Scraping is a skill that is more difficult than wood carving. It is the starting point for precision machine tools to have basic accuracy. Scraping eliminates our dependence on other machine tools and can also eliminate deviations caused by clamping force and heat energy.

The scraping track is less likely to wear, thanks to the excellent lubrication effect. Scraping technicians need to know many techniques, but only experience can give them the feeling of achieving that precise leveling.

When you pass by a machine tool manufacturer and see technicians doing scraping by hand, you can't help but wonder:

"Can they really improve the current machine-processed surfaces by scraping? (Can people be better than machines?)"

If you are referring purely to its appearance, then our answer is "no", we won't make it more beautiful, but why do we still scrape? Of course there are reasons, one of which is the human factor: the purpose of machine tools is to make other machine tools, but it can never replicate a product that is more accurate than the original. Therefore, if we want to make a machine that is more accurate than the original one, we must have a new starting point, that is, we must start with human efforts; in this case, human efforts refer to manual scraping.

Scraping is not a "freehand" or "arbitrary" operation. It is actually a method of replication, which almost perfectly replicates the mother body, which is a standard plane and is also made by hand.

Although scraping is hard work, it is a skill (art-level technology); it is perhaps more difficult to train a scraping master than to train a woodcarver. There are not many books on the market that explore this topic, especially fewer materials discussing "why scraping is needed". This may be why scraping is regarded as an art.

If a manufacturer decides to use a grinder to grind instead of scraping, the guide rails of his "mother machine" grinder must be more accurate than the new grinder.

So where did the accuracy of the first machine come from?

It must come from a more accurate machine, or it must rely on another method that can produce a truly flat surface, or it may be copied from a flat surface that has already been done well.

We can use three kinds of drawings The method of circles is used to illustrate the process of surface creation (although circles are lines rather than surfaces, they can be used to illustrate the concept). A craftsman can draw a perfect circle with an ordinary compass; if he traces a circular hole in a plastic template with a pencil, he will replicate all the inaccuracies of the circular hole; if he draws the circle freehand, the accuracy of the circle is determined by his limited skills. In theory, a perfectly flat surface can be produced by alternating friction (lapping) between three surfaces. For simplicity, let's use three rocks, each with a fairly flat surface. If you rub the three planes alternately in a random order, you will grind the three planes more and more flat. If you only use two rocks to rub, you You will get a concave and convex mating pair. In practice, in addition to using lapping, a clear pairing order is also followed. Lapping masters generally use this rule to make the standard jigs (straight gauges or flat plates) they are going to use.

When using, the lapping master will first apply the color developer on the standard jig, and then slide it on the surface of the workpiece to reveal the areas that need to be scraped off. He keeps repeating this action, and the surface of the workpiece will become closer and closer to the standard jig, and finally he can perfectly replicate the work that is the same as the standard jig.

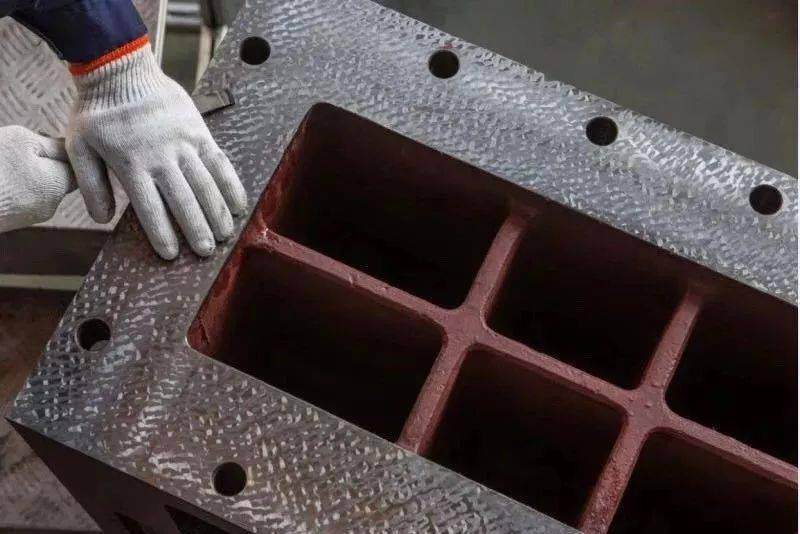

Castings that need to be lapping are usually first milled to a few thousandths more than the final size, then sent for heat treatment to release the residual pressure, and then sent back for surface cleaning before lapping. Grinding. Although scraping takes a lot of time and has high labor costs, it can replace processes that require high equipment costs. If you don't want to use scraping operations as a substitute, the workpiece must be finished with a very high-precision and expensive machine for the final finishing.

