In this guide, we explore Vertical Lathe vs. Horizontal Lathe. Our focus is their differences. This knowledge helps in choosing the right lathe for specific needs. Each type has unique features and applications.

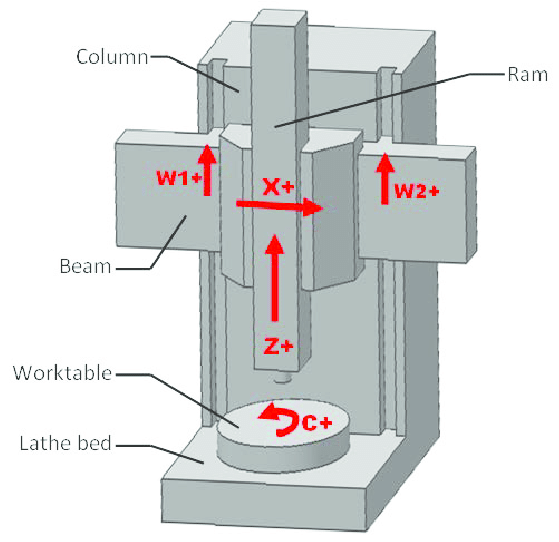

In vertical lathes, the workpiece spins vertically. This setup handles heavy, large items. Horizontal lathes rotate workpieces horizontally. They are ideal for longer, cylindrical parts. The main spindle holds the workpiece in both types. The chuck connects to the spindle, gripping materials securely.

Tool turrets hold cutting tools, essential for shaping. Carriages move the tools along the workpiece. Tailstocks provide additional support, ensuring accuracy. The bed forms the lathe's base, giving stability. Controls allow precision adjustments, vital for quality.

Each lathe type has a specific headstock design, fitting its orientation. Motors power the spindle, crucial for operation. Cooling systems prevent overheating, preserving the machine. Chip conveyors remove debris, maintaining cleanliness. Safety guards protect users, a must in workshops.

These components form the backbone of lathe operations. Their design varies between vertical and horizontal lathes, reflecting different uses. Understanding these differences is key for selecting the right lathe.

In lathe machines, the material rotates. In a Vertical Lathe (VL), materials stand upright. In a Horizontal Lathe (HL), materials lay sideways. VL handles heavy, large items better. HL is great for longer, slender pieces.

Both VL and HL have cutting tools. These tools shape materials. VL's tool moves vertically and horizontally. HL's tool also moves in two directions, but differently due to the material's position.

Feed control is crucial. It controls how the tool meets the material. In VL, gravity helps with downward feed control. In HL, feed control is more manual, needing careful adjustment.

Depth adjustment lets the tool cut correctly. VL and HL have knobs for this. They change how deep the tool cuts into the material. This adjustment is vital for precision.

Speed control is key in lathes. VL often has a range of 100-300 RPM (rotations per minute). HL offers 30-2500 RPM. Speed variation affects the finish and quality of the piece.

Vertical lathes stand up, good for tall parts. Horizontal lathes lay flat, better for long parts. Verticals handle heavy, large pieces. Horizontals are great for longer, slender pieces.

Verticals have a top-to-bottom setup. Horizontals spread out side-to-side. Verticals often need less floor space. Horizontals offer easier access to the part being worked on.

Computer controls help CNC lathes. Vertical CNCs specialize in precise, complex cuts. Horizontal CNCs excel in fast, repetitive tasks. Both types use digital precision for accuracy.

Vertical tool room lathes suit specialized tasks. Horizontal tool room lathes are versatile for various jobs. Each type has specific strengths for certain tasks.

Bench lathes come in vertical and horizontal forms. Vertical bench lathes save space. Horizontal bench lathes are common in many workshops. Both types fit smaller work environments well.

Vertical lathes, often abbreviated as VTLs, excel in handling large, heavy workpieces. Unlike horizontal lathes, VTLs hold the workpiece vertically. This design maximizes stability for bulky items. Key components include a vertically oriented spindle and a chuck for clamping.

The spindle speed in VTLs ranges from 0 to 2500 RPM. The diameter of the chuck varies, often reaching up to 10 meters. This design minimizes the footprint, optimizing space in workshops.

VTLs are ideal for turning, boring, and facing large parts. Their configuration allows easy access to the workpiece, enhancing operator safety. Transitioning to horizontal lathes, the contrast becomes evident in their design and application.

Vertical lathes excel with heavy materials. Their design allows handling big, bulky items. Unlike horizontal lathes, gravity aids in securing the material. Verticals handle weights up to several tons. They're ideal for heavy, large-scale work. This makes them a top choice in heavy industries.

Large parts find a match in vertical lathes. Their vertical orientation means less floor space is needed. They can accommodate diameters up to 10 meters. Horizontal lathes require more room. For large part machining, verticals offer efficiency and precision.

