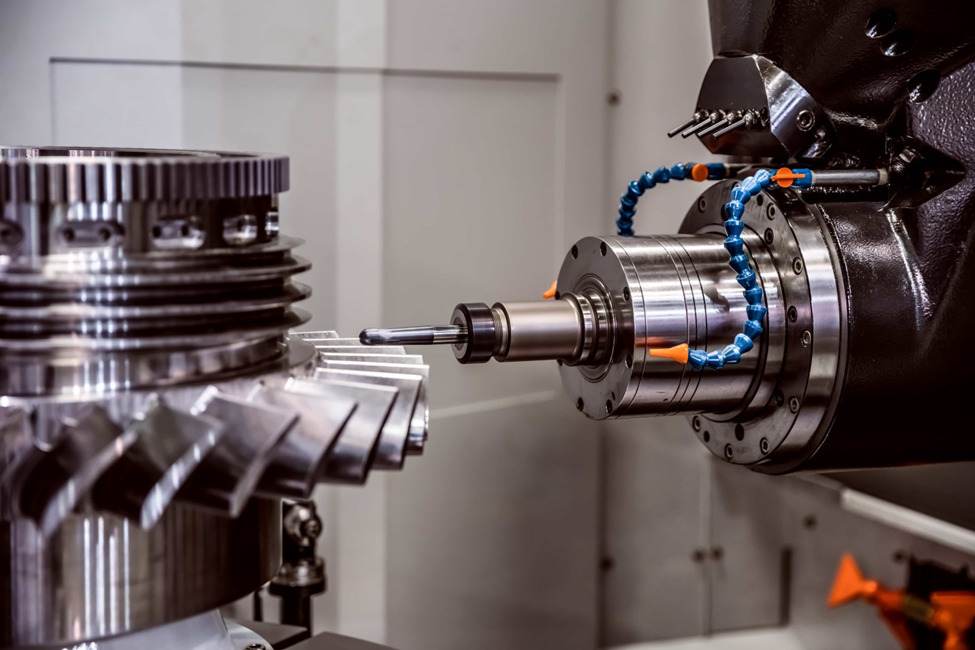

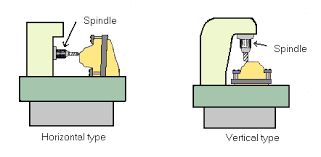

A horizontal milling machine, also known as a horizontal machining center or HMC, features a cutting tool that is oriented horizontally. Their horizontal design allows chips to fall away from horizontal machining centers.

