CNC machining also continues to provide the points of choice and decision for artisans and engineers who see the tradeoff between Water Cooled Spindle vs. Air Cooled counterparts as a critical factor. These ventures make us travel through the depths of cooling effectiveness, noise levels, high operational costs, and short performance period. Balancing the spindle alloy precision consideration with the ambient slack is our target as this pointer will indicate the direction to the Match-up of the apt spindle ally and you can take a step forward to start your projects with excellence and innovation.

· The role of spindles in CNC machines

The spindles of the CNC machines not only control quality cutting speeds and the accuracy of the cutter, but are also essential in controlling the jerking motion of the cutter. In that regard, whether to go for water-cooled or air-cooled spindles is something that will have a significant impact on performance. For instance, you may want to consider a water-cooled spindle, which allows for a consistent temperature and thus extends durability and perceptual uncertainty (especially at high RPMs).

However, water-cooled systems use air-cooled spindles, which are less complicated and require fewer maintenance procedures, particularly in these environments that the again focusing of water is problematic. Kind of gender controls particular ones, therefore, the finishing and tool lives are influenced.

Water cooled spindles shine through the high cooling capacity exerting the coolant to disappear the heat from this place. Air-cooled systems use ambient air which is almost 100% less efficient under high load (in comparison with liquid-cooled solutions).

Water cooling enables the system to have lower spindle temperatures, which consequently positively affects performance as well as quality. So, water coolers have not been displaced completely by air coolers because of the reason that the air coolers are used for lighter jobs while the water coolers are applied for continuous, heavy-duty use.

The thermal efficiency is high in the water cooled systems owning to a wide range of uses including superior and effective cooling. Their sustainability could be utilized even under harsh environmental conditions such as prolonged operations. However, the best performing air based solutions lag in prolonged intense run-ups, when they are unable to keep up the heat dissipation, which is crucial for their proper functioning.

Spindle operation temperature can be precisely regulated by using water cooling, meaning heat generation is minimized and stability is maintained, which are key when performing specific operations.

FPM limitation can be chosen among different temperature cooling methods. Heat management is the leading restriction of air cooled spindles' application throughout relatively low RPM.

Water cooled units can keep RPM high, given the fact that temperature controls are switched on and expedite their regulation. It makes operations efficiently speed up; beat any time or high volume production by doing so. Selecting the one cooling system among various applications can play a crucial role in ensuring not only operational efficiency but also output quality.

The noise level is a notable difference when indoors and outdoors Spindles with air-cooled design have fans that have to work hard to blow the heat out. So, the resulting activity is loud. It is often the case that water cooled systems keep their operation very calm, for the liquid nominally soaks up the heat of the system.

Setup complexity contrasts between the two. Air cooled spindles are plug-and-play, requiring minimal installation effort. Water cooled systems need a coolant source, pump, and proper routing, increasing setup time and complexity. However, the performance benefits of water cooling often justify the additional setup efforts. Each system's complexity must be weighed against operational needs and technical capabilities.

Air cooler systems contain fans which transmit air around the spindle, draining heat. This operation is to a great extent heavily reliant on external ambient temperature, with the consequence of reduced efficiency. A free air-flow must be provided therefore untroubled, clean, and dust-free atmosphere is required. Highly effective air cooling system controls the temperatures of spindles for operation between safe maximum limits and the other participating in moderate use.

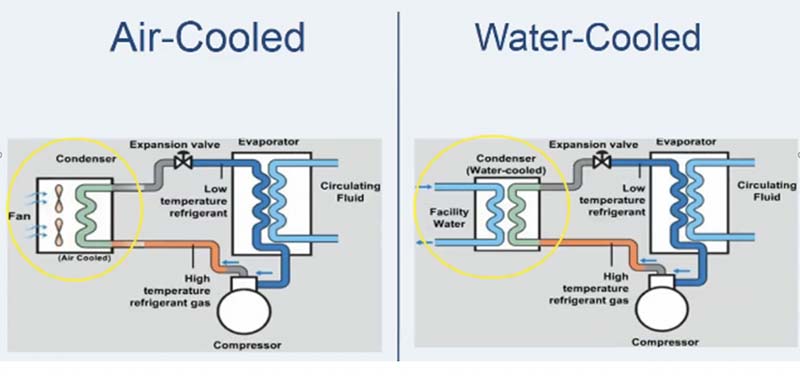

Coolant flow is achieved by pumping it through the channels which are constructed in the center of a spindle. The coolant is actually in close contact with the spindle so see should absorb the heat directly from it and the coolant should carry the heat away.

