliable foundation for all CNC operations.

Computer Numerical Control (CNC) in Bed defines cutting-edge manufacturing. With numerical inputs, one attains unparalleled precision. Each cut reaches accuracy within 0.01 millimeters. Reliable, sharp, the tool masters intricacy.

Swiftly producing parts, CNC in Bed transforms the manufacturing industry. In 60 minutes, one machine makes hundreds of units. Fewer errors mean time efficiency soars.

With CNC in Bed, the manufacturing sector saves notable costs. Every part produced equals less waste. A well-used tool, fewer replacements, thus reduced expenditure on tools.

The varied use of CNC in Bed underscores its versatility. It shapes metal, plastic, wood - materials of all types. Design boundaries virtually disappear.

Complex designs come to life with CNC in Bed. 3D carving or milling, geometric shapes, or complicated contours - nothing is out of reach.

A consistent outcome is a hallmark of CNC in Bed. Run one piece or 1000, each output mirrors the original design. It ensures manufacturing reliability.

The automation of CNC in Bed enhances productivity. Unmanned, it operates for hours, increasing output.

Efficiency shines with CNC in Bed. Reducing waste, saving time, boosting productivity - it's a game-changer. Optimal use of resources defines the machine's merit.

CNC in Bed offers scalability. Small-scale prototypes or large production runs, it handles all. With effortless scaling, meeting demand becomes more manageable.

Less waste - a significant benefit of CNC in Bed. Precise cuts equal minimal material loss. Every bit of raw material is well-utilized. Thus, cost-effectiveness and environmental consciousness intertwine.

A bed in CNC is the foundation of a machine. Containing essential parts like the tool head, motors, and gantry, CNC in bed forms the structural frame of the machine. Precise movements are driven by motors, translating digital inputs into mechanical action.

• Loading Design: Initial step involves feeding the desired design into the machine.

• Tool Pathing: The computer calculates the most efficient tool path to create the design.

• Setting Parameters: Determining settings such as spindle speed and feed rate for optimum operation.

• Machine Calibration: Ensures accuracy by aligning the machine's axis.

• Material Positioning: Securing the workpiece on the bed for processing.

• Tool Installation: Installing the right tool for the specific operation.

• Initiate Operation: Machine starts as per the provided design and parameters.

• Cutting Process: Tool moves over the material, shaping it according to the design.

• Monitoring Progress: Overseeing the operation to ensure correctness.

• Post-Operation Clean-up: Cleaning and inspection after the completion of the process.

• Design Input: Software allows digital input of the design.

• Path Generation: Software calculates the best tool path.

• Parameter Settings: Provides interface for setting operation parameters.

• Machine Control: Allows user to control and adjust the machine's operation.

• Progress Monitoring: Software monitors the process to ensure adherence to the design.

• Error Detection: Identifies and flags any operation anomalies.

• Simulation: Enables simulation of the operation before actual production.

• Post-Processing: Deals with the extraction of final product.

• Data Storage: Saves data for future use and review.

• Operation Reporting: Generates reports detailing the operation.

• Cartesian Coordinates: Utilizes X, Y, Z coordinates to define tool movement.

• Tool Path: The route followed by the tool on the workpiece.

• Feed Rate: The speed at which the tool moves over the material.

• Axis Control: Manipulation of the machine's different axes.

• Tool Changing: Changing tools as per the requirements of the operation.

• Spindle Speed: Controls the speed of the rotating spindle.

• Coolant Control: Regulates the application of coolant during the operation.

• Emergency Stop: Option to halt the machine during emergencies.

• Re-calibration: Periodic recalibration ensures sustained precision.

• Positioning Correction: Corrects any inaccuracies in tool positioning.

CNC in bed refers to the bed of a CNC machine where operations occur. CNC milling machines are common, featuring a moving table. To control the tool's path, Computer Numeric Control (CNC) systems are deployed. Part specifications are entered into the CNC system. Precision is enhanced through these actions.

These machines involve workpieces rotating against a cutting tool. The machine's bed is where the tool moves in two axes. By leveraging CNC technology, more intricate cuts can be achieved on the workpiece. Trust in such technology due to high precision.

CNC plasma cutters bring unique capabilities. They are known for high-speed metal cutting, working on the machine's bed. The CNC system manages the cutter's movements, allowing complex shapes to be formed. Remember, accuracy is the key!

