Computer Numerical Control (CNC) machines play a pivotal role in modern manufacturing. By digitally automating machining processes, CNC technology has revolutionized production capabilities. Two of the most common CNC machines used are drilling and milling machines.

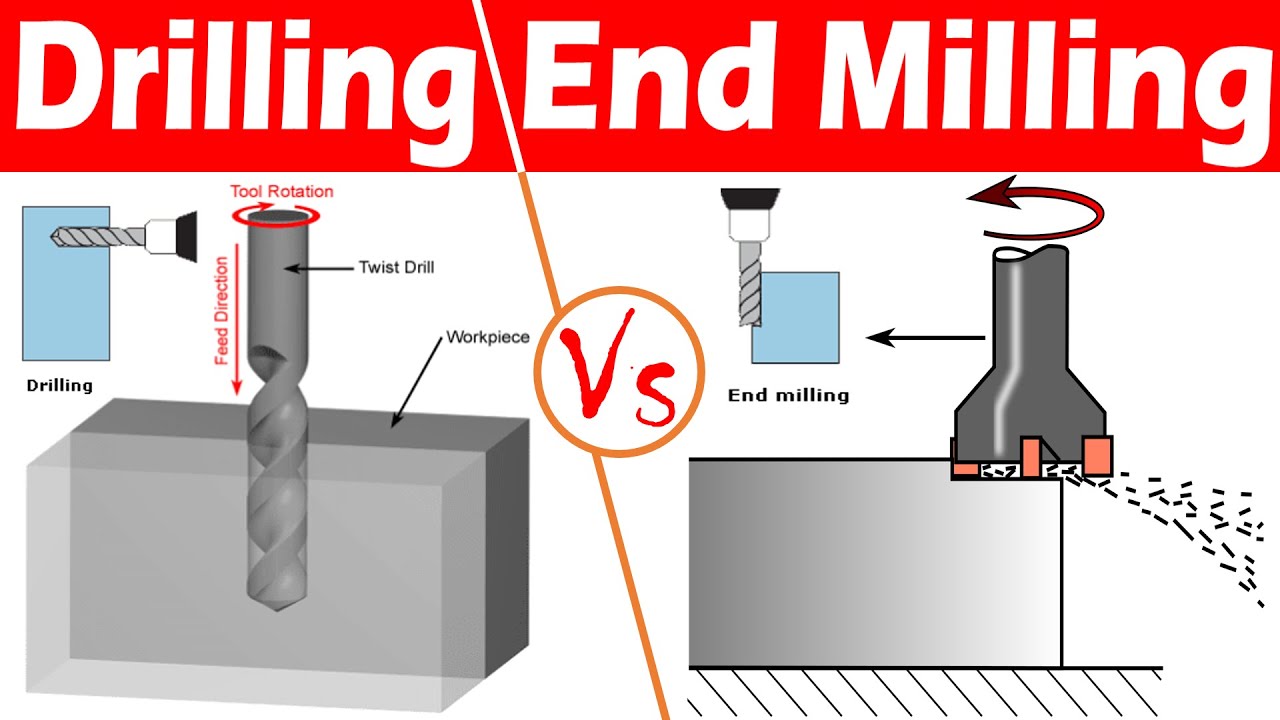

At a glance, CNC drills and mills may seem similar—they both use rotating cutters to remove material. However, these machines employ distinct methods and excel at different applications.

CNC drills and mills have some considerable differences regarding their work envelope, type of cutting tools used, direction of cut, and more. Understanding these key differences allows for properly matching the right CNC machine to the machining application.

A vital difference between CNC drilling and milling machines lies in the size of their work envelope. The work envelope denotes the maximum part size a CNC machine can handle.

CNC drilling machines typically have a smaller work envelope that’s ideal for boring holes or cavities. Their work area may range from just a few cubic inches up to approximately 25 cubic feet. This compact size makes CNC drills well-suited for drilling holes into small to medium-sized parts.

Meanwhile, CNC mills possess a more expansive work area covering several cubic feet to even 1,000+ cubic feet. By accommodating larger parts, CNC milling machines can take on more substantial surfacing and machining applications. The more massive work envelope provides the extended travel needed for milling cutters to move across big parts.

Another core difference arises from the cutting tools used. As their name implies, CNC drilling machines primarily employ drill bits to bore round holes into parts. They use twist drills or various specialty drill bits best suited for applications like counterboring, countersinking, spot facing, and more. These allow precisely boring holes with specific diameters and depths.

Instead of drill bits, CNC milling machines outfit themselves with end mills for cutting operations. End mills have a flat bottom and come shaped with square, rounded, or corner radii cutting edges. The various types of end mills can achieve facing, profiling, slotting, pocketing, engraving, and drilling (by plunging vertically like a drill bit). This versatility suits end mills for more complex part geometries.

