The present-day manufacturing sector includes the CNC machine as one of its most crucial machines. The various types of CNC machines available today vary in their method of operation, cutting tools, materials, and the number of axes they can pierce at once.

There are twelve types of CNC machines: CNC Mills, CNC Lathes, CNC Routers, CNC Plasma Cutters, CNC Water jet Cutting Machine, CNC Laser Cutter, CNC Grinder, CNC Drilling Machine,3-D printing, CNC Electrical Discharge Machine, CNC 5-Axis Machine and CNC Pick and Place Machine.

Depending upon the CNC machine types, their price can range from a few hundred dollars to tens or even hundreds of thousands of dollars.

In this article, you will explore the CNC machine definition, the types of CNC machines and their prices, and a complete CNC machine price breakdown.

CNC is an acronym for "computer numerical control." A CNC machine is a computer-controlled tool that streamlines the production of components and various products.

Alternatively, a CNC machine is a subtractive manufacturing technique that often uses computerized controls and machine tools to remove layers of material from a stock piece and create a custom-designed item.

As you know, there are twelve CNC machine types. Each machine varies depending on the task it completes, the materials it works with, and the underlying technology. Let's discuss the CNC machine price guide in detail.

One of the most popular kinds of CNC machines is the CNC mill. One can use it for milling, drilling, and cutting activities.

Most CNC milling machines range from 3 to 6 axes of motion. The three axes of the basic 3-axis CNC stand for the X-axis (left-right), Y-axis (front-back), and Z-axis (up-down) movements.

For routing and placing the spindle in various ways, mills derive and convert specialized programs composed of letters and numbers. The computer takes the command following the insertion of the workpiece into the milling machine.

|

CNC Milling Machine |

Price |

|

Hobby-Grade CNC Mill |

$2K – 7K |

|

Professional CNC Mill |

$7K – $50K |

|

Industrial 3-Axis Mill |

$60K – $100K |

|

Industrial 5-Axis Mill |

$200K – $500K |

|

Vertical Machining Center Production Mill |

> $500K |

CNC lathe machines can rotate materials while operating. They have fewer axes than CNC milling machines, which makes them shorter and more compact.

Further, at the core of CNC lathe machines is a lathe programmed to control and transmit material to the computer.

One of the main differences between a lathe and a mill is the working products. Lathes often perform better for products with cylindrical, conical, or flat geometries, while CNC mills can work on any shape.

Additionally, CNC lathes are less expensive and ideal for quick, effortless work because they are less precise and adaptable than CNC mills.

|

CNC Lathe Machines |

Price |

|

Hobby-Level CNC Lathe |

$2K – $12K |

|

Professional 2-Axis CNC Lathe |

$15K – $50K |

|

Industrial 2-Axis CNC Lathe |

$60K – $100K |

|

Production CNC Lathe (7-13 Axes Horizontal Machining Center) |

> $500K |

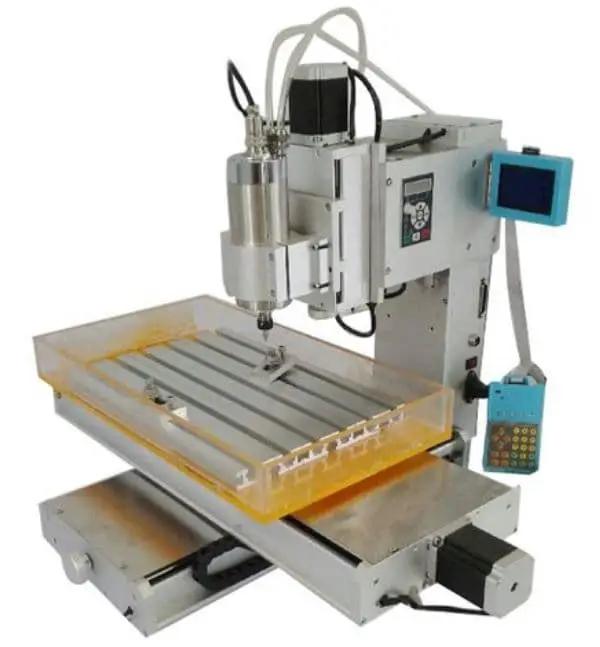

A CNC router machine resembles a CNC mill or lathe machine. However, it is often used for softer materials and is less accurate and more affordable than CNC mills.