The system includes a radiator and pump, which are the core components responsible for conducting the flow of the Antifreeze. Water cooling's direct heat dissipation proves to be more efficient in long-term time-critical situations compared to air cooling.

Transfer of thermal energy in a water cooled system is at the highest levels that a radiator would be used to shed the heat from the coolant. In air cooled spindles, air medium means that operating spindles are warmed directly by the surrounding air thus, not very effective compared to other cooling means when functioning under a heavily loaded power.

Corrective heat transfer is imperative for spindle operations, and cognates water cooling supply highest quality solution for the heaviest tasks.

Thermal control in the water cooled spindles is very exact and the mechanisms commonly use thermostats to maintain the temperature requirements. There is a greater degree of certainty in water-cooled systems and that is because temperature control isn't affected by the surroundings. Adequate precision through efficient heat control adds years to the life of a spindle as well as improving a spindle's accuracy in high-precision jobs. Hence water cooled machines is the best for this purpose.

RPM regulation may simply be different depending on the different cooling methods. Heat creep may cause the road speed of the bearings run in oil to shift at high speeds that will undoubtedly create accuracy problems. Water cooled systems running along a regime map successfully keep the temperatures steady but the RPMs may become irregular even under high loads. They (water cooling) may well have superiority of being stable for these tasks and missions that are aiming for high precision CNC machined and speed.

Choosing between water cooled and air cooled affects precision. Water cooled systems maintain stable temperatures, crucial for precise cuts and detailed work. Air cooled may fluctuate, impacting accuracy. For tasks demanding high precision, water cooling is the superior choice.

Durability hinges on consistent temperature on the accuracy control. Water cooled spindles run cooler, extending life by preventing overheating. Air cooled systems, less effective in heat management, may lead to faster wear. Thus, water cooling enhances spindle longevity, a key factor in operational lifespan.

Efficiency in cooling translates to operational benefits. Water cooled systems offer higher thermal efficiency, keeping spindles at optimal performance levels. Air cooled alternatives struggle under heavy loads, reducing efficiency. The right choice boosts overall productivity, with water cooling leading in demanding applications.

Performance peaks with proper cooling. Water cooled spindles sustain high speeds without thermal penalties, enabling consistent output. Air cooled spindles may suffer from heat-induced performance drops. Selecting water cooling ensures peak performance, especially in intensive machining processes.

Initial setup costs and long-term operation expenses differ. Air cooled spindles are cheaper upfront but may incur higher maintenance costs. Water cooled options, though pricier initially, offer lower operating costs due to enhanced durability and efficiency. Balancing these factors is crucial for cost-effective spindle operation.

Air cooled spindles outdo the complex cooling systems therefore excels in the cases in which high RPMs are the need. Their cooling systems are based on air surroundings and they are well suited for those operations where the speed is the major consideration instead of long lasting heavy loads.

Whilst air cooled spindles are perfect for use with the ambient air, they are ideal on operations occurring in room temperatures. Their operation is the best ones in environment without the cooling aid from outside, making them the most mobile in different occupations

For the initial spending stage, an air cooled spindle will be cheaper in comparison with a water cooled option. This cost advantage allows them to be a viable and pretty deal for the companies that want to pay minimally and obtain repeatable performance.

Spindles, whose cooling elements are a small portion of spindle components placed, in air lessening cooling system complexity even though many think it requires a big deal. This brings us to the ready-to-use plug-and-play approach which literally reduces the installation time and enables quicker rollout of deployment in production.

Air cooled spindles as a result makes it easier to go through unsophisticated maintenance procedures due to their fewer parts to attend. This simplicity is being translated into less downtime and lower overall operational costs over time, therefore making CNC machines practical and widely applicable as machining tools.

