Milling machines are essential tools in the world of machining. They are responsible for shaping countless everyday items. Among these machines, the vertical milling machine is a workhorse that stands out in various industries, such as manufacturing and metalwork. The article aims to explore the intricate anatomy of the vertical milling machine by breaking down its seven major components that combine to make precision machining possible.

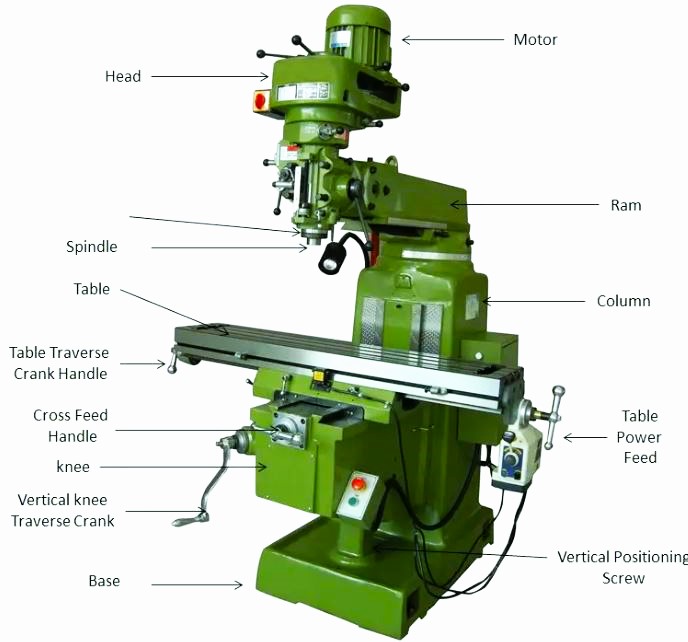

Each part plays a crucial role in the machine's operation. The base provides stability, the column houses the spindle, the knee enables vertical movement, and the saddle offers horizontal motion. The worktable accommodates the workpiece, while the spindle, powered by the machine, rotates the cutting tool to create intricate designs and precise measurements.

Understanding these components is essential for machine operators and those curious about the engineering marvels that shape our modern world. The article delves into the core elements of vertical milling machines, shedding light on the inner workings of these intricate machines.

Milling machines, whether manual or CNC, remove metal from workpieces and attain the desired shape and dimensions. This is achieved through a spinning tool known as a milling cutter. Unlike a lathe machine that spins the workpiece and moves the cutting tool into it to create cylindrical shapes, the milling machine uses a variety of milling cutters, including end mills, face mills, and dovetail cutters, to machine flat and irregular surfaces. This includes surfaces that are concave or convex in shape.

We have compiled a list of the seven crucial components of a vertical milling machine that you must comprehend.

1. The Base

2. The Column

3. The Knee

4. The Saddle

5. The Worktable

6. The Spindle

7. The Control Panel

At the foundation of every vertical milling machine lies the base, a robust structure that provides essential stability and support for the entire machine. This component is the starting point for the intricate milling process, ensuring the machine remains steady and precise throughout its operations.

The base is typically constructed from heavy-duty materials such as cast iron or steel, known for their strength and rigidity. Its design and composition are vital, as any vibrations or instability can lead to inaccurate milling results. The base is often large and flat to distribute the machine's weight evenly and minimize potential wobbling.

One of the notable features of the base is its ability to absorb and dampen vibrations generated during the milling process. This quality ensures the workpiece remains steady, allowing for precise cuts and consistent outcomes. Additionally, the base may have adjustable feet to level the machine and ensure it is perpendicular to the workpiece.

In the world of vertical milling machines, the column is a towering presence, quite literally. Rising vertically from the base, this critical component is the primary support structure for the entire machine, housing the vital elements that facilitate precise and controlled material removal.

Constructed from materials like cast iron or steel, the column is engineered for strength and stability. Its sheer height is a defining characteristic, allowing for the vertical movement of the knee and the entire milling head assembly. This vertical movement is essential for milling processes, as it enables the machine to engage with the workpiece at various heights and angles.

