A perfect example can be found in the precision machining industry, where the BBT50 tool holder is pivotal. This is because it unites durability with a level of accuracy that has no rivals. It is a go-ready manual for both the engineers and machinist, acquiring the best quality within the application and daily checking procedures. Technology products have presented a complex landscape for the consumer.

Layers of technical specification, compatibility variations and operational guides characterize the high-tech world. Using an innovation-prism each word would only mean touching the peak of the art which get done with just the help of BBT50.

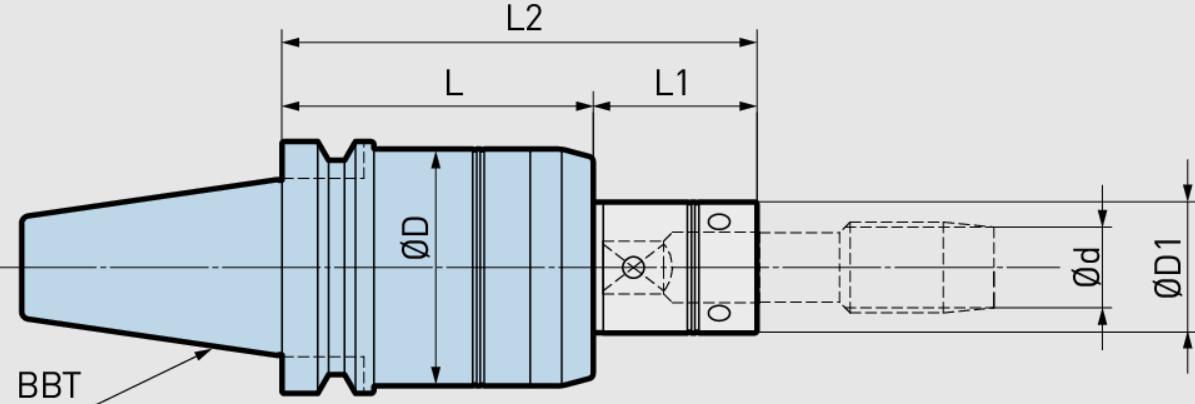

BBT50 Tool Holder, in turn, maintains tools on the CNC machine. - This will assure self-sufficiency in terms of its smooth bolting design. The diameter of flange increases to 69.85; thereby improves tensional stiffness when the load is subject to high-speed operations. Twin-touched face brings more strength and vibration removes with it.

The finishing job becomes easier because of this system which accommodates several tool types. This generator is made for desert conditions and it provides the survivor with life without complaints. BBT50's compatibility with all the machines including the ones from other manufacturers saves time, labor, and cost making it a pipe dream.

Match BBT50 tool holders with spindle size precisely. Ensuring compatibility enhances precision and performance. Key specs include interface design and flange diameter. Confirm spindle taper meets BBT50 specifications for optimal engagement. Precise fitment is crucial for high-speed vertical machining operations.

Optimal balance in BBT50 tool holders is critical. It reduces vibration, ensuring smoother operations. High-quality holders maintain balance at varying RPMs. Check G2.5 rating at 25,000 RPM for superior performance. Balanced tools extend lifespan of both holder and machine.

Clamping strength is paramount for BBT50 holders. It secures the tool, preventing slippage during intense operations. Look for holders offering robust clamping mechanisms. Hydraulic and mechanical clamping systems provide reliable strength. Ensure clamping force meets operational demands for maximum efficiency.

Tool length affects BBT50 holder performance. Shorter tools minimize deflection and enhance accuracy. Consider maximum tool length capacity of the holder. Match tool length with operational requirements for optimal results. Proper length selection ensures precision mold in detailed machining tasks.

Vibration damping enhances BBT50 holder performance. Damping technology reduces noise and improves surface finish. Select holders with built-in damping features for high-precision machining. Advanced materials and design techniques contribute to effective vibration control. Improved damping extends tool life and machine health.

Coolant flow is crucial in BBT50 tool holders. It prolongs tool life and prevents overheating. Check for holders designed with efficient coolant channels. Compatibility with high-pressure coolant systems is a plus. Efficient coolant delivery ensures optimal temperature control during machining.

The BBT50 tool holders are not compatible so the interface of spindle is extremely important for them. Assure that taper of spindle is in accordance exactly with BBT 50 specs. By eliminating precision in connection, machines do not shaken handle, improving work on the tool. Also, the auto camper's manual for the compatibility details. Fitting is done in the optimal manner will result into overall increased machining precision and performance.

Possible human body contact of this tool holder results in an exquisite precision level. Universal tool holders cause tool deflection to decrease, with an added aim on machining quality. The best real-time synchronization by codec innovation brings the desired softness, applicable to high speed work. Look out for the surface of the tool so that you can have the same experiences with the tool and the tool itself can last longer and be more efficient.

Tool changers need proper flange location as a start point to get stable. Flange diameter will be the key factor in the center of gravity and tool alignment being maintained. Check flange dimensions to make sure they are in proper dimensions compatible with machine interface. Correct sizing result in smooth running of the device and; precision in cutting job is the outcome.

