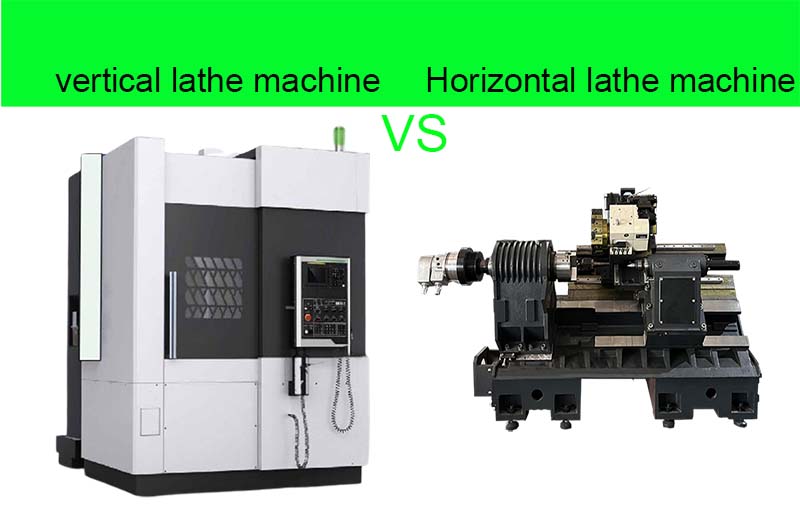

The CNC lathe is a numerically controlled machine tool used for cutting and machining rotating workpieces. It is one of the most basic and important machine tools in the metalworking and woodworking industries. The main function of a lathe is to hold a workpiece on a rotating spindle and use tools to cut its surface into the desired shape and size. Various processing operations can be automated. The main feature of CNC lathes is based on digital control, adopting preset operating procedures, and using dozens of turning tools for automatic processing. They can control the machining position such as horizontal and vertical turning, centers well as cutting with high precision through the horizontal, vertical, and height coordinate axes, and can freely control the machining by controlling the rotation speed and the moving speed fixed position of the tool according to the material and target shape of the workpiece. When it comes to turning operations in the machining process, vertical lathes and horizontal lathes are two common tools. They each have different characteristics and applications. This article will compare and analyze these two lathes.

Vertical lathe orients spindles in line with gravity work the vertical plane orientation. The workpiece rotates to position the spindle and tool according to the gravity of the desired tool. The vertical lathe is more complicated than a horizontal machine. These horizontal machines can offer a better option when focusing heavy workpieces on one side such as heavy workpieces as large metal plates and sinking dies. They can offer advantages to horizontal lathes when rotating workpieces and sagging may occur.

The stability advantage of Vertical Lathes structure is, vertical lathes can usually provide higher machining accuracy. For the turning of various machines and large workpieces and machines, efficient vertical axis turning lathes can maintain better rigidity and reduce vibration, resulting in higher-quality machined surfaces.

Due to its ability to handle larger workpieces and its advantage of high rigidity, vertical lathes are widely used in aerospace production, the automotive industry production, heavy machinery manufacturing, and production, and other fields. They are often used for turning large wheel hubs, wind turbine blades, aircraft engines, and other parts.

The structure of cutting, tooling, and equipment for the vertical lathe machine is complex and usually relatively heavy cuts bulky, requiring more installation space. This may be limited in some small workshops.

The footprint of a vertical lathe of equipment is primarily determined by the size and length of the lathe's bed and the swing diameter of a single machine, which is the maximum diameter of the workpiece that can be accommodated by the machine. In general, the larger the swing diameter, the more floor space the vertical lathe will require.

