Horizontal milling machines are one of the most versatile and widely-used types of milling equipment in industrial applications. Compared to other milling machines, horizontal mills have a few distinct advantages that make them an indispensable asset for manufacturers.

It is a type of milling equipment where the spindle that holds the cutting tool is oriented horizontally. This spindle feeds into the workpiece that is fixed to a table, allowing for complex cuts and patterns to be machined. The key defining feature is this horizontal orientation of the cutting tool spindle, which provides unique benefits.

Horizontal mills find usage in a diverse range of industries including automotive, aerospace, construction, general machining, and many more.

They allow manufacturers to efficiently machine large and heavy workpieces that may be impractical on vertical milling machines. Precision requirements are also met thanks to increased rigidity and minimized deflection of the cutting tool.

In this article, we’ll clearly understand what horizontal milling machines are, their advantages and the latest technological trends associated with them.

So let’s get started!

Milling machines are one of the most versatile industrial equipment used for machining operations. They are capable of performing complex and precise cuts on a workpiece, thus finding extensive use for shaping metals and alloys in various industries.

Based on the orientation and capabilities, milling machines can be broadly classified into three main types:

● Vertical milling machines: The cutting tool spindle is oriented vertically above the worktable. They provide high precision and accuracy, hence are ideal for intricate jobs and dies/molds manufacturing.

● Horizontal milling machines: The spindle holding the cutting tool is placed horizontally. This allows for machining larger workpieces with increased stability.

● Universal milling machines: Combine the flexibility of both vertical and horizontal mills in one single unit. With multiple spindle orientations available and attachments to extend capabilities, universal mills offer superior versatility.

Understanding these primary types of milling equipment based on spindle orientation helps appreciate their ideal applications in various production environments and machining requirements.

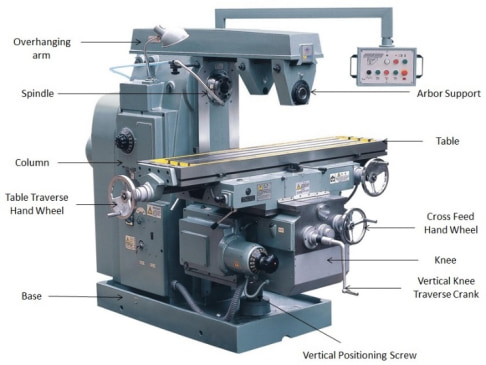

To appreciate why horizontal mills offer unique advantages, it is important to first understand their basic components and structure.

At its core, a horizontal mill contains a horizontally-oriented spindle that rotates the cutting tool at high speeds. This spindle is fed into the stationary workpiece mounted on the worktable to machine complex geometries.

Some key components that give horizontal mills their distinctive capabilities are:

● Spindle: The shaft that holds and spins the milling cutter. It is powered by an integrated motor to provide necessary torque and RPMs for material removal.

● Arbor: An intermediate tapered shaft that attaches the actual cutter or tool bit to the spindle. It provides rigidity and allows for quick changes.

● Worktable: A sturdy platform on which the workpiece component is mounted securely using fixtures like vises or clamps. It can move in horizontal X and Y axes.

● Saddle: A cross-slide unit that sits on the bed and supports the worktable, allowing the entire workpiece unit to be repositioned linearly or at angles.

These core structural elements work together to manipulate the cutting tool and workpiece relative to each other to achieve precise material removal and intricate final geometries.

Horizontal milling machines can be further classified into three major types based on structural and functional differences:

The most basic design with a horizontal spindle mounted to the column. It uses a saddle that slides along the bed for feeding the workpiece under the cutter. Best suited for simple milling operations and light-duty work. Provides basic horizontal milling function at lower costs.

An advanced, versatile type that adds additional swiveling capability of the horizontal spindle. This allows angular milling operations with the workpiece set at an angle. The saddle table can also be swiveled to compound angles for complex cuts. Ideal for intricate machining jobs.

Features a movable ram on the column to provide rigid support for the spindle when machining heavy workpieces. The sturdy box-shaped column and ram design gives stability for removing large amounts of material. Typically used to machine large castings and fabrications weighing over 2 tonnes.

Horizontal milling machines provide distinct benefits over other machining equipment that contribute to their rising popularity across various production environments.

Understanding these technical and operational advantages is essential to recognize why modern manufacturers are increasingly adopting horizontal technology.

Here are the some advantages of Horizontal milling machines:

A key advantage of horizontal milling machines is their ability to handle heavier cuts while maintaining precision.

This stems from their rigid construction with wide, box-shaped columns combined with a low center of gravity saddle design. Together, this rugged build minimizes unwanted vibration and chatter.

The overall stability allows for deeper cutting parameters leading to superior material removal rates. You can get the most out of newer high-performance tools.

Milling operations produce problematic chips and swarf that can cause secondary quality issues if not properly evacuated.

Horizontal mills are unmatched when it comes to efficient chip control thanks to gravity working synergistically with the milling process.

Chips and burrs naturally fall away from the work table instead of re welding or impeding future cuts. This delivers superior surface finish and also reduces secondary cleanup/deburring time.

The horizontal orientation provides access for cutters to engage from multiple sides and angles in a single setup.

