When you’re working on machines to create different workpieces, there are a lot of instances when you need to thread holes in the metals. Threading is believed to be invented around two millennia ago, and it was invented to bring water to crops and people with no natural reservoirs of water. However, the advent of electricity and, consequently, pumps made bringing water through threaded fasteners more convenient.

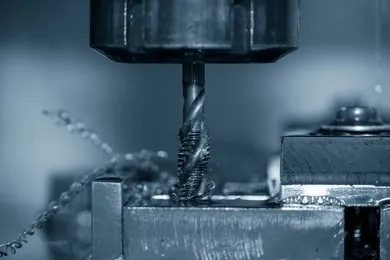

However, threading is still a complicated subject, and there is a lot you need to take care of. Therefore, drilling and threading are not manual and relying on machines is essential. There are specialized machines and equipment for screwing threads. There are two techniques used to screw threads: thread milling and tapping.

In today’s article, we will talk about tapping, types of tapping, types of taps, how it works, and what tapping is in CNC machining. So let’s get into it.

To begin, it’s important that we explain the tapping and tapping in machining. So we will start with tapping in general.

When you look at a tap, it will look like a bolt or screw except the grooves running down its sides. The purpose of grooves is to do chips up and out of the hole during the machining process for cutting the threads. Taps are like rotary tools gripped in a special floating tool holder (chuck/collet) to screw holes in any workpiece at a specific feed rate.

So we can define tapping as follows:

The process of cutting threads on the inside surface of a drilled hole in manufacturing is called tapping. Special tools called taps are used to cut threads. Tapping aims to develop the full strength of the connecting bolt or screw. The tapping process is often used in manufacturing to create threads in holes and inner surfaces of nuts.

Some different approaches or techniques can be used for tapping the holes in the workpieces:

• Hand Tapping

• Milling Machine

• Tapping Machine

• Lathe Machine

However, we will be briefly talking about hand tapping and more about tapping in machining.

Hand tapping is a manual approach to cutting threads using hand taps. There are three types of hand taps used for manual cutting from beginning to end: taper tap, centre tap, and finishing tap. We will talk about these taps in the coming section of the article. The hand tap consists of a square shaft that is clamped in thread-holding tools for secure cutting.

CNC tapping, on the other hand, is a machining process of cutting threads from inside surfaces using machines. The purpose of CNC tapping is also the same to thread screws and bolts inside the holes of workpiece parts.

The types of taps available for tapping depend on the technique being used. So there are the following types of taps: hand, power, and tapered thread.

Hand taps are used in manual hand tapping, and there are the following types of hand taps:

The most popular type of tap used in hand tapping is the taper tap which is used for blind holes. A taper tap usually has 7-10 threads chamfered. The taper tap gives a gradual, less aggressive cutting application for straight holes.

A bottoming tap has 1-2 thread chamfered, and the best application of these taps is after the initial thread has been cut with a plug or taper tap.

The plug tap has around 3 to 5 threads chamfered, supporting gradual cutting action like a taper tap. However, the aggression of the plug tap is higher than the taper tap. When you want through-holes, a plug tap is the best option.

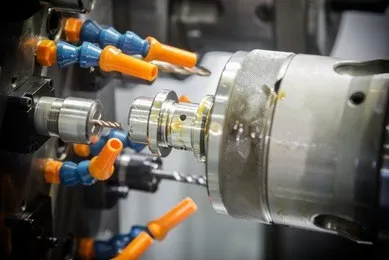

Power taps are used for CNC tapping, and the type of power tap used depends on the CNC application or machining work. The power tap types are as follows: spiral flute tap, spiral point tap, form tap, etc.

Now we will talk about the article’s main topic: tapping in machining.

Tapping in machining, or more popularly, CNC tapping, involves cutting threads from inside surfaces of holes on workpieces during the machining process. Basically, CNC tapping is a manufacturing process used for part threads.

When different parts of a workpiece have to be connected together to give it a form, screws and bolts are needed. Therefore, tapping creates threads inside the drilled holes for a secure seal of screws and bolts.

CNC tapping machines are pre-programmed and controlled. The benefit of using CNC tapping overhand tapping is the higher efficiency and accuracy of the threads.

As mentioned earlier, power taps are used in CNC tapping. It’s important to understand different types of taps so that you know which kind of tap is used for a specific CNC tapping job.