Type pull stud choosing as it is primary for BBT50 holders. Pull stud is a spring loaded clip that holds device to machine securely. A machine is not safe unless pull stud matches its specification in such a case when the fit is reliable. Periodic inspection protects machinery against premature wearout; therefore probable failure of the equipment will be evaded.

Design of coolant exits in BBT50 cutter holders should be made in such ways that they allow the best chips ejection. A too coolant flow provides is there to cool the tips of the tool that help to extend the tool time. Pick out the holders with perfect coolant exit routes to strengthen the machining effectiveness.

As part of the natural progression of life, individuals experience a wide range of emotions, ranging from happiness to sadness. Interestingly, these emotions can be influenced by both environmental and internal factors. This lets the radiator to work normally without poor discharge of coolant through the obstruction of the tubes. The coolant will prevent the engine from getting overheated.

BBT50 tool holders come in varied lengths to suit diverse machining needs. Length options range widely, accommodating precision tasks. Selecting the correct length ensures optimal tool performance and accuracy. Measure application needs against holder specs for the best match.

Diameter options for BBT50 holders are designed to fit multiple machine types. Varied diameters support a range of operational demands. Ensuring the right diameter fit enhances stability and machining precision. Cross-reference holder diameter with machine requirements for seamless integration.

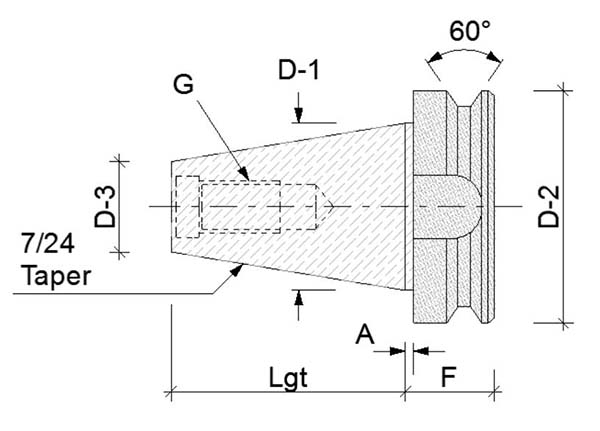

Taper accuracy in BBT50 tool holders is critical for machine spindle fit. High precision tapers ensure tight, vibration-free connections. Accuracy levels affect machining quality directly. Verify taper specifications to match exact machine needs, optimizing tool life and performance.

Flange standards for BBT50 tool holders conform to industry norms. Correct flange integration secures tool alignment and balance. Standards ensure uniformity across machines and tooling systems. Familiarize with flange specifications to guarantee compatibility and operational efficiency.

|

Feature |

Length Range |

Diameter Variability |

Taper Accuracy |

Flange Standards |

|

Description |

Measurement from base to tip |

Variance in tool holder size |

Precision of the taper fit |

Compliance with interface norms |

|

Typical Values |

100-350 mm |

40-100 mm |

<AT3 to AT5 class precision |

ISO, ANSI, JIS standards |

|

Importance |

Determines tool reach |

Fits different tool sizes |

Ensures snug spindle fit |

Guarantees holder-spindle compatibility |

|

Variability |

Fixed per model |

Model-specific |

Industry-standard precision |

Universal across models |

|

Measurement Units |

mm (millimeters) |

mm (millimeters) |

AT Grade |

- |

|

Impact on Use |

Affects machining depth |

Tool compatibility |

Vibration reduction, precision |

Mounting ease, interchangeability |

|

Selection Criteria |

Workpiece dimensions |

Required tool diameter |

Machining precision required |

Machine spindle type |

Table on Dimensions and Specifications!

BBT50 tool holders are crafted from high-grade alloy steel. Alloy steel ensures strength, durability, and resistance to wear. It withstands high machining forces, essential for precision work. Regular inspection for integrity maintains optimal performance.

The hardening process of BBT50 tool holders enhances their durability. Heat treatment increases resistance to physical deformations. This ensures a longer lifespan under rigorous machining conditions. Opt for holders that have undergone thorough hardening for reliability.

Surface treatment on BBT50 tool holders fights corrosion and wear. Processes like black oxide coating improve resilience. A treated surface ensures smoother operation and protection against harsh conditions. Always check the type of surface treatment to gauge longevity.

Fatigue resistance is crucial for BBT50 tool holders. Materials and manufacturing processes determine their ability to resist cyclic loading. High fatigue resistance means less downtime and replacements. Invest in tool holders known for enduring repeated stress with minimal wear.

BBT50 tool holders feature dual contact for spindle and flange, ensuring unparalleled stability. This design minimizes vibrations, enhancing machining precision. Dual contact maximizes tool life and improves surface finish on workpieces. A key differentiator, it sets BBT50 apart in high-performance machining.

