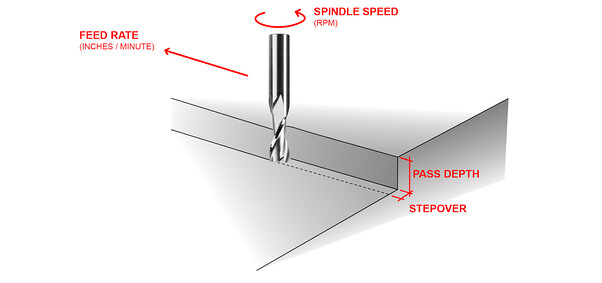

In the processing process of CNC machines, feed rate, and cutting rate are two very important parameters. Simply put, the cutting rate is the rate at which the tool cuts on the surface of the part, and the feed rate is the rate at which the cutting edge moves deep into the workpiece.

CNC machine tool feed rate and cutting rate are very important in its machining process because they determine the rate and amount of material removed and affect the service life of the machine tool processing tools. The difference between CNC machine tool feed rate and cutting rate can be determined by a key factor called cutting temperature, as higher cutting temperatures affect parameters such as tool life and surface roughness.

Feed rate and cutting rate are different in a physical sense. Since the physical cutting rate is different from the feed rate of the machine tool, it is inaccurate to call the feed rate cutting rate. The main function of feed rate is to determine the depth of processing and processing quality, while the main function of cutting rate is to determine cutting quality and tool service life.

CNC lathe operators must correctly understand and master the concepts of feed rate and cutting rate. First of all, different cutting rates must be used according to different processing materials. In addition, attention should also be paid to adjusting the feed rate to ensure the depth of processing and surface quality. In actual operations, it is necessary to make judgments based on the actual situation and gradually adjust the feed rate and cutting rate to ensure the processing effect and quality.

Feed rate and cutting rate are two very important parameters in the CNC lathe processing process. Correctly understanding their concepts and differences is crucial to operating CNC lathes, which can ensure the quality and effect of processing. Processing personnel need to master and further improve their operating skills in practice, remain highly alert at all times, and strictly abide by safe operating procedures.

Are cutting rate and feed rate the same?

No, cutting rate and feed rate are not the same. Cutting rate refers to the rate at which the cutting tool moves through the material being cut. Feed rate refers to the rate at which the material being cut moves past the cutting tool.

What does SFM mean in machining?

SFM, also called surface rate, refers to surface feet per minute and is a commonly used cutting rate measurement method in machining. It represents the number of feet the tool can move on the workpiece in one minute. The higher the SFM, the faster the cutting rate.

Why must engineers and machinists consider cutting rates and feed rates during CNC machining?

Engineers and machinists must consider cutting rate and feed rate during CNC machining because it directly affects the quality of the finished product. If the cutting rate is too slow, the material will not be cut cleanly and may have burrs or other defects.