Typically, it includes a mechanical base, a spindle, stepper motors, drivers, controllers, and a power source.

Furthermore, CNC routers employ computer numerical control to route spindle and machine tool paths to design and shape various materials. The material can be foam, plastic, steel, aluminum, composites, and wood.

|

CNC Router Machine |

Price |

|

Hobby-Level CNC Router |

$200 – $3000 |

|

Professional CNC Router |

$3K – $10K |

|

Industrial CNC Router |

$40K – $200K |

|

Production CNC Router |

$200K – $400K |

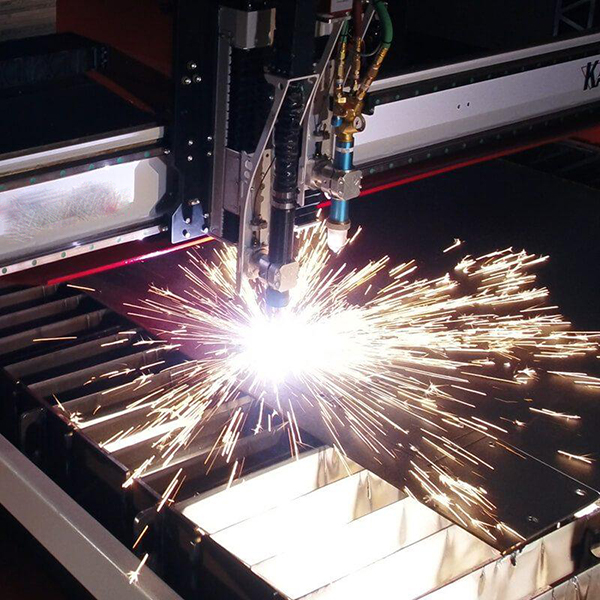

CNC plasma cutters and CNC milling machines function alike as they remove material to make the necessary cut.

The plasma-cutting device features a powerful flame that can cut through steel and titanium, two highly resistant materials. These CNC plasma cutters operate using an electric discharge system. As a result, they can only be used to electrically conductive machine materials.

The heavy industries where CNC Plasma cutters are most frequently employed are shipbuilding, auto manufacturing, chemical production, and industrial steel construction sites.

|

CNC Plasma Cutting Machine |

Price |

|

Entry-level CNC plasma cutters |

$5000-$25,000 |

|

Industrial CNC plasma systems |

$25,000- $100,000+ |

As its name implies, this device cuts through materials using high-pressure water jets. Plastic and aluminum are two common materials that benefit from CNC water-jet cutting since they are temperature-sensitive and could melt at high temperatures.

These devices can cut with just water. However, additional abrasives, like garnet or aluminum oxide, are frequently added to the water for better cutting.

A CNC water-jet cutter has the disadvantage of being slower than CNC plasma and laser cutters.

|

CNC Water Jet Cutting Machine |

Price |

|

Small CNC water jet cutting machine |

$20,000-$100,000 |

|

Industrial CNC water jet system |

$100,000- $500,000+ |

A CNC laser cutting machine can pierce hard materials with the help of a sturdy, precisely focused laser beam.

Many different kinds of laser-cutting equipment are available. One can divide them into gas, liquid, and solid-state lasers. However, solid-state and CO2 lasers are the two principal laser types used.

Considering lasers have a smaller area of contact and spread than torches, CNC laser cutting machines frequently provide higher-level precision and superior surface polish.

|

CNC Laser Cutting Machine |

Price |

|

Entry-level CO2 CNC laser cutters |

$5000-$20,000 |

|

Fiber CNC laser cutters |

$20,000- $100,000+ |

The CNC grinding machine is an exceptionally effective, precise tool. It uses a spinning wheel to cut metal away from the metal.

This CNC machine is generally used for working parts like camshafts, ball bearings, gearbox shafts, and other things that need an accurate and precise finish.