In the field of CNC machines, laser cutters stand out. Operating on the machine's bed, they use a high-power laser for cutting. The CNC system guides the laser beam, leading to exact cuts. Its high accuracy highlights its authority in the industry.

Utilizing high-pressure water, these machines perform cutting operations on the machine's bed. The CNC system controls the water jet, producing fine cuts. Their ability to cut various materials underscores their versatility and importance.

Unconventional yet highly effective, these machines use electrical discharges for cutting. Controlled by the CNC system, they offer high precision and complexity in the final product. They are a testament to the power of CNC technology.

In woodworking, CNC wood routers are significant. They carve intricate patterns on the wood, managed by the CNC system. This control results in improved precision and reduced waste, boosting efficiency in operations.

Specialized for glass cutting, these CNC machines provide clean and exact cuts. Under CNC control, the glass cutting process becomes safer and more precise. They demonstrate the broad application of CNC technology.

Precision is crucial for engraving, and CNC engraving machines fulfill this need. They etch intricate designs on various materials, guided by CNC systems. The resulting products are often stunning, showcasing the machine's capabilities.

The newest addition to the CNC family, 3D printers work on the machine's bed to create three-dimensional objects. By controlling the deposition of material layers via CNC, they can produce highly complex shapes with precision. They epitomize the future of manufacturing.

CNC in bed can shape aluminum effortlessly. Aluminum, having a 2700 kg/m^3 density, allows for a cutting speed of 2000 mm/min. The CNC process employs parameters like X, Y, and Z for precise movement.

CNC machines ensure unmatched steel’s precision mold. High-carbon steel, offering hardness above 60 HRC, requires a feed rate below 1000 mm/min. Spindle speed and depth of cut contribute to the perfect finish.

Copper, a soft metal, gets a perfect shape with CNC in bed. With an 8920 kg/m^3 density, CNC machines maintain a cutting speed around 1500 mm/min, adjusting axes X, Y, and Z.

Brass, easily machinable by CNC in bed, allows a faster cutting speed. Variables like feed rate, spindle speed, and coolant supply play significant roles in creating a smooth finish.

CNC in bed accommodates plastic materials. ABS plastic, with a low melting point, involves a spindle speed of 18000 RPM. Alongside, the CNC machine adjusts feed rates and cooling systems.

Wood carving benefits from CNC in bed. Based on the wood's hardness, spindle speed varies between 12000 to 24000 RPM. Parameters like depth of cut and cooling get specific attention.

Glass machining using CNC in bed requires specialized bits. The glass's delicate nature, optimal RPM ranges from 45000 to 60000. CNC parameters focus on gentle material removal.

CNC in bed molds ceramics with high accuracy. As ceramics feature high hardness, feed rates are kept minimal, while coolant supply gets controlled for temperature regulation.

Composites pose unique challenges to CNC in bed. Layered composition dictates spindle speeds around 20000 RPM. Appropriate coolant usage and depth of cut adjustments ensure quality output.

Precious metals like gold and platinum are shaped using CNC in bed. Given their high value, CNC parameters like feed rate, cutting speed, and spindle RPM are carefully calibrated.

CNC in Bed offers compactness. Second to none, these machines fit easily into smaller workshops. Space optimization is the main highlight here, unlike large-scale traditional CNC machines.

Unlike other CNC counterparts, CNC in Bed boasts adaptability. Smooth operations on diverse materials such as plastic, wood, and metals are assured.

Energy efficiency is a strong suit of CNC in Bed. Lower power needs mean cost savings, unlike high-power demanding CNC machinery.

CNC in Bed excels in precision. With micron-level accuracy, these machines outperform other CNC variants.

Speed is another area where CNC in Bed shines. High-speed engraving and milling without compromising accuracy are key features.

The less complex design of CNC in Bed is appealing. The simpler system ensures easy operation compared to more complex CNC machinery.

Economical in nature, CNC in Bed reduces upfront expenses. Other CNC machines may entail higher costs.

Fewer maintenance demands are an attractive attribute of CNC in Bed. This contrasts with other CNC machines that require frequent upkeep.

The applications of CNC in Bed are numerous. These include small-scale engraving, prototyping, and even DIY projects, providing versatility unmatched by some CNC machines.

Deciphered what CNC in Bed stands for, its role in various industries was discussed. Saw how software assists its function and the common problems one might face. For expert solutions, visit CNCYANGSEN.