"Computer-aided design" and "computer-aided manufacturing," or CAD/CAM, refer to the software used to develop and create prototypes, final goods, and production runs. It is often used with a computer numerical control (CNC) machine, a motorized, flexible tool, and a platform operated by a computer by predetermined instructions. It gives design through manufacture.

Geometrical characteristics assist the development of computer models using computer-aided design (CAD). These models often display a three-dimensional depiction of a component or system of parts on a computer screen, which may be easily changed by altering pertinent parameters. With CAD tools, designers may test their creations by mimicking various real-world scenarios while seeing them under multiple representations.

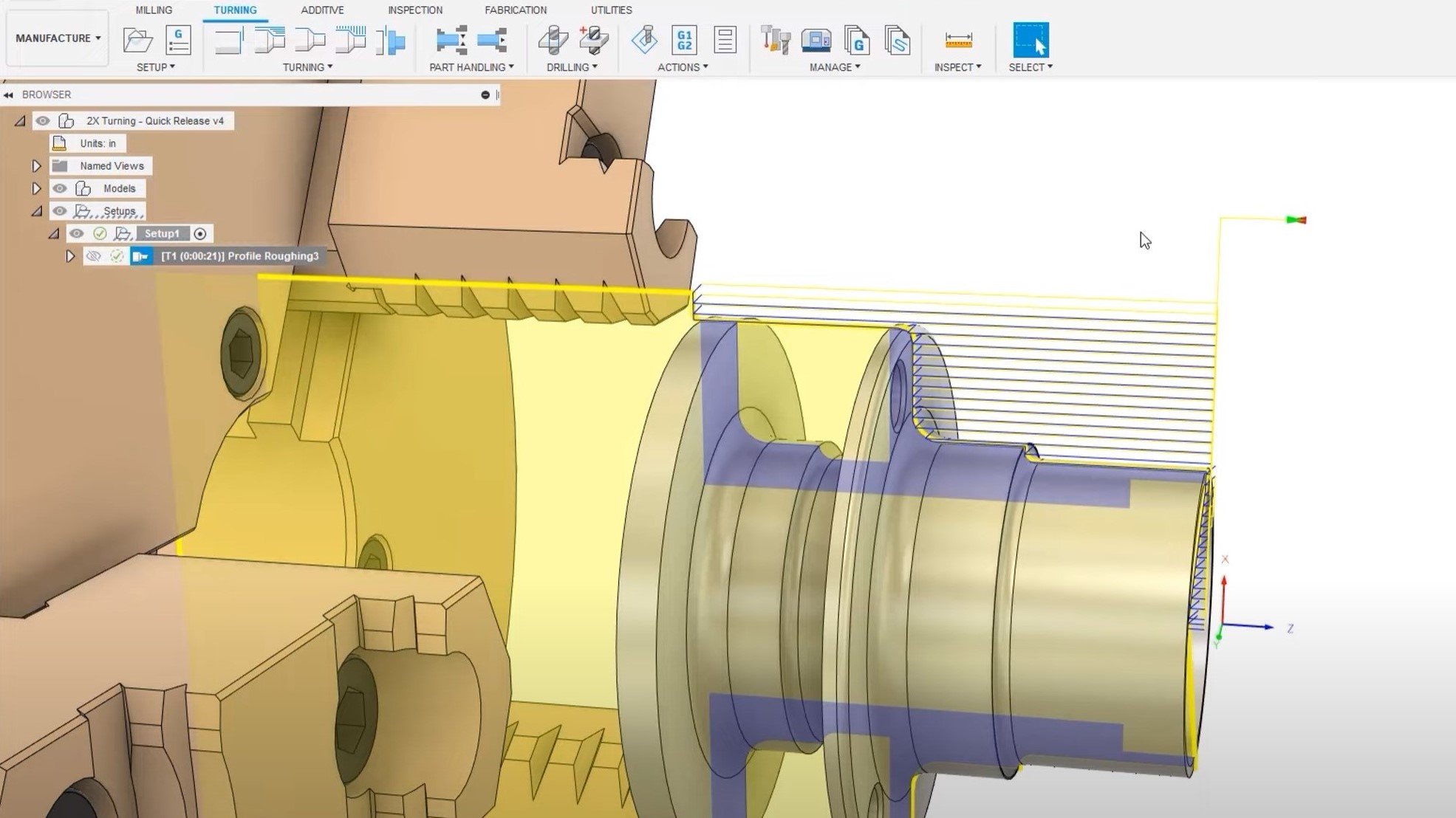

Geometric design data is used in computer-aided manufacturing (CAM) to operate automated equipment. Direct numerical control (DNC) or computer numerical control (CNC) systems are related to CAM systems. The geometrical data in these systems are mechanically encoded, which sets them apart from earlier types of numerical control (NC). The geometrical data is encoded using computer-based techniques in both CAD and CAM, allowing for high levels of integration between the design and manufacturing processes. Below is a breakdown of each phrase to help you comprehend CAD/CAM.

