Have you ever heard of milling or grinding to achieve a product of the desired shape?

Both milling and grinding involve machining techniques for the manufacture of smooth materials by removing material from the workpiece in the manufacturing industry. These processes handle a variety of materials, such as iron, copper, aluminum, steel and metal alloy.

Both processes are similar as they remove the undesirable material from the workpiece but differ in working. Machining operations handle hard materials like metals. No matter what, milling and grinding each works in different ways.

Let's discover the difference between milling and grinding and know which ones are better.

Milling involves a basic machining process that uses a cutting tool to pass against a stationary workpiece to cut the materials from it. Its cutting blades rotate and press against the workpiece. However, the workpiece is fixed, so it doesn't rotate at the pivot.

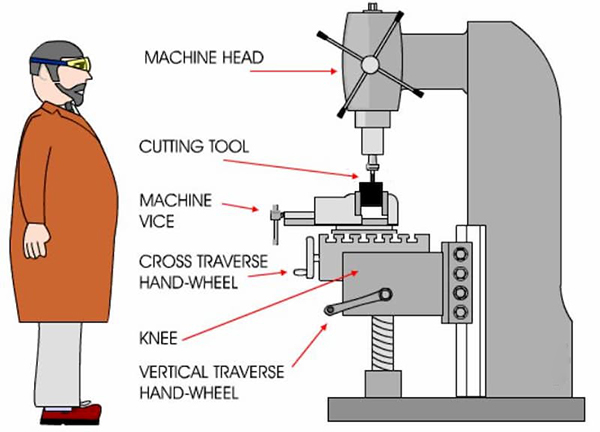

Milling machines can be horizontal or vertical, machining irregular surfaces through drilling, boring, cutting, threading and slotting. The most common milling machine in the market is a vertical mill, also known as a column and knee mill.

Depending on the milling cutting tools, milling processes are classified into two types:

1. Face Milling

2. Peripheral Milling

Both types work on the same principle. Use a rotating cutting tool to separate the material from the workpiece.

The machining center or lathe is adjusted perpendicular to the workpiece when operating a face milling process. The cutting tool does not perform the milling action; only its top is involved in the process. It has cutting edges on the sides and face, performing cutting action at the tool's corner.

This type of milling is used for surface machining, removing the material from the workpiece through horizontal and vertical spindles.

Parallel to the milling cutter is the workpiece. Unlike face milling, workpiece sides also perform the removal operation. It uses horizontal spindles for the removal of large materials from the workpiece. The cutting tool has a cutting edge at a single side running at its circumference. Mostly, machinists use peripheral milling for deep cuts and gear teeth.

Check out the parts of milling machines to understand it’s working.

The main purpose of the column and base is to support the rest of the components of the milling machine.

A saddle is mounted on the knee to support the worktable. The knee is screwed vertically, known as an elevating screw. The swivel table is fixed to the saddle that moves horizontally.

The milling machine's spindle is a shaft for all cutting tools.

A horizontal beam, overhanging or over arm, is on the column's top. It's a single casting that slides over the channels.

Milling machines cut metals to produce components of different shapes and sizes. Different parts work in conjunction with one another to form an end-machined product.

So, before heading forward, let's understand how the machine works.

A milling machine has a worktable on which machinists place and fix a workpiece. The working table controls the workpiece from the rotating cutter. The rotating cutter attaches to the spindle and revolves at a high speed in rotatory motion.

With the rotation of the cutter, the workpiece advances, removing the metal from the surface through the cutter's sharp teeth. It cuts the material to achieve the desired shape.

Once you understand the working principle of milling, it's easier to know it's set up and working. Check out the steps used in the milling machines:

Before the milling starts, machinists set up the tools properly to get the desired results. The crucial thing in milling is the cutting tool. It's mounted on the arbor that is attached to the spindle.

When you have set up the milling machine tools, the knee moves downward to adjust its position. Adjusting the knee to the right position ensures the stability of the machine.

After setting all the tools on the milling machine, it's time to clamp the workpiece on the worktable. It's clamped rigidly with the clamping screws.

Before cutting the material, zero adjustment is necessary for the exact position. All the controlling points, including saddle and knee position, should be set to zero to avoid errors and maintain accuracy.

It is the main step of milling machines. The cutting tool on the arbor attaches to the spindle. The cutting tool and spindle rotate around its axis at a high speed.

The cutting tools continue to rotate. However, the milling machine's parts, including the worktable, knee and saddle, changed the workpiece position to get the desired cutting and shape.

This last step helps you obtain the desired shape of the product. The controlling axis maintains the workpiece position for properly cutting and removing metal pieces. When it's cut into a shape, the rotatory motion tools reach the stationary position.

The milling machine mainly aims to remove the tough and rough material chips through cutters' high-speed rotation around the axis.

Here's why milling is performed in the material manufacturing industry:

1. Cutting metal

2. Smoothing surface

3. Drilling strong solid materials (metals)

Milling has numerous advantages, making desired products easier than ever before. Machine cutting tools are efficient, reliable and user-friendly. If your manufacturing hasn't employed milling machines, consider them to enhance the efficiency of the operation.

Have a look at the advantages of using milling machines:

1. Produce complex shapes

2. Produce small and large pieces

3. Rotating cutting tools enhances precision

4. A quick and efficient way to cut material

5. Reduce operational costs

Milling machines are used in the manufacturing industry to create complex products.

● It creates gears

● Makes slots and grooves

● Processes flat and irregularly shaped surfaces

Feeding the worktable with a cutter of different diameters produces V-blocks through angular milling. Milling machines saves much of the machining time and reduces the cost simultaneously.