When combined with integrated B-axis or rotary tables, complex 3D shapes can be machined by contouring along several axes simultaneously.

This facilitates fast material removal while retaining precision on intricate geometries like airfoils that are impossible on standard vertical equipment.

Today's advanced horizontal mills feature servo-driven pallet changers that enable mounting a second workpiece while the first is being machined.

This minimizes non-cut time between production cycles allowing manufacturers to run lights-out unmanned. Quick tool and job changovers translate into lower operational costs and faster delivery for customers.

An extension of horizontal milling providing superior vibration dampening is their ability to retain precision even when operating at maximum spindle speeds.

The wide column combined with the low saddle position help counteract centrifugal forces acting on the arbor and cutter.

This allows manufacturers to implement faster material removal strategies with lighter depths of cut without losing accuracy or finish quality.

The spacious work zone in front of the spindle provides clearance for indexing unusually shaped long or tall workpieces not suiting vertical mills.

With the ability to access features from both sides, horizontal mills can handle very thin wall sections and deep cavities or pockets.

The simplicity of loading heavy chunks from the top also avoids dangerous overhead lifting or crane adjustments. This flexibility is invaluable when dealing with new prototype geometries.

While the initial capital expenditure may be higher than vertical counterparts, horizontal mills offer the lowest cost per part making them ideal for large production batches.

Putting more cutting edges in contact with the material at faster rates results in dramatically lowered cycle times. Combined with efficient chip removal, tool life is also improved significantly. This directly translates into higher profit margins through reduced operational expenses.

The horizontal configuration provides a much more natural and ergonomic workspace access for machine operators. Controls can be positioned at waist level within easy sight of the machining process.

Front loading of workpieces eliminates awkward maneuvers and minimizes repetitive heavy lifting that commonly leads to operator fatigue or even injuries. Overall, horizontal mills promote greater workplace efficiency.

When dealing with high precision components that will undergo additional benchtop inspection, a horizontal orientation eases setting datums and coordinates.

Quality checks like spin tests or using touch trigger probes mounted directly on the machine are also straightforward.

Upon completion, finished parts can simply be unloaded off the top of the worktable avoiding messy collection bins or conveyors beneath vertical machines.

The modular construction and accessible workzone of most horizontal mills allows easily automating part movement tasks associated with high volume production. Worker robots can be deployed for repetitive loading/unloading duties.

Conveyor systems transport palletized workpieces in and out of the work area. Large ATC capacities also enable extended lights out operations. This flexibly expands unmanned production.

Horizontal milling machines are transforming production across diverse manufacturing sectors. Some prominent industries at the forefront of adoption include:

● Aerospace and Defense: Aircraft and turbine parts have complex 3D shapes demanding extreme dimensional precision over large surface areas. Horizontal mills meet these stringent aviation-grade requirements while rapidly hogging out lightweight alloys. Leading aerospace OEMs now depend on horizontal 5-axis capabilities for machining wing components and engine blocks.

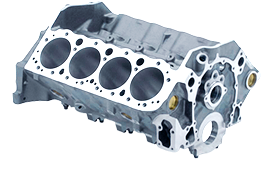

● Automotive: From raw engine block castings to precision cylinder heads and transmission cases, horizontal mills are the norm for machining high volumes of critical automotive components. Their stability allows cutting challenging materials like compacted graphite iron with tight tolerances. Automakers leverage this for engine parts production.

● Mold and Die: Larger die/mold surfaces and deeper core cavities make horizontal machining centers ideal for these shops. They provide the best balance between fast material removal and fine finishing while effectively evacuating problematic chips from enclosed die details. This reduces quality issues caused by redeposited swarf.

|

|

|

|

| cylinder block | pump body | Gear box housing | hydraulic control valve |

Horizontal machining is rapidly evolving by incorporating the latest technological advances in automation, data-driven optimizations and smart connected systems. Understanding where horizontal milling is headed next provides even more incentive to adopt this platform now.

Some notable innovations on the horizon include self-learning CAM systems that leverage AI and machine learning for autonomous process improvements, expanded adoption of cobots and mobile robots for flexible automation, widespread connectivity enabling remote monitoring and diagnostics.

Upgrades on the machine itself include further spindle power and torque density increases enabling heavier roughing without losing high RPM capability, hybrid machine construction using composites and 3D printed components for rigidity and vibration damping, as well as ultra-fast tool changers and pallet swaps minimizing non-cut time.

Cloud-based software platforms will also emerge for centralized management of networked horizontal milling fleets on the shop floor. This lays the foundation for optimizing production based on overall manufacturing system constraints rather than just individual tool constraints.

The incoming wave of Industry 4.0 focused enhancements will make horizontal mills an even more appealing driver of next-gen smart production strategies. Now is the time to embrace this cutting-edge technology trajectory.

Horizontal milling machines have many advantages that make them useful for different manufacturing needs. Their special design allows heavier and more stable cuts, faster production setups, and easier workflow. Major industries already use horizontal mills to machine complicated parts accurately and efficiently.

As new smart technology upgrades emerge, these advanced mills will become even more important for modern factories. The future is flexible manufacturing using data to improve processes.

So, if you want to make things faster, save money, and be part of the future of making stuff, it's a smart move to start using horizontal milling machines now. Don't miss out—get on board with the horizontal milling revolution today!