Flange production favors vertical lathes. They allow easy access to the part surface. This access simplifies complex machining tasks. Horizontal lathes can struggle with such parts. Vertical lathes provide precision in flange shaping and drilling.

Ring shaping is another vertical lathe domain. Their setup facilitates symmetrical machining. Horizontal lathes can't match this efficiency for ring-shaped parts. Verticals ensure uniformity and accuracy in circular parts, essential in ring production.

In die molding, vertical lathes stand out. They offer superior accessibility for intricate shapes. Horizontal lathes may face challenges with complex dies. Verticals deliver precision in creating and refining molds, crucial in die manufacturing.

Vertical lathes excel in compactness. They occupy less floor space than horizontal lathes. This is crucial in tight workshops. Vertical designs integrate key components upwards, not outwards. This vertical arrangement maximizes workshop layout efficiency. Comparatively, horizontal lathes spread over more area. Vertical lathes offer more room for other machines or activities.

Loading materials onto vertical lathes is straightforward. Their vertical orientation facilitates overhead crane access. This eases the handling of heavy or bulky materials. Horizontal lathes require more manual labor for material placement. Vertical lathes ensure easier, safer material loading. It reduces the risk of injury and material damage.

Vertical lathes support heavier workpieces than horizontal lathes. Their base provides a stable foundation for large, heavy items.

Horizontal lathes can struggle with such loads. Vertical lathes manage these with less stress on machine components. Thus, they are ideal for heavy-duty machining tasks.

The design of vertical lathes enhances stability. Workpieces are evenly balanced on the base. This minimizes wobble and inaccuracies during machining.

Horizontal lathes can experience stability issues with unevenly balanced workpieces. Vertical lathes consistently deliver precise results, even on complex jobs.

Vertical lathes, or VTLs, often face restrictions in handling varied shapes. Unlike horizontal lathes (HLs), VTLs struggle with non-cylindrical parts.

VTLs excel in handling large, heavy workpieces. For complex shapes, HLs offer more flexibility. VTLs are less adaptable for diverse machining tasks.

VTLs generally cost more than HLs. The price difference arises from their robust structure. VTLs require more material in their construction. This results in a higher initial investment.

Operating costs for VTLs can also surpass those of HLs. VTLs need specialized tools and maintenance, adding to the overall expense.

Setting up a VTL is more intricate than an HL. VTLs demand precise alignment due to their vertical orientation. This complexity increases setup time.

Skilled operators are essential for accurate VTL setup. The complexity can delay production. HLs are simpler to set up and start.

VTLs are bulkier than HLs. They take up more floor space. It can be a drawback in limited-space workshops. VTLs' size affects transportation and installation.

HLs are more compact, easier to move and set up. Size is a crucial factor when choosing between VTLs and HLs.

Horizontal lathes feature a spindle in a horizontal orientation. Workpieces mount on these spindles. This layout suits cylindrical or conical shapes. Operators find horizontal lathes easy for chip removal. Their design promotes better operator visibility. Vertical lathes have a vertical spindle. They excel in handling heavy, large diameter workpieces.

Their footprint is smaller, saving floor space. Vertical lathes often feature a rotary table for holding the workpiece. This setup aids in machining complex parts. Both types use CNC technology for precision. Horizontal lathes are more common in general machining.

Vertical lathes specialize in particular applications. Each type has distinct advantages based on the project.

Horizontal lathes excel in shaft turning. Their design suits long, cylindrical workpieces. Conversely, vertical lathes handle larger, heavier items.

Precision in horizontal lathes is key for shafts. Sizes and capabilities vary, but horizontal lathes often have a swing over bed of up to 40 inches.

Prototyping benefits from horizontal lathes. They offer flexibility for diverse shapes. Vertical lathes, however, are less versatile but stronger for heavy-duty tasks.

Horizontal lathes can quickly adjust for small, intricate parts. Their speed ranges 30-3000 RPM, aid in precise prototyping.

In mass production, horizontal lathes shine. They handle high-volume, repetitive tasks efficiently. Vertical lathes can manage larger parts but with less speed.

Horizontal lathes often feature multiple spindles, enhancing production rates. Their tooling options adapt easily for various production needs.

Thread cutting requires accuracy, strength of horizontal lathes. Their design supports detailed work on smaller diameters. Vertical lathes focus on larger diameters and surfaces.

Horizontal lathes' chuck sizes, commonly ranging from 6 to 24 inches, accommodate diverse threading jobs.

Horizontal lathes work with a broad array of materials. They shape metals, plastics, and wood. This makes them a go-to for diverse jobs. In comparing Vertical Lathe vs. Horizontal Lathe, the horizontal type often wins in versatility.

These lathes are user-friendly. Operators find them simpler to work with. Their design is straightforward. Controls are easy to reach and manage. New users learn them quicker than vertical ones.