One of the most significant functions of the column is to house the spindle, which is the heart of the milling machine. The rigidity and stability of the column directly influence the spindle's precision and accuracy. Any deviations or vibrations in the column could lead to irregularities in the machined parts.

The column's design can vary, with some machines featuring a fixed column while others offer options for tilting or rotating columns, adding versatility to the machining capabilities. Furthermore, many columns have dovetail ways or other mechanisms for attaching and guiding the saddle and knee, enabling controlled and precise movements.

The knee is a dynamic and pivotal component responsible for the machine's vertical movement. Situated between the saddle and the worktable, the knee allows for precise adjustments in the vertical plane, making it a fundamental element in the machining process.

The knee is typically a large, box-like structure made from robust materials like cast iron or steel to ensure stability and rigidity. Its design and construction are meticulously engineered to provide controlled, smooth, and accurate vertical movement. This ability is crucial for a wide range of milling tasks, allowing the operator to lower or raise the cutting tool with the workpiece, achieving varying depths and dimensions in the final product.

One of the most notable features of the knee is its ability to be adjusted by the operator. This manual adjustment is typically done through a vertical handle or crank, which allows for precise control over the positioning of the work tool. This fine-tuned control is indispensable when working with different materials or aiming for exceptionally tight tolerances in the final product.

The knee plays an integral role in the versatility of vertical milling machines. Its adjustability enables machining of various workpiece sizes and shapes, making it a key component for slot cutting, drilling, and even complex contouring tasks. Combining the knee's vertical movement and the machine's horizontal axis creates diverse possibilities for milling operations.

Within the intricate framework of a vertical milling machine, the saddle plays a pivotal role, contributing to the machine's versatility and precision. Situated on the knee, the saddle facilitates horizontal movement, enabling the machine to traverse the worktable and engage with the workpiece from various angles.

Constructed from durable materials like cast iron or steel, the saddle provides strength and stability. Its flat and robust structure ensures that the horizontal motion is smooth and precise. The saddle is often equipped with a dovetail or other guiding mechanisms, enabling it to move smoothly along the knee.

The horizontal movement of the saddle is particularly important for tasks that require side-to-side motion, such as cutting keyways or performing horizontal boring operations. This lateral adjustability empowers operators to access different workpiece areas without repositioning the entire machine.

The saddle and the knee's vertical movement allow for a dynamic range of motions in two dimensions. The operator can combine these movements to create intricate cuts, contours, and complex shapes, making the milling machine a versatile tool for various machining applications.

Moreover, the saddle's precision is vital in maintaining accuracy during operations. The ability to lock the saddle in place ensures that the machine can consistently produce workpieces with tight tolerances, contributing to the overall quality of the final product.

In vertical milling machines, the worktable is a fundamental component that directly interacts with the workpiece, making it a critical element for machining operations. This flat, typically rectangular surface provides a stable platform for securing the workpiece and offers a range of positioning options for precise material removal.

Worktables come in various designs, including plain, universal, and rotary tables, each tailored to specific machining needs. These tables are constructed from durable materials such as cast iron or steel, ensuring they can withstand the forces and vibrations generated during milling.

One of the worktable's primary functions is securely holding the workpiece in place. This is often achieved using clamps, vises, or fixtures attached to the table's surface. The worktable's flatness and stability are crucial for maintaining the accuracy of the machining process, as any deviation can result in imprecise cuts or contours.

The worktable is also designed with T-slots or other holding mechanisms, which provide flexibility in workpiece positioning and securing. These slots allow for the attachment of various clamps and fixtures, enabling operators to adapt the table to a wide range of workpiece shapes and sizes.

Furthermore, the worktable can be adjusted along the X and Y axes, allowing for precise horizontal movements and positioning. This flexibility is essential when making intricate cuts, slots, and holes or contouring the workpiece from different angles.

The spindle, often called the heart of a vertical milling machine, is a critical component that defines the machine's ability to shape and cut materials precisely. It plays a central role in converting rotary motion into the linear motion required for various machining operations.

Constructed with the utmost precision and typically made from high-quality materials like alloy steel or other durable alloys, the spindle is engineered for stability and strength. Its design and construction ensure it can withstand heavy loads and high speeds while maintaining rigidity.