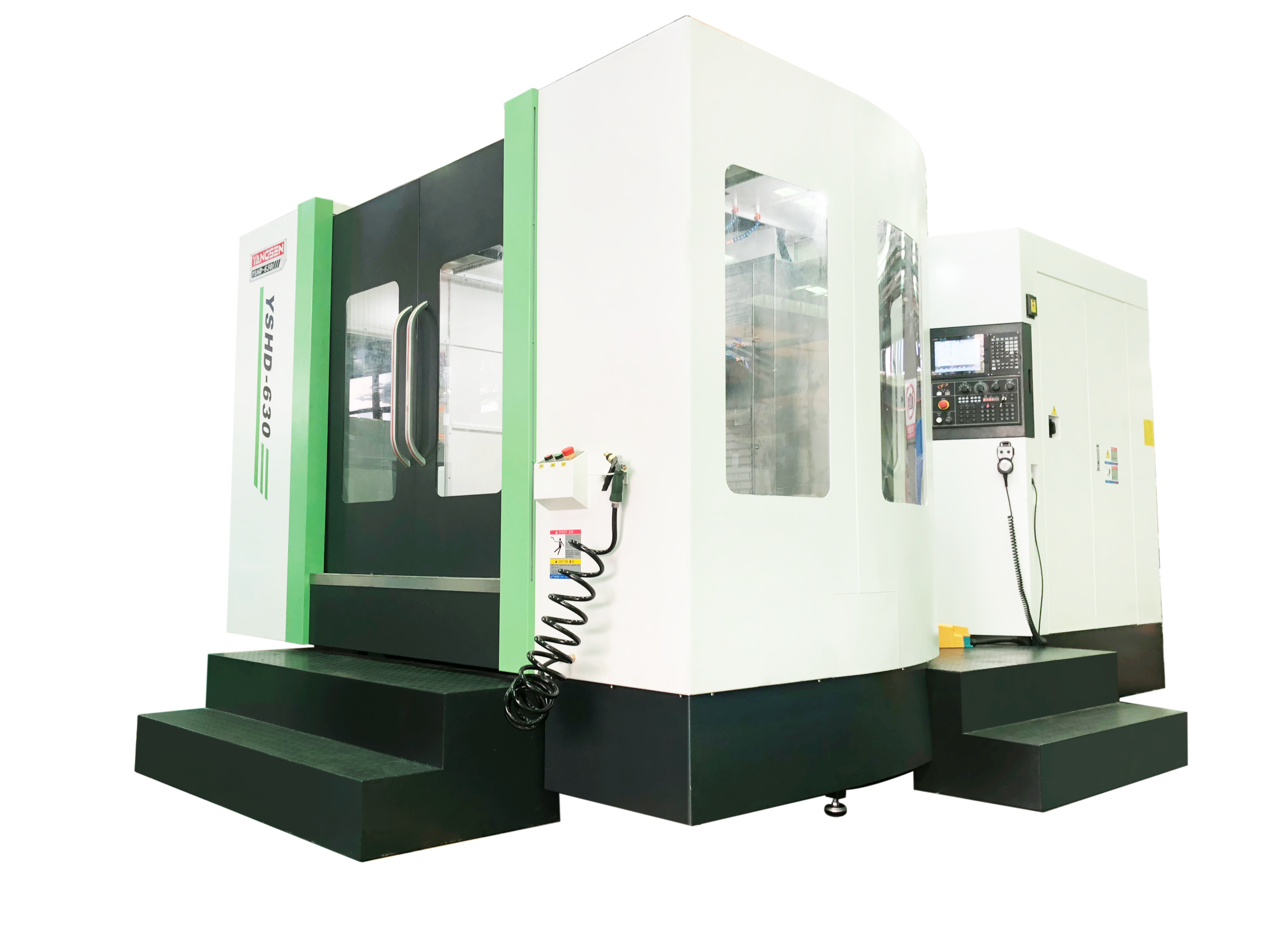

CNC machining centers describe a wide range of machine tools including CNC milling and drilling machines, which include vertical machining centers ( VMC ), horizontal machining centers ( HMC ) as well as 4th and 5th-axis machines. In a single set-up, our multiple axis CNC machining centers combine all axes simultaneously to produce everything from extremely complicated geometries to simple, basic shapes. HMC milling differs from vertical machines, which use a vertically-oriented spindle and table for their operations. HMCs typically offer faster cutting times and more efficient chip removal than their vertical counterparts. They are also capable of producing high-precision parts with few failures due to the accuracy of their spindles.

HMC milling (also known as cnc milling) is a type of high speed machining that uses a cnc milling machine to produce parts with intricate shapes and features. This process involves cutting away material from the workpiece in order to create the desired shape or feature. HMC milling utilizes specialized tools and techniques that make it much faster than traditional types of machining, allowing for quick production of complex parts with tight tolerances. This makes HMC an ideal choice for creating high-precision components for a wide variety of industries such as aerospace, automotive, medical device manufacturing and more. With its ability to produce parts quickly and accurately, HMC milling has become one of the most popular forms of cnc machining.

HMCs are most commonly used for the production of complex parts such as those found in medical, aerospace, automotive, and electronics industries. HMCs feature a horizontal spindle with a cutting tool attached to it, which allows it to cut at various angles more efficiently than vertical machining centers can. HMC mills are also capable of handling heavier components than other types of CNC machines and can be programmed to perform multiple operations simultaneously. This makes HMC milling the preferred choice for many companies who need consistent results from their production processes. HMCs are also typically more cost-effective than other CNC machines, making them an attractive option for many manufacturing operations. HMC milling is a powerful and reliable solution for producing complex parts quickly and precisely.