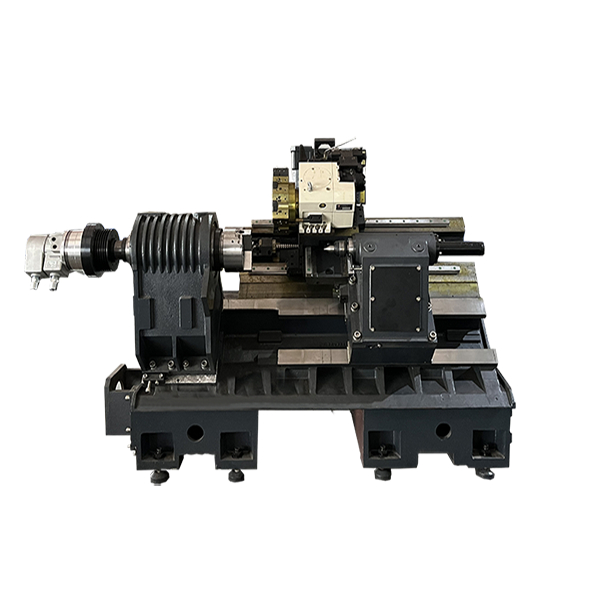

The spindle of the horizontal lathe is placed horizontally, the workpiece is oriented vertically and clamped on both sides of the spindle, and the vertical turning or tooling part cnc lathe is cut above the spindle or on the side of the spindle on single side of the spindle on one setup of the workpiece. Horizontal lathes are suitable for smaller and lighter workpieces because of their relatively simple structure and are suitable for machining small parts.

Horizontal lathes are suitable for simpler turning operations, and for the machining and production of some precision machines and parts, more attention may be required to control vibration and maintain machining quality. However, horizontal lathes can perform complex machining tasks more efficiently in some cases, especially when producing similar machines and machine parts in high volumes.

Horizontal milling lathes are widely used in the various other milling machines, vertical milling turning machines, general machining and metalworking industries. They are suitable for milling and vertical turning smaller workpieces such as shaft parts, gears, pins, threads, etc.

Compared with vertical lathes, horizontal lathes are more compact and suitable for workshops with horizontal lathe machines having limited space.

The biggest difference between a vertical lathe and a horizontal lathe is the spindle. The vertical type of spindle means that the machine or main shaft is upright, straight turning and the horizontal type means that the machine or main shaft is recumbent.

Since the weight of the workpiece is directly loaded on the workbench when the vertical lathe is working, and the workbench distributes the weight to the bed, the vertical lathe has a large load capacity and good rigidity and is very efficient and suitable for processing large-scale, large-diameter, and conveyor small-length Workpieces, such as discs, hubs, gear blanks bar feeders, etc.

The workpiece clamp of the cutting head of two main types of the horizontal lathe is on the axis of gravity of the chuck, and the load is transmitted to the axis of the main shaft spindle, which is borne by the front and rear main bearings, so the carrying capacity is small and the rigidity is also poor. But the observation and operation of the horizontal lathe are very convenient and efficient, so it is suitable for processing small and medium-sized drill roulette and shaft parts.

CNC turning centers are more common because they are flexible and have greater tooling capabilities. with both CNC turning centers and horizontal turning centers used, lathes continue to have an important position in part machining and milling machines. These 5 common functions most commonly performed by lathes:

Turning: Turning is the primary function of a lathe and involves removing material from a rotating workpiece to create cylindrical shapes. The workpiece is held in the chuck or mounted between centers, and a cutting tool is brought into contact with the workpiece to create the desired shape and dimensions.

Facing: Facing is a machining operation where the cutting tool is moved radially across the end of the rotating workpiece to create a flat surface perpendicular to the axis of rotation. This process is often used to create a smooth and even surface on the end of a workpiece or to remove any uneven material.

Drilling: Lathes can also be used for drilling holes in workpieces. A drill bit is mounted on the lathe's tool holder, and the workpiece is rotated to create a hole of the desired diameter and depth.

Boring: Boring is a process that enlarges or refines existing holes in a workpiece. It is achieved by mounting a boring tool on the lathe and rotating the workpiece while the cutting tool moves into the hole, removing material to create the desired size and surface finish.

Tapering: Tapering involves turning a workpiece with a gradual decrease or increase in diameter along its length. This can be achieved by adjusting the angle of the tool relative to the workpiece as it rotates, allowing for the creation of conical or tapered shapes.

These functions represent only a fraction of the capabilities of main types of lathes, as they can perform a wide range of other operations, including threading, grooving, knurling, and more. The specific tasks a lathe can perform depend on its design, tooling, and the skill and equipment of the operator.

Both vertical and horizontal lathes play an important role in machining. Choosing a suitable lathe depends on the size of the workpiece, processing requirements, machining times, production efficiency, and the actual situation of the factory. For larger and heavier workpieces, and where there is a higher requirement for machining accuracy, a vertical lathe is a better choice. However, for smaller and lighter workpieces and for high-volume production, horizontal lathes may be more advantageous. No matter which lathe you choose, proper operation and maintenance are key to ensuring machining quality and productivity.