CNC drills and mills further differentiate themselves regarding their direction of machining or metal removal. On a drilling machine, the rotating drill bit approaches the stationary workpiece's top face along a vertical Z-axis. As the drill bit contacts and bores into the part, material chips discharge through the tool’s flutes upwards until the desired hole depth is achieved. This vertical direction of cutting suits CNC drilling machines for boring deep cavities.

Contrastingly, CNC milling employs a horizontal cutting approach. The milling cutter revolves parallel to the work surface and moves laterally across a stationary or rotating workpiece. This horizontal movement flexibility suits end mills for intricate surfacing operations like face milling, slab milling, side milling, and contour milling. The technique allows intricate forms to take shape compared to purely vertical plunging.

While their work envelopes limit part sizes, CNC drilling machines provide unparalleled accuracy and efficiency at boring holes. Manufacturers across industries adopt CNC drilling technology for various small-scale precision drilling needs.

CNC drilling plays an indispensable role in aircraft component manufacturing. Aviation parts frequently call for accurately boring thousands of small holes for fasteners, fuel pipes, hydraulics, and other assemblies. An airplane may require over a million rivets and screws alone. Hence, aerospace factories use CNC drills to mass-produce tiny holes with extreme consistency in wings, fuselages, turbines, landing gear, and control surfaces.

Through automation, CNC delivers higher drilling speeds and repeatability over manual boring at aircraft factories. Machining hundreds of identical holes per minute with tight diameter and depth tolerances also minimizes wasted raw material. Thanks to their reliability at precision boring, CNC drills continue seeing widespread aviation use.

Medical device production also heavily utilizes CNC drilling machines. From surgical power tools to joint replacements, medical components commonly feature small, intricate holes. Knee and hip implants, for example, integrate minuscule openings, enabling attachment into patients’ bone structure. Automated CNC drilling ensures these holes achieve proper sizing with smooth, clean walls ideal for bonding with natural tissue or fastening hardware.

Dental drill bits likewise require CNC boring matching dental anatomy. Hospital diagnostic equipment like catheters have microscopic internal channels for fluid delivery, which is only feasible through accurate CNC hole boring. Owing to healthcare’s extreme precision demands, CNC drills constitute a fundamental apparatus across medical device workshops.

Applying automation for error-free consistency, CNC drilling also assists telecom manufacturing. Printed circuit boards (PCBs) in phones, routers, and other electronics harness high densities of microscopic vias between layers.

These vertical copper interconnects then enable soldering components like resistors and integrated circuits. With digital programming, CNC drills repeatedly produce hundreds of vias per PCB while avoiding misalignments causing shorts.

Smartwatches and smartphone chassis further need buttons and ports for interface components like charging sockets, SIM cards, speakers, and cameras. Employed for cleanly boring matching holes in a phone’s enclosure thousands of times over, CNC drilling is vital to mass communication product manufacturing.

While CNC drilling machines specialize in accurate hole boring, CNC mills have capabilities for far more robust and complex part fabrication. Manufacturers worldwide adopt milling technology for machining accuracy and flexibility, producing components of all sizes.

One major CNC milling application is die and mold making. Dies and molds are custom tooling used for mass replication of plastic and metal parts across nearly all industries. Everybody from automakers to toy producers to smartphone case manufacturers requires dies and molds for rapid, consistent part shaping.

Crafting these dies and molds demands CNC milling. The molds call for rapidly and precisely clearing various-sized cavities matching intended product geometries. Only CNC mills have the work envelope capacity and dynamic cutter direction to clear these large voids faster than manual machining permits.

The consistency also ensures every molded part has identical dimensions. Hence, CNC's combination of power, speed, and accuracy makes it integral to die and mold creation.

The aerospace sector again also utilizes CNC mills for larger aircraft components. Milling larger wing ribs, fuselage frames, turbine housings, and landing gear forgings requires significant material removal across big surface areas and deep voids.

CNC mills employing dynamic horizontal and vertical cutter movement make light work of huge metal removal demands planes present over drills.

Machining turbine disks capable of withstanding extreme rotational speeds further need mills holding tight tolerances.

CNC enables programmers to input specifically required aerospace tolerances to shape these safety-critical rotating parts precisely. Aviation consequently depends extensively on milling for both prototyping and production.

CNC milling applications even extend into crafting permanent medical replacements. Producing metallic knee, hip, and dental implants requires significant custom material removal from medical-grade cobalt, titanium, and chromium blanks.

The complexity of anatomical shapes means sculpting each joint substitute, which is essentially a one-off project requiring a manual machinist, potentially weeks per piece.

However, modern CAD/CAM software permits the programming of personalized CNC tool paths for each implant. By accommodating any anatomical model size within their work zone, CNC mills machine personalized implants within hours instead.

Streamlining fabrication directly translates to more affordable and quicker joint replacement surgeries the world over. Milling technology has hence been instrumental in enabling millions to achieve renewed mobility.

With an understanding of CNC drills and mills' fundamental differences and real-world roles, engineers can make informed selections between both technologies based on application needs. Several considerations guide the appropriate matching of parts to either machine process.