HMC milling (also known as cnc milling) is a type of high speed machining that uses a cnc milling machine to produce parts with intricate shapes and features. This process involves cutting away material from the workpiece in order to create the desired shape or feature. HMC milling utilizes specialized tools and techniques that make it much faster than traditional types of machining, allowing for quick production of complex parts with tight tolerances. This makes HMC an ideal choice for creating high-precision components for a wide variety of industries such as aerospace, automotive, medical device manufacturing and more. With its ability to produce parts quickly and accurately, HMC milling has become one of the most popular forms of cnc machining.

Horizontal machining centers (HMCs) are a type of CNC milling machine used for effective metal cutting. These machines are designed to cut in the horizontal plane and provide high precision, accuracy and speed. Horizontal machining occurs when machining is performed on a horizontal plane, compared to vertical machining which is done on a vertical plane. HMCs are also known as horizontal milling machines and can be used for a variety of materials such as metals, wood and plastics. These machines have the capability to produce complex parts with accurate results and are often used in industries such as automotive, aerospace, medical and electronics. Horizontal machining centers also allow for two - pallet changer integration to facilitate unattended operation and reduce part cycle times.

Horizontal machines are different in size and style with N/C and CNC capabilities. These machines feature high dynamics, rapid tool change and superior precision. Where versatility is key, machines should offer 3, 4, and 5 axis capabilities.

HMCs are typically used for high-volume production, allowing multiple parts to be made quickly and efficiently with reduced downtime. These machines can also accommodate a variety of cutting tools, enabling them to produce complex geometries with precision. HMCs are extremely versatile, making them a great choice for many different manufacturing applications. With their automated pallet changers, horizontal machining centers can work on multiple parts simultaneously, drastically reducing the amount of time and labor required to complete a job. As a result, these machines are often found in industries where speed and precision are of the utmost importance.

VMs are used as a cutter to remove pieces of metal and also employ a rotating vertical shaft. The tools used at the VMC are often positioned vertically. HMCs utilize spindles that rotate horizontally and use cut tools for removal of steels from their workpieces.

Rigid designs allow for fast acceleration and increased repeatability.

Large tool storage capacities enable increased part-production versatility.

Various spindle speed and torque selections for materials ranging from aluminum to titanium.

3, 4 and 5-axis capabilities for infinite possibilities as to the part shapes you can process.

Whether you're manufacturing large, small, or in-between parts, there's a horizontal machine that fits with your operation.

HMC milling is often the preferred cnc machining option because it offers a number of advantages. Its high speed allows for quick production, and its accuracy makes it ideal for creating intricate features that can't be produced with traditional machining methods. HMC also allows for increased flexibility in tool selection, allowing you to choose the best tool for the job. This results in better surface finishes, higher precision and more reliable performance. Additionally, HMC milling requires less setup time than other cnc processes, which helps to reduce downtime and increase overall efficiency.

HMC milling is a new technology used to produce intricate parts with greater productivity and accuracy. This type of machining allows for more intricate designs than traditional methods, as its advanced computer numerical control (CNC) system enables faster cutting times and higher precision of parts. Additionally, HMC milling often requires fewer setups, which reduces production time and improves efficiency. The machine’s larger work envelope also makes it possible to create complex part features in one setup. With these advantages, this technology can help companies achieve their goals for intricate parts manufacturing more quickly and accurately than before. Through the use of HMC milling, manufacturers can reduce lead times while increasing quality and output levels at the same time. By investing in this technology, businesses can remain competitive while ensuring they have the capability to produce intricate parts quickly and efficiently. In conclusion, HMC milling is a new technology used to create intricate parts with greater productivity and accuracy than traditional methods.