In supporting the manufacturing processes, most companies would integrate the most suitable machining for their industries. As the manufacturing world keeps developing, technology should be able to adapt by providing better, more accurate machinery.

Manufacturing processes can be quite a challenging topic to talk about as there are so many different functions and operations one needs to put into mind. However, in order to overcome these manufacturing challenges, the proper knowledge is always required. After all, manufacturing and machinery are two topics that need a deep level of understanding.

Of course, the proper knowledge here isn’t just about how they work, but also about their advantages so that the companies can make use of the most suitable and effective working methods to support their manufacturing process.

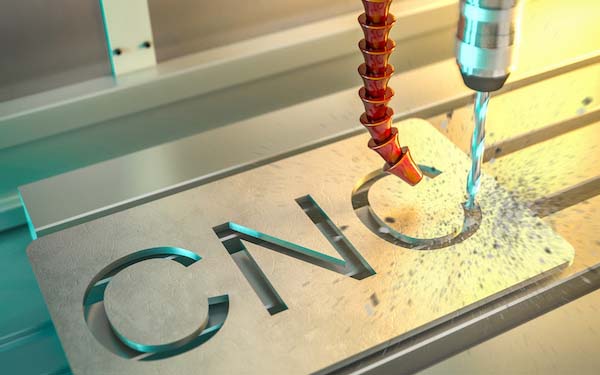

In this article, we will explain a few things about the differences between CNC machining and precision machining. See more in the explanation below:

Before we discuss the difference between CNC machining and precision machining, it would be best if we understand the concept of machining beforehand. Machining was invented back in 700 B.C. when everything was much simpler

Yes, they didn’t do it to get profit back then. However, the concept of machinery helped them to survive by creating the necessary instruments for hunting and crafting. The general idea of machinery was tool creation to help human needs.

Fast forward to the 1700s A.D., the steam power was finally invented, and everything changed since then. The power lets people do the automation for the very first time. It helped them to automate the production process of general goods, and things significantly improved during the Industrial Revolution.

From there on, people went full gear with the machinery. A lot of improvements were made to further enhance the functionality of the machinery. Mass production became a thing, and factories have never worked harder.

Ultimately, the machinery tools that were used on such a large scale upgraded the process of steel-making and other essential product manufacturing, which resulted in more innovations.

In 1the 940s, the improvement hasn’t stopped. In fact, it got significantly better as computers came into play. The development of computer technologies has also significantly supported machinery innovations.

Integrating advanced programming technology and machinery has resulted in a much better and more efficient production by minimizing human errors while improving the automation aspect of the machinery itself.

The development, however, continues. With a lot of new innovations and ideas born to change the industry, companies have no choice but to adapt to the increasing production demand from all over the world.

Therefore, several machinery technologies are used to keep up with the demand, including CNC machining and precision machining, which each have their own capabilities, functionalities, and also advantages.

Now, let us first understand what CNC machining is all about. CNC stands for Computer Numerical Control, which is a pretty common technology found in the manufacturing process. The reason why manufacturers would use it in the first place is because it enables a larger scale of production for machined parts, which is highly demanded.

Additionally, the CNC machine is also a great tool for companies to make prototypes of their products. There are CNC milling and CNC turning, each with its own unique functions.

The CNC milling works by utilizing the functions of computers to operate the cutting tools. These tools will work using the minimal 3 axes or possibly more, depending on the complexity. When activated, the machine will rotate the cutting tool that will cut the surface of a stationed workpiece. The cutting tool will rotate at such a high speed to remove all unwanted materials.

Meanwhile, CNC turning, which is also known as the metal fabrication process, is a technique that’s mostly used for creating conical, cylindrical, and rounded parts. It is a part of CNC machining, but not as versatile compared to CNC machining as its ability is limited.

Aside from being known as a metal fabrication process, CNC turning is also known as CNC turning centers and lathes machines. The structure consists of a gripping tool and a rotating spindle. The way it works is also different from the CNC milling.

The multi-axis that the CNC machine has makes it possible for it to create more versatile creations. Thus, companies can always make machined parts, even complex ones, without having to focus more on manual reorientation.

The way the CNC machine works is really simple. As we’ve previously explained, many manufacturers are now using CNC machining for their basic machine parts production. Its ability to make various complex machine parts using its multi-axis cutting tool is unbeatable, and it’s up to today’s standards.

CNC machining is also an essential part of the manufacturing process as it enhances automatic production and reduces the likeliness of human errors.

To operate the CNC machines, the operators will use CAM or CAD software, which functions to produce files that will later be scanned by the CNC machines. From that step, the CNC machine will use the scanned file to handle the machining.

Now, many would say that CNC machining and precision machining are different. How come? Although both have similar structures, the specs may be different. Just as the name tells you, precision machining was created with higher standards as it highly focuses on precision.