When dealing with particularly tight dimensional and geometrical tolerances, CNC drilling generally proves the superior process. The vertical approach of drill bits allows smoothly plunging tiny holes within a few thousandths of an inch, even when boring several inches down. Advanced micro drills nowadays can repeatedly hit tolerances as minute as +/- 0.005 inches.

Milling cutters tracing lateral paths governed by ball screws inherently introduce some play. So, while entirely acceptable for most components, certified aviation, and medical parts with little room for deviation tend towards precision CNC drilling. Programming appropriate feeds and speeds for intended tool and material pairs also optimizes drilling accuracy.

Applications demanding angular boring similarly benefit from CNC drilling machines. Inclined drilling introduces tool deflection without proper fixturing. However, various CNC drilling techniques like orbital drilling implements workpiece rotation to access holes requiring orientation off perpendicular. This neatly offsets the cutter flexing when operating even slightly off-axis.

Oblique angles do stretch milling's capabilities, though. The horizontal approach sees end mills deflecting when plunged at anything beyond vertical.

Fragile tooling also risks snapping and attempting overly ambitious angular slotting. So, where hole walls need precision orientation, CNC drills have the edge for angular machining stability.

When dealing with exotic and difficult-to-machine materials like titanium alloys and Inconels, milling often proves better suited. The dynamic milling method’s chip thinning action creates smaller, more manageable chips, even in gummy metals over drilling’s tendency to work harden materials. Millingtools' larger cross-sections also withstand high temperatures and fracture better.

However, when dealing with composite materials like carbon fiber or G10, CNC drilling is often preferable. The sensitive and brittle nature of composites risks delamination and cracking under a milling cutter’s shearing loads. Meanwhile, drill bits plunge cleanly through layered composites, although they require peck drilling cycles. So, material properties guide tool selection.

For small batch production where the reduction of setups over pure metal removal rates matters more, CNC drills also simplify planning. Quick-change tooling, pallet shuttles, and part fixturing allow multiple drill bits and blank workpieces to be kept ready for automated rapid-fire machining. Operators then minimize manual intervention between short-run drilling cycles.

Conversely, given their work envelope sizes, CNC mills inherently demand more reconsideration around work holding fixturing per operation. Engineers must also account for the possibility of the larger end mills requiring replacement from tool wear over longer production runs. These considerations just extend milling's programming and setup lead times.

Budgetary constraints likewise play a role in picking between drilling and milling solutions. CNC vertical machining centers (VMCs) provide exceptional versatility, combining both drilling and milling capabilities for smaller parts. But businesses just starting CNC adoption may better implement separate machines instead.

Dedicated CNC drills cost notably less than heavy-duty CNC mills with all positioning axes needed for intricate milling. The scaled-down nature behind drilling also shrinks associated with fixturing, tooling, and training investments.

While offering less flexibility than VMCS, low-cost CNC drilling still enhances production beyond manual processes for startups. Then, as means allow, more advanced milling becomes affordable.

While already greatly enhancing manufacturing flexibility over manual methods, CNC drills and mills continue seeing innovations improving capabilities further. Machinery engineers foresee several upgrade paths allowing next-generation CNC drilling and milling technology to overtake current barriers.

One forthcoming advancement combines drilling and milling capabilities into singular multitasking CNC platforms. Rather than choosing between stand-alone drilling or milling centers, hybrid machines incorporate best-of-both technologies. The integration blends heavy milling muscle with delicate yet accurate drilling proficiencies, otherwise demanding separate machines.

For small shops where floor space is limited, hybrid mills and drills eliminate the need for duplicate fixturing, CAM programming seats, and storage requirements. Multitasking also condenses production down to a single rigid setup.

The flexibility means switching from milling to drilling modes in minutes through easy tool changes without disturbing work holding alignments. Setup automation and stability thereby translate into faster changeover times and improved precision.

Both CNC drilling and milling technology look towards maximizing unmanned “lights-out” machining cycles. Through systems continuously monitoring tool wear, machine upkeep, and fixturing statuses, suitable setups will drill or mill autonomously 24/7. Removing labor dependence promises significant hourly machine uptimes rivaling simpler single-operation CNCs like laser and water jet cutters.

Further productivity improvements may arise through integrating robotic part loading/unloading. Offline automated workpiece changing would minimize costly pauses between machining cycles. Paired with smart monitoring for tool management and predictive maintenance, such solutions signal a major leap, eliminating redundant manual oversight.

CNC drilling and milling machines each serve important and distinct purposes in manufacturing. CNC drills excel at repeatedly boring small precision holes thanks to their vertical approach, while mills’ dynamic horizontal cutting capabilities allow machining larger, more complex parts.

Factors like tolerance requirements, angles, materials, changeovers, and costs guide engineers toward selecting one process over the other for a given production application. Yet innovations in multitasking machines blending both drilling and milling now offer businesses flexible solutions within singular workshop footprints.