Computer-assisted design, or CAD, is the process of using computers to create, alter, and analyze designs for physical models of objects. Computer-aided drafting is another name for computer-aided design. Making 2D technical drawings and 3D models is the goal of CAD. Therefore, CAD gives the computer a representation of your component geometry. Engineers often use software for computer-aided design (CAD).

AutoCAD, Autodesk Inventor, CATIA, Solid Works, and other programs are examples of CAD software.

CAM refers to the process of producing modules while using computer software to manage machine equipment. Engineering ideas are turned into finished products through CAM. CAM uses automation in the production process, which sets it apart from traditional manufacturing. Computer-Aided Modelling or Machining are other names for computer-aided manufacturing. CAM's purpose is to generate machining processes from 3D models. The geometry is efficiently translated to the machine tool via CAM. Therefore, computer-aided manufacturing (CAM) is only meaningful with computer-aided design (CAD). Most skilled machinists utilize computer-aided manufacturing (CAM) software.

Work NC, Siemens NX, Power MILL, SolidCAM, and more CAM software examples are available.

It's time to examine how CNC uses CAD/CAM software. In a typical workflow, the programmer selects the design for the CAD model and evaluates the steps and equipment needed to create or assemble the necessary pieces. The person specifies the toolpaths, speeds, and feeds in the G-code. The machine operator then receives this program and configures the CNC machines by loading the G-code program and configuring tools. The machine will begin its preprogrammed activities once the system is ready.

|

Sr. No |

CAD |

CAM |

|

01. |

The acronym CAD stands for computer-aided design. |

CAM is an abbreviation for Computer Aided Manufacturing. |

|

02. |

Computers are used in computer-aided design, or CAD, to help create, modify, and analyze designs. |

CAM refers to the process of producing modules while using computer software to manage machine equipment. Engineering ideas are turned into finished products through CAM. |

|

03. |

Computer-aided drafting is another name for computer-aided design. |

Computer-Aided Modeling is another name for computer-aided manufacturing. |

|

04. |

The goal of CAD is to create 2D technical drawings and 3D models. |

CAM's purpose is to generate machining processes from 3D models. |

|

05. |

A technician needs a computer and CAD software to develop a design for the Computer-Aided Design procedure. |

A CAM machine is necessary for Computer-aided manufacturing, which is often also required for a CAM software package. |

Parts, fittings, and assemblies are designed using CAD software. It may be used to design new components, change current designs, or prepare parts for manufacturing. CAM software is used to program toolpaths and create G-code, which is used to drive CNC machines such as mills, routers, lathes, and wire EDMs. CAD/CAM software is used to move components from design to manufacturing in a streamlined manner. There’s a variety of CAD/CAM software free to download.

The use of CAD/CAM software is essential for CNC machining. Engineers may use 3D modeling methods to create components and assemblies using computer-aided design (CAD) software. Additionally, they can test designs for strength, durability, and dependability before making them, thanks to the software, which can imitate actual environmental factors.

The design from the CAD program is converted into machine-readable code by computer-aided manufacturing (CAM) software, which then commands the CNC machine. CAM software produces tool paths to optimize machining processes and automatically chooses cutting speeds and feeds. Manufacturers may enhance productivity and decrease programming time using CAM software, eventually lowering costs and boosting profitability.

Over time, CNC machine firms that used CAD-CAM software saw the benefits listed below.

One of the main advantages promised by the CAM is this. Prototypes are simple to build for the designers to test their ideas. These prototypes may be used to test different design elements.

Software for CAD-CAM offers great design freedom, making it simple for users to adjust certain design elements. Before the development of this program, design modifications were performed by draftspeople who would spend days redoing the design. However, users may quickly make tiny adjustments using CAD-CAM software packages. Using the program, they may also model the behavior of the invention.

