In CNC machining, the milling process is crucial for shaping and finishing workpieces. Two fundamental methods are conventional milling (up milling) and climb milling (down milling). Understanding their differences, characteristics, and selection principles is essential for optimizing machining processes.

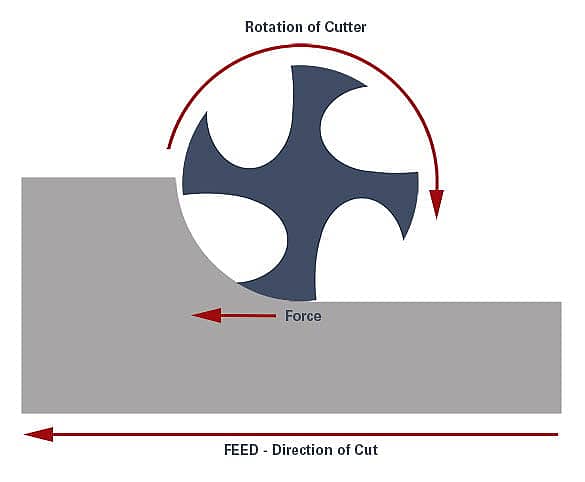

• Tool Movement: In conventional milling, the cutter rotates against the direction of the feed. As the cutter teeth engage the material, they start at the bottom and move upward, gradually increasing the chip thickness.

• Chip Formation: Chips start thin and become thicker as the cutter progresses. This can cause the material to push away from the tool.

• Cutting Forces: The cutting force in conventional milling pushes the workpiece away from the cutter, which can lead to vibration and chatter, making it harder to achieve a smooth surface finish.

• Heat Generation: Since the cutter is moving against the material, more heat is generated at the cutting edge, which can affect tool life and the surface finish of the workpiece.

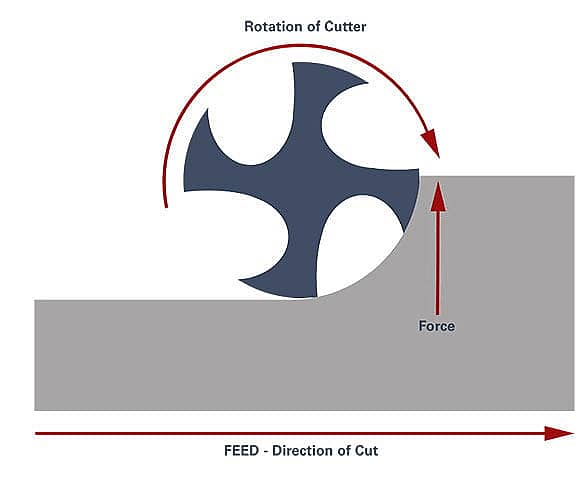

• Tool Movement: In climb milling, the cutter rotates in the same direction as the feed. The cutter starts at the top of the material and moves downward, decreasing chip thickness.

• Chip Formation: Chips start thick and become thinner, which helps in producing a smoother surface finish.

• Cutting Forces: The cutting force pulls the workpiece towards the cutter, stabilizing the process and reducing vibrations.

• Heat Generation: Less heat is generated in climb milling because the cutter is moving with the material, which can help in maintaining the integrity of the cutting edge and improving tool life.

• Surface Finish: Often results in a rougher surface due to the increasing chip thickness. The impact forces at the start of the cut can cause slight deflections.

• Tool Life: Tools tend to wear out faster in conventional milling due to the higher friction and heat generated at the cutting edge.

• Material Removal: More aggressive material removal is possible, making it suitable for tougher materials. However, care must be taken to control the forces and avoid excessive vibration.

• Setup: Conventional milling is more forgiving on older machines with backlash because the cutting force direction helps to keep the backlash in check.

• Surface Finish: Typically provides a better surface finish because of the decreasing chip thickness and reduced vibration.

• Tool Life: Generally extends tool life due to the more gradual engagement of the cutting edge and lower heat generation.

• Material Removal: Efficient for softer materials and results in less deformation and work hardening.

• Setup: Requires a machine with minimal or no backlash for optimal performance. Excessive backlash can cause the cutter to dig into the material unpredictably.

Choosing between conventional and climb milling depends on several factors:

Hard Materials: Conventional milling is preferred for hard materials like stainless steel and titanium because it provides better control and stability.

Soft Materials: Climb milling is more effective for soft materials like aluminum and plastics due to its smoother operation and superior finish.

For applications requiring a superior surface finish, climb milling is the better option. The gradual reduction in chip thickness reduces the likelihood of surface imperfections.

Climb milling typically results in longer tool life and lower tool costs over time due to the reduced heat generation and smoother cutting action.

Machines with high backlash are better suited for conventional milling. The forces generated help to stabilize the machine's movement.

Precision machines with minimal backlash can effectively utilize climb milling, taking advantage of its smoother and more efficient cutting process.

If stability and reduced vibration are priorities, climb milling is advantageous. The pulling action of the cutting force helps to stabilize the workpiece and the machine.

Roughing Operations: Conventional milling may be preferred for its ability to handle more aggressive material removal. It provides better control over the forces involved.

Finishing Operations: Climb milling is ideal for achieving a high-quality surface finish and is particularly useful for final passes where precision is critical.

Conventional milling generates more heat, which can be a concern for heat-sensitive materials. Climb milling's reduced heat generation is beneficial for maintaining material properties and preventing thermal expansion.

Climb milling tends to produce chips that are easier to manage and evacuate from the cutting area, reducing the risk of recutting chips and improving overall surface quality.

Both conventional and climb milling have unique advantages and limitations. The choice between the two should be guided by the specific requirements of the machining operation, the material of the workpiece, the desired surface finish, and the condition of the CNC machine. By carefully considering these factors, machinists can optimize their processes for efficiency, tool life, and product quality.

In summary, understanding the differences and characteristics of conventional and climb milling allows for better decision-making in CNC machining. Selecting the appropriate method can significantly impact the outcome of the machining process, ensuring high-quality results and efficient production.