Enhanced rigidity in BBT50 tool holders comes from their robust construction. This design aspect reduces deflection, allowing for heavier cuts with great precision. Rigidity translates to higher accuracy and efficiency in demanding applications. It's a cornerstone of BBT50's reliability in heavy-duty machining.

Precision locking mechanism in BBT50 tool holders ensures secures mounting and easy tool changes. This feature minimizes runout, crucial for achieving tight tolerances. It enhances operational safety and tool performance. Precision locking underpins the BBT50's reputation for consistent, high-quality machining results.

BBT50 tool holders deliver unmatched accuracy in machining. Precision design minimizes runout, enhancing tool performance. This accuracy benefits complex part production. High precision ensures parts meet stringent specifications. BBT50 stands out for tasks requiring extreme precision.

BBT50 tool holders are built for longevity. Robust materials resist wear, extending holder life. This durability supports continuous use, reducing replacement frequency. Long-lasting performance translates to cost savings. BBT50's resilience is a key advantage for high-volume machining environments.

BBT50 tool holders contribute to superior surface finishes. Their stability during operation reduces vibrations, improving finish quality. Achieving smoother surfaces becomes effortless. This benefit is crucial for aesthetically sensitive and high-precision parts. Superior finishes set BBT50 apart in quality-focused industries.

Enhanced stability is a hallmark of BBT50 tool holders. Their design ensures steady tool support, even under high torque. This stability optimizes cutting conditions, improving safety. Reduced vibration from enhanced stability also extends tool life. BBT50's stability is essential for heavy-duty machining tasks.

BBT50 tool holders excel at high speeds, optimizing cutting efficiency. Adhere to manufacturer's speed guidelines to maximize tool performance. Correct speeds reduce wear, enhancing tool life. Speed adjustments may be necessary based on material hardness.

Optimal feed rates are critical for BBT50 tool holder efficiency. Adjust feed according to material and cutting tool type. Balancing feed rates improves surface finish and prolongs tool life. Consult cutting parameters for best results.

Depth of cut impacts BBT50 tool holder performance. Optimal depths vary by material and application. Adjusting depth optimizes cutting efficiency and tool life. Use manufacturer's recommendations to determine ideal cutting depths.

Effective coolant use with BBT50 tool holders extends tool life and improves cuts. Select coolant type based on machining material. Proper coolant flow ensures efficient heat dissipation. Regularly check coolant paths for blockages to maintain optimal cooling.

Coolant rings enhance BBT50 tool holder performance by directing fluid precisely. This targeted coolant flow cools tools effectively, reducing wear. Increased cooling efficiency aids in prolonged tool life. Ensure compatibility of rings for optimal results.

Balance rings adjust BBT50 tool holder balance, optimizing rotational stability. Precise weight distribution minimizes vibration, improving machining accuracy. Utilizing balance rings enhances surface finish quality. Select rings based on the specific balancing requirements.

Variants in collets allow BBT50 tool holders to adapt to diverse tool diameters. Precision collets secure tools tightly, ensuring accurate machining. Choose collets based on tool size for best performance. Regular replacement of collets maintains high precision.

Tool tights secure cutting tools in BBT50 holders, preventing slippage. Enhanced grip ensures consistent tool performance under various loads. Selecting high-quality tool tights contributes to safety and accuracy. Verify tool tight compatibility for secure fitting.

The particularity of the aviation milling is that there are no ways without the BBT50 tool holders. They use precise ways during the process of creating aircraft parts. High accuracy and stability are key to any safety-critical design component. The tough, resilient nature of aerospace materials demands the resistance which BBT50 provides. These metal tags set forth a high standard.

The BBT50 tool holders are the most popular types of tool holders in automotive drilling when it comes to their dependability. They perform topping ups in short periods of time, effectively at the essence of massive production. The materials used in automotive sector can be from one element for example aluminum to high grade steel. BBT50 remains very flexible catering to the different needs to avoid poor drilling even though this may bring a great challenge to drilling.

Not only do the tool holders of BBT50 work well with mold making, but these holders also make it easy for milling or sub milling insert cavities. Their precise and stable nature plays a fundamental role in producing diversified molds. Tooling for injection molds sometimes use BBT50, the latter material can be deployed for other items and materials which BBT50 is appropriate for.

The BBT50 tool holders are designed for use in part of the heavy fabrication work. Their solid built-in package allows big blocks of metal and structures to be machine-processed. Reinforced stiffness is provided with good precision under demanding conditions. It includes the most rugged model BBT50 that can be used in harsh environments and as heavy industry, like construction and shipbuilding.

Through this lecture we have been able to catch glimpses of various features of the BBT50 tool holder, investigated its selection, use, and upkeep. Equipped not just for metal machining, but also engineering artisan, performs of the highest quality of the job. With the narrating closing off, see to it that yours should be about working hard with precision, and skepticism filters. Probe further into the domain-leading work of BBT50, via the website of CNCYANGSEN, where expertise meets innovation.