At its core, the spindle houses the tool holder, which grips the cutting tool securely. This tool holder is critical for ensuring the precise and consistent operation of the machine. It allows for easy tool changes, essential when performing various machining tasks.

Spindles come in various designs, including both belt-driven and direct-drive options. Belts and pulleys power belt-driven spindles, while direct-drive spindles are connected directly to the motor. The choice of spindle type depends on the specific requirements of the machining task, as well as factors like power and speed.

Spindle speed and power are key considerations when selecting a vertical milling machine for a particular job. Spindles often have variable speed controls to accommodate different materials and cutting tools. Higher spindle speeds are typically used for precision work, while lower speeds are suited for heavy-duty cutting.

The spindle's precision and stability are essential for achieving the desired results in milling operations. Any imperfections or inaccuracies in the spindle can lead to subpar machining outcomes. Therefore, proper maintenance and alignment of the spindle are crucial to ensure consistent performance and the production of high-quality workpieces.

The control panel serves as the operation's brain and central nervous system, allowing the operator to fine-tune and execute precise machining tasks. Technology and human expertise converge in this component to shape raw materials into intricate components.

The control panel is typically equipped with an array of switches, buttons, knobs, and a digital display, allowing the operator to control various aspects of the machine's operation. These controls may include spindle speed adjustment, power on/off, feed rate control, and direction of travel. Additionally, more advanced milling machines may have computer numerical control (CNC) interfaces, enabling automated and highly precise machining processes.

One of the critical features of the control panel is its safety measures. Emergency stop buttons and safety interlocks are often integrated into the design to ensure the well-being of both the machine and the operator. These safety measures can immediately halt the machine's operation should an unexpected issue arise, preventing accidents and damage.

Moreover, the control panel provides a means to adjust and program the milling machine for different tasks. For CNC machines, it's the interface through which G-codes and M-codes are inputted, guiding the tool's movement with incredible precision. This level of automation and control ensures repeatability, consistency, and the ability to produce complex parts efficiently.

The control panel is where the operator's expertise and creativity merge with technology, allowing for the production of intricate and precise components. It empowers machinists to adapt to various materials, workpiece designs, and cutting tools while maintaining the highest level of accuracy.

Vertical milling machines offer many benefits, making them a cornerstone of machining in various industries. These advantages stem from their design, versatility, and precision. Here are some key benefits of vertical milling machines:

Vertical milling machines are incredibly versatile. They can perform various tasks, including face milling, end milling, slot cutting, drilling, and more. This versatility makes them invaluable in manufacturing, aerospace, automotive, and toolmaking industries.

Precision is a hallmark of vertical milling machines. With the ability to control spindle speed, feed rate, and tool depth, they can achieve extremely tight tolerances, ensuring the highest quality finished products.

Vertical milling machines are highly efficient. They can remove material quickly and precisely, reducing production times and minimizing material waste. This efficiency is crucial in industries where time and cost-effectiveness are paramount.

Vertical milling machines can be easily customized to suit specific production needs. Operators can choose the appropriate cutting tools, work-holding devices, and CNC controls, tailoring the machine to the job.

These machines consistently produce uniform results. Whether machining a single prototype or mass-producing parts, vertical milling machines deliver consistent quality, reducing the risk of defects and rework.

Many vertical milling machines are equipped with CNC controls, allowing for automation. This feature streamlines production, reduces operator error, and enables the machining highly complex and intricate parts.

Vertical milling machines can work with various materials, including metals, plastics, and composites. This adaptability makes them fit for a wide range of applications.

Vertical milling machines stand as versatile workhorses in the realm of precision machining. Their robust components, including the base, column, knee, saddle, worktable, spindle, and control panel, offer exceptional efficiency, precision, and adaptability for a wide array of industrial applications. Their ability to handle diverse materials, produce consistent results, and be customized to specific tasks makes them a vital asset in manufacturing and engineering. The numerous benefits they bring, from cost-effectiveness to automation, underscore their enduring significance in shaping our modern world through precision engineering.