Material waste is one of the main challenges businesses encounter worldwide as the cost of energy and materials rises. CAD-CAM is a technologically sophisticated program with excellent simulation capabilities. These capabilities enable users to monitor the machining process and simulate designs by specifications efficiently. The simulation function covers cycle times, toolpaths, part deviation analysis, and many other topics. In other words, by allowing users to see the toolpath before the material is cut, these software programs assist users in reducing material waste. This becomes essential for several applications where pricey metal alloys, intricate geometries, or components that need a lot of material may be present. Another benefit is that reduced material waste means less energy, money, and tool wear.

One of the primary differentiators for many CNC machine businesses has grown to be customization. Customized CAD-CAM has aided customized product growth. Custom designs are now created by CNC machine shops using CAD-CAM, which was formerly time-consuming and costly due to the labor required. These days, CAD-CAM companies provide creative or finely designed modules to create CNC components with artistic designs.

All cutting-edge CAM software programs guarantee high-speed tool paths, enabling machine operators to make deeper cuts faster. Cycle times can be cut by at least 70% with these fast toolpaths.

It's noteworthy that other less well-known fields employ CAD/CAM technology, like dentistry and clothing design, to mention two. While it is commonly known that CAD/CAM is used in AEC activities (Architecture, Engineering, Construction, and Manufacturing), there are other uses for this technology. In reality, CAD/CAM is used in one form or another by almost every business that creates a physical product or machine. This is the list created:

The aerospace sector produces devices and components for them, including satellites, airplanes, and missiles. These are expensive objects. Hence CAD/CAM software is essential to the design process. The program is used to visualize and design every aspect of a product before it is created.

Another substantial and costly project is building. Perfect planning is essential when designing anything as significant and expensive as a building. Another situation where both 2D and 3D CAD is utilized is this one. The program establishes accurate specifications, including measures, volumes, and weights, before construction starts, in addition to a project's actual design and layout.

Then, 2D floor plans are used for the actual building, and 3D visualizations are utilized to both check the correctness of the 2D programs and to assist potential supporters see the project's completion so they will be more willing to provide funding. Although housebuilders and designers are also increasingly using 3D visualizations, this is especially true for office buildings and other commercial constructions.

CAD/CAM software is employed to design components like tires, engines, upholstery, and circuit boards, and to manufacture 3D prototypes of new automobile body elements, CAD/CAM software is employed.

Bridges, parks, industrial buildings, office complexes, and other types of urban infrastructure are all planned by urban planners using CAD/CAM software. If not completely, but at least mainly, 3D CAD is also being utilized in this sector. Taxpayer money and resources are needed for urban planning. Most people need help seeing a park or playground from a two-dimensional graphic, much less a large professional stadium. Therefore, 3D CAD visualizations are the way to go if the planners want financial backing and support for a taxpayer vote. Find out more about the services offered by computer-aided engineering.

Fashion businesses employ CAD/CAM for large manufacturing. The program chooses the most effective cloth cut and modifies the design scale to accommodate various sizes. Even the fit and movement of the apparel may be shown using it.

In dentistry, CAD/CAM is used to virtually build-essential and complicated prosthetic pieces by digitizing dental anatomy and the oral cavity.

Forensic scientists can use CAD/CAM software to determine ages, analyze injuries, and identify postmortem remains. The software may provide a 3D representation of a crime scene.

CAD is used to develop digital designs, whereas CAM is used to build actual objects from those drawings. The combination of CAD and CAM technologies is known as CAD/CAM and is widely employed in contemporary production.

Q. Why does manufacturing employ CAD/CAM software?

Ans. Manufacturing uses CAD/CAM software to boost automation. This automation makes the production process more precise and productive, eliminating mistakes and saving time.

Q. Who makes use of CAM software?

Ans. Manufacturing experts utilize CAM software to create machining instructions for building components and tools from 3D digital CAD models.

Quality teams often use CAM software to define digital inspection.

Q. How does CAM software function?

Ans. To create instructions for Computerised Numerical Control (CNC) equipment, CAM software directly accesses the 3D CAD model geometry. Roughing and finishing activities need many sequences. Roughing sequences quickly use an excellent cutting tool to remove significant stock material. Finishing processes remove the residual stock material using smaller cutting tools. Advanced machining procedures provide multi-axis tool control to remove material from hard-to-reach sections of the model.