A horizontal lathe handles big and small pieces. It works on long shafts and tiny components. Its range is impressive. This is a key point in the Vertical Lathe vs. Horizontal Lathe debate.

Operators see their work clearly on a horizontal lathe. This clear view helps in precise cutting. It reduces errors. Good visibility is crucial for complex tasks.

Setting up a horizontal lathe takes less time. This means more work done in less time. Shops save time and boost productivity.

Horizontal lathes demand more floor space. This need can be a constraint in smaller workshops.

When it comes to handling very large or heavy pieces, horizontal lathes falter. This is where the debate of Vertical Lathe vs. Horizontal Lathe gains attention. Vertical lathes, with their upright orientation, manage these tasks better.

Operating a horizontal lathe needs specific skills. The learning curve can be steep for new users.

These lathes require regular upkeep. Parts like the chuck and tailstock need frequent checks. Maintenance ensures precision in machining tasks.

Vertical lathes, with their upward orientation, consume less floor space. This design allows for a smaller footprint in a workshop. In contrast, horizontal lathes stretch outwards, requiring more room. The choice here often depends on workshop size and layout.

Vertical lathes excel in handling heavy, large parts. Their structure allows for more even distribution of weight. Horizontal lathes, while versatile, face challenges with very heavy loads. This limitation stems from their horizontal axis, which can lead to uneven weight distribution.

Horizontal lathes offer greater flexibility in terms of the range of operations. They can perform turning, boring, facing, and threading with ease. Vertical lathes, while less versatile, are ideal for specific tasks like heavy-duty metal cutting.

Both lathe types can achieve high precision, but their CNC linear rail types play a vital role. Precision in horizontal lathes is often higher due to their stable setup. Vertical lathes, while precise, may face challenges with very tall parts.

Cost-wise, vertical lathes are generally more expensive. This is due to their specialized design for handling larger and heavier parts. Horizontal lathes, being more common, tend to be more affordable.

Vertical lathes often produce higher decibels due to their design. Engineers use sound dampening materials to reduce this noise. In contrast, horizontal lathes typically have lower noise levels. Effective noise control in vertical models includes installing sound barriers.

This approach ensures a quieter working environment. Both types need regular maintenance for optimal noise reduction.

Vibration in vertical lathes can affect precision. Solutions include using vibration dampeners and robust machine bases.

Horizontal lathes experience less vibration, attributed to their horizontal axis. Stabilizing components in vertical lathes is crucial for accuracy. Regular checks help maintain low vibration levels in both types.

Heat generation in vertical lathes can be significant. Cooling systems are essential in these machines. Horizontal lathes also generate heat, but to a lesser extent.

Effective temperature management involves using fluids and fans. Regular temperature checks ensure the longevity of both lathe types. This practice prevents overheating and maintains performance.

Chip disposal in vertical lathes requires strategic design due to gravity. Horizontal lathes benefit from easier chip removal. Both types use conveyors for efficient chip disposal.

Regular cleaning of disposal systems is vital. This maintenance prevents clogs and ensures smooth operation. Proper chip management is key for both vertical and horizontal lathes.

|

Operating Challenges |

Solution 1 |

Solution 2 |

Solution 3 |

Key Metrics |

Industry Standard |

Potential Improvement |

|

Noise Control |

Soundproof Enclosures |

Acoustic Dampening Materials |

Active Noise Cancellation Systems |

Decibel Reduction |

≤ 50 dB |

-10 to -15 dB |

|

Vibration Reduction |

Anti-Vibration Mounts |

Vibration Dampening Pads |

Tuned Mass Dampers |

Vibration Frequency |

< 5 Hz |

20-30% Reduction |

|

Temperature Management |

Liquid Cooling Systems |

Thermal Interface Materials (TIMs) |

Heat Sinks and Ventilation |

Temperature Range |

0-35°C |

-5 to -10°C |

|

Chip Disposal |

Automated Collection Systems |

Eco-Friendly Disposal Methods |

Reuse and Recycling Programs |

Disposal Efficiency |

90% Efficiency |

5-10% Increase |

|

Power Efficiency |

Energy-Efficient Components |

Renewable Energy Sources |

Smart Power Management Systems |

Power Usage Effectiveness (PUE) |

< 1.5 |

10-15% Reduction |

|

Maintenance |

Predictive Maintenance Algorithms |

Modular Component Design |

Remote Monitoring and Management |

Downtime Reduction |

< 2 Hours/Year |

30-40% Reduction |

|

Cost Effectiveness |

Outsourcing Non-Core Activities |

Automation of Repetitive Tasks |

Lean Manufacturing Principles |

Cost Reduction |

10-20% of Total Cost |

5-15% Decrease |

This discussion on Vertical Lathe vs. Horizontal Lathe reveals critical differences. Understanding these differences helps in making informed choices for specific projects. For more insights, visit CNCYANGSEN. Here, deepen your knowledge and find the right lathe solutions.