With the more precise machines, the parts you can create out of it will be more accurate as well. The difference is apparent in the tolerance standards. While the CNC machine has 0.008” or as close as 0.005”, the precision machine has a tolerance standard of 0.0001”.

Although the difference might seem pretty slim, it actually means a lot. Using precision machines, manufacturers can make even more complex machine parts that were unable to be created in standard CNC machines. For the industries like medical and aerospace, this is a matter of life and death.

Although CNC machines are not more accurate than precision machines, it still has several advantages that the manufacturers may consider, such as

Many companies look for better efficiency, and it’s exactly what CNC machines can offer. The process of CNC milling usually requires only a small batch of parts for a single manufacturing process. As a result, the material it will use to make machine parts will be less as well.

Furthermore, CNC milling also supports electrical, thermal, and chemical processes. Therefore, it can nicely fit all kinds of industries at a better efficiency.

Another thing that CNC machines can offer is an increased production capability. As the production will require small batches of parts, the whole process basically needs a low material consumption. In the long run, it can be a great way to increase the production capacity for huge projects.

What’s great about the CNC machine is the kinds of cutting tools it has. Thanks to them, the CNC machine can work in a much better and more efficient way compared to the other machines.

The cutting machine makes it possible for the manufacturers to create machine parts with more complex structures. Therefore, it’s just logical to think that most manufacturers are now optimizing their production processes using CNC machines.

Aside from the complexity of the design, CNC machines are also capable of creating a wide range of parts with their own unique specifications. Even the complex ones can be treated in the same way as the simple parts.

Now, let us talk about precision machining. Just as we’ve told you before, precision machining is basically an upgrade of the CNC machining. It involves the manufacturing process that lets users create parts with better accuracy and better tolerances.

Aside from handling the metal parts, precision machining is also suitable to make parts out of plastic. Thanks to its precision in the work, the machining is highly compatible for so many manufacturing projects both individual and bulk orders. It can nicely fit the customer’s needs no matter how complex and specific the requested parts are.

In the section above, we’ve mentioned that precision machining is suitable for plastic and metal materials. However, its actual capabilities are actually beyond that. There are several materials that can be processed through precision machining:

● Bronze

● Steel

● Titanium

● Brass

● Glass

● Graphite

● And other metals.

With that, it can be said that precision machining is a very dependable machine as it can process a wide range of materials. It’s suitable for so many manufacturing needs, and the precision that can be obtained through the combination of saws, grinders, and milling machines is just hard to miss.

Of course, due to the high precision, consistency, and also accuracy, precision machining became one of the most essential factors in the manufacturing business. Having the machine around you can ensure that your production capabilities stay effective no matter what the client’s needs are.

In order to carry out the manufacturing duties more effectively, the manufacturers have to consider a few essential points before getting the machines, such as:

|

Essential Aspects |

Requirements |

|

Accuracy |

In order to maintain the production’s accuracy, the manufacturers have to find a machine that’s able to work by making the exact cuts to reduce the scrap material thrown away. |

|

Speed |

To handle a large manufacturing task, you need to have a machine that can work as fast as possible without sacrificing quality and accuracy. |

|

Complexity |

As clients order different machine parts, the manufacturers have to get machinery that can handle more complex production processes. |

|

Consistency |

Maintaining consistency for all products is necessary. Therefore, the process of manufacturing has to be as consistent as possible. |

|

Durability |

Ensure that the machining can last for a long time to handle more production processes. |

As time continues to go on while technological development also doesn’t show any sign of stopping, it’s just understandable that more companies are looking for a better way to support their manufacturing business

Following the client’s needs can be different at all times, the manufacturing can always accomplish the important manufacturing objectives by using precision CNC machining. Here are a few of its best benefits:

Due to the high level of precision, precision CNC machining is able to maintain consistency and effectively reduce the possibility of an error. Most of the manufacturing processes will be handled automatically as well, so any mistakes made by human error will be minimized as well.

In a manufacturing process, scraps can be produced on a large scale. The less precision a machine has, the more waste it will produce later on. Thus, as the precision CNC machine has a high degree of precision, this results in much less waste due to production errors.

The high precision also makes it possible for precision machining to make more accurate parts. With higher consistency, the quality of the parts produced from the machining is carefully maintained. This can effectively result in increasing profits as there’s a consistent product quality on every single production.

Another notable benefit of precision CNC machining is the shorter production cycle, which is also one of the reasons why it’s more effective compared to the other older methods.

As you can bring more products to the market due to the high production level, you may also have a chance to be more adaptable to any production changes brought by individual customers or industry rules.

The type of machining you’d use will highly affect how the manufacturing process goes in your production company. Therefore, choosing the one that can be considered effective in maintaining the quality of production and consistency is a must.

With a high level of tolerance and precision, CNC machining can be a great solution to a wide range of manufacturing needs. Now, it is the time to find the best machining solutions. And you can get one at Yangsen.