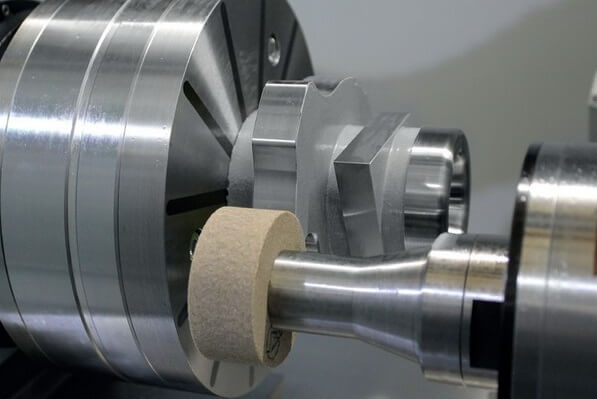

The grinding process is similar to milling. However, it also performs an additional process. It has a disc-shaped grinding wheel that grinds the material away from the workpiece surface.

The grinding machine uses an abrasive wheel to give slight cuts on materials ranging from 0.25 to 0.50mm in depth and achieve the finishing of the end product. It involves a machining operation to enhance the accuracy of the workpiece and ensure a high level of surface quality.

Grinding machines have grinder wheels of different shapes and sizes. These wheels vary in texture and are constructed of stones, diamonds and inorganic materials.

There are three basic types of grinding wheels:

1. Grindstones

2. Angle grinders

3. Grinding machines

Different parts of grinding machine include the following:

The base is the support system of the grinding machine, present in a horizontal position at the machine's bottom. The grinding machine's base is made of cast iron. The bed acts as a vibration absorber since the machine vibrates a lot during work.

The machine's vertical support is the column. It's mounted near the wheel head, wheel guard and abrasive wheel. The column is made of cast iron.

Headstock is present at the left position of the worktable. It's also known as a live center because it has a casing containing a motor, gearbox and a wheel-driving system. Its exterior side consists of control buttons to adjust the speed.

The right position of the worktable has a tailstock, offering grip to the workpiece. Its main purpose is to hold the workpiece in different alignments.

Saddle mounts on the base, keeping the table raised. It moves back and forth on the antifriction on the ball bearings to cross-feed the workpiece.

A worktable is a magnetic chuck holding the workpiece and gliding to give it the desired shape. The grinding mill has two tables, one above the other. Newer grinding machines replace the headstock and tailstock with a workpiece. The worktable moves in a transverse motion for feeding either manually or electrically.

The wheel head is situated at the center of the work table. A grinding wheel and a motor make the wheel head. It removes unnecessary materials from the workpiece to produce a smooth and finished product.

When the machine's operating temperature becomes higher than a coolant nozzle, it's used to reduce it. Mostly, the temperatures are higher between the wheel and the workpiece. If a coolant isn't fixed in the grinding machine, it causes wear and tear. Some coolant includes oil and water.

One of the primary tools of the CNC drilling machine is the abrasive or grinding wheel. Grinding wheels grind four abrasive materials, such as aluminum oxide, silicon carbide, cubic boron nitride and diamond.

Process

When you place the workpiece under the grinding wheel, it rubs the material, removing it and polishing it. The grinding wheel makes the abrasive particles of the coarse surface smooth, also polishing the surface.

Grinding machines remove all the unwanted stuff from the workpiece through abrasion. The grinder wheel is made with abrasive particles aligned together. However, they alter in shape, size and hardness.

During the grinding, it's essential to hold the workpiece securely with tools or manually for its stability and precise material removal. The electric motor helps rotate the grinding wheel to eliminate abrasive materials easily from the workpiece.

The operator is used to apply pressure on the grinding wheels to clear up the surface of the workpiece. The rotating wheels remove extra material to form the desired shape and finish of the surface. Depending on the requirements, the motion of the grinding wheel may be linear or circular.

During this process, a cooling component is applied to maintain the temperature and avoid overheating. It also helps reduce friction, remove grinding debris, dissipate heat, and enhance grinding wheels' lifespan and efficiency.

Grinding machines comprise various mechanisms to ensure control and accuracy, such as table adjustment, depth and feed mechanisms. For perfect results, operators must be precise and accurate.

It's important to take safety measures while working with grinding machines to reduce hazards caused by speedy rotational and abrasive particles. Wear protective gear, set up the machine and avoid direct contact with the grinding wheel.

Grinding machines offer several operations such as cutting tools, cylindrical, surface and grinding. These features allow the machine to meet specific needs and productive optimization.

Non-precision grinding involves snagging, and off-hand grinding squeezes the material against the grinder wheel to obtain a finished product. Snagging is preferred to remove a considerable amount of metal when you don't have to consider the accuracy of the product's surface. Some examples include surface trimming, grinding lines on castings, removing metals left on welds, cracks and imperfections on alloys.

This grinding operation ensures a finished and high-surface quality product with high accuracy. The grinder wheels work in precise paths to produce products with accurate dimensions.

There are four types of precision grinding:

1. External cylindrical grinding

2. Internal cylindrical grinding

3. Surface grinding

4. Form grinding

Here’s why you should use the grinding process:

1. Deals with strong, hard materials

2. Products have accurate dimensions

3. Produces a highly finished product

4. It also works on high-temperature

5. Operate complex materials

6. Produces smooth surfaces

Perform grinding to obtain the following components:

1. Manufactures engine components, gears, brake rotors

2. Making turbine blades and gear parts

3. Orthopedic implants and surgical instruments

4. Produces semiconductor wafers and connectors

5. Manufacture cutting tools, molds and dies

The milling and grinding processes involve the physical removal of material, but they aren't the same. The milling and grinding machines are available in various shapes and sizes. Choosing the correct machine or process is a critical job. This guide will help you understand better.

If you want to save time and enhance productivity, milling machines is the best option.