Additionally, there are many types of CNC grinders, such as cylinder, roll, and surface grinders.

CNC grinding machines typically cost between $10,000 to $500,000 or more.

Mass production frequently uses the CNC drilling machine. Such drilling machines usually feature a multipurpose machining center. They drill exact and detailed holes into the workpieces.

Based on the input from the CNC programmer, a CNC drilling machine automatically regulates several parameters, including the feed rate, depth of cut, plunge rate, and spindle speed.

|

CNC Drilling Machine |

Price |

|

Small-level CNC drilling machine |

$10,000-$50,000 |

|

Industrial CNC drilling system |

$50,000- &250,000 |

A 3D printer is a CNC that builds three-dimensional items layer by layer. At first, the CAD and CAM processes develop the design and sketch. Following that, 3D printers print the design.

Since we add material rather than remove it while creating products on this machine, we usually refer to it as additive manufacturing. Additionally, you can use this device for printing buildings and locations.

|

CNC 3-D Printing Machine |

Price |

|

Desktop grade |

$1,000-$5,000 |

|

Small business |

$5,000-$20,000 |

|

Industrial grade 3-D printing machine |

$20,000- $500,000+ |

This specific CNC machine manipulates materials into the required shape using electric sparks. It is also named a spark CNC machine.

Furthermore, it generates a sequence of carefully timed sparks or repeated electrical discharges that can reach temperatures up to 21,000 °F, vaporizing the material and forming it into the required shape.

|

CNC Electrical Discharge Machine |

Price |

|

Entry-level |

$10,000-$50,000 |

|

Mid-range machines |

$50,000- $200,000 |

|

Industrial machines |

$200,000- $1000,000+ |

The 5-axis CNC machine has five individual axes in all. It initially has three axes, X, Y, and Z. It indicates that any tool's cutting action happened in three directions.

However, two more axes, A and B, were added, making five axes. This CNC appliance is utilized to create sculptures.

|

5-Axis CNC Machine |

Price |

|

Entry-level |

$50,000-$150,000 |

|

Mid-range |

$150,000-$500,000 |

|

High-end |

> $500,000 |

The industry makes use of this CNC machine. It contains several nozzles that raise and position electrical parts for electronic devices in the proper spot. You can see their usage in the production of tablets, computers, and cell phones, among other products.

|

CNC Pick and Place Machine |

Price |

|

small-scale |

$2,000-$10,000 |

|

Medium level |

$10,000-$50,000 |

|

Industrial scale |

$50,000-$- Several thousand dollars |

Understanding CNC machine costs is essential. It guides you to buy the product according to your requirements and budget. The expense varies based on several elements.

Here are some CNC machine price factors to consider:

The representative X, Y, and Z coordinate range measurement for all types of CNC machines significantly impacts machine cost. The size of CNC machines can range from minimal to truck-sized.

The complexity of a machine's design and construction has an impact on its price as well. For instance, more complex equipment, such as those with integrated automation, often cost more.

Some types of CNC machines offer higher accuracy and precision levels. So they were more expensive. The cause is the challenge of designing and fabricating devices with complex calibration mechanisms. As a result, these elements might raise their price.

High-speed machines are usually more expensive than ones with lower operating speeds. The crux is that high-speed machines demand more potent motors, specialized parts, and durable control systems.

Most types of CNC machines can work with multiple materials. Such devices are more expensive. The matter can be metallic, plastic, or wood.

The reputation and position of the producer may also have an impact on the machine's price. For instance, machines from well-known and reputable manufacturers like Yangsen are typically more sophisticated and affordably priced.

I hope the above CNC machine price guide gives you a pretty good idea of the types of CNC machines and CNC machine price factors.

CNC machines are basically computer-controlled. They increase production, cut waste, and even eliminate the potential for human error.

Remember, the choice of machine depends on the workpiece's shape, the material used, the level of accuracy required, and the machining operation.

For more information on these types of CNC machines, you can also get in touch with the experts at Yangsen. Our top-notch machine tools come with an unwavering warranty and first-rate support, whether you're a seasoned machinist or a hobbyist.