Water-cooled spindles sparkle in effective temperature control, that vital element for businesses focused on tight thermal control. - This control deteriorates thermal drift which brings along and maintains previous exact machine performance across long periods of time.

This water cooled motors Mutter flatly, generating less sound compared air cooled alternatives. Among many facilities, this function is especially essential for sound-sensitive workplaces that raise productivity and enhance the communication among people.

The out class’s thermal stability of water cooled spindles obviously brings to your mind high-precision applications. Regular temperatures are like a stable base for the best quality tools and hence the majority of them are applied on detailed tasks that need complexity and accuracy.

Operating with desired temperatures, water-cooled spindles enable the reduction of thermal deformations, wear, and tearing. Consequently, this extends their lifetime that guarantees durability and reliability aspects in applications where both are compulsory with either a while capacity or a long duration.

Water cooled spindles outperform air cooled in cooling efficiency, offering precise temperature control even under high loads. This efficiency is crucial for maintaining performance and preventing overheating, making water cooled the preferred choice for intensive machining tasks.

Air cooled spindles generate more noise due to fans; whereas water cooled spindles operate quietly. This difference makes water cooled spindles suitable for environments where noise reduction is a priority, enhancing work conditions and reducing acoustic stress.

While air cooled spindles provide high RPMs suitable for various tasks, water cooled spindles maintain higher speeds more consistently. This capacity for sustained high-speed operation makes water cooled spindles ideal for demanding applications requiring precision and efficiency.

Air cooled spindles offer simpler setup with minimal requirements, ideal for quick deployment. In contrast, water cooled spindles require a more complex setup involving coolant systems, but the performance benefits often justify the initial effort.

Maintenance for air cooled spindles is straightforward due to fewer parts; whereas water cooled spindles require regular checks on the coolant system. Despite this, the enhanced performance and durability of water cooled spindles can offset the more involved maintenance routine.

|

Feature |

Water Cooled Spindles |

Air Cooled Spindles |

|

Cooling Efficiency |

High; direct coolant contact |

Moderate; dependent on ambient air |

|

Operation Noise |

Low; quiet coolant flow |

High; fan operation |

|

Speed Capacity |

Higher; stable temperatures allow |

Lower; affected by ambient temperature |

|

Setup Demands |

Complex; requires coolant system installation |

Simple; minimal components |

|

Maintenance Routine |

Regular coolant checks, system maintenance |

Less frequent; mainly fan and filter cleaning |

|

Temperature Stability |

Excellent; consistent cooling |

Good; can fluctuate with environment |

|

Cost |

Higher initial; lower operational costs |

Lower initial; potentially higher maintenance costs |

Table on Comparative Analysis: Water Cooled vs. Air Cooled Spindles!

Consider the project's demands: air cooled spindles interestingly fit light tasks, whereas water cooled ones are the go-to option for extremely intensive and heavy-duty works. Picking the correct spindle matches the performance and quality with the type of the job thanks to this.

Ambient temperature plays a critical role: water cooled spindles get spoiled in environment with high temperature; however spindles with air cooling continue to have performance to provide consistent cooling. Select the size of your air conditioning unit considering the temperature of the room that is the most frequent for your workspaces. This will ensure that it functions properly.

Evaluate maintenance capabilities: air cooled spindles come along with simplistic support while water cooled systems encompass realizing whether the coolant is replaced or not and performing the system service at regular intervals. Select the location which has the most balanced parameters in accordance with your team's ability to satisfy them.

Budget impacts selection: although air cooled machine spindles feature lower initial price, the water cooled ones can bring better long-term savings through performance and reliability. Analyze what you will be paying in the beginning and during the process to make the best educated decision.

The controversy between water cooled spindles vs. air cooled system reflects the route of high-precision and great-efficiency CNC operation. With the objective to decide whether to go for serene operation, which requires less heating or on the other hand, simplicity and maintenance project's main goal comes into play. Find your own wonderfully crafted spindle at The Wondrous Spindles website at CNCYANGSEN, the junction of innovation and craftsmanship.