The following are the types of power taps:

Spiral flue taps contain an open spiral-like endmill and are best suited to eject chips up and out of the holes. When you want to have blind holes, spiral flute taps are the most advantageous ones.

Spiral point taps contain spiral cuts with relief grooves. Spiral point taps are similar to hand taps, but the spiral angle on the front cutting edge allows ejecting the chips. At the same time, the angled edge provides superior cutting performance.

Spiral fuse taps contain flutes around the tap’s axis in a spiral or helical configuration. The spiral fuse taps are generally a good choice for tapping threads in blind holes.

The interrupted thread taps contain a tooth for threading. The improved chip extraction can be achieved by using the interrupted thread taps.

Let’s talk about how to carry out tapping operations in machining manufacturing processes. Here is a step-by-step guide on how tapping operations are conducted in CNC machining:

The preliminary requirement for carrying out tapping operations is drilling. It implies that the holes in the workpiece parts must be drilled before the tapping process is carried out. The tapping process’s preparation also includes ensuring the holes are smooth without rough edges or imperfections. The drilled holes’ imperfections can affect the tapping process’s accuracy and precision.

Once the holes have been drilled in the workpiece, the next step is to select a tapping tool, depending on the type of the hole. You have to consider several factors before you begin the tapping process. And the selection of a tapping tool also depends on the screw size, threads per inch, workpiece material, hole diameter, etc.

Unlike hand tapping, workpiece feeding is not done manually in CNC tapping. Before beginning the tapping process, the technician must ensure that the CNC tapping machine’s center is set at the appropriate speed. Besides, you need to make sure that the installed tapping tool has been set to the required depth.

Once the tapping process begins, the turning center will rotate the parts during the process. However, make sure that you perform the process at a slow spindle speed between the range of 40-60 rpm.

You don’t need to do anything else; the system will notify you once the tapping process is completed.

Once the tapping operation is completed, you will need to chamfer the workpiece to remove the rough edges of the holes. Once the finishing is done, the operation is completed.

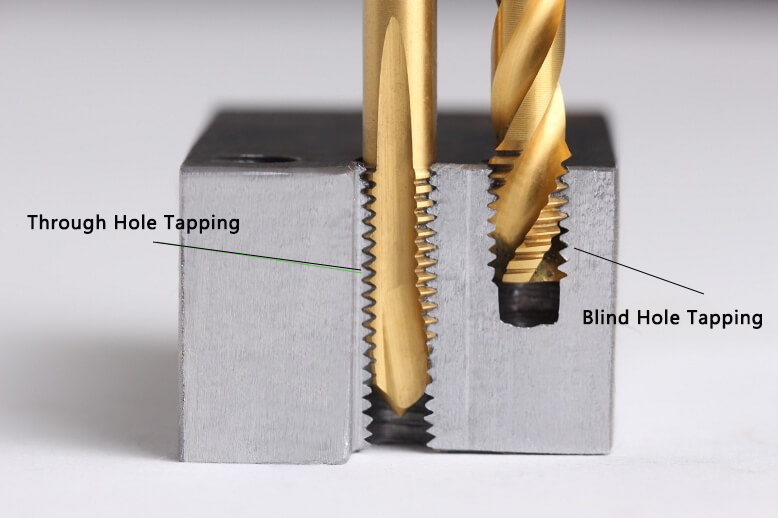

As mentioned earlier, there can be different techniques of tapping. Similarly, CNC tapping can be carried out for different types of holes. So here are the types of CNC tapping processes you might need to carry out for different workpieces:

The through-hole tapping allows the chips to leave from the bottom of the hole, and the quality of threads created is the best among all types of tapping. The spiral flute and spiral point taps are generally used for through-hole tapping.

In blind hole tapping, the chips can’t evacuate from the other side of the piece, and you need to remove chips from the entrance point. When you’re using larger taps, the blind hole tapping can be difficult. Spiral flutes are commonly used for such holes due to their capability to remove chips from the workpiece.

The tap used in the floating tapping is allowed an axial float to follow the hole in the workpiece. The small axial float will decrease the chances of breakage in misaligned holes. However, control is very important in this type of tapping, as a small loss of control can affect thread quality.

Rigid tapping is done by holding the tool holder and tapping the head rigidly to synchronize the tap’s rotation and feed to match the spindle speed. There sare zero axial floats to provide the best tap control, but the risk of breakage is high in misaligned holes. When you want to work with shallow holes, rigid tapping works best.

Self-reversing tapping is done by allowing tap rotation reversal at the end of each cycle. You can skip the need to stop and reverse the spindle for tap retraction in synchronous tapping. Through holes are often tapped using self-reversing tapping.

Form tapping works with hardened taps to displace materials for forming threads instead of cutting them. The faster tapping speeds of the form tapping with higher machine torque and rigidity are supported for certain materials.

Which tapping process you will carry out on CNC machines and which tapping tools will work depends on several factors. For instance, you can use rigid tapping for cutting through-holes in softer materials.

Here are the things you need to consider before choosing the tapping process.

• Material Hardness –how hard is the material of the workpiece under use?

• Material Type –what kind of material is used in the workpiece being worked on? For instance, steel, hardened steel, cast iron, etc.

• Depth Of Screwholes –how deep are screw holes?

• Workpiece Thickness –what is the thickness of the workpiece?

• Type Of Screwhole –what type of hole are you working on? A blind hole, through-hole, etc

• Size And Type Of Hole –what is the size and type of threaded hole?

If you want to get the best efficiency of the CNC machines for tapping and neat threads, here are some tips you should consider:

1. Oiling during the tapping process supports the smooth evacuation of chips, assistance in the cutting process, and prevention of overheating. Therefore, make sure to add the oil to the workpiece and tap before tapping operation.

2. A center drill is needed for tapped holes to align a larger bit to the center. As most of the drills are not centered perfectly, the center drill can allow you to drill correctly without walking across the part of the workpiece.

3. Don’t apply an access downward force that can cause tap breakage. Use a rational force-and-pecking method to avoid tap breakage.

4. Optimization of the tapping process is also necessary for good results.

CNC tapping is a manufacturing process used when manufacturing different products, parts, and machines for various industries. The common applications of CNC tapping can be found in the following industries:

• Automotive Parts Manufacturing

• Plumbing Fittings

• Electronics And Telecommunication Equipment

• Mold And Dye Components

• Aerospace Parts Manufacturing

• Oil And Gas Industry Parts

• Medical Device Manufacturing

• Optics

• Hydraulic Cylinders

Drilling and tapping are two entirely different operations in CNC machining or manual machining. Drilling is the simple process of drilling holes in a material. Tapping occurs after drilling to create threads inside the drilled holes for fitting screws and bolts.

Cutting threads inside the holes is referred to as tapping. In comparison, the process of cutting threads with dies is called threading. Tapping deals with internal threads, whereas the threading of external surfaces of bolts is carried out by threading operation. Another difference between the two processes is that a single tool is enough for threading, but different sizes of taps are required for different types & sizes of internal holes in tapping.

|

Drilling |

Tapping |

Threading |

|

Drilling is a machining process for making holes in the workpieces or parts of workpieces. |

CNC tapping is a manufacturing process for cutting threads on the inside surfaces of drilled holes in workpieces or parts of workpieces. |

Threading is also the manufacturing process for cutting threads with dies, but it is done on external surfaces like bolts, |

|

Drilling is a generic term used for the holes drilled through different materials in manufacturing processes as well as other purposes like breaking through rocks. |

Tapping is a kind of threading technique that focuses on cutting threads on the internal surfaces of drilled holes. |

Threading is the process that was first invented for bringing water to the crops. |

|

A simple process of drilling holes in a material is a preliminary requirement before the tapping process begins. |

Create threads inside the drilled holes for fitting screws and bolts.

|

Threading is independent of drilling and tapping as it is done on the outer surface of the materials. |

|

Different sizes and types of drilling tools are required to drill different types and sizes of holes in materials. |

You need specialized tools called taps for cutting threads in the tapping process. Besides, the type of tap also varies depending on the type and size of the hole you’re working with. |

A single tool is enough for threading purposes, as it can work on holes of all depths, diameters, and sizes. |

We have discussed everything you need to know about tapping in machining. We have summed up everything starting from techniques of tapping, tapping in machining, types of taps you need to use, types of holes, factors to consider for tapping different holes, and tips to achieve the best results from tapping operations.

Whether you’re a technician just beginning to explore the tapping operations or a student trying to understand CNC tapping, the article provides enough information you need to get started.