In addition to the high-cost equipment involved in finishing in the final stage, there is another factor to consider. When machining parts, especially large castings, some gravity clamping actions are often required. When the machining reaches a precision of a few thousandths, this clamping force often causes the workpiece to twist, which endangers the accuracy of the workpiece after the clamping force is released; the heat generated during machining can also cause the workpiece to twist.

This is one of the many advantages of scraping. Scraping has no clamping force and the heat it generates is almost zero. Cast iron is supported at three points to ensure that it will not deform due to its own weight.

When the scraping track of the machine tool is worn, it can also be corrected by re-scraping, which is a great advantage compared to discarding the machine or sending it to the factory for disassembly and reprocessing.

When a machine tool track needs to be re-shoveled, this work can be performed by the factory maintenance personnel, but we can also find someone to do the re-shovel work locally.

In some cases, manual and electric spading can be used to obtain the final required geometric accuracy. If a set of table and saddle tracks have been spaded and the accuracy has been met, but the table is found to be out of parallelism with the spindle (which takes a lot of effort to correct), can you imagine the level of skill required to remove the correct amount of metal in the correct position without losing flatness and properly correcting the misalignment with just a spading machine?

This is certainly not the original purpose of spading, nor should it be used as a method to correct large misalignments, but a skilled spading master can complete this type of correction in a surprisingly short time. Although this method requires skilled technology, it is more economical than machining a large number of parts to very accurate or making some reliable or adjustable designs to prevent misalignment.

Practical experience has proven that scraped rails can reduce friction through better quality lubrication, but there is no consensus on why. The most common opinion is that the scraped low points (or more specifically, the pits cut out, the extra oil pockets for lubrication) provide many tiny oil storage pockets, which are scraped out by the many tiny high points around them.

Another logical statement is that it allows us to continuously maintain a layer of oil film for the moving parts to float on the oil film, which is the goal of all lubrication. The main reason why this happens is that these irregular oil pockets create many spaces for oil to stay, making it difficult for the oil to escape. The ideal situation for lubrication is to maintain a layer of oil film between two perfectly smooth surfaces, but then you have to deal with the problem of preventing oil from flowing out, or it needs to be replenished as soon as possible. (Whether there is scraping or not, the rail surface is usually made of oil grooves to help distribute the oil).

This statement makes people question the effect of contact area. Scraping reduces the contact area, but it will form a uniform distribution, and distribution is the key. The flatter the two matching surfaces, the more evenly the contact surface is distributed. But there is a principle in mechanics that "friction is independent of area", which means that whether the contact area is 10 or 100 square inches, the same force is required to move the worktable. (Friction is another matter. The smaller the area under the same load, the faster it will wear.)

The point I want to make is that we are looking for better lubrication, not more or less contact area. If the lubrication effect is perfect, the track surface will never wear. If a worktable has difficulty moving as it wears, it may be related to lubrication, not contact area.

Before finding the high points that must be scraped, first apply the color developer to the standard jig (a flat plate or a straight gauge jig for scraping V-type rails), then rub the standard jig with the color developer on the track surface to be scraped, and the color developer will be transferred to the high points of the track surface. Then use a special scraping tool to scrape the colored high points. This action should be repeated until the track surface shows a uniform and consistent transfer.

A scraper must know a variety of techniques. I will talk about two of them here.

First, before we do the coloring, we usually use a blunt file to gently rub the surface of the workpiece to remove the burrs.

Second, wipe the surface with a brush or hand, never with a rag. If you use a cloth to wipe, the fine linen left by the cloth will cause misleading markings when you do the high point coloring next time.

The scraper will check his work by comparing the standard fixture with the track surface. The inspector only needs to tell the scraper when to stop working, and there is no need to worry about the scraping process. (The scraper can be responsible for the quality of his work)

In the past, we had a set of standards for how many high points there should be per square inch and what percentage of the total area should be in contact; but we found that checking the contact area is almost impossible, and now it is up to the scraper to decide the number of points per square inch. In short, the scraper generally strives to reach the standard of 20 to 30 points per square inch.

In the current scraping process, some leveling operations use electric scrapers, which are also a kind of manual scraping, but can eliminate some strenuous work, making the scraping operation less tiring. When you are doing the most delicate assembly work, the feeling of